Professional Documents

Culture Documents

API 650 Tank Design Calculations

Uploaded by

ツ ツCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

API 650 Tank Design Calculations

Uploaded by

ツ ツCopyright:

Available Formats

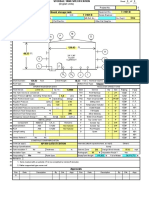

STORAGE TANK SPECIFICATION (English Units)

Project No.

1 Service : 2 Location : 3 Manufacturer : 4 P&ID No. 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Shell Diameter : 25 Roof Type : 26 27 Fluid Stored : Model : Plot Plan No. :

Sheet

1 of 1

Rv N . e. o

1952.000 T-400 & T-405

No. Req'd :

CRUDE OIL Storage

Unit :

Equipment No. :

Kirwin

Mfr Ref. No. :

Design Engineer :

Two

PID115-EPF-01-112A1

Other Ref. Dwg No. :

M G

67.00 Ft 48.00 Ft E L F N1

67.00 Floating

Feet Shell Height :

H

48" X 48" FLUSH CLEANOUT

E D

N2

J

48.00 Feet

I

Nominal Volume :

30,141

Barrels

Bottom Floor Type: Sp. Gr. : Cyclic

Sloped

NOZZLES/CONNECTIONS Qty 2 2 1 1 1 1 1 1 1 1 1 1 1 1 Size 24" 24" 48"x48" 6" 1" 8" 10" 30" 4" 8" 3/4" 3/4" 4" 2"

OPERATING/DESIGN DATA CRUDE OIL

0.7900 5.5

psia Design 0.50 2.00

Mark A E F G H I J K L M N1 N2 P D

Service Roof Manway Shell Manway Flush Cleanout MW Stilling Vent Temperature Indicator Outlet Nozzle Fill Nozzle Mixer Manway Water Draw Nozzle Top Center Vent Sample Tap Sample Tap Roof Nozzle Spare

28 This Tank Service is considered: 30 Flash Point (Closed Cup) : 31 Negative Pressure 32 Positive Pressure 33 (Hydro)test Pressure expressed in Psig 34 Minimum Fluid Temperature 35 Maximum Fluid Temperature 36 Emergency Vacuum Design ? 37 38 40 Roof 41 Lining/Coating 42 43 Stress Relieve ? 44 45 Code (as appl.): 46 Design Specifications: 47 Tank Insulation ? 48 Insulation Type: 49 Fireproofing ? 50 Remarks 51 52 No Hot Yes for: Component 39 Shell & Bottom Material 283 Grade C 283 Grade C Yes F F F

29 Vapor Pressure @ Max. Operating Temperature oz/in.2 psig 0.00 1.00

Operating

----25 200

Set @ CA, in. 0.1250 0.1250 0.0.3 oz/in.2

METALLURGY Remarks Normalized Normalized

Rating 150# 125# 125# 125# 150# 150# 150# 150# 150# 150# 150# 150# 150# 150# 150# 150#

Others: 100 Yes

Face F. F. R. F. R. F. F. F. L. J. API L. J. F. F. R. F. API R. F. F. F. L. J. API API API

CONSTRUCTION/FABRICATION

API 650 LATEST EDITION

Thickness : Paint Spec. in.

Internals (attach separate sheet, as req'd): Sump Seismic Zone Radiograph 85 EmptyTank Weight

Design Wind Velocity % Inspection Req'd ? lb Full of Water

mph lb

Yes

1. Items marked with an asterisk (*) to be completed by Vendor/Fabricator. 2. Fixed cone roof with internal floating roof.

Approvals

Rev 0 Date Description For Inquiry By Chk. Appr. Rev Date Description By Chk. Appr.

