Professional Documents

Culture Documents

Cps Crane Maintenance

Uploaded by

Trần T Như QuyênOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cps Crane Maintenance

Uploaded by

Trần T Như QuyênCopyright:

Available Formats

CPA BEST PRACTICE GUIDE

INSPECTION, THOROUGH EXAMINATION AND MAINTENANCE OF CRANES

Published by: Crane Interest Group Construction Plant-hire Association 27/28 Newbury Street Barbican London EC1A 7HU Telephone: 020 7769 3366 Reference No. CIG 9901(1) Published 16 Sept 1999

CPA BEST PRACTICE GUIDE

INSPECTION, THOROUGH EXAMINATION AND MAINTENANCE OF CRANES

CONTENTS

1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. Introduction Scope Definitions Personnel Carrying Out Inspections and Thorough Examination Periodic Checks Thorough Examination Testing Rated Capacity Indicator/Limiter and Overload Protection Details of Written Examination Schemes Non-destructive Testing Techniques Data Logging Maintenance Record Retention Page 1 2 2 3 4 6 7 7 8 8 9 10 11

1.

INTRODUCTION

1.1. The coming into force of Lifting Operations Lifting Equipment Regulations (LOLER) and the Provision and Use of Work Equipment Regulations (PUWER) on the 5th December 1998 have brought in changes to the requirements for all lifting equipment regardless of where it is used. Details of the Regulations plus an Approved Code of Practice plus HSE guidance can be found in the HSE books Safe use of lifting equipment reference number ISBN 0-7176-1628-2 and Safe use of work equipment reference number ISBN 0-7176-1626-6 both of which can be obtained from the HSE. 1.2. The Regulations are short and goal setting in nature and LOLER replaces most of the Sectoral Law relating to the use of lifting equipment. The existing Docks Regulations 1988 and the Mines (Shaft & Winding) Regulations 1993 are either partially revoked, amended or left unchanged and details are given in Schedule 2 of Safe Use of Lifting Equipment referred to in 1.1 above 1.3. This Best Practice Guide has been developed for the crane industry by the CPA and should always be used in conjunction with LOLER and its ACoP and Guidance, PUWER and its ACoP and Guidance and BS7121. The Best Practice Guide is intended to give more detailed and specific guidance for crane owners and users on the terminology and periodicity of thorough examinations and inspections (under the new regulations these terms also include any necessary testing). Guidance is also given on the production of written schemes of thorough examination introduced by LOLER and maintenance as required by PUWER.

2.

SCOPE

This best practice guide is intended to give practical guidance for the pre-use checks, in-service inspections, thorough examination, testing, maintenance and documentation of cranes. These are common for all industries in which cranes are used.

3.

DEFINITIONS

3.1. Competent person A person who has such appropriate practical and theoretical knowledge and experience of the lifting equipment to be thoroughly examined as will enable them to detect defects or weaknesses and to assess their importance in relation to the safety and continued use of the lifting equipment. 3.2 Appointed Person The person who plans and manages crane operations and whose duties are defined in BS 7121. 3.3 Mobile Crane 3.3.1. Fully Mobile: Cranes capable of travelling under their own power with loads up to the maximum for which they are designed, suspended at any point within the working range. 3.3.2. Semi-mobile: Cranes that are not designed to travel with suspended loads. 3.3.3. Portable: Cranes that are designed for easy transportation and erection but are unable to travel under their own power. This will include cranes which have the means of transportation removed to leave them operating on a fixed base. 3.3.4. Loader Cranes: Cranes fitted on vehicles (including trailers) and designed for loading and unloading the vehicle/trailer. 3.4 Testing 3.4.1. Functional Testing - Operation of each crane motion without load on the hook. 3.4.2.. Performance Testing - Operation of each crane motion with the rated load on the hook for the configuration. 3.4.3 Overload Testing (Static) - Applying a load to the hook which exceeds the rated load by an amount determined by the competent person conducting the test.

