Professional Documents

Culture Documents

Textbook of Production Engineering by K. C. Jain - Chitale A. K.

Uploaded by

Baljinder SinghOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Textbook of Production Engineering by K. C. Jain - Chitale A. K.

Uploaded by

Baljinder SinghCopyright:

Available Formats

IN&lING

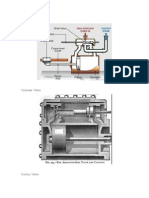

Bac;/r;wattl ,~xJrusl(Ju, Im.. soUd baCkward ,~tm$~onl.bi1l d~lll~s ~t@d I(ln tb!1l ~d of ~. ~oU(lW rom, .-md it el!l!Wr,s, ~,e. coneaiaeras shown l~ ,F:i,g, 25;,].1. Ehnillg ~imve~ 'oftb.e mtn. (he di.e a,pp]~espre:sSlIDreQliJi Ime bJU~(. ,MId th~ deformed mem1!. now:s, '~ugh the d~e, opmin,g in the dillreOOon opposite lO ~~t of the :mm molio:nru~ he,ncc thename oocbi/(],rd extru~io~:. Here tbelimlOWlit of scrap ~sredl.!l:oed to~t S~O 6% (in. fonvmd e~s~on it is albou~ l8: to::ZO%) of Ia.e billIe" we,jpt,. wd the ell:tms:.i.oIl.~o[fCle is less by ,00OOlil .25 ~o 3O%,.l)ue to the ,oomplex design oftie-looJs, it "!!Ids ooruy.llimted! appic81tioll.

IHealed IIOOIal bmet FIIg •. 25.18 Fo.lI'Wati'd .or dime<t eX'lruiSicn.,

HoI splnnJrn:g: HOI ~pb!:!1Ii!:lgissJ:miLM' n~ 'oo~d spi!lmiU!~g, ~~:I: 1fua(:~n b()l~pi!l!l]n:g the blw of the sheet ~e~31i!li,ifir.st, heaJ~ed mid. then he:ld ~gai.t: l'he rul3ti!ng chilllck of m~ lame .. Thi:s prooessisquil.e !cQ.r.IIDlon1:y lu,ed I~O shape thkbr Rl,eta11ic: sheeu,

HllIt df'awing; ~ti~~ ~s~d to: make ctl(p-sba:ped Gom~J1iel:lilS from sbeel metaillb]wb .. Us:ual1y drawing is pe~om1e:d whe:m ~i1.e memal ~:!l in eorud ((If:J:mtmo:l1,. bMit. whe4UC 6e me~al m:ickl:lessismoli'e;, hot, dril.w:i:!IDg is ,carried Ollt In ho~. d!;i'l.w:i[lg •. the b~ted b1:a.Ilk: isplaooo ~m. pooi:I1'on over ~h,e dii,e, ImJiI ~'pul1c;h of the;p:ress :i:sa]]Qw~d ·kI· $ww_ke the blu!k: <Illid ilhl.l!spu_sh tbemtlillerial loto' tbe die,

1. Wlla~ are ~.tI.e cornd worlti:1lig andh.O!I, wurki.lruf,'!: pr-ocesse:s:?

2, Differelllillate ~tween bo] wl}:ddng 8iod.cold "WOrking of metals ..

3. ExpJain. with '1Jl'e hclp of !l~t$tetche.')~ ~tly lWoco!.d 'WQrki!~g,!Uld ~J~y two bot 'Wo:rklling precesses,

,41,. .Ex;plruitilRe hCDt eMr\lsioflp~oces;seSi. w:i~t1. nell~: ste~cl1es,. :; Write SbOA tlOtil11S on me: foUowLrrug~ (a) Ctild sp,jnl1l,tllg (cl Hot $prullni~

(b), C'QJd ~~iQJl (d):lDrawi~ or CllIppilmg.

6. Describe ~iliI.e Hl[ie~igh. ooU:i[l~lIIa~Il!nlcl dtfferelHllllt.e bel'io'l'ee:mJ d:le tW~th;,gh. [i()ru~irlg mi.nilJ:ld tllle- tbree-

Mgh f>O:1lin,g~m. . .

7. .E;li;;pl~i!l d~i,::respecliw: effe-ct s Qr hOl W!O.r'k;lng, a;~d co~d WGlfikj~~!i!l.