Art Montemayor

API 650 Storage Tank

March 12, 2002 Rev: 0

API 650 Design Calculations

D = Normal tank diameter , in feet H = depth of tank , in feet Shell Design : 67.00 48.00

FROM ( BOTTOM COURSE) PLATE TO (TOP COURSE) PLATE td = 2.6(D)(H -1)(G)/Sd= td =

0.353 in. Wall Thickness Miniumum shell thickness, in inches, td = td / tt = 2.6(D)(H-1)/(St) 0.391 in. (Includes Corrosion Allowance)

G = design Specific gravity of liquid 1 Sd = allowable Stress for Design condition 23,200 E = joint efficiency 0.85% St = allowable stress 516-60 Hydro Test 24,900 CA = Corrosion Allowance 0.0625 For First Course (Bottom) 516-60 Plate td = 2.6(D)(H -1)(G)/Sd = td =td / tt = 2.6(D)(H-1)/(St) = td = Miniumum shell thickness, in inches = D = Normal tank diameter , in feet = H = depth of tank , in feet = G = design Specific gravity of liquid = Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress516-60 Hydro Test CA = Corrosion Allowance For Second Course 516-60 Plate td = 2.6(D)(H -1)(G)/Sd= td =td / tt = 2.6(D)(H-1)/(St) td = Miniumum shell thickness, in inches D = Normal tank diameter , in feet H = depth of tank , in feet G = design Specific gravity of liquid Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress 516-60 Hydro Test CA = Corrosion Allowance For Third Course 516-60 Plate 0.258 67.00 28 1 21,300 0.85% 24,000 0.0625 0.3750 0.404 67.00 48.00 1 21,300 0.85% 24,000 0.0625 0.5000 0.221 0.415 0.384

Page 2 of 8

FileName: 61253004.xls WorkSheet: Steel Design

Art Montemayor

API 650 Storage Tank

March 12, 2002 Rev: 0

API 650 Design Calculations

Shell Design : td = 2.6(D)(H -1)(G)/Sd= td =td / tt = 2.6(D)(H-1)/(St) = td = Miniumum shell thickness = D = Normal tank diameter , in feet H = depth of tank , in feet G = design Specific gravity of liquid Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress 516-60 Hydro Test CA = Corrosion Allowance For Fourth Course 516-60 Plate td = 2.6(D)(H -1)(G)/Sd= td =td / tt = 2.6(D)(H-1)/(St) td = Miniumum shell thickness, in inches D = Normal tank diameter , in feet H = depth of tank , in feet G = design Specific gravity of liquid Sd = allowable Stress for Design condition E = joint efficiency St = allowable stress 516-60 Hydro Test CA = Corrosion Allowance For Fifth Course 516-60 Plate Annular Bottom Plate Thickness D = Diameter in Feet H = Height in Feet V = Volume in Cubic Feet Tank Shell surface = Tank Roof surface = Tank Floor surface = 67.00 48.00 0.1342 94.5 8 1 21,300 0.85% 24,000 0.0625 0.2500 0.3750 0.2365 inches 94.5 18 1 21,300 0.85% 24,000 0.0625 0.2500 0.081 0.196

D*H = D2/4 = D2/4 =

10,103 Ft2 of Shell surface area 3,526 Ft2 of Roof Area (estimated) 3,526 Ft2 of Bottom Floor area

Page 3 of 8

FileName: 61253004.xls WorkSheet: Steel Design

Art Montemayor FOUNDATION DESIGN: Per API 650 (Appendix E)

API 650 Storage Tank

March 12, 2002 Rev: 0

Tank is unanchored, use equations pertaining to unanchored tanks, for seismic loading. DATA GIVEN: Seismic Zone; Zone Coefficient Importance Factor Diameter of Tank Height of Liquid Content (Design) Shell Height Design Specific Gravity Thickness of Bottom PL Under Shell Yeild Strength of Bottom PL Weight of Shell Weight of Roof + Live Load = 107.4 + 210.4 Weight of Product PI()/4(94.5)2 (44.5)(.79)(62.4) CALCULATIONS: Seismic Coefficients: Xs = C1 = D/H = Per Fig. E-2 W1 / Wt = W2 / Wt = Per Fig. E-3 X1 /H = X2 /H = Per Fig. E-4 K = 0.6 Lateral Force Coefficients: T =K (D 0.5 ) =.6 *(94.5 0.5) = If Greater Than 4.5 seconds 3.375 (s/T2) = 3.375*1.5/5.832 = E-3.3 5.83 Seconds 0.149 Seconds 0.38 0.59 X1 = X2 = 16.7 26.3 0.54 0.45 W1 = W2 = 8,231 6,924 19.69 Ft 0.60 2.12 3 0.3 1.0 94.5 44.5 48 0.79 0.3750 36,000 PSI 221 Kips 317.8 Kips 15,386 Kips

