Professional Documents

Culture Documents

Sterling Mk4 SMG Manual

Uploaded by

mjs6029100%(5)100% found this document useful (5 votes)

2K views24 pagesCopyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

100%(5)100% found this document useful (5 votes)

2K views24 pagesSterling Mk4 SMG Manual

Uploaded by

mjs6029Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 24

aa

USER HANDBOOK

STERLING

SUB-MACHINE GUN

9-mm. MK 4

(S.M.G. 9mm. L.2.A.3.)

STERLING ARMAMENT COMPANY LIMITED

DAGENHAM | ESSEX ENGLAND

CONTRACTORS TO MINISTRY OF DEFENCE, HER MAIESTY's GOVIANMENT.

CROWN AGENTS, AND OVERSEAS GOVERNMENTS.

Telephone: 01-595 2226 Cables: STERLING. DAGENHAM, ENGLAND

STERLING SUB-MACHINE GUN S-mm. MK. 4.

Above: Shown with butt extended and bayonet fitted

Below: Shown folded

SECTION I-GENERAL

Introduction

Technical Details

Special Features

Bure

Body

Trigger and Safety Mechanism

Backsighe

Bayonet

SECTION 2—DESCRIPTION AND

OPERATION

‘The Backward Action

The Forward Action

‘Action ef the Trigger Mechanism

Single Shot Fire

Automatic Fire

Applied Safety

To Open Butt

To Close Burt

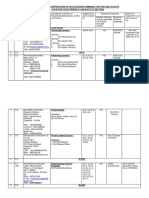

CONTENTS

pege pars.

‘0

10

3

8

“4

“4

to

20

30

a

32

33

34

3S

a

a

30

st

52

53

60

20

SECTION 3_STRIPPING AND

ASSEMBLY

Elementary Stripping and “Assembly

To Remove Return Spring

To Remove Trigger Group

Ascombly

Advanced Stripping and Assembly

To Remove Ejector

To Strip Trigger Group

To Remove Extractor

To Remove Patol Grip

To Remove Barrel

To Strip Magazine

To Remove Foresight

To Remove Backsight

To Assemble Trigger Group

To Replace Barrel

To Assemble Foresight

To Assemble Backsight

To Assemble Magazine

SECTION 4—ZEROING

SECTION 5—CLEANING

age pare,

Is

Is

6

‘6

7

7

la

19

9

20

u

a

a

a

Bw oRORB

80

81

a2

a3

9.0

9d

92

93

94

95

26

97

98

99

9.10

ony

912

3.13

10.0

SECTION I—GENERAL

10 INTRODUCTION. The Sterling Sub-Machine Gun, Mark 4, isa light and easily handled weapon which will selectively

fire automatically or single shot. Seandard 9 mm Parabellum ammunition is used.

Ici a shore range weapon normally used for engagement at ranges up t0 200 yards. Ie may be used at longer ranges

dependant on the skill of the fire.

(On account of its accuracy, lightness and reliability, the gun can be regarded ax a general purpose weapon,

It is automatic, being operated by cate reaction or" blow back '* whether fired “single shot "* or in bursts,

20 TECHNICAL DETAILS

Calibre 9 mm 9mm

Length —butt folded 19 inches 48.2 ems

butt extended 27 inches 69 cms

Weight—machine gun only 6 Ibs (approx) 2.7 Ke (approx)

—with full magazine (34 rds) 7 lb 10 02 (approx.).. 3.5 Kg (approx.)

—with full magazine and bayonet... 8lb 40: (approx.). 3.73 Kg (approx.)

Barrel length... . 7.8 inches 19.8 ems

—number of grooves... 5 "

pitch of rifling... | turn in 9.84 inches. 25 ems

twist of rifling. 5 Right hand

Sights radius ...22-6..0c 0085 16.1 inches Alems

ype é Rear—aperwure

Fore—tlade

range settings: 100 and 200 yards... 100 and 200 metres

Cyclic rate of fire... 550 r.p.m. approx.

TECHNICAL DETAILS (CONTINUED)

TERMINAL VELCCITY AND KINETIC ENERGY OF STANDARD 9 mm BULLET

RANGE VELOCITY KINETIC ENERGY

Yards Metres Fr/SeeM/See Fe/ibs Kem

° ° 1280390 “7 a2

109 100 Wis 340 339 a9

218 200 ms 18 262 36.4

37 300 on ee 207 207

436 400 7008 67 22

54s 500 700 (24 Bs 188

654 600 2 193 09 182

763 700 sm 78 89 123

an 800 sig 188 ” 10.2

at

32

33

4

3.0 SPECIAL FEATURES

BUTT. When not in use the butt is folded under the weapon reducing the ove

folded the weapon can be used as a pistol,

length by 9 inches. With the butt

BODY. The forward part of the body. ie, the birrel casing, is perforated to assist cooling. It will be found that even,

after prolonged firing the body remains comfortably cool. Finger guards are fitted at both ends of the barrel casing.