8. LiS:1 ~e respeclive adv,an.~3i.ge'.s of hot w:odting aad oorud· worlWtg.

C- HA·· ~ I.n."

___ .... ,J, .. C~

2-.,6· .. ·.··•.· .. ·

...•......

26.1 INTRODUCTIO:N

Formiilg 'cat! 'be: defined.a.':i a Pl(lCcs,"i· in whichlhc d~s,ired :~i~ arid sb~pe ;Me Qb~l1ed (hIwugh dle' plMti~ defom1atlon of ilicmale.ri;ul The sttesses ~nduccd during lheproce~s ate.grc:a.mf!hIWI ilhcYlcild S'~ngd],; 'bu~ less ~. die. frac~l!lfc iS~gth of tilite. ma1cciaL The type of lOOldlng mil.)!, betensile, compres~iy,c,. bending; s;~ng, or a combimlJtion of :lhese~ ThiSi ts a very ecenomical !IJOOI!e'Ss~ as tbe desired shape. :Slle and finish can be ob~ne:d without any s]~if]cant loss of materltiiW. M.oooo\iier, ~.panof the ~~pl,l!l energy is utilized in fmpl'o'ri'ing fire: strength of the p:mdIlC![ ~8h s'train h~ell~ng,.

W\hQn ai. m~ta~ is deformed by a tliloou!facrnriQg. process, the total w'Otk per \!Inl~. yOtll!une don.e (In dJ.e meiml is g~Yeill iby

IV1· .. "" W._,*, \V/'. ,of W.·

l' . r-

where W~ is; the ideil1woikof deJOm:lOlU,OIl:

1" .. . " . .. ".

WI is W w(itk tu av¢rco~· frit::tion at th~ .m~tm-tool i_~UtrfB:c¢,~ W_ is the redundant work.

T

]be i!iCdnntffiaru work ~s the work in\!'Ql\~din the: t!loomal she.!llril!'!gprocess; due to :oou..:a!i\'if'Om'!. de:fonnatinn.

It due.s net ,eantri.bute to the: ,ehmge inlhe; shape of the body. fth: :Cfiiice,pl Is expi.ained iii1J Fig. 26.,1. WheR:i a billet hlshownbefQre cQ:mpres~jQ:f! and after oompres-s[on, [f there is iP¢d"ee!~. 'h:tbricadon :at w; m~,nflil~~ooll ~nrncffao~, the grid wi:n remain l!J:lild~sloned, The square .grid (before coOmpreSS[OH) wUlbeco.me.rec!1anSlular

633

Copyriphted materia'

>. .-.~.r..:'~-

..... ..0: ': .. ..:....=;~';_

••••• 111. ........

,q3!fte:rcO"mp.re~lOIl). D.e bei.,ghl otesch grid ,~be!fore oompooss~oll) willbeeome :re.ctMagui,m: (af~cr (lO!illP~SS:iOll). The be~.gffi1i1: of eaeh grid Mock wIn gel, sbonem.ed. and itslell£!m will ge~11lI:c:re.8ised .. Sueh deformation is ,ca.il~ed .unijo·rm: dif/omltJtro.ll. Ho.wevel;.~f flic,tlOl1I is preSUI. 'It tlle m~tal.-tool interfUioe, then the grid wHl beeeme di.s,w!ltted. accom.pru:ded by ~-e~n~!lg or bulging 00 the sides. De e-Xtro work. w~ichgoos initIO d~SliQrti[lg the grid <!Indal~Q~tu.o (fOOting bulge isa WasIElllUl(!! ]S caUed rnllile re.iJmdanl work.

I I

I I

I I

I I

I

I I III I II Wiltl ~riclion

,{~) 8I;lf(l~Q 'OOf!i"lp'~~if;$t'Q~ (b), Ahr~:;;(mlp~$$rQ.rl

Rgun!I' 26.11 M:ode 'Oit clefonnatlon.

The. (:o~no!1ly used methods fo·], the ana!!ysi$, ,of metal forming: processes .~; I .• S1<iib methed

z, Up.pe-:r~ooHdl1H:~lOO 3. SHp·li.!!l,e metllod.