3.4.4. Overload Testing (Dynamic) - Operation of each crane motion with a load on the hook which exceeds the rated load by an amount determined by the competent person conducting the test. 3.4.5. Non Destructive Testing (NDT) - Tests carried out on the crane structure to establish the presence, location and extent of any defects that may affect the integrity of that structure. The techniques employed are such that they do not damage or alter the material under test. 3.5 Bare Lease Where a crane is hired (normally without a driver) from the owner and the user is responsible for all repairs, maintenance, consumables, thorough examinations, inspections and checks.

4. PERSONNEL CARRYING OUT INSPECTIONS AND THOROUGH EXAMINATIONS

4.1 Inspections Inspections shall be carried out by a person who has been trained and assessed to inspect that crane. Crane drivers may perform this task provided that they meet the above criteria. 4.2 Thorough Examinations Thorough examinations shall be carried out by a competent person. It is essential that the competent person is sufficiently independent and impartial to allow objective decisions to be made. This does not mean that competent persons must necessarily be employed from an external source. If employers and others within their own organisations have the necessary competence then they can use it. However, if they do, they must ensure that they also have the genuine authority and independence to ensure that examinations are properly carried out and that the necessary recommendations arising from them are made without fear or favour. Where the competent person identifies defects affecting the continued safe use of the crane, the responsibility for the rectification of these defects rests with the employer of the person using the crane (See LOLER Guidance paragraphs 38 43). On a construction site, where cranes are often hired in, any rectification of defects is normally carried out by the crane owner, however the employer / hirer is responsible for ensuring that the work has been done. If a crane is owned by the using employer or has been hired under a bare lease agreement the employer will need to make arrangements for the work to be done. In all cases the Appointed Person responsible for lifting operations will need to assure themselves that before a crane is used, all defects have been rectified in accordance with the competent persons report.

5. PERIODIC CHECKS (PRE USE AND WEEKLY INSPECTIONS)

5.1 General The appointed person should ensure that the checks have been carried out. NOTE: The crane driver may be authorised to carry out periodic checks to the extent that he is considered to be competent. 5.2 Daily Pre-Use Checks At the beginning of each shift or working day that the crane is in use the following routine checks, as appropriate for the type of crane, should be carried out. (a) Checks as required by the manufacturer's handbook. (b) Check that all ropes are correctly positioned on their sheaves and drums have not been displaced. (c) Visually check that no electrical equipment is exposed to contamination by oil, grease, water or dirt. (d) Visually check, by inspecting relevant levels and/or components, that no loss of fluids such as lubricating/hydraulic oil and coolant is apparent. (e) Check the operation of all limit switches or cut outs and the dead man's handle or lever, using caution in making checks in case of malfunction. (f) Check that the rated capacity indicator (r.c.i.) (previously known as the automatic safe load indicator) is set for its correct duty and that the manufacturer's daily test is carried out. (g) Check that the load radius scale is appropriate to the jib configuration fitted if the equipment is separate from that in item (f). (h) By varying the load lifting attachment radius without load, check the correct movement of the equipment in items (f) and (g). (i) Check that the correct air pressure is maintained in any pneumatic control system, e.g. brakes. (j) Check that lights, windscreen wiper(s) and washers operate efficiently. (k) Visually check the security of wheels and the condition of tyres on wheel mounted cranes. (l) Check correct function of all crane controls without load. (m) Check satisfactory operation of all audible warning devices. (n) In the interests of safety and fire prevention, check that the crane is in a tidy condition and free from tins of oil, rags, tools or materials other than those for which storage provision is made, that access and egress are adequate and that appropriate safety and fire fighting equipment is readily available. (o) Check that there are no obstructions in the path of travel of the crane.