TRIGGER AND SAFETY MECHANISM. The trigger mechanism is fitted with a change lever which can be set

to give either automatic fire or single shot. The change lever also has a SAFE position which locks the trigger and sear,

irrespective of the position of the bolt, which eliminates the possibility of a round being fired if the weapon is dropped.

BACKSIGHT. The rear peephote sight is instantly changed from 100 to 200 yards range setting by rocking over.

BAYONET. The bayonet Is mounted so that it is off-set when the weapon is in the firing position. It will be found

that, when the weapon is held in the "* on-guard " position for bayonet fighting, the natural balance of the weapon, with

for without magazine, brings the bayonet into the upright potition.

SECTION 2_DESCRIPTION AND OPERATION

40 The weapon (Fig. |) is operated by case reaction or "' blow back

Fonusiont cocKiNG HANDLE scorweruan

racers

tional arrangement

41 THE BACKWARD ACTION (Fiz. 2), When the cartridge is fired the propellant gases exert an equal pressure

against both the bullet and the cartridge case, the latter being supported by vie bolt and the compression of the return

spring, ‘The gas pressure accelerates the bullet also the cartridge case and bolt in opposite divcctions and at ehe weight

of the bullet is considerably less than that of the combined weight of the cartridge case and bale, ehe bullet attains a much

‘greater velocity than that of the cartridge case and bolt. When the bullet clears the muzzle all have reached thelr maximum

Yolocities but the cartridge case has not yer cleared from the chamber, thus preventing the gases escaping from the breech,

‘The cartridge case does not clear the breech unti| the gases behind the bullet have disperted into the air, ensuring that

pressures are down to safe limits belore the breech is untesled

The bolt is now being decelerated by the compression of the return spring.

‘The empty cartridge cate, held against the face of the bolt by the extractor, is carried back until it strikes the ejector

and is ejected through the opening on the right side of the wexpon

RETURN SPRING Ansa ms

Fig. 2. Backward action

42 THE FORWARD ACTION (Fig. 3)

When the volt reaches the limit of its backwatd travel it is forced

forward by the compression of the return spring. During its forward

travel the bolt contacts the top round in the magazine and, guided by

magatine lips, the round is fed into the chamber. The bolt then

follows up on the round, feeds it into the chamber, and fires it jest

before the forward movement ceases, During the forward movement

of the round from the magazine, the firing pin of the bole cannot come

into line with the percussion cap of the cartridge until the round is

actually in the chamber. This provides the mechanical salety for this

type of weapon. Upon firing, the backward action again commences.

Fig.3. Forward action

5.0 ACTION OF THE TRIGGER MECHANISM (Figs. 4,5, § and 7).

5.1 SINGLE SHOT FIRE (Figs. 4 ond 5). When the change lever (I) is set to the single shot position R, the Inner arm

Of the change lever is located under the tall of the tripping lever (2)

When with the weapon cocked, the trigger (3) is pressed, the sear cradle (4) is rocated about the sear axis pin (5),

the sear (6) Is lowered and the bolt is carried forward by the pressure from return spring. During this movement the

tail of the tripping lever contacts the inner arm of the change lever causing the tripping lever partially to rotate.

Continued pressure on the trigger causes further rotation of the tripping lever until the upper arm disengages from

the step on the sear. At the same time the sear plunger and spring (7) are compressed.

When the round is fired, the sear is held down by contact with the under surface of the bolt, but as the bolt reaches

the end of its rearward movement and Is clear of the sear. the sear Is forced upward by pressure of the sear plunger

and spring. ‘Then as the boit is moving forward, the sear engages against the bent on the face of the bolt and holds the

bolt in the cocked position.

When the pressure on the trigger is released, the rear end of the cradie rises, lifting the tripping lever and causing it

to rotate about its axis pin until the upper arm of the tripping lever re-engages on the step of the sear

‘The trigger must be fully released and again pressed for each single-shot.

Bok pry whdrown

Fig. 4. Action of trigger mechanism (single shot fre)

52 AUTOMATIC FIRE (Fig. 6). When with the change lever (1) set at automatic A and the weapon cocked, the trigger

{is pressed, the projection on the upper part of the tr

Pin (5). This depresses the sear (6) freeing it from contact with the face of the bent on the bolt, and allowing the bole

tofly forward. The movement of the sear cradle compresses the sear cradle spring (8).

ger its the end of the sear cradle (4) rotating it about its axis

‘The weapon will now continue firing until either the trigger is released or the magazine is empty.

