Professional Documents

Culture Documents

Operations Management: For Competitive Advantage

Operations Management: For Competitive Advantage

Uploaded by

Luís CostaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operations Management: For Competitive Advantage

Operations Management: For Competitive Advantage

Uploaded by

Luís CostaCopyright:

Available Formats

Operations Management

CHASE

For Competitive Advantage

AQUILANO

ninth edition

JACOBS

Operations Management

For Competitive Advantage

Chapter 4

Process Analysis

CHASE AQUILANO JACOBS

The McGraw-Hill Companies, Inc., 2001

ninth edition

Operations Management Chapter 4

For Competitive Advantage

ninth edition

Process Analysis

Process Analysis Process Flowcharting Types of Processes Process Performance Metrics

CHASE

AQUILANO

JACOBS

The McGraw-Hill Companies, Inc., 2001

Operations Management

For Competitive Advantage

ninth edition

Process Analysis Terms

Process: Is any part of an organization that takes inputs and transforms them into outputs. Cycle Time: Is the average successive time between completions of successive units. Utilization: Is the ratio of the time that a resource is actually activated relative to the time that it is available for use.

CHASE AQUILANO JACOBS

The McGraw-Hill Companies, Inc., 2001

Operations Management

For Competitive Advantage

ninth edition

Process Flowcharting Defined

Process flowcharting is the use of a diagram to present the major elements of a process. The basic elements can include tasks or operations, flows of materials or customers, decision points, and storage areas or queues. It is an ideal methodology by which to begin analyzing a process.

CHASE

AQUILANO

JACOBS

The McGraw-Hill Companies, Inc., 2001

Operations Management

For Competitive Advantage

ninth edition

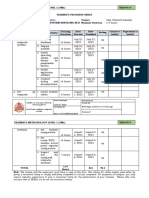

Flowchart Symbols

Tasks or operations Examples: Giving an admission ticket to a customer, installing a engine in a car, etc.

Decision Points

Examples: How much change should be given to a customer, which wrench should be used, etc.

CHASE

AQUILANO

JACOBS

The McGraw-Hill Companies, Inc., 2001

Operations Management

For Competitive Advantage

ninth edition

Flowchart Symbols (Continued)

Storage areas or queues Examples: Sheds, lines of people waiting for a service, etc.

Flows of materials or customers

Examples: Customers moving to the a seat, mechanic getting a tool, etc.

CHASE

AQUILANO

JACOBS

The McGraw-Hill Companies, Inc., 2001

Operations Management

For Competitive Advantage

ninth edition

Example: Flowchart of Student Going to School

Go to school today? Yes Drive to school Walk to class

No

Goof off

CHASE

AQUILANO

JACOBS

The McGraw-Hill Companies, Inc., 2001

Operations Management

For Competitive Advantage

ninth edition

Multistage Process

Stage 1

Stage 2

Stage 3

CHASE

AQUILANO

JACOBS

The McGraw-Hill Companies, Inc., 2001

Operations Management

For Competitive Advantage

ninth edition

Multistage Process with Buffer

Buffer Stage 1 Stage 2

CHASE

AQUILANO

JACOBS

The McGraw-Hill Companies, Inc., 2001

Operations Management

For Competitive Advantage

ninth edition

10

Other Types of Processes

Make-to-order

Only activated in response to an actual order. Both work-in-process and finished goods inventory kept to a minimum.

Make-to-stock

Process activated to meet expected or forecast demand. Customer orders are served from target stocking level.

CHASE AQUILANO JACOBS

The McGraw-Hill Companies, Inc., 2001

Operations Management

For Competitive Advantage

ninth edition

11

Process Performance Metrics

Operation time = Setup time Run time Throughput time = Average time for a unit to move through the system Velocity = Throughput time Value-added time

CHASE AQUILANO JACOBS

The McGraw-Hill Companies, Inc., 2001

Operations Management

For Competitive Advantage

ninth edition

12

Process Performance Metrics (Continued)

Cycle time = Average time between completion of units

Throughput rate =

1 . Cycle time

Efficiency = Actual output Standard Output

CHASE AQUILANO JACOBS

The McGraw-Hill Companies, Inc., 2001

Operations Management

For Competitive Advantage

ninth edition

13

Process Performance Metrics (Continued)

Productivity = Output Input Utilization = Time Activated Time Available

CHASE

AQUILANO

JACOBS

The McGraw-Hill Companies, Inc., 2001

Operations Management

For Competitive Advantage

ninth edition

14

Cycle Time Example

Suppose you had to produce 600 units in 80 hours to meet the demand requirements of a product. What is the cycle time to meet this demand requirement? Answer: There are 4,800 minutes (60 minutes/hour x 80 hours) in 80 hours. So the average time between completions would have to be: Cycle time = 4,800/600 units = 8 minutes.

CHASE

AQUILANO

JACOBS

The McGraw-Hill Companies, Inc., 2001

Operations Management

For Competitive Advantage

ninth edition

15

Process Throughput Time Reduction

Perform activities in parallel. Change the sequence of activities.

Reduce interruptions.