5.3 Weekly Inspections Once a week, when the crane is in use, in addition to the checks recommended in 5.2. the following checks as appropriate for the type of crane should be carried out: (a) as required by the manufacturer's handbook. (b) the r.c.i. in accordance with the operating instructions. (c) visually inspect all ropes for broken wires, flattening, basket distortion or other signs of damage, excessive wear and surface corrosion. (d) all rope terminations, swivels, pins and retaining devices and check all sheaves for damage, worn bushes or seizure. (e) inspect the structure for damage, e.g. missing and bent bracings on bridges and strut jibs, bulges, indentations and unusual rubbing marks on telescopic jibs. cracked welds and loose bolts and other fasteners. (f) hook(s) and other load lifting attachments, safety catch(es) and swivel(s) for damage, free movement or wear. Check the hook shank thread and securing nut for undue movement, which may indicate wear or corrosion. (g) operation and adjustment of controllers. (h) on hydraulic machines check for creep of hydraulic rams. (i) effectiveness of brakes and clutches. (j) on wheel mounted mobile cranes check tyres for pressure as well as damage and wear on walls and tread. Also check wheel nuts for tightness. (k) slew lock if fitted. (l) on rubber tyred cranes check steering, brakes (both foot and parking), lights, indicators, horn, windscreen wipers and washers. (m) enter results of checks in the records of inspections. 5.4 Crane Not in Regular Use In cases where a crane is not in regular use, it may be necessary to carry out a special programme of checks before it is used. The extent and thoroughness of this programme will depend not only on the length of the period that the crane was out of use but also on the location of the crane during this period. A crane standing under cover or inside a workshop may require very little in addition to the checks recommended in 5.2 and 5.3. but a crane that has been out of use in the open and therefore exposed to the weather and atmospheric pollution, etc. may require an extensive appraisal to ensure its fitness for work. The appraisal should include at least the following: (a) Any checks that may be recommended by the manufacturer. (b) Examination of all crane ropes for signs of corrosion and damage and ensuring that there is thorough lubrication. (c) Examination of all control linkage for evidence of seizure or partial seizure and ensuring that there is correct lubrication. (d) Testing of every crane motion for several minutes without load, each motion individually at first then by combination of two or more

(e) (f)

motions simultaneously as appropriate, and then repeating the test with a load on the crane. Checking the correct functioning of all the crane safety devices. Checking of hoses, seals or other components for evidence of deterioration.

6.

THOROUGH EXAMINATION

The implementation of LOLER provides the opportunity for crane users to either have a specified period or an examination scheme approach to examination. (In the LOLER regulations the term examination can also include testing). Whichever approach is adopted, there is a requirement to take into account the pre-use checks [reg. 8] and weekly inspections [reg. 9(3)(b)] as required by LOLER and as detailed in paragraph 5.3 and BS 7121 part 1. 6.1 Specified Period 6.1.1.Six Monthly Thorough Examination Cranes used to lift persons must undergo a thorough examination by a competent person at least once every six months unless a shorter interval has been imposed by the competent person. 6.1.2.Twelve Monthly Thorough Examinations Cranes shall be subject to a thorough examination by a competent person at least once in every twelve months. After carrying out the thorough examination the competent person will specify when the next thorough examination is to be carried out, which may be less than but not more than twelve months. 6.2 Examination Schemes An examination scheme is a written scheme of thorough examination drawn up by a competent person. This is a written schedule of suitable steps to be taken so that the condition of the crane is continuously assessed (condition monitoring) to ensure it remains safe to use. Before thoroughly examining a crane subject to a written scheme the competent person should take into account the age, loading, environmental and duty cycle history of the crane. Cranes that do not have a complete record of past usage will need to be subject to periodic thorough examination and testing in accordance with clause 6.1 and 7.2. The competent person shall prepare the scheme with the co-operation of the crane supplier/manufacturer and crane user (owner). The crane supplier provides limiting criteria based on the crane design e.g. number of load cycles, load spectrum, critical parts, exceptional circumstances. These criteria should not be based on time alone. With the exception of large cranes that have a complete record of each lift undertaken from new, it is most unlikely that this scheme will be suitable for other cranes unless they have been fitted with data loggers from the time of first use.

7.