The~ anirl.ys~s is bask:IlIHyLl1e same fQrcold fomrumg.amId ~ot fOirmii:I"DJg" wilh difference Qllirny ~I!I. flow a:ncd. fri'cl~on clMracte:rili~~cs. The anal,ysls ~ftbe meat fonnitlg:pl'OOosses b:y' the aJoove methods is onrnyapproximrue:, dl!!.!cro 'lhelitlaJilY assum,pLi.o:ns nlade :reg;u:dJng ~.~e IbChalliourroflhe wOork maieri,alln1d ~:ll,e mede of de.fo:r.ma!~o~. The appm.li:milltiOmJ is bd~:e[ ;Ei!t low o~Jlld:ellt: ,offrk:l1lOll. Thus, the oom:~ill:icnil Is better w~tb. cold workintg" ]ow~:frictioll prooesoos ~~an W~(b. hOot WO:l'ttill:g, h~glil.-fti.c~lCill: p!fOCesse:s.

IIlI thIs ,CMpter,we shall deaW with QnWy the sl~b metbOOl .: , SlOl!lHlfl~lYs~s ~:ec~:rIflqJue' or ·elemem:u.lC)' theO'l:Y'

mal::e:.s, the FoJ!o,wililg assu:mp~iO:llis~

I .. Tbe .nlaJ~eri!al ~s ~s:otr,opffic Imd mooMp'mss~bl~, and theelastic SI1'l!li!M B!m n('lg~~~bl~.

2. Def(l!:Jl1l ... ~iol'l hi homoge!l10ouslbr-ougih,(lut the de:fO:fl1I1ii:IliS marerials uader study.

3. S~S('lS on a p'I~J1i(;: rlll:ml:J!l to the: now dir~ctilJl'laa:-e pri,m:::irai suesses,

In ~is method. ill. 's}ab' of iwnhcs,im8tl*ickm-:ss is comiidcood ,oodaf'()rctl baJ!3lIloo {eqlliHbrhllm equation} is made (l~ it D.e :resuhillg ,differenrtial equation 'of saatlc equi~~bri:lJm is solved w~(h tlm he]iP Qf appr.oiPri:!ii!le OOlJl"u:lary OOlild]i~iQrnJs amd )/IJeld c-nteria.

Ana'ysis of ,metal t'orming mechanics

DUiri:ng the process of metll] fol:T:tl~rlg" .;'1. ~~L~ri:!'d ~s diefQjrl!Dedl:nelasdcam~,y .. COiltside:ri:ll!l!; a.letl;S~~e ~.esm specilmen,. le;[ 1. be;lihe :iNJitillill g:aIlS:e ]e:nlgth ... DUliEI! ~t1e p:rooeS5 of p1;ast;ic Row and ~.ecki1ilig. thegalllg:e:len~]h cikal1gesils. v.rune OO!uJ~uollsLy. HO'w,e.v,clD':. cQ.ntSlderi~g di~.coote ~oop's of ~uge ]~.gthll' '2' IJ ••••• weean 'W.rI.oo

. = I'~f ( .. ·'d .. f).' = ~ .(. If ) .

€-- =!lrI-

.'~ . 1 '. t·

. l.

whe~ ltiS Lhell1~~ leng~baii,dJ I{ is the ~~j~io\'lil ]e;n.glh.

Si:nce 1levo~ume: V'is CM:Ma..'I1U,. the eqmni,oll can be WntOOn 'OIl¥O~lIm.e oo[lstmcy as

y==.A.1

I, Al

Copyr'ghtcd materia

'Thudsb:.1!in ~ Tme strain ""'= s ="'= .~. (AJ ... ) ..

At.

The work dbneper u~~ volume in homogeneous d!e~orm.atio:l:'I is

IV ~ Tm. ,1m, "Tru. strsln =0":" x In ( ~ )

If ~he eiects o:f b1!t~maJ friction due 10 [11~e:r.rn.a] metallic :sllirearing m :ineax or s~~ppl~!:!es WS [lot acoo!.m~ed for, and ,eliJemaJ] frieli!on is alsa not QO!ll$iedeiCd, the above rO:m1:Iil!I~l ca:~·be appned ~(!l problems sll'Cb ·as· e-xtm:s:iK:lnJ or WlOO; drawing, In ,~tnJ$ioil'!. 'CQ!1!sJd.~ri!)g (h~ :ram p:res:Sll~ p snd ILh~ !'!:_ma I. tb~ work d~ .~ u!1!it V{l~!ml.e of ~leJT.ial for :9. d~splacem~nl (Kf lb., bj]]~llby 1:1:!1i~t di£iUmlCl1l is given by

pxl= !T.,XIn(~]