‘When the trigger is released the sear cradle returns to its former position under the action of the sear cradle spring,

the sear is raised into the boltway and contacting the bent on the bolt, holds the bolt in the cocked position.

5.3 APPLIED SAFETY (Fig. 7, Cocked), When with

the weapon cocked, the change lever (I) is set at

safe'S the Inner arm of the change lever Is positioned

directly under the shorcarm of che eripping lever (2).

When the crigger is pressed the sear cradle and

sear (6) cannot be depressed because the shore arm.

of the tripping lever is held immovable by the Inner

arm of the change lever.

(Fig. 7, Bole forward). When with the bolt

forward, the change lever (I) sec atsafe S, the weapon

cannot be cocked because the sear (6) is engaged in

the safety slot (9) at che rear of the bolt, and the sear

cannot be depressed because it is held immovable

7. Applied Satecy as described In previous paragraph.

a

60

19

Fig. 9 To-clowe butt

TO OPEN BUTT (Fig. 8). Hold the weapon with the left hand near the backsight with the barrel pointing towards

the ground. Pull the bute plate (11) outwards with the right hand to release the bute catch (12) and swing the bute

to the rear of the weapon. With the thumb of the left hand press the back cap catch (13) and snap the butt into

‘engagement with the lugson the back cap. pen the butt frame to forma triangle andthe butt plate catch (14) will engage

to lock,

TO CLOSE BUTT (Fig. 9). Release the butt plate catch and collapse the triangle by pushing the tubular member

into the frame. With the thumb of the left hand press the back cap catch, at the same time push the back cap forward

and swing the butt away from the back cap. Pivot the butt to its folded position, swing the butt plate out to operate

the Lute catch te-engage in the barrel casing, then fold the butt plate flat to lack in position.

SECTION 3—STRIPPING AND ASSEMBLING

8.0 ELEMENTARY STRIPPING AND ASSEMBLING (Figs. 10 and |). Before stripping, ensure that the weapon is

not loaded and remove sling fitted. Set change lever to A, place butt in the folded position and bolt forward.

TO REMOVE RETURN SPRING AND BOLT. Press back capcatch (13) to full depth. Push back cap (15) forward

and rotate anticclockwise until locking lugs disengage from locking recesses. Remove back cap and draw cocking

handle to rear of weapon. Lift cocking handle outwards snd withdraw return spring assembly (16) from rear of body.

sembly

Remove bolt from rear of body. Re-assemble in reverse order. The spring-loaded fouling pin will prevent mis

since the cocking handle cannot be inserted until his pin is pushed forward by

the centre pin on the spring assembly, This ensures that the cocking handle must

pass through the hole in the centre pin,

Fig. 10, To remove return spring and bolt

8.2 TO REMOVE TRIGGER GROUP (Fc. |/)

Set change lever at “ Safe", and with 2 small

turn the slot in the head of the trigger group retaining pin (7) in line with the word "* Free "" on the right side of the

pistol grip. With the nose of 2 bulle: or the blunt end of the cocking haridle push trigger group retaining pin out and

remove. Pull trigger group towards sear of weapon, disengage [rom step In underside of barrel case and swing front of

trigger group out and remove from bedy. Te remove trigger guard, push out forward pin, swing guard downward,

pivoting about its rear fixing, and unhook from underplate

in or rim of a cartridge

NOTE Elementary stripping doot not include any further

pring of

B83 ASSEMBLY. Assemble in the reverse order of stripping

Fig. Il. To remove trigger group

14, 15 ond 16). STRIPPING.

‘when if is required to replace worn or breken parts,

fon the mechan'sm and operation of the weapon, Com-

TO REMOVE

and magazin

through eject

1 unscrew magazine catch screw (18), remove spring (19

Beant ster ie Tap aus siesae BON eae

"

Fig. 13. Toutrip trigger group

92 TO STRIP TRIGGER GROUP (Fig. 13), Pus": out sear axis pin (5) and fe

‘out trigger axis pin (23) and remove trigger (3) downwards through trigges

ut sear group from trigger group. Push

Push out tripping lever axis pir (24) and lift tripping lever (2) 1rom sear cradle (4) and life sear (6) from sear cradle,

2

94

Fig. 14, To remove extractor

TO REMOVE EXTRACTOR (Fig. 14). Push out extracior retaining pin (28) and remove extractor (26). During

this operation hold extractor with thumb or forefinger otherwise it may shoot out. Remove extractor plunger and

spring (27).