TESTING

Thorough examination may include testing. This can take many forms including; functional testing, performance testing, non-destructive testing (NDT), overload testing, etc. The competent person should decide whether a test is necessary and determine the most appropriate method of carrying it out. It is important therefore that the competent person takes account of the instructions and other relevant information provided by the manufacturer or other appropriate specialist. 7.1 At Time of First Supply Cranes should be overload tested prior to initial use as required by the European standard for cranes (normally carried out by the manufacturer/supplier). 7.2 As Part of Examination Past experience (on construction sites) has shown that it has been necessary to carry out overload testing (as described in BS 7121 Part 2) of mobile cranes at least every four years. This practice should continue with the exception of cranes: a) That fully comply with the scheme of thorough examination (see clause 6.2) or b) Mobile cranes with a rated capacity in excess of 500 tonnes (which are not permanently installed at one location). These need only be overload tested on the configuration for which the rated capacity indicator was calibrated at the twelve monthly thorough examination. 7.3 Major Repair or Modification Cranes should be thoroughly examined in accordance with the manufacturers written instructions (e.g. the manufacturers original test criteria/certificate) after every major repair or modification.

8. RATED CAPACITY INDICATOR / LIMITER AND OVER LOAD PROTECTION

At least every twelve months the calibration of the rated capacity indicator/limiter (r.c.i.) shall be confirmed by the suspension of calibrated weights on the crane for at least one configuration to ensure that the rated capacity indicator is working to within the tolerances given in BS 7262 1990. A different configuration should be chosen each time so that eventually all configurations are systematically covered. Where the crane is fitted with overload protection this shall be tested at least every twelve months by the suspension of weights representing 110% of rated capacity at a given radius.

9.

DETAILS OF WRITTEN EXAMINATION SCHEMES

The written scheme of thorough examination for a crane should, as a minimum, contain the following information:1. The name and address of the owner of the crane. 2. The name, qualifications and address of the person drawing up the scheme. If the competent person is not working on their own account, the name of their employing organisation and their position in that organisation should be given. 3. The make, model and unique identification number of the crane. 4. Any information references used in drawing up the scheme. This may include the manufacturers manual, or specific information from the designer on the design life of the crane structure and mechanisms as detailed in clause 7 of ISO 12482-1. 5. Details of any data logging system fitted to the crane, including a listing of the parameters monitored and the means by which data retrieval, monitoring and storage is achieved. 6. Details of the environment in which the crane will be used during the period covered by the scheme. 7. Identification of those parts of the crane requiring thorough examination. 8. Frequency of thorough examination for those identified parts of the crane which may include time or loading or duty cycle limits and vary for different parts of the crane. 9. Method of thorough examination of those identified parts of the crane requiring thorough examination which may include the degree of dismantling required, NDT techniques, timed replacement etc. 10. An indication of the resources required to carry the inspection. This may include qualified personnel, workshop facilities, specialist NDT and metallurgical facilities etc. 11. Any changes to crane condition, operational or environmental parameters that would require a review of the scheme by the competent person. These may include damage to the crane structure, change of use from general use to heavy duty grabbing work, or moving from an inland location to a marine environment. 12. The date of drawing up the scheme and the date at which any routine review is required.

10. NON DESTRUCTIVE TESTING TECHNIQUES

During inspection of a crane's structure and mechanism in accordance with a written scheme of examination it may be appropriate to use certain nondestructive testing (NDT) techniques to assess the integrity of components. These techniques can assist in the detection of any material cracks or defects that might grow in service and ultimately lead to failure.