A:!! areslJIU of :meta] 'W(!i!l'!t_g.g ~~h. Rowe f~ 985),. J.Oh~5Qfl a!Ild S('l~ others ~ave; :fQIJ~d fluu

P=l++bl"(~)l

where a=,~17, a fac~:Qr ~};a(.aocolll~ls fail" the: fC>d!lnd,a~u wol:k or Ilhe inJ~m31 n'!~larunc: shear. amid b = l.5:" 3i faelOf lliatil.tCotlJillliS fill:' thie·Crlcti,OIl be!].WOOffilI tile billet and the oollt<l:ille~ w31l..

:2)6.3, FO:RGIING A.NAL Y:SIIS lJSINIG SLAE!1IMETHOD

Jmru Ibis sect~on, om a.DlJ~IDysis is mwmy devetedte dlete:mti:rniDg ttiJJe maximum fo.ree [e.qu~r.edfor forging ... strip and iii disc between two parallel diies. Ohviol!llsJy, it. is. a case of Oipen di!eforgi:RJg ..

Forging O'f strip'

FIgtu.e 26.2 a .slQw.sa [ypJcal open di.e fo:rg;i~~ ora natsuip, To s:i:mpruify our amal.Y'8~s, we shall make:lhe fQl1:owing assUilln~Hi.QlJis:

(~) 'The;~orgLngforce .F I:I!ttilruns itamuxirrmm '!!'aillJlC <It tbe, end of the o;perodon;

O~) The: 'c(JodficJen~ ,of fijC!l:iOfl /1: b~lW~n the workpiec~ and the dies (pruiIJmns}~s ooost:mt;

(i~~) The tbickness o.ftbe: workp]eoe, is small as compared wi~ its OIR:ew dimellsioillS, land itbe var:lalLion o.f

the stres:sfje~d aIDong the y.di:recuo.llJ ~s tnl:eg~rug~iO.l.e:;

(~v) The ~e:lligth oil" Il.e :S!~rip is Wlli.uih mere than tihe w~d~J mrud '!he; p[\oblem is. one ofp]iImJe strain ~; '(\,) The; ,e~:I1ilire wQrkp~ooe ~~: ~~ the;D~ac5~ic st~]e d~riflS 1il1!~; pt'g~e1l:f;,

AI tlle: .lostatn1: sbown 1n .Fig. 26.:2(a). ~helh~cb:e-ss of the waikpi,ece is it i.l.Thd the w:idtb~s 21. .l.et Uis cQ!liLsioor Mil ,eleme;rJll. of width dx <.lit a d~&taill.oe x from. the origin. [M ,OUI analy8iiS~. W~ .tak0 me Ie:[lgth of tblll \liorkp:i.ece .ilSlInhy {in tbe .:'::-dhieCtlQIl) . .] Flpre.26.2(b) sb.owsthe same ele:m.e:Jilit~milU. th,es.tr:esses actmg on it, Conslderjng l1:e >eqllj]ibdllml. (If the ~L~rn~!u in ~e -:r-dir;eolio:o. we gL'l~

hdO"x +2~::.: 0 (26 • .1)

w~et:e;da;!; ;;;: (Uk) dx·ris ~J:ie m.ctiona~sll:res:il. 'Fa make; tbeMia~ysi.s :S~i:tip.le[. pad O'~ are cOmwdcfed It.e priillcipal stresses, The, !prob~elmlbeillig of II. p]3:ne .... s~rnjn ~y;pe"Eq, (26.1) ntiliy be u~d as the; yield c:ri:~ri:on. Thus

CopyJlighled materia

{<li~ :D~r~ o1fQ~g[ngl Qp;E!!'atioo (b'}1 :St~ QI) ~~m~n~

F[glure :2fk2 FOiI'C8 a~ds,~resses du~rng fo:~'ging.