Assemble in reverse order,

TO REMOVE PISTOL GRIP. Unscrew grip retaining screw using A” Allen key. Withdraw grip.

Assemble in reverse order.

TO REMOVE BARREL (fig. 15\. Partially unscrew the two barrel retaining

screws (28) as shown using 2” Allen wey. Protect these with s piece of wood and using

42 mallet drive barrel back from its seating. Remove screws and rotate barrel (29) to

dlear bayonet lug and withdraw from body,

TO STRIP MAGAZINE (Fiz. 16). Depress stud protruding through bottom plate

(20) and slide plate from magazine case, cantralling the magazine spring with hand

eo

———

to prevent ie fying (ree

Withdraw platform and

spring assembly (31)

rocking platform at bot.

com of magazine case to

clear indentations.

20

Fig. 16, Te strip magazine

9.7 FORESIGHT. The foresight fits into 2 doversil in the barrel case. It is a spring fit, there being no retaining pin or

screw. To remove, tap right out from either side with a drift

9.8 BACKSIGHT. This should not be removed unless absolutely necessary.

To remove the backsight, drive out the pin, lft out sight and spring, taking care not to lose small collars.

ASSEMBLY

9,

TRIGGER GROUP.

9.9.1 Ensure change lever is at automatic A.

99.2 Replace tripping lever and its axis pin in sear cradle, ensuring that che head of the tripping lever is engaged on the

lower step of the te

9.9.3 Insert sear group into trigger group housing. Line up the sear, sear cradle and trigger housing, using trigger group

retaining pin as a érift, and t.7..¢e sear axis pin

794 Insert trigger upwards through trigger guard ensuring that the erigger plunger is depressed within its housing. Line

‘up, using trigger group retaining pin asa drift, and replace trigger axis pin

99.5 Test trigger group for correct functioning at safe, single-shot and automatic

9.10 BARREL.

9.10.1 Insert barrel into case and push forward, rotating the barrel to clear bayonet lug. The extractor clearance groove

in the barrel face should be in line with the ejector opening

9.10.2 Replace barrel retaining screws hand tight, then finally tighten, a litele on exch screw at atime using Allen key.

9. FORESIGHT. To assemble, insert foresight into dovetall and tap into the required poticion

wu

9.2

9.13

100

tor

102

ma

a

BACKSIGHT. Place spring and sight in housing, line up and insert pin. Insert collars and peen ends of pin over

into countersinks in collars.

MAGAZINE, Feed platform and spring into magazine casing, rocking past the indentations—the upper roller it on

the left side when viewed from the rear of the magazine. Compress spring into casing and slide on bottom plate,

engaging the stud in its hole in bottom plate.

SECTION 4—ZEROING

‘The weapon Is zeroed before issue to the vier and should require little attention other than correction for line, or

direction. Thisis effected by tapping the foresight to lelt or right. The foresight is a spring ft in its seating and requires

no securing screw,

Vertical zeroing is effected by loosening the 4 BA grub screw securing the blade (4 turns) with a yk Allen key and rotating,

the biade in or out as required, one of more full turns. The grub screw must be tightened to relock. One turn of

the bhde gives 4 variation of M.PA. of 5} inches at 100 yards,

‘The weapon may be zeroed at either 100 yards or 100 fees. For 100 yards the Mean Point of Impact should be on sight

line. For 100 feet M.P.. should be 2 inches above sight line.

SECTION 5—CLEANING

Carry out elementary stripping. Clean the bore of the barrel using a pull-through and flannelette size 4 inches x 3 inches.

‘When the bore is clean, cil it, using flannelette size 4 inches x 2 inches. Clean and oll the chamber using 1 piece of tick:

with flannelette on it. Clean the remaining pares of the weapon with an oily rag. Particular attention being paid to the

cilling of the face of the bolt, inside the bolt run and to the elector.

Magatines shoul be cleaned with an olly rag. Ensure that the platform is easy to move inside che magazine care.

[BRIEF HISTORY OF SUBMACHINE GUNS AND CARSINES.

Steting

‘Thebutiness ofStering Engineering began etthe tum ofthe cerry. n the mid 1940's the Company wsinvolvedin the developmant of lightweight ntry mortar

‘withthe Ministry of Defenca In 1858 the Lanchertr machine carsine, which wa Saaad on tha Garman MP2 1 wos Soaignad by GM Larchastar of tha Storing ER

‘ineering Company. Over 10,000 ofthese weapons ware mantactured andaupplied tothe Royal Nevy and Briah Commonwealth Navies, The Company azo man-

[Ufactured the De Lila sient carbine which was in ation nrerstance forces ir Europe within 28 hours of the fist weapon being produced. The Company also manufac

‘ured components for other weapons.