NDT techniques should only be carried out by adequately trained and experienced personnel who should be briefed on the extent of the NDT examination required in accordance the written scheme of examination. BS EN 473:1993 gives guidance on qualification and certification of NDT personnel and, unless the operator is working to a detailed written procedure, they should be qualified to level two. The three most common types of NDT used for in-service inspections of cranes are:Magnetic Particle Examination In this technique a magnetic field is induced in the area under examination whilst the surface is flooded with ferrous particles suspended in a liquid. Any cracks or defects will cause a discontinuity in the magnetic field which will in turn cause the ferrous particles to cluster over the defect indicating it as a dark line. This technique is only suitable for magnetic materials (most structural steels and some stainless steels) and will only detect surface defects and large defects just below the material surface. Further guidance is given in BS 6072 :1981 Dye Penetrant In this technique the surface of the material to be examined is flooded with a liquid dye which penetrates into any surface cracks or defects. After a suitable period the dye is cleaned off and the surface sprayed with an absorbent developer" which draws the dye from any defects indicating the presence of the defect. The technique is often employed on non-ferrous materials such as aluminium alloys, but can only locate surface defects. Further guidance is given in BS EN 571-1:1997 Ultrasonic Examination In this technique pulses of high frequency sound waves are transmitted from the surface of the material into its interior. Any defects or discontinuities cause the sound waves to be reflected back to the surface where they can be detected and, by measuring the time delay from the time of transmission, an estimate of the defects depth below the surface can be made. The technique can be used for a wide range of materials and will detect both surface and subsurface defects; however, it requires both a skilled operator and specialist equipment and would normally be carried out by hiring in a specialist firm. Further guidance is given in BS EN 583-3: 1997

11. DATA LOGGING

There are several suppliers of software packages available for introducing data logging and condition monitoring. These address the various levels of complexity at which condition monitoring is undertaken. Systems range from simple storage of results and the generation of trends from those records, to the most sophisticated which can process data and generate reports and warnings to

assist the competent person with the decision making. The following are some examples of the information that data loggers can record: Time, Date, Duration of Lift Configuration Details of average and maximum load Radius, Angle, Boom length Number of lifts carried out S.W.L. exceeded and percentage The number of times that manufacturers set limits are exceeded Reeving changes Operating Mode Road travel or on-site working Distances travelled Start & Stop times in real time Driver Identification Over speeding Harsh braking Idling time

12. MAINTENANCE

Introduction It is a legal requirement (Regulation 5 (1) of PUWER) that equipment is maintained so that it is safe to use. 12.1 Frequency The frequency at which maintenance activities are carried out shall take into account the intensity of use, operating environment, variety of operations and the risk to health and safety from the possibility of malfunction or failure. The maintenance programme should be based on the manufacturers recommendations and the owners risk assessment and address those parts of the equipment, that are likely to deteriorate and lead to health and safety risks. A formal system of planned preventative or condition-based maintenance should be adopted. Maintenance instructions, manufacturers or in-house, must be available to the people involved in maintaining the equipment. 12.2 Maintenance Personnel Maintenance activities should only be carried out by those who are both familiar with the equipment and competent to carry out the work. The Health and Safety of maintenance personnel must be ensured. They should be provided with such training and instruction to enable them to carry out the work in a safe manner. Where cranes are on hire it is important for both the owner and the hirer to establish which party is responsible for maintenance. The terms of the agreement should be set out or recorded in writing.

10

12.3 Records of Maintenance Good Business Practice requires that relevant records are; (a) kept up to date, and (b) are retained. An up to date record detailing all maintenance activity should be kept. This will provide evidence of maintenance and be useful in planning future maintenance schedules.

13

RECORD RETENTION

Introduction The keeping and retention of records, is both essential and a Good Business Practice. Whilst regulation sometimes requires retention of records, the minimum periods of retention set out in regulations are used as guidelines only. In many business sectors established Good Business Practice seeks to establish lifetime records and this practice is to be commended as a key tool in improving safety standards as well as possibly enhancing the residual value of equipment. PUWER (Reg. 5) and LOLER (Reg. 11) deal with the issue of record retention, PUWER with retention of maintenance records, LOLER retention of records of Through Examination. 13.1 Maintenance Records There is no legal requirement for the keeping of records of maintenance, however Reg.5 of PUWER states that when any maintenance log is kept it should be kept up to date. Therefore it is good practice to retain records of maintenance for the life of the machine in order to identify repeated defects or trends and pass this information onto new owners. 13.2 Records of Through Examination Reg. 11 of LOLER requires that records of inspection and through examination must be kept and the retention period depends on the circumstances in which the relevant inspection/through examination were conducted: Thorough examination of the lifting equipment before it is first put into service; keep report until the equipment is taken out of use. Thorough examination of an accessory for lifting, (lifting tackle), before it is first put into service; keep report for two years. Subsequent thorough examinations of lifting equipment and accessories; keep records until the next report is made or for two years, whichever is later. Inspections at intervals between thorough examinations; keep report until next report is made; Thorough examination of lifting equipment after assembly and before use on a new site; keep report until the equipment is no longer used on that site. Conclusion Whilst there is considerable flexibility and discretion within PUWER and LOLER regarding record retention, the adoption of a Good Business Practice on retention policy is recommended.