Z= I = D= H= Hs = G= tb = Fby = Ws = Wy = Wt =

Page 4 of 8

FileName: 61253004.xls WorkSheet: Foundation Design - 1

Art Montemayor

API 650 Storage Tank

March 12, 2002 Rev: 0

FOUNDATION DESIGN: Seismic Loads: M = (Z)(I) { (C1)(Ws)(Xs)+(C1)(Wr)(Ht)+(C1)(W)(X)+(C2)(W2)(X2)} (0.3)*(1.0)[ 0.6(221)(19.685)+ 0.6(317.8)(48.0)+ 0.6(8232)(16.7)+ 0.149(6924)(26.3)] 0.3 2610 9155 82485 27133 36415 Ft-Kips V = (Z)(I) {(C1)(Ws)+(C1)(Wr)(Ht)+(C1)(W)(X)+(C2)(W2)(X2)} (0.3)*(1.0)[ 0.6(221)+ 0.6(317.8)+ 0.6(8232)+ 0.149(6924)] 0.3 132.6 190.68 4939.2 Reistance to Overturning:( E.4.1) API 650

WL = 7.9tb Fby G H (G18)*(G16)*(G14)/(G13)2 )

1031.68

1888 kips

3,333 1125

# / ft

Constant = 3,333 # / ft

1265580 7.9 Not to exceed 1.25*GHD

4153 USE 4153

# / ft # / ft

Shell Compression: Per E-5 M= 36415 ft-kips 6 Kips

Wt + WL = 583.8 / (PI()*94.5) + 4.153 M / D2 (Wt + WL) (G76)/(G13)2(6.12) 36415

54653 b =

0.666 > 0.785 7.0 7.0

b = 1.815+1.273*36415/94.5^2 Max. Longitudinal Compressive Force

UnAnchored Longitudinal Compressive Stress 7000 / 6 Allowable Longitudinal Compressive Stress GHD2/t2 1.255 * 106 = Fa=106 (t) / D = Anchorage Not Required

1167 5.29 Kips

Page 5 of 8

FileName: 61253004.xls WorkSheet: Foundation Design - 1

Art Montemayor

API 650 Storage Tank

March 12, 2002 Rev: 0

FOUNDATION DESIGN:

Max. Overturning Moment Due To Seismic Loads. Compression or Tension Due To Moment: Seismic Base Shear: RINGWALL DESIGN: Use Following Weight Values for Materials Wt. of Steel Wt. Of Compacted Soil Wt. Of Concrete Wall Wt. Of Product in Tank Horizontal Pressure on Ring Wall: F=Kah(*p*H+1/2 soh)+270 0.3*6.0[(50*44.5+0.5*110*6.0)]+270 Hoop Tension: 1/2FD= 1/2(4869)(94.5) As= 231/24.0 USE - 6 # 9 Bars Ea. Face USE - # 4 Bars at 12" on Center Minimum RingWall Thickness: T = 2W / *p*h - 2h ( c - so) W = 1100 1.26 Use 16" Thick Concrete Wall 230 kips 10 in. 490lb/ft3 110 lb/ft3 150 lb/ft3 50 lb/ft3 36,415 Kips 5.19 kpf 0.27 kips

4,869 kips

(2)(1100)/50(44.5)-2(6.0)(150-110)

12" 16" 48"

Top of Ground Elevation

12"