Patchett

Design work proceeded during the War wo achsive a ighter.more accurate. compact and completely riabie waspon. Extensive work by Sirting’s deaigh team under

{G.W: Patchett eoulted in the Potchet Sub Machine Gun. Limited quantities saw service Europa shorty before foe and oF Werld Wat I

‘Aver the War, frthar development and improvemerts ware made and, ates series of competitive tata hed by tha British Government, twas adopted as the san:

‘daré woapon fo: HM Forces bathe Sub Machine Gun mm L2A3in 15k

{ZAY and L2A2 ware ari versions mde mad quanties Between 195 a 889 Wt he agony tha Brith Fores the wapon Bec known a he

tering.

‘Stating Merk 4 (L283)

|With the adoption of the woepan bythe British Forew. production was increased andthe weapon hasbeen supplied and ie tli being supped tothe Armed and Police

Forces of over 30 courtria inthe frea word. More than 2milion Mark 4's have boon mada The deni of tho Starling Mark (243) haa not beet changed inary mavtod

\deg'e0 since its ntroductionand curent spare parts wl it any Mask 4 ever mase. Improvements have been made egulay in production tchniques a many cum.

‘nem are now made from extruded section material o precision castings but ntecchangeabity of all components has mained unalteree.

‘Starting Mark 5(L34A1)

ABrish Genera Stat requirement for wnspon of single shot and ful automat capably that met the standart of “mechanical noe tobe unhaard at 20 metras and

‘not o be recognised aa a frac at 80 metren” was expressed i the oe. Resoorch and design were undertaken Dy GW. Patchett who mat tha requirements fortis

‘weapon based cn the SMG L2A3. Aft extensive Vii an order was paced by he British Government and neolaboration wit) G.W. Patchett, Stelingundrook the

‘manufacture of te SMG Senn LAY (String Patcher SMG Ser Mark § —Sionced).

‘Thematnod ot slencing We described in oa itarature k should be eehaisns thao have an effectively senced weapon the bullet must be subsonic, ther

‘amaine the “creck” ofthe bullet an passed through the ar wich immeciataly disclose the prasance oftheir and thet of «warm. The Sterling Patchett |

silenced firearm. not merely sound moderated or suppressed.

‘TheMark has row become vailabe forsale to triendly Governments along with the Mark 4 which, ofcourse, continues in product an the proven standard Sub Machine

Gun,

‘Steng Mark 6 Semi-Automatic Carbines

‘The Mark 6s identical in appearance tothe Sterling Submachine Gun Mark 4 except thatthe bere hes been lengthened to conform Wit U.S, Regulations and the

\woepon is capable of semi-automatic fire only. The vaapon is primary designed to meet the demand f US cvilan wnthusiaate

‘Steding Para Pistol Mark 7

‘This in 9 special compact version ofthe standard Mark 4 Submachine Gun, The Para Pil range wes develops and put into croduction in tte 1963 by the Woska

Director, Mr, 0.7. Howroya The Mark ?isdesignedior vehicles special una pilots andrews’ pectoral weapons where conned space iitethe storage t wandard

‘Submachine Guns. The Mart 7 gives thesame fre power and characteristice a a ull length Submachine Gor. The weapon comes in four erent moda tha Miltary

versions Ad and AB which fire from the open bolt andhave the capably of fiing single snot ot automatic rapid fire At denotes 4” barel and AB denotes 87,8" Darel

length. A suppressorsilencer is available forthe Aé unt. The Police varions ae designated C4 ord CB, The Cares free from aclosad bolt and has afosting fring pin,

All dosed bolt units ire in the wingle shot mode only. AC series guns have two locating butions onthe upper sia of Une gun cating to enable a dovatl scope al tobe

fitted The buttons are ready drilled and tapped and the String scope ral son thamn act Thi awl take moet angurn rae of right and optical sights,

Storing Carbine Mark 8

‘TheSterfing Mark 8 Carbine mm ¢ closed bot ring weapon designed specticlly for Police usage whore if lite accuracy ia damandedand yatthe ute f pistol am-

‘munition obvistss some ofthe normal dusdvantages associated wit high velocity ammuntioninaucha fle. iacapabie of sam-automatictire ont, Allweapons have

‘wo Locating Buttons on the upperside cl the gun cating to enabe the dovetslied scope ri to be fries

“Comparative reterance numbers and nomenciature

Manutecturern Raferance Lritan Gaveenrent Retwrce

Patcheet Sterling SMG'8 mm Nar 1} NG Patchet 9mm

‘Stevting SMG B mm Mark 2 ‘SMG 9 mmL2a?