11

You might also like

- THE BASIC CRANE OPERATION AND RIGGING SAFETY Hand Outs A4Document21 pagesTHE BASIC CRANE OPERATION AND RIGGING SAFETY Hand Outs A4RosalyNo ratings yet

- Review Safety Rigging and LiftingDocument4 pagesReview Safety Rigging and Liftingferry ferdiansyah pradanaNo ratings yet

- Ten Points For Safe LiftDocument8 pagesTen Points For Safe LifthazopmanNo ratings yet

- Code of Practice For Safe Lifting Operations at Workplaces OnlineDocument38 pagesCode of Practice For Safe Lifting Operations at Workplaces OnlineSaminathan Munisamy100% (1)

- February 2012 Wire Rope ExchangeDocument80 pagesFebruary 2012 Wire Rope ExchangeWire Rope ExchangeNo ratings yet

- Rigging and Slinging TechniquesDocument15 pagesRigging and Slinging TechniquesShiraz Najat100% (2)

- CraneDocument17 pagesCraneJustin ChongNo ratings yet

- A17 Telescopic Handler: General Safety Information For CPCS Technical TestDocument12 pagesA17 Telescopic Handler: General Safety Information For CPCS Technical TestNicolae Burca0% (1)

- Slinger Signaller Study Guide 19-07-22Document36 pagesSlinger Signaller Study Guide 19-07-22Dominican MontanoNo ratings yet

- ToolboxTalks D-D Ratio 041315 PDFDocument1 pageToolboxTalks D-D Ratio 041315 PDFkaniniuserNo ratings yet

- 2 - DSM Notes Hoisting MechanismDocument13 pages2 - DSM Notes Hoisting MechanismsanketNo ratings yet

- Guide To Mobile CranesDocument7 pagesGuide To Mobile CranesvigneshNo ratings yet

- Podem - Crane Components - Technical Catalogue (En)Document32 pagesPodem - Crane Components - Technical Catalogue (En)GogyNo ratings yet

- ITI Bull Rigging-Webinar Markup 081618Document51 pagesITI Bull Rigging-Webinar Markup 081618Rezende JulioNo ratings yet

- Crane Safety Training ModuleDocument29 pagesCrane Safety Training ModuleBergensur100% (3)

- Lifting Beams and SpreadersDocument2 pagesLifting Beams and SpreadersNadeem MalikNo ratings yet

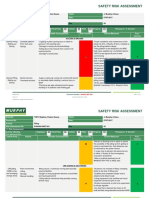

- Safety Risk Assessment: THFC Stadium, Paxton House J. Murphy & Sons 07/07/2017 Piling POH0001/MST/001 Rev 00Document14 pagesSafety Risk Assessment: THFC Stadium, Paxton House J. Murphy & Sons 07/07/2017 Piling POH0001/MST/001 Rev 00nico AlpaNo ratings yet

- Basic-Rigging & SlingingDocument118 pagesBasic-Rigging & SlingingsidraNo ratings yet

- Slings, Rigging and Lifting EquipmentDocument11 pagesSlings, Rigging and Lifting Equipmentgshdavid0% (1)

- Method Statement For Lifting Operations: 1 - IntroductionDocument3 pagesMethod Statement For Lifting Operations: 1 - Introductiontravman1No ratings yet

- Chapter 1-Fundamental Safety Instructions (JT262.12)Document11 pagesChapter 1-Fundamental Safety Instructions (JT262.12)mliugongNo ratings yet

- Operationalising Lifting Plan Safe Cranes OperationDocument62 pagesOperationalising Lifting Plan Safe Cranes Operationtklok99No ratings yet