(216.2)

Nie. tile f~e end:!>. Le~, wil1en x ~:s small (amd .aJl!so .all.); ... 21;. the problem being :s,ymmemcabouiI: the midphme. w,e: are~ c,(losiderimg ooilly one--.balUo. our maly.."is,. Le .• 1[11 :s~ x ~ l), srn~dj[Jg between the Wiorkpiooe.md d:le dile-s must ~ake. p]acel.O, ;.dlrnvlol' the teql!lired exp3JThS~Ofi of tile workprere. lIow,eNef, beyond aCe:rt:aJ]IDl value o.f x (ito die regi:o.ll O~X S l), :83y~ x~, ~re is; no, sliding ootween. the 'Wlorkpiooe and ithe. dies. 'Ehi:s is, doe ~o tile lncreasMg mc,ti.olllal stress wbJiclru 1eadls to Ire. maxl:m1l!Dl vaIDue,. eqa)J. 1:0 ®ks~eW" y~eld! stress, at ,:II: ~. x~ 8illdre~llii:llls so' illl t!he restof the zoee, Xi ;S; x:::: ,I. Hence,for O~; x: ;S; Xj

t' == JJp 1~'26 . .3)

(26,.4)

However.~[: s.homfld be noted that mhis assumpLi.ol1 isilncCI:l.'f:eC[.i'I!l: the stress 'ffiets on tbe p~!j}mJes, on. w~.eb, -1" ~s a;cli~g (oo~ Fjg .. 26.,2) ..

For, the 8~~dj~!g (wQIls;tid,:j~g) Z(!r!Il1. t!8~!lgEq,. (26.3). if! Eq, (26.4) ~f!d i!!!~eg~ting. we h~v~

J·dp_ =2# I~ dx + C~ (0 ~x ~ ,~)

P Il JI .

If!! P= '.4JDt+ e, It

N;ow. at,.x "" 0, G~ "" 0, ~.e.,p' "" 2K (LfomLhe ),]eld cri;~erio~.).. So·

C1 =ln2K

P~2K~P(2:)

Pm ~ ~t.iC:k~!lg .im.ne:, ush'Jig sq. (26.4) :lnEq. (26.2) ,m'Id jnrogratim.g, w~ ha ... ~

Id' 2K J..t- ~.

'lr= ='.=. . .w,t + (:';2 h '.

Copyrighled material

VS~D:g Eq. ,(26.11 ),' the fcree pe~r writ le['J~ we, ge~t is

[183 ,,-.... 148 ]-1

: -, ,", II· "."' .',',' II!J_--OI£I!J " 1'-'" _'" _,',~ _ ._ I' ,'., _- ",:' ",I

F:= 2,.',., 8.OSe "tlr +1 .... ,,8.~().6M + O.16'x}dt. NJmm

'(! -8,)" ,

- -

"" 36(}25 Nlmm

Sinoe the lengtil, of the strip is 150 nwl.,. the total fOfgi:ngfoICe is rso x 3602.5 N == 0.54 x lO() N.

Eumpltl!: 263 SorvefuiH:ple,26,,1 when tbe coefficient offrictlion j,l- flUS. Solution 'Us,in,g Bq, {2!6.9)"we obuoo.

6 ln 1 .. --:- -. . ' - .- - ,

,"t~ = .'--, -, n ~::;37.;:5 x 1.83= 68.74 mm - ,(U6 0.16

Since X.IS more than 1.1lllile. entiFc:wneis noniS,tickiiQc.

~ ~

p = 8J}S eC!.mx N/mm2 (0 s l;5;48 mm)

. ++

S<l, F·~:2 ~ij!J:8,08e,omhd.l: ~ 1$88.:5 N/rnm2

JQ

TOlalforgingfo.rce= 150 x 1588,5 N c:::= 0.238 x H~ N

26,.4FLAJ IAOlLliNG ANALVSII,S; USING· SILAB, IMlE,TIHOD

'The typical! flat. TOUing of plaies. sheets, 'or strips is es~nliaUy a ,1lI1001!:-5trillO o~r:a(~OtlJ, since liiUle W~de;llfullg.of the workpiece resulls,.This can, be, expJained by examining lle shape of the de:fonrnuion :ront as sho,wn in Rg;.l6.c],The 1~nglh()f OODtact.L between the :rol~s and the· workpiece ~sllisuidly mucll s:malfe;r than, the w.id~h w 'of the ~bect. AJj,the oolls jndl.l~ a comp.rc::shl,e stress u .... , the plu."itic ro~e i~ thj~!:!ed ~!:!d ~s free to c"~pand .in the rolling direction.x. bull '11I!_'aJj (nrpansion jp the y ~tion is cffectiivcb!' restrained by the undefot':!'nilog mOltmal on 00ili s.Me'S ofdJe roll gap. Th.e net effectfsil coodlldoD. of plane: stmin. wheree", ,,., () ill1!d e, "'",e~, C~a!p~ at

the ,edg,es: ofllle workpiece. ~ ,."