Staring SMG 9 mm Mark 3 ‘SMG @mm (22

Sugling SMG 91mm Markt SMGOmm 2A Po

‘Sterling Patchett SMG 9 mm Mack SMGBmm USAT

Sterling Carbine men Mare 8 Na

Staring Para Pino! mm Mark? Ad nd AS NA

Staring Pistol O mm Mark? C4 ana.ca : NA

Sterling Carbine 9 men Marks NA

Taste ane Toa

Exihnive tents wee caring out by the Beth Authotitesbatorw adopting the Staring and tha StelingPatchet. Thea ara retarreo in komen the

iterate

Inthe catn ofthe standard weopon,theve involved immersion in md, sandstorm ana Arcveconditions and is rlabity and continued functioning

Undorauch adverer conditions sled iota compactnass. strength and axcaptional accuracy compared with tx competitors tram many counties ied

{outs adyption Enauranoe Wise were dacontunwed ahs: 1.008 ‘ounds au the weapane showed no Jone of accuracy and thare was "0 messi

Similar texts were cried out en the sient weapon with equaliy good results, wii anything, even mare accuracy, due tothe ang

aseaich and development comtinve

DTEH 1984

You might also like

- Practical Guide to the Operational Use of the PPS-43 Submachine GunFrom EverandPractical Guide to the Operational Use of the PPS-43 Submachine GunNo ratings yet

- Practical Guide to the Operational Use of the PPSh-41 Submachine GunFrom EverandPractical Guide to the Operational Use of the PPSh-41 Submachine GunRating: 5 out of 5 stars5/5 (2)

- 7CBCE Full Auto Vol 3 MAC-10 Single PagesDocument58 pages7CBCE Full Auto Vol 3 MAC-10 Single Pagesangelines123100% (4)

- Sterling mk4 SMG PDFDocument24 pagesSterling mk4 SMG PDFDejan BuckicNo ratings yet

- MP44 BlueprintsDocument90 pagesMP44 BlueprintsNorm100% (8)

- The English Sten Sub Machine Gun ExplainedDocument11 pagesThe English Sten Sub Machine Gun Explainedknockelflies100% (3)

- The Thompson Submachine Gun Drawings IndexDocument7 pagesThe Thompson Submachine Gun Drawings Indextyrant8850% (4)

- M-45 Armorers Manual Swedish KDocument61 pagesM-45 Armorers Manual Swedish Klobosolitariobe100% (4)

- Sten Building BookletDocument22 pagesSten Building Bookletpamrick100% (1)

- Liberator Pistol BlueprintsDocument31 pagesLiberator Pistol BlueprintsCaprikorn88% (16)

- Sterling Build V2Document16 pagesSterling Build V2Nester Tovar100% (2)

- Us1517483 PDFDocument10 pagesUs1517483 PDFJin SongNo ratings yet

- Sten GunDocument0 pagesSten Gunwanderingjoe100% (1)

- Instruction Manual For I.O. Inc S Semi-Automatic Pistol Caliber 7.62X25 TokarevDocument20 pagesInstruction Manual For I.O. Inc S Semi-Automatic Pistol Caliber 7.62X25 TokarevRobert L Buettner80% (5)

- Sten mk2 Complete Machine InstructionsDocument24 pagesSten mk2 Complete Machine Instructionsmic2996% (83)

- Sten Mkii: Complete Machine PlansDocument24 pagesSten Mkii: Complete Machine Planszafnequin100% (1)

- Sten Blueprints Parts Mk2 ADocument22 pagesSten Blueprints Parts Mk2 Aapi-374043498% (43)

- Practical Guide to the Operational Use of the M79 Grenade LauncherFrom EverandPractical Guide to the Operational Use of the M79 Grenade LauncherNo ratings yet

- Practical Guide to the Use of the SEMI-AUTO PPS-43C Pistol/SBRFrom EverandPractical Guide to the Use of the SEMI-AUTO PPS-43C Pistol/SBRNo ratings yet

- Practical Guide to the Operational Use of the UZI Submachine GunFrom EverandPractical Guide to the Operational Use of the UZI Submachine GunNo ratings yet

- The Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsFrom EverandThe Gun Digest Book of Firearms Assembly/Disassembly Part V - ShotgunsRating: 5 out of 5 stars5/5 (3)

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- Gun Digest Guide to the Modern AK: Gear, Accessories & Upgrades for the AK-47 and Its VariantsFrom EverandGun Digest Guide to the Modern AK: Gear, Accessories & Upgrades for the AK-47 and Its VariantsRating: 5 out of 5 stars5/5 (1)