CHASE

AQUILANO

JACOBS

The McGraw-Hill Companies, Inc., 2001

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Financial Statements and Analysis IIMBDocument141 pagesFinancial Statements and Analysis IIMBsridhar789286% (7)

- Complete Contact Book SynopsisDocument25 pagesComplete Contact Book Synopsisvdreams13No ratings yet

- Troubleshooting SIPDocument151 pagesTroubleshooting SIPzakaria26100% (4)

- Kotler SlidesDocument37 pagesKotler Slidessridhar7892No ratings yet

- Homens Maus Fazem O Que Homens Bons Sonham by Robert I SimonDocument2 pagesHomens Maus Fazem O Que Homens Bons Sonham by Robert I SimonBianca Araújo0% (2)

- RUCSM PrinciplesDocument8 pagesRUCSM Principlessridhar7892No ratings yet

- Engaging The Millennial Workforce - Opportunities and ChallengesDocument7 pagesEngaging The Millennial Workforce - Opportunities and Challengessridhar7892No ratings yet

- Enterprise Social ComputingDocument13 pagesEnterprise Social Computingsridhar7892No ratings yet

- Enterprise Social ComputingDocument7 pagesEnterprise Social Computingsridhar7892No ratings yet

- Rural Banking Just ReadDocument13 pagesRural Banking Just ReadMinal TeliNo ratings yet

- Grennell FarmDocument41 pagesGrennell FarmPrateek Chaudhary100% (1)

- Chapter 8 Profit Maximization &cmptitive SupplyDocument92 pagesChapter 8 Profit Maximization &cmptitive Supplysridhar7892No ratings yet

- Cirque Du SoleilDocument16 pagesCirque Du Soleilsridhar7892100% (2)

- Buk98150-55 - 2 MOSFETDocument9 pagesBuk98150-55 - 2 MOSFETOlga PlohotnichenkoNo ratings yet

- UAV Thermal Imaging For Unexploded Ordnance DetectDocument19 pagesUAV Thermal Imaging For Unexploded Ordnance DetectTrịnh Doãn TúNo ratings yet

- ACS Training PPTDocument9 pagesACS Training PPTShameer KhanNo ratings yet

- A R P Senior Secondary School, Halduchaur Half Yearly Examination (2022-23) Subject: Computer TIME: 2:30 HRS Class: Viii Max. Marks 60Document2 pagesA R P Senior Secondary School, Halduchaur Half Yearly Examination (2022-23) Subject: Computer TIME: 2:30 HRS Class: Viii Max. Marks 60Ajay bishtNo ratings yet

- A New Method For Real-Time Monitoring of High-Voltage Transmission-Line Conductor SagDocument11 pagesA New Method For Real-Time Monitoring of High-Voltage Transmission-Line Conductor SagHussein AhmedNo ratings yet

- Married Is Your - .: For Both Men and Women Has Improved Greatly in The Past 20 YearsDocument4 pagesMarried Is Your - .: For Both Men and Women Has Improved Greatly in The Past 20 YearsPhuc CaoNo ratings yet

- UIButton ClassDocument32 pagesUIButton Classadil054No ratings yet

- Hik Ipmd V2.0 201404Document191 pagesHik Ipmd V2.0 201404Jose Luis FernandezNo ratings yet

- It Application Tools in Business: Getting StartedDocument33 pagesIt Application Tools in Business: Getting StartedKhristian Joshua G. JuradoNo ratings yet

- IPR Aakriti 02Document17 pagesIPR Aakriti 02Meghna Singh100% (2)

- REHEGOO LICENSING Distribution AgreementDocument32 pagesREHEGOO LICENSING Distribution AgreementZack BeenasiNo ratings yet

- مغامرة في شارع هولي - مكتبة المغامراتDocument80 pagesمغامرة في شارع هولي - مكتبة المغامراتalaa alaa0% (1)

- O232E - 05p1 - Protection Blocks - 161104Document23 pagesO232E - 05p1 - Protection Blocks - 161104RK KNo ratings yet

- Training Report Undone Repaired)Document26 pagesTraining Report Undone Repaired)Nimitt GuptaNo ratings yet

- Edimax Ew 7206apg Wireless Access PointDocument12 pagesEdimax Ew 7206apg Wireless Access PointLasith HashanthaNo ratings yet

- Step by Step Process To Fill Online ApplicationformDocument4 pagesStep by Step Process To Fill Online ApplicationformSabya Sachee RaiNo ratings yet

- Mohamed Nihmal 3D PortfolioDocument35 pagesMohamed Nihmal 3D PortfolioMohamed NihmalNo ratings yet

- Diseno Simulacion y Optimizacion de Un Circuito SAG Utilizando JKsimmetDocument16 pagesDiseno Simulacion y Optimizacion de Un Circuito SAG Utilizando JKsimmetRommel Heredia TejadaNo ratings yet

- 520CMD01 CS enDocument4 pages520CMD01 CS enDJ ThangNo ratings yet

- Internet of Things-Enabled Smart Cities. State-Of-The-Art and Future TrendsDocument18 pagesInternet of Things-Enabled Smart Cities. State-Of-The-Art and Future TrendsJanneth TQNo ratings yet

- WPPPPSDocument5 pagesWPPPPSHamza KhiyaliNo ratings yet

- Internet BankingDocument9 pagesInternet Bankingashutoshmonirba480% (1)

- Blur and Motion Blur Influence On Face Recognition PerformanceDocument5 pagesBlur and Motion Blur Influence On Face Recognition PerformanceDhanya BNo ratings yet

- Trainees Progress Sheet PanuncialmanDocument2 pagesTrainees Progress Sheet PanuncialmanJovenal MalonhaoNo ratings yet

- Activity 2Document4 pagesActivity 2Markjustin AguilaNo ratings yet

- Cyber Security Unit 2Document27 pagesCyber Security Unit 2Raj Kumar YadavNo ratings yet

- RFQ 10406475 - RWSCM00015F-Rev05-RequestforQuotationSupplyandDelivery - 20230929112300.955 - X 23 October 2023TDocument11 pagesRFQ 10406475 - RWSCM00015F-Rev05-RequestforQuotationSupplyandDelivery - 20230929112300.955 - X 23 October 2023TPfunzo MammbaNo ratings yet