Fig. 26.3 .sctiemalilcdiaglramofdefo:rIii.Ii.Ia1ion zone Infliat lI'on'lng ..

'The e,l'fec'ls of ron geometry andfiricl:ilon on lbe :ro.11in8 pro;c.ess; esn 00 understood in terms or the frict!,oo .. :j;lill eJliect. Com,srder ~iIlcmmng geo:m,{lU, i~1 Fig. 26.4. wheire at som.e PO~f1t N in ~be li"Oll pp the

Copyriphted materia'

You might also like

- Drug of Abuse PDFDocument94 pagesDrug of Abuse PDFPatrick Perez100% (1)

- How Magnetism Works - Maurice CotterellDocument24 pagesHow Magnetism Works - Maurice Cotterelldawsecs100% (6)

- Keyword Reference - Alphabetical - QB64.org WikiDocument34 pagesKeyword Reference - Alphabetical - QB64.org WikiJoseph G. TaypinNo ratings yet

- MET 306 N-Sided SurfaceDocument2 pagesMET 306 N-Sided Surfaceneeraj kumar100% (1)

- Geography Workbook - 1 by Manocha S. K.Document31 pagesGeography Workbook - 1 by Manocha S. K.Chandan MukhopadhyayNo ratings yet

- Abner Doble PapersDocument13 pagesAbner Doble PapersAlvaro HiginoNo ratings yet

- WErbsen CourseworkDocument562 pagesWErbsen CourseworkRoberto Alexis Rodríguez TorresNo ratings yet

- (1834) British Manly Exercises - Donnald Walker PDFDocument443 pages(1834) British Manly Exercises - Donnald Walker PDFSamurai_Chef100% (2)

- Michael R Meyer - A Handbook For The Humanistic AstrologerDocument311 pagesMichael R Meyer - A Handbook For The Humanistic AstrologerAdriano_5100% (10)

- Acoustic Tractor Beam: 35 Steps (With Pictures) PDFDocument38 pagesAcoustic Tractor Beam: 35 Steps (With Pictures) PDFAmirNo ratings yet

- Carlton Chaisaw Chain ManualDocument35 pagesCarlton Chaisaw Chain ManualstarkopeteNo ratings yet

- Super Sunray PlansDocument7 pagesSuper Sunray PlansAlphamatrix01No ratings yet

- Journalism Asia 2004Document60 pagesJournalism Asia 2004Center for Media Freedom & Responsibility100% (1)

- Hovercraft Building PlansDocument3 pagesHovercraft Building Plansinfineum100% (1)

- Fresh PerspectiveDocument96 pagesFresh PerspectiveKhanh Dam100% (1)

- Mole Calculations and Polymerization ReactionsDocument8 pagesMole Calculations and Polymerization Reactions_patmurrayNo ratings yet

- Magnetron Operation & ConstructionDocument15 pagesMagnetron Operation & ConstructionJeans PascaleNo ratings yet

- Silo PDFDocument1 pageSilo PDFYan Fade BlackNo ratings yet

- Another Arduino Laser TripwireDocument5 pagesAnother Arduino Laser TripwireswoneraNo ratings yet

- TM11-2405 Meteorological Balloons, 1944Document51 pagesTM11-2405 Meteorological Balloons, 1944david_graves_okstateNo ratings yet

- En CD00201961 PDFDocument39 pagesEn CD00201961 PDFIrini Fountouli - LadopoulouNo ratings yet

- 1943 Jamaica Plain HS YearbookDocument91 pages1943 Jamaica Plain HS YearbookCAP History LibraryNo ratings yet

- Servo 2008 - 02Document84 pagesServo 2008 - 02Jose SeVi100% (1)

- What Is C++?: C++ Interview Questions and AnswersDocument42 pagesWhat Is C++?: C++ Interview Questions and AnswerssimraniaNo ratings yet

