Professional Documents

Culture Documents

2003 05 MOC Gear Box

Uploaded by

Harshad Solanki0 ratings0% found this document useful (0 votes)

12 views1 pageA mechanic was draining oil from a gear box when he connected an air hose. The gear box fractured, blowing a large piece off and onto the floor. Many pieces of equipment in a chemical plant are not designed for pressure. Before implementing a good idea, be alert to subtle changes that might not be safe.

Original Description:

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA mechanic was draining oil from a gear box when he connected an air hose. The gear box fractured, blowing a large piece off and onto the floor. Many pieces of equipment in a chemical plant are not designed for pressure. Before implementing a good idea, be alert to subtle changes that might not be safe.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

12 views1 page2003 05 MOC Gear Box

Uploaded by

Harshad SolankiA mechanic was draining oil from a gear box when he connected an air hose. The gear box fractured, blowing a large piece off and onto the floor. Many pieces of equipment in a chemical plant are not designed for pressure. Before implementing a good idea, be alert to subtle changes that might not be safe.

Copyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

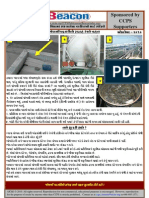

CENTER FOR CHEMICAL PROCESS SAFETY

CCPS

An AIChE Industry Technology Alliance

PROCESS SAFETY BEACON

Messages for Manufacturing Personnel

May 2003

Heres What Happened:

A mechanic was draining oil from this large gear box. The oil was draining out very slowly, so he decided to speed the job up by connecting an air hose to push the oil out faster. It didnt take long for the results shown to happen. The cast iron gear box fractured, blowing a large piece off and onto the floor. Fortunately, no one was hurt.

A GOOD IDEA CAN TURN BAD . . .

Why Did This Happen?

The gear box was not a pressure vessel More air was added than could be vented, so the pressure built up MOC was not used to review the change

WHEN YOU IGNORE MANAGEMENT OF CHANGE!

What Can You Do?

Many pieces of equipment in a chemical plant are NOT designed for pressure. Check the equipment folder, but if there is no ASME code stamp, assume that it is not pressure rated. Adding air to the gear box was a change and should have been checked through the sites MOC process. Be alert to subtle changes that might not be safe.

Heres What Should Happen:

Good ideas improve operations and reduce risk every day. However, before implementing a good idea, it is essential to review the change to ensure that it doesnt introduce any new hazards or risks to the workplace. In this incident, the mechanic should have recognized what he was about to do as not like-in-kind and reviewed the change through the MOC process. This would have identified that the gear box was not designed for pressure.

Not everything works better under pressure. Connect utility hoses with care !

AIChE 2003. All rights reserved. Reproduction for non-commercial, educational purposes is encouraged. However, reproduction for the purpose of resale by anyone other than CCPS is strictly prohibited. Contact us at ccps@aiche.org or 212-591-7319. http://www.aiche.org/ccps/safetybeacon.htm

You might also like

- Beacon-Ignoring MOC PDFDocument1 pageBeacon-Ignoring MOC PDFjargiaNo ratings yet

- MKPK Tugas 5Document4 pagesMKPK Tugas 5Tri MitraNo ratings yet

- Knowledge in Control: Is It Possible To Control Critical Machinery With Technology Alone?Document3 pagesKnowledge in Control: Is It Possible To Control Critical Machinery With Technology Alone?VanBa MrNguyenNo ratings yet

- Unit 1 CMTDocument25 pagesUnit 1 CMTMelvin