Page 6 of 8

FileName: 61253004.xls WorkSheet: Foundation Design - 2

Art Montemayor

API 650 Storage Tank

March 12, 2002 Rev: 0

Concrete Tensile Stress: fct = c(Es)(As)+T / Ac + n (As) .0003(29*106)(10)+231000/(16*72)+(9*10) 318000 1242 .15(3000) Soil Bearing: Try 3'- 6" Footing Weight. of Wall = 1.33*5.0*.150 Weight of Footing = 3.5*1.0*.150 Weight of Fill = 2.17*4.0*.110 1.0 kips 0.525 kips 0.95 kips 2.48 kips 256 psi 450 psi OK

Case 1 Load from Shell + Roof + Live Load = Weight of Wall +Footing + Fill = Bearing Pressure = Case 2 Dead + Live Load + Earthquake Load = P = 3.58 + 5.19 = H= Moment at Base of Footing = 8.77 kips 0.270 kips 1.62 kips 3.58/3.50 1.1 kips 2.48 kips 1.0 kips

.270(6.0)

Bearing Pressure Under Footing = 8.77/3.5*1 2.51+.79 Allowable Pressure = 3.0*1.33

2.51 kips 3.30 kips 3.99 OK

USE -4 # 9 Bars in Footing USE - # 4 Bars at 12" Horizontal

Page 7 of 8

FileName: 61253004.xls WorkSheet: Foundation Design - 2

Art Montemayor DETAILED FOUNDATION DESIGN:

API 650 Storage Tank

March 12, 2002 Rev: 0

47" - 3"

Center Line of Tank

Slope 1" per ft.

12"

10" Pad of Sand Well-Compacted Gravel 95% Compacted 50 / 100 % Passing # 4 Sieve 6 # 9 Bars Each Face Eq. Spaced

10"

4'-0"

# 4 Bars 12" O/C Each Face

95 % Compacted Subgrade or fill Material

1'-4" Wall 12"

(4) # 9 Bars Eq. Spaced 3' - 6"

NOTES:

1. Oiled sand to be mixture of sand and liquid asphalt (mc70): 2. Use 10 gallons of asphalt per cubic yard of sand: 3. Top of concrete to be smooth and level with 1/8" +/- in any 30 feet of circumferential length: 4. Maximum Deiation to be less than 1/4" overall:

Page 8 of 8

FileName: 61253004.xls WorkSheet: Foundation Design - 3

You might also like

- Tank Stability 10.0: Shell Dimension, NewDocument4 pagesTank Stability 10.0: Shell Dimension, NewjonedNo ratings yet

- Tank Calc - Api650Document90 pagesTank Calc - Api650kamleshyadavmoney100% (4)

- Total Middle East New Bitumen Terminal in TlbuDocument25 pagesTotal Middle East New Bitumen Terminal in TlbuAnupam Jana100% (2)

- Tank 620 US 0002 API 620 Calculation ReportDocument39 pagesTank 620 US 0002 API 620 Calculation ReportPhượng NguyễnNo ratings yet

- Storage Tank Design Calculation - Api 650Document21 pagesStorage Tank Design Calculation - Api 650miteshpatel191100% (3)

- WIND MOMENT (Per API-650 SECTION 5.11)Document9 pagesWIND MOMENT (Per API-650 SECTION 5.11)ramu karri100% (1)

- Tank Anchor Bolt DesignDocument9 pagesTank Anchor Bolt Designgon972001100% (1)

- Sample Calc - API 620Document13 pagesSample Calc - API 620Natarajan RavisankarNo ratings yet

- Premium TankDocument26 pagesPremium TankAnonymous p0iwBo100% (1)

- 16.0 M Dia X 18.0 HT Fire Water Tank Rev 4 (2) - CommentedDocument29 pages16.0 M Dia X 18.0 HT Fire Water Tank Rev 4 (2) - CommentedKP SAHU100% (1)

- 21910-CAL-01 Tank Design Calculation For NMA TankDocument56 pages21910-CAL-01 Tank Design Calculation For NMA TankShayan Hasan KhanNo ratings yet