- Nonlinear Finite Element Analysis of Shells: Part I. Threedimensional ShellsDocument32 pagesNonlinear Finite Element Analysis of Shells: Part I. Threedimensional ShellsJorge PalominoNo ratings yet

- Trex450SE-V2Manual EbookDocument36 pagesTrex450SE-V2Manual EbookdomsNo ratings yet

- Ch-10 Rotational MotionDocument20 pagesCh-10 Rotational MotionEasyPhysics100% (3)

- Thin Film Technology Hand BookDocument42 pagesThin Film Technology Hand BookJems BondNo ratings yet

- Quick ReferenceDocument7 pagesQuick ReferenceDanielTovarNo ratings yet

- tipsPREVIEW2 PDFDocument13 pagestipsPREVIEW2 PDFBaljinder SinghNo ratings yet

- Computer Integrated ManufacturingDocument121 pagesComputer Integrated ManufacturingRahulNo ratings yet

- CH 24Document9 pagesCH 24EasyPhysics100% (2)

- Rubiks Cube Solver PDFDocument10 pagesRubiks Cube Solver PDFpbikerator100% (1)

- Forming metal sheets using superplasticityDocument2 pagesForming metal sheets using superplasticitysibimsNo ratings yet

- Section Modulus and Bending Inertia of WingsDocument6 pagesSection Modulus and Bending Inertia of WingssupermarioprofNo ratings yet

- Powerengineering201512 DLDocument53 pagesPowerengineering201512 DLjosetxoxNo ratings yet

- DRO-550 Construction GuideDocument23 pagesDRO-550 Construction GuidePeterNo ratings yet

- HP-19C & 29C Solutions Games 1977 B&WDocument42 pagesHP-19C & 29C Solutions Games 1977 B&WjjirwinNo ratings yet

- Homemade Nixie TubesDocument6 pagesHomemade Nixie TubesRulo VillanoNo ratings yet

- Air MuscleDocument18 pagesAir Musclemohit616No ratings yet

- Servo2008 11Document84 pagesServo2008 11Karina Cristina ParenteNo ratings yet

- How To Fly A Human Powered Hydrofoil The AquaDocument12 pagesHow To Fly A Human Powered Hydrofoil The Aquamarandan85No ratings yet

- LaserDocument29 pagesLaserGaurav YadavNo ratings yet

- Dse at 27771112Document82 pagesDse at 27771112it-adminNo ratings yet

- Khmer Fashion Magazine 2009Document56 pagesKhmer Fashion Magazine 2009Sophal HuotNo ratings yet

- 1904-Instruments For Forest Work-NeDocument33 pages1904-Instruments For Forest Work-NespaytNo ratings yet

- Beginners Guide To Connecting Your RC Plane Electr PDFDocument11 pagesBeginners Guide To Connecting Your RC Plane Electr PDFMehroos AliNo ratings yet

- Steam ValveDocument6 pagesSteam ValveuaisouauNo ratings yet

- Service PS2 Part 1Document5 pagesService PS2 Part 1refadewaNo ratings yet

- 2D and 3D TransformationDocument42 pages2D and 3D Transformationachintya0105No ratings yet

- Inflatable SailboatDocument9 pagesInflatable SailboatSorin DirjanNo ratings yet

- Part 1 - Forbidden Poems of Abu NawasDocument49 pagesPart 1 - Forbidden Poems of Abu NawasAfifa El SamadNo ratings yet

- Air Muscle PresentationDocument23 pagesAir Muscle PresentationNm5793No ratings yet

- Barco: Tools CatalogDocument30 pagesBarco: Tools Catalogeternal_harpyNo ratings yet

- Air MusclesDocument32 pagesAir MusclesMohammed ShahinNo ratings yet

- BbasdjknbdkjDocument1 pageBbasdjknbdkjsurya0% (1)

- 040617032235Document436 pages040617032235Ahmed HaaNo ratings yet

- Manual em Ingles e Bem Explicado Tig 200 AcdcDocument16 pagesManual em Ingles e Bem Explicado Tig 200 AcdcMarcelo CarnicelliNo ratings yet

- Metal SpinningDocument2 pagesMetal SpinningPlymouth3DDesignNo ratings yet

- 1996 Phantom Fireworks CatalogDocument36 pages1996 Phantom Fireworks Catalogjkendall1436No ratings yet