- SRISE - Rigging & Crane Safety TrainingDocument68 pagesSRISE - Rigging & Crane Safety TrainingMohammed Sadruddin100% (1)

- Opito Rigger TrainingDocument61 pagesOpito Rigger TrainingTasia DiNo ratings yet

- Crane & Sling 2Document29 pagesCrane & Sling 2g5nb100% (2)

- Banksman Slinging R2Document31 pagesBanksman Slinging R2Ilyas ZeriNo ratings yet

- Cranes & Lifting Appliances: Guidance On TheDocument41 pagesCranes & Lifting Appliances: Guidance On Thethongchai_007No ratings yet

- New LiftingDocument88 pagesNew LiftingGaurav JindalNo ratings yet

- Crane Rule PresentationDocument44 pagesCrane Rule PresentationbangladragosNo ratings yet

- Web SlingsDocument8 pagesWeb SlingsmadihcoNo ratings yet

- Yale PE2 Lever Hoist - 40192 ADocument16 pagesYale PE2 Lever Hoist - 40192 AAthox QhurienNo ratings yet

- 02-17-V1risk Assessment (Sheaves Replacement) v1Document4 pages02-17-V1risk Assessment (Sheaves Replacement) v1Mohamed ElnagdyNo ratings yet

- TBT Rigging SafetyDocument1 pageTBT Rigging SafetyRajendraNo ratings yet

- Crane Safety ProgramDocument11 pagesCrane Safety Programsekhargm100% (1)

- Generators, and A Wide Variety of Other Building MaterialsDocument17 pagesGenerators, and A Wide Variety of Other Building MaterialsAmeerUlHaqNo ratings yet

- Grinding SafetyDocument19 pagesGrinding Safetyjaykotak12345No ratings yet

- Loler AcopDocument71 pagesLoler AcopMoheb BotrosNo ratings yet

- Critical Lift ChecklistDocument5 pagesCritical Lift ChecklistMohamed HadjkacemNo ratings yet

- Construction Technology-Static CranesDocument14 pagesConstruction Technology-Static CranesPrarthana roy RNo ratings yet

- Crane Supervisor (A62)Document3 pagesCrane Supervisor (A62)Niel Brian VillarazoNo ratings yet

- 0.1 SI - 11 - Hand - Chain - Block - SI - 11.4Document2 pages0.1 SI - 11 - Hand - Chain - Block - SI - 11.4Achmad ChusnadiNo ratings yet

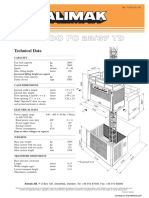

- Alimak Hek 65 - 32Document5 pagesAlimak Hek 65 - 32Zhoro Boyssan LestaluhuNo ratings yet

- Lifting and Supporting Loads, Mobile Equipment Awareness: Ashaka 16Mw CPP Project NigeriaDocument100 pagesLifting and Supporting Loads, Mobile Equipment Awareness: Ashaka 16Mw CPP Project NigeriaPhilip AdewunmiNo ratings yet

- Hooks and Shackles: Clevis Grab Hook Clevis Slip HookDocument7 pagesHooks and Shackles: Clevis Grab Hook Clevis Slip HookWade SperryNo ratings yet

- Authorised Examiners Lifting EquipmentDocument13 pagesAuthorised Examiners Lifting EquipmentdunglxNo ratings yet

- Lifting Method For Material HandlingDocument6 pagesLifting Method For Material Handlingasdasd asdasdNo ratings yet

- Assessment of Lifting OperationDocument18 pagesAssessment of Lifting Operationafif atmajaNo ratings yet

- TaiLing by Duo CraneDocument9 pagesTaiLing by Duo CraneHaGun Gunawan100% (1)

- Hand Operated Chain Lever Hoists SI 12.3Document2 pagesHand Operated Chain Lever Hoists SI 12.3reda mesbahNo ratings yet

- Material Handling On Construction Sites: HerniaDocument4 pagesMaterial Handling On Construction Sites: HerniaCarl Kyu100% (1)