- Practical Guide to the Operational Use of the HK69A1 Grenade LauncherFrom EverandPractical Guide to the Operational Use of the HK69A1 Grenade LauncherNo ratings yet

- A History of the Small Arms Made by the Sterling Armament Company: Excellence in AdversityFrom EverandA History of the Small Arms Made by the Sterling Armament Company: Excellence in AdversityRating: 4 out of 5 stars4/5 (1)

- Advanced Gunsmithing: A Manual of Instruction in the Manufacture, Alteration, and Repair of Firearms (75th Anniversary Edition)From EverandAdvanced Gunsmithing: A Manual of Instruction in the Manufacture, Alteration, and Repair of Firearms (75th Anniversary Edition)Rating: 3.5 out of 5 stars3.5/5 (2)

- Practical Guide to the Operational Use of the RPD Machine GunFrom EverandPractical Guide to the Operational Use of the RPD Machine GunNo ratings yet

- Gunsmithing the AR-15, Vol. 3: The Bench ManualFrom EverandGunsmithing the AR-15, Vol. 3: The Bench ManualRating: 2.5 out of 5 stars2.5/5 (4)

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationFrom EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationNo ratings yet

- Gunsmithing the AR-15, Vol. 1: How to Maintain, Repair, and AccessorizeFrom EverandGunsmithing the AR-15, Vol. 1: How to Maintain, Repair, and AccessorizeRating: 4.5 out of 5 stars4.5/5 (2)

- Practical Guide to the Operational Use of the MAG58/M240 Machine GunFrom EverandPractical Guide to the Operational Use of the MAG58/M240 Machine GunNo ratings yet

- Building or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsFrom EverandBuilding or Restoring Your Muzzleloader: Making Muzzleloaders from Kits and Damaged GunsNo ratings yet

- Practical Guide to the Operational Use of the TT-33 Tokarev PistolFrom EverandPractical Guide to the Operational Use of the TT-33 Tokarev PistolRating: 5 out of 5 stars5/5 (2)

- Gunsmithing Modern Firearms: A Gun Guy's Guide to Making Good Guns Even BetterFrom EverandGunsmithing Modern Firearms: A Gun Guy's Guide to Making Good Guns Even BetterRating: 5 out of 5 stars5/5 (1)

- Building a Home Defense Remington 870 ShotgunFrom EverandBuilding a Home Defense Remington 870 ShotgunRating: 3.5 out of 5 stars3.5/5 (5)

- Practical Guide to the Operational Use of the MP5 Submachine GunFrom EverandPractical Guide to the Operational Use of the MP5 Submachine GunNo ratings yet

- Gun Digest Book of Automatic Pistols Assembly/DisassemblyFrom EverandGun Digest Book of Automatic Pistols Assembly/DisassemblyRating: 3 out of 5 stars3/5 (3)

- DIY GUNS: Recoil Magazine's Guide to Homebuilt Suppressors, 80 Percent Lowers, Rifle Mods and More!From EverandDIY GUNS: Recoil Magazine's Guide to Homebuilt Suppressors, 80 Percent Lowers, Rifle Mods and More!Rating: 4 out of 5 stars4/5 (4)

- Custom Gunsmithing for Self-Defense FirearmsFrom EverandCustom Gunsmithing for Self-Defense FirearmsRating: 5 out of 5 stars5/5 (3)

- Pyrotechnic DatabaseDocument23 pagesPyrotechnic Databasemjs6029No ratings yet

- ID4801 IllDocument34 pagesID4801 Illmjs6029No ratings yet

- ID 4801 SchematicDocument1 pageID 4801 Schematicmjs6029100% (1)

- Hornet Ultralight Autogyro PlansDocument137 pagesHornet Ultralight Autogyro Plansmjs6029100% (7)

- SPH-4 Suspension HistoryDocument24 pagesSPH-4 Suspension Historymjs6029No ratings yet

- Operator's Manual Army Model UH-1H/V HelicoptersDocument432 pagesOperator's Manual Army Model UH-1H/V HelicoptersVoltaireZero75% (4)

- Hiller Rotor Cycle InfoDocument17 pagesHiller Rotor Cycle Infomjs6029100% (1)

- The Citadel's Blue BookDocument70 pagesThe Citadel's Blue BookSusan SvrlugaNo ratings yet

- List of Approved Contractors - 2016-2020-Kolkata PDFDocument157 pagesList of Approved Contractors - 2016-2020-Kolkata PDFKamal AroraNo ratings yet

- First Sino-Japanese War PDFDocument20 pagesFirst Sino-Japanese War PDFdzimmer60% (1)