- June 2012 Wire Rope ExchangeDocument84 pagesJune 2012 Wire Rope ExchangeWire Rope ExchangeNo ratings yet

- Louis Belet Cutting Tools Watchmaking Jura Suisse Vendlincourt Switzerland Brochure Hob Cutters enDocument16 pagesLouis Belet Cutting Tools Watchmaking Jura Suisse Vendlincourt Switzerland Brochure Hob Cutters enLogan RaoNo ratings yet

- Application For Registration: Save Time - Apply On-Line atDocument4 pagesApplication For Registration: Save Time - Apply On-Line atBaljinder SinghNo ratings yet

- Fried Chapter3 PDFDocument161 pagesFried Chapter3 PDFBaljinder SinghNo ratings yet

- Application For Registration: Save Time - Apply On-Line atDocument4 pagesApplication For Registration: Save Time - Apply On-Line atBaljinder SinghNo ratings yet

- Dea in Stata (Draft) by Choonjoo LeeDocument13 pagesDea in Stata (Draft) by Choonjoo LeeChoonjoo LeeNo ratings yet

- Hemp Industries Association v. Drug Enforcement Agency, 9th Cir. Case No. 17-70162, Filed April 30, 2018 (Hemp III)Document5 pagesHemp Industries Association v. Drug Enforcement Agency, 9th Cir. Case No. 17-70162, Filed April 30, 2018 (Hemp III)Robert KossackNo ratings yet

- OfficialNotification PDFDocument201 pagesOfficialNotification PDFBaljinder SinghNo ratings yet

- Fried Chapter3 PDFDocument161 pagesFried Chapter3 PDFBaljinder SinghNo ratings yet

- Hemp Industries Association v. Drug Enforcement Agency, 9th Cir. Case No. 17-70162, Filed April 30, 2018 (Hemp III)Document5 pagesHemp Industries Association v. Drug Enforcement Agency, 9th Cir. Case No. 17-70162, Filed April 30, 2018 (Hemp III)Robert KossackNo ratings yet

- Application For Registration: Save Time - Apply On-Line atDocument4 pagesApplication For Registration: Save Time - Apply On-Line atBaljinder SinghNo ratings yet

- Registrant Record of Controlled Substances DestroyedDocument2 pagesRegistrant Record of Controlled Substances DestroyedBaljinder SinghNo ratings yet

- TR11 Wolf OMG PDF PDFDocument197 pagesTR11 Wolf OMG PDF PDFxxxfarahxxxNo ratings yet

- Uso de Modelos de Eficiencia PDFDocument5 pagesUso de Modelos de Eficiencia PDFCarlos BlancoNo ratings yet

- DeaDocument42 pagesDeaMonjurul Karim RajuNo ratings yet

- Get Me Off Your Fucking Mailing ListDocument10 pagesGet Me Off Your Fucking Mailing ListboTT1ENo ratings yet

- Fuck NuanceDocument10 pagesFuck NuanceDean PyeNo ratings yet

- Dlbook PDFDocument78 pagesDlbook PDFFran MifsudNo ratings yet

- MODEL 3330: Optical Particle SizerDocument4 pagesMODEL 3330: Optical Particle SizerBaljinder SinghNo ratings yet

- Ibps PoDocument25 pagesIbps PoKabya Srivastava100% (3)

- OPS Model PDFDocument113 pagesOPS Model PDFBaljinder SinghNo ratings yet

- MV 44Document3 pagesMV 44Chandani DesaiNo ratings yet

- Official RBI Office Assistant Recruitment Notification 2017Document28 pagesOfficial RBI Office Assistant Recruitment Notification 2017KshitijaNo ratings yet

- MODEL 3330: Optical Particle SizerDocument4 pagesMODEL 3330: Optical Particle SizerBaljinder SinghNo ratings yet

- JohkjbkjDocument14 pagesJohkjbkjErvina Pratiwi Simangunsong IINo ratings yet

- Advertising and PR Basics: Definitions, Classifications and GrowthDocument369 pagesAdvertising and PR Basics: Definitions, Classifications and GrowthriomjNo ratings yet

- AdvtDocument15 pagesAdvtSiddharth SinghNo ratings yet