- Cranes Hoisting and RiggingDocument25 pagesCranes Hoisting and Riggingkanakarao1No ratings yet

- Crane Accidents InvestigationDocument1 pageCrane Accidents InvestigationLeonardo RoncettiNo ratings yet

- Tips For Heavy Lifting AND Rigging Engineering: Inspection: 1Document25 pagesTips For Heavy Lifting AND Rigging Engineering: Inspection: 1pablodugalNo ratings yet

- How To Manage A Crane Accident: Guest Speaker: Joe Collins, Heavy Lift Manager, Becht EngineeringDocument45 pagesHow To Manage A Crane Accident: Guest Speaker: Joe Collins, Heavy Lift Manager, Becht EngineeringTrainer 1 TVSNo ratings yet

- Crane Safety IS StandardsDocument22 pagesCrane Safety IS StandardsWasim AkramNo ratings yet

- Iso4310 1981Document6 pagesIso4310 1981somsak9100% (2)

- API Recommended Practice 4G - Exceprt Section 6Document4 pagesAPI Recommended Practice 4G - Exceprt Section 6ANTONI RamNo ratings yet

- Crane Tata SteelDocument39 pagesCrane Tata Steelbabu maheshNo ratings yet

- AS2550 (1) AbstractDocument14 pagesAS2550 (1) AbstractkeepcalmandcarryonNo ratings yet

- SS 497 - Code of Practice For Design, Safe Use and Maintenance of Gantry CranesDocument20 pagesSS 497 - Code of Practice For Design, Safe Use and Maintenance of Gantry CranesTest75% (4)

- Liebherr LTM 1120 120-Ton All Terrain CraneDocument9 pagesLiebherr LTM 1120 120-Ton All Terrain CraneTarek HareedyNo ratings yet

- Mobile Crane Normal Lift and Rigging Plan FormDocument4 pagesMobile Crane Normal Lift and Rigging Plan FormTarek HareedyNo ratings yet

- Terex R T 35 Spec.tDocument1 pageTerex R T 35 Spec.tTarek HareedyNo ratings yet

- Lifting PlanDocument14 pagesLifting PlanTarek HareedyNo ratings yet

- Alimak Hek Construction Elevator Hoists Spec Ff96b5Document2 pagesAlimak Hek Construction Elevator Hoists Spec Ff96b5Tarek HareedyNo ratings yet

- ALIMAK SC 65 32 1541 EN Aug 2020 1Document8 pagesALIMAK SC 65 32 1541 EN Aug 2020 1Tarek HareedyNo ratings yet

- Alimak Hek Construction Elevator Hoists Spec 022b20Document8 pagesAlimak Hek Construction Elevator Hoists Spec 022b20Tarek HareedyNo ratings yet

- Mistral 630 - en PDFDocument44 pagesMistral 630 - en PDFTarek HareedyNo ratings yet

- Mazzella WireRopeAtAGlance 0919Document5 pagesMazzella WireRopeAtAGlance 0919Tarek HareedyNo ratings yet

- Segmental Launching Gantry Introduction and Project Huada Heavy Industry China Supplier and Manufacturer PDFDocument6 pagesSegmental Launching Gantry Introduction and Project Huada Heavy Industry China Supplier and Manufacturer PDFTarek HareedyNo ratings yet

- Full Span Launching Gantry Introduction and Project Huada Heavy Industry China Supplier and ManufacturerDocument4 pagesFull Span Launching Gantry Introduction and Project Huada Heavy Industry China Supplier and ManufacturerTarek HareedyNo ratings yet

- إضافات الخرسانةDocument34 pagesإضافات الخرسانةAhmed IbrahimNo ratings yet

- 1 2005 Mistral MRL Documantation Eng PDFDocument12 pages1 2005 Mistral MRL Documantation Eng PDFTarek HareedyNo ratings yet

- Présentation Algeria 2007 2008Document20 pagesPrésentation Algeria 2007 2008Tarek HareedyNo ratings yet

- Produced by An Autodesk Educational ProductDocument1 pageProduced by An Autodesk Educational ProductTarek HareedyNo ratings yet