- संयुक्त राष्ट्र संघ सुरक्षा परिषद्को प्रस्ताव नं. १८२० सम्बन्धी जानकारी पुस्तिका 1Document20 pagesसंयुक्त राष्ट्र संघ सुरक्षा परिषद्को प्रस्ताव नं. १८२० सम्बन्धी जानकारी पुस्तिका 1jagannath marasiniNo ratings yet

- Killing LincolnDocument3 pagesKilling LincolnNam NguyenNo ratings yet

- Flight and Ground Instructor Knowledge Test Guide: FAA-G-8082-7DDocument12 pagesFlight and Ground Instructor Knowledge Test Guide: FAA-G-8082-7DHarold MangahasNo ratings yet

- United Nations Observer Mission in LiberiaDocument14 pagesUnited Nations Observer Mission in LiberiaDumitru BugaNo ratings yet

- Rizal Begging For Reforms Within The Spanish Colonial Set-Up Maria ReflectionDocument3 pagesRizal Begging For Reforms Within The Spanish Colonial Set-Up Maria ReflectionMaria Angela LibreNo ratings yet

- AoS Exhalted Deathbringer enDocument2 pagesAoS Exhalted Deathbringer enknavealphaNo ratings yet

- Jaeger Character Sheet FillableDocument3 pagesJaeger Character Sheet Fillable3.141592653589793238462643383279502884197169399375105820974944592307816406286208998628034825342117060% (1)

- Baran Sieg Master Army List Epic ArmageddonDocument10 pagesBaran Sieg Master Army List Epic ArmageddonDon SlaterNo ratings yet

- Flight From Terror - Otto StrasserDocument247 pagesFlight From Terror - Otto StrasserJeffrey Michael Wood100% (1)

- FM 10-23-2 Tactics, Techniques, and Procedures For Garrison Food Preparation and Class 1 Operations ManagementDocument286 pagesFM 10-23-2 Tactics, Techniques, and Procedures For Garrison Food Preparation and Class 1 Operations ManagementMark Cheney100% (1)

- Desing Thinking Workshop GroupsDocument6 pagesDesing Thinking Workshop GroupsDid You Know ?No ratings yet

- Ciceronian Vocabulary: A List of Words Which Occur Frequently in in Catilinam But Are Not in The Moreland and Fleischer Vocab ListsDocument2 pagesCiceronian Vocabulary: A List of Words Which Occur Frequently in in Catilinam But Are Not in The Moreland and Fleischer Vocab ListsliberaliviaNo ratings yet

- Rinex The Receiver Independent Exchange Format: Werner Gurtner Astronomical Institute University of BernDocument44 pagesRinex The Receiver Independent Exchange Format: Werner Gurtner Astronomical Institute University of BernSuzi Tessa DeyoskyNo ratings yet

- The Witcher TRPG Complete Craftsman's CatalogueDocument48 pagesThe Witcher TRPG Complete Craftsman's CatalogueJocelyn MarleauNo ratings yet

- History QuizDocument2 pagesHistory QuizGlaiza CorminalNo ratings yet

- Naruto MangaDocument20 pagesNaruto MangaAnwar Sadat50% (2)

- Rok Question and AnswerDocument28 pagesRok Question and AnswerVeaceslavNo ratings yet

- WWII 759th Light Tank BattalionDocument42 pagesWWII 759th Light Tank BattalionCAP History Library100% (2)

- Contraindicated Exercises PDFDocument19 pagesContraindicated Exercises PDFconejogris2012No ratings yet

- Savage Worlds Adventure Edition Deadlands Lost Colony ArchetypeDocument7 pagesSavage Worlds Adventure Edition Deadlands Lost Colony ArchetypeArikitaunTaunTaun100% (1)

- David Mckee DoneDocument10 pagesDavid Mckee Doneapi-354914950No ratings yet

- Boer WarDocument3 pagesBoer WarshadeyNo ratings yet

- Warforged FeatsDocument7 pagesWarforged FeatsMassimiliano LuisiNo ratings yet

- 891425-DD 5e - Gear - Expanded Armory Gear (Printer Friendly)Document4 pages891425-DD 5e - Gear - Expanded Armory Gear (Printer Friendly)Heath Wannemacher100% (2)

- Tongue TwistersDocument55 pagesTongue TwistersShantanu NandaNo ratings yet

- Modifying Weapons - Palladium After The Bomb / Heroes UnlimitedDocument7 pagesModifying Weapons - Palladium After The Bomb / Heroes UnlimitedChristopherPearsonThompson100% (1)

- ARM130A1 - Aermacchi MB.339 Series Archived NOVDocument5 pagesARM130A1 - Aermacchi MB.339 Series Archived NOVLava R5s2019No ratings yet