Professional Documents

Culture Documents

Case Study - Hydrotesting Fatality

Case Study - Hydrotesting Fatality

Uploaded by

Robert R. RaoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Case Study - Hydrotesting Fatality

Case Study - Hydrotesting Fatality

Uploaded by

Robert R. RaoCopyright:

Available Formats

LESSONS LEARNED & SAFETY ALERT

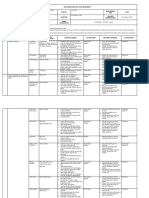

On 19 February, 2008 hydrostatic test preparation started in the morning for the test package located at the Train 2 pipe rack. At 16:45, test pressurization started. During the pressurization, 3 crew were on the top of the pipe rack (13m from the ground) checking the conditions, and one foreman was on the ground directing them. At 17:40, before reaching the highest pressure, 30 pipes burst at the 45degree joint located 9m from the ground. The force of the blast threw one pipe fitter 14m from the top of the pipe rack . He hit the scaffolding on the other side and fell 7m to the ground and died as a result of a skull fracture.

Likely trajectory of the victim after he was thrown from the pipe rack

Conditions of Pipe Rupture

Location of the pipe fitter at the time of the incident

The victim struck the scaffolding here

30 CS pipe

0.3m

13.0m

9.0m

Site of pipe rupture The victim struck the asphalt surface head first

1.1m

30 CS pipe

TapRoot Root Cause Analysis

Reference No: JGC-HSE-LL2008003 Issue Date: 2008/3/17 Country /Location: Saudi Arabia Date of Incident: 19 Feb 2008 Type of Incident: Hydro test failure/fall from height Incident Status: Fatal incident Message from Yokohama :

Direct & Contributory Causes: Test pressure was wrongly selected and higher than it should have been No depressurizing was performed when the crew found a leakage The Pipe fitter was working on top of an unfixed grating The Pipe fitter was working at height without tie-off Air was likely trapped inside the pipe during the test preparation Root Cause Category: Procedure not available No training objective Quality control inspection technique inadequate

Corrective Actions To Be Taken:

Greater attention needs to be given to minimizing the effects on safety of incidents such as a burst pipe during a hydrostatic test. Particularly in this case, consideration should have been given to the impact of pipe failure when such a large-sized piping system was involved.

Poor communication system Management enforcement system inadequate Human engineering complex Inappropriate supervision

Develop new procedure for test pressure determination and implement it Conduct risk assessment for hydro-test, and develop new hydro test procedure reflecting the assessment and implement it Develop new procedure for working at height associated with grating removal permit system and implement it Develop air release control system for hydro-test and implement it Develop and use new training materials reflecting all of the above.

HSE Committee

You might also like

- Inspection ReportDocument4 pagesInspection ReportThe Vancouver SunNo ratings yet

- 15.5b - Pre-Qualification Questionnaire (Sample)Document8 pages15.5b - Pre-Qualification Questionnaire (Sample)karthikeyan elangoNo ratings yet

- 1 WAH ChecklistDocument2 pages1 WAH Checklistvirendra kumar singhNo ratings yet

- DM HSD GU35 URAS2 Technical Guidelines For Usage of Rope Access System V2.1Document20 pagesDM HSD GU35 URAS2 Technical Guidelines For Usage of Rope Access System V2.1Natalie BlackmoreNo ratings yet

- Method Statement For The Installation of Water Treatment PlantDocument12 pagesMethod Statement For The Installation of Water Treatment Plantafraz_xec89% (19)

- Wire Brush Safety InstructionsDocument2 pagesWire Brush Safety InstructionsMohamed FaroukNo ratings yet

- Practical LOLERDocument29 pagesPractical LOLERJamie Taylor0% (1)

- 39-98 - Safe Use of Lifting Machines and Lifting Tackle - 0Document59 pages39-98 - Safe Use of Lifting Machines and Lifting Tackle - 0JakesNo ratings yet

- Jsa GRIT BLASTINGDocument3 pagesJsa GRIT BLASTINGPrajnay ShettyNo ratings yet

- JSA For KAHSDocument6 pagesJSA For KAHSFrancis Enriquez TanNo ratings yet

- Work Method Statement: Maxworks LTD Montebello, Pailles Mr. Georges Yueng Wye Kong 2086463Document15 pagesWork Method Statement: Maxworks LTD Montebello, Pailles Mr. Georges Yueng Wye Kong 2086463Vinaye GopaulNo ratings yet

- QP Blasting JSADocument6 pagesQP Blasting JSAMohammed Mujahid100% (1)

- HT & PWHT JsaDocument3 pagesHT & PWHT JsaNature BeautiesNo ratings yet

- Check List (Pre Entry) For Portable Grinding Machine: Doc No:Tippl/Mitl/Hse/13Document1 pageCheck List (Pre Entry) For Portable Grinding Machine: Doc No:Tippl/Mitl/Hse/13MuhRachmat100% (1)

- 10.1 Jha Box-Up Spool or Valve 19.11.15Document6 pages10.1 Jha Box-Up Spool or Valve 19.11.15RahimNo ratings yet

- SWP-06 ScaffoldDocument9 pagesSWP-06 ScaffoldShafiqNo ratings yet

- Lifting ChecklistDocument13 pagesLifting ChecklistEric T100% (1)

- HSE Alert - Fall From Ladder - JDE #72866Document1 pageHSE Alert - Fall From Ladder - JDE #72866Edwin M. MolinaNo ratings yet