- Anchor ChairDocument3 pagesAnchor ChairrsubramaniNo ratings yet

- Single Col - Tank-2013Document35 pagesSingle Col - Tank-2013Hgagselim SelimNo ratings yet

- MecaStack MatindokDocument59 pagesMecaStack MatindokmedyNo ratings yet

- Floating Roof DesinDocument5 pagesFloating Roof Desindimdaliak_985662241No ratings yet

- Storage Tank CALC Api 650Document10 pagesStorage Tank CALC Api 650kuselanml100% (3)

- Storage Tank Design CalculationDocument32 pagesStorage Tank Design CalculationE Santosh Kumar100% (1)

- Anchor Chair Design FinalDocument26 pagesAnchor Chair Design FinalLe Bacha Bacha100% (4)

- API-650 Water Storage Tank TK-2Document27 pagesAPI-650 Water Storage Tank TK-2Athira ZahraNo ratings yet

- Etank Full ReportDocument108 pagesEtank Full ReportFaizal Sattu100% (1)

- T-707-Calculations Based On Actual Thickness-R2Document25 pagesT-707-Calculations Based On Actual Thickness-R2SachinNo ratings yet

- API 650 Storage Tank TCA PreparationDocument86 pagesAPI 650 Storage Tank TCA PreparationBimal DeyNo ratings yet

- Storage Tank Alumnuim Roof - LatestDocument22 pagesStorage Tank Alumnuim Roof - LatesthgagNo ratings yet

- Tank DesignDocument89 pagesTank DesignDietrich von BismarckNo ratings yet

- Calculation API 650Document78 pagesCalculation API 650isonwas 1966No ratings yet

- TankDocument7 pagesTankBolarinwaNo ratings yet

- API 650 Water Storage TankDocument60 pagesAPI 650 Water Storage TankAlexanderNo ratings yet

- 3191-CS-01 Rev A-009-011Document3 pages3191-CS-01 Rev A-009-011Syed Zain AliNo ratings yet

- GERMANY TANK FULL REPORT-9 Updated As Per Client CommentDocument45 pagesGERMANY TANK FULL REPORT-9 Updated As Per Client CommentSalmanNo ratings yet

- Supported Cone Roof (CS) Add.4Document21 pagesSupported Cone Roof (CS) Add.4skhurramq100% (2)

- Frangible RoofDocument8 pagesFrangible RoofamevaluacionesNo ratings yet

- Tank-API-650-SI-Manzanillo-30 mbls-API-650-Calculation-Report - 1Document52 pagesTank-API-650-SI-Manzanillo-30 mbls-API-650-Calculation-Report - 1Tony Lozada Mahuen100% (1)

- Api 650 Uplift ForcesDocument2 pagesApi 650 Uplift ForcesGerman DiBaccoNo ratings yet

- For Buildings and Other Structures For Wind LoadsDocument28 pagesFor Buildings and Other Structures For Wind LoadsMarinos Giannoukakis100% (1)

- Nozzle Calculations 01Document32 pagesNozzle Calculations 01Rohith V VNo ratings yet

- H200141 - Calculation of Basering Rev 0 PDFDocument9 pagesH200141 - Calculation of Basering Rev 0 PDFSani Adipura WinataNo ratings yet

- API 650 Water Storage TankDocument6 pagesAPI 650 Water Storage TankJoeNo ratings yet

- CAL - Polished Condensate Tank 14.0 Dia. X 19 HT - R.1 (12-04-2022)Document34 pagesCAL - Polished Condensate Tank 14.0 Dia. X 19 HT - R.1 (12-04-2022)kpsahuNo ratings yet

- Tank Design APIDocument63 pagesTank Design APIBSK entertainmentNo ratings yet

- Design Calculation For Anchor Chair API 650Document1 pageDesign Calculation For Anchor Chair API 650Mohammed Faizal Nv100% (2)

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design CalculationNorazlan Shah Mahadi100% (1)

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design CalculationHoracio RodriguezNo ratings yet

- API 650 Tank Design CalculationDocument9 pagesAPI 650 Tank Design CalculationSunday PaulNo ratings yet

- API 650 Tank Design CalculationsDocument8 pagesAPI 650 Tank Design CalculationsMohammed EljammalNo ratings yet

- TangkiDocument8 pagesTangkiCarey Rich67% (3)

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationlecongdinh100% (1)

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationmail_younes659283% (29)

- API 650 Tank Design CalculationsDocument8 pagesAPI 650 Tank Design CalculationsVinoth Rajendra50% (4)

- API 650 Tank Design 1Document5 pagesAPI 650 Tank Design 1Jose Ortiz100% (1)

- API 650 Tank Design 1Document5 pagesAPI 650 Tank Design 1Nguyễn Thành Trung100% (1)

- Hfo Service Tank - ht003 Data Sheet r1 PDFDocument4 pagesHfo Service Tank - ht003 Data Sheet r1 PDFsocomenin2013No ratings yet

- API 650 Tank Design 1Document5 pagesAPI 650 Tank Design 1Fabian Nuñez Diaz100% (1)

- API 650 Tank Design 1 1Document5 pagesAPI 650 Tank Design 1 1samy7354100% (1)

- Diesel Tank TaluksangayDocument70 pagesDiesel Tank TaluksangayBert EngNo ratings yet

- Oil Storage Tank Foundation Design Spreadsheet - 2Document5 pagesOil Storage Tank Foundation Design Spreadsheet - 2Vince2686% (7)

- Storage Tanks CalculationsDocument21 pagesStorage Tanks Calculationsjimallen21288% (26)

- Design Calculation TankDocument28 pagesDesign Calculation Tankibiceng100% (4)

- FinalDocument12 pagesFinalchompink6900No ratings yet

- API 650 Tank Design 1foot MethodDocument4 pagesAPI 650 Tank Design 1foot Methodjakjak67% (3)

- CalDocument19 pagesCalpandiangv100% (1)

- Welding EducatorDocument30 pagesWelding Educatorツ ツNo ratings yet

- Welding HandbookDocument48 pagesWelding HandbookMohan Prasad.M93% (27)

- Welding Handbook ESABDocument529 pagesWelding Handbook ESABErdinc_Bal_1026100% (8)

- ASME Code Case PautDocument10 pagesASME Code Case PautAnonymous kIrNuhNo ratings yet

- Hydrostatic and Settlement Tests ProcedureDocument12 pagesHydrostatic and Settlement Tests Procedureツ ツ100% (1)

- Triangle SolverDocument3 pagesTriangle Solverツ ツNo ratings yet

- SLOFEC TankScanningDocument7 pagesSLOFEC TankScanningツ ツNo ratings yet

- 650 150Document10 pages650 150ツ ツNo ratings yet

- 650 150Document10 pages650 150ツ ツNo ratings yet

- MT 200 User ManualDocument48 pagesMT 200 User Manualツ ツNo ratings yet

- Commercial Pipe Size and Wall ThicknessesDocument2 pagesCommercial Pipe Size and Wall Thicknessesvk2111No ratings yet

- LevelMe-DataSheet ENG 130702Document2 pagesLevelMe-DataSheet ENG 130702ツ ツNo ratings yet

- Flaw Manufacturing TechnologyDocument31 pagesFlaw Manufacturing Technologyツ ツNo ratings yet

- Ust Operator Study GuideDocument82 pagesUst Operator Study Guideツ ツNo ratings yet

- Tank Inspection NotesDocument5 pagesTank Inspection Notesaneeshjose013No ratings yet

- API-653 Tank Inspection Sample ReportDocument19 pagesAPI-653 Tank Inspection Sample Reportツ ツ93% (15)

- API-653 Tank Inspection Sample ReportDocument19 pagesAPI-653 Tank Inspection Sample Reportツ ツ93% (15)

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationmail_younes659283% (29)