- Investigation Report Mongstad Naphta - 102417Document24 pagesInvestigation Report Mongstad Naphta - 102417Cepi Sindang KamulanNo ratings yet

- JHA Welding Arc and Cutting (Hotwork)Document2 pagesJHA Welding Arc and Cutting (Hotwork)Popo EaldamaNo ratings yet

- LCC DOCS-11568884-V1-HS-PRO-013 Working in On Over or Adjacent To WaterDocument13 pagesLCC DOCS-11568884-V1-HS-PRO-013 Working in On Over or Adjacent To WaterabogadieNo ratings yet

- 200 Liter Foam TrolleyDocument1 page200 Liter Foam Trolleyvivekvpsfe100% (1)

- Jha Lin FillingDocument6 pagesJha Lin FillingLuqman OsmanNo ratings yet

- Pressure Testing Safety Awareness PDFDocument15 pagesPressure Testing Safety Awareness PDFShailendraNo ratings yet

- JHA Arc WeldingDocument2 pagesJHA Arc WeldingechaNo ratings yet

- Valve ReplacementDocument7 pagesValve ReplacementKamarularifin Kamel100% (2)

- Isolation & Lock Out - Tag Out (LOTO)Document24 pagesIsolation & Lock Out - Tag Out (LOTO)Becha MouradNo ratings yet

- Basf Jsa SaferadDocument3 pagesBasf Jsa SaferadExsan OthmanNo ratings yet

- Checklist For Pressure Testing Safely 2Document2 pagesChecklist For Pressure Testing Safely 2Jonathan CambaNo ratings yet

- Cable Installation Risk AssessmentDocument2 pagesCable Installation Risk AssessmentWanwaniouan Pomme100% (1)

- OCP 12 - Working at HeightDocument2 pagesOCP 12 - Working at HeightVipin Kumar Parashar100% (1)

- Lifting Equipment RegisterDocument6 pagesLifting Equipment RegisterJosiahNo ratings yet

- Daily Observation SheetDocument2 pagesDaily Observation Sheetarun100% (2)

- Proof Pressure Test Leak Detection Test PDFDocument2 pagesProof Pressure Test Leak Detection Test PDFDan Nicole DadivasNo ratings yet

- JSA For DPTDocument3 pagesJSA For DPTMohammed Minhaj100% (1)

- 8 JSA Holyday TestDocument3 pages8 JSA Holyday TestYosua SitumorangNo ratings yet

- Safety Alert Incident-Left Eye Injury Dated 02042010Document1 pageSafety Alert Incident-Left Eye Injury Dated 02042010NethiyaaRajendran100% (1)

- SOP For Pneumatic Testing.Document2 pagesSOP For Pneumatic Testing.Ernst_SNo ratings yet

- Bulletin HSE SampleDocument4 pagesBulletin HSE SampleeliNo ratings yet

- JHA # 009 - Hot WorkDocument7 pagesJHA # 009 - Hot WorkkumarNo ratings yet

- Ptw-Kec - Final v3 - SparkDocument1 pagePtw-Kec - Final v3 - SparkXiang JintaoNo ratings yet

- Sand Blasting Cabinet Safe Work ProcedureDocument3 pagesSand Blasting Cabinet Safe Work ProcedureGhazi Kallel100% (1)

- JSA HCK MOC Hot Tap Drilling Rev1Document6 pagesJSA HCK MOC Hot Tap Drilling Rev1Ijaz Hussain100% (2)

- Permit To Work Inspection Checklist: Document Control. DescriptionDocument5 pagesPermit To Work Inspection Checklist: Document Control. DescriptionAui PiandoNo ratings yet

- RA For Air BlowingDocument9 pagesRA For Air BlowingAriel Dela CruzNo ratings yet

- Scffold & Lifitng Supervisor & Safety InspectorDocument9 pagesScffold & Lifitng Supervisor & Safety InspectorMuhamedragabNo ratings yet

- 1 WAH ChecklistDocument3 pages1 WAH ChecklistCristiane RibeiroNo ratings yet

- TBT Welding FiresDocument4 pagesTBT Welding FiresNaiduSatyanarayanaNaiduNo ratings yet

- Pneumatic Test ProDocument4 pagesPneumatic Test ProWalha WassimNo ratings yet

- Is 3832 2005 PDFDocument18 pagesIs 3832 2005 PDFSachin5586No ratings yet

- Cold Cutting Guideline ChecklistDocument2 pagesCold Cutting Guideline Checklisttahatekri100% (1)

- Installing BlindsDocument1 pageInstalling Blinds최승원No ratings yet

- Lifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneDocument7 pagesLifting Plan No:-Project IWWTP at Banyan Project: Mobile CraneHtin Lin Aung100% (1)

- F.e.& Scba InspectionDocument5 pagesF.e.& Scba InspectionAviects Avie JaroNo ratings yet

- HVAC Duct Work Installation Method StatementDocument7 pagesHVAC Duct Work Installation Method StatementNeguib FarahNo ratings yet

- PVCMS-BMV-HSE-JSA-001 InsulationDocument6 pagesPVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNo ratings yet

- HYDROTESTDocument144 pagesHYDROTESTJean GheorgheNo ratings yet

- JSA - Suface Preparationand Brush PaintingDocument5 pagesJSA - Suface Preparationand Brush PaintingAzad pravesh khanNo ratings yet

- Confined Space Entry Log SheetDocument1 pageConfined Space Entry Log SheetJobin FrancisNo ratings yet

- Job Safety Analysis Form HydrotestDocument3 pagesJob Safety Analysis Form Hydrotestyayongjcs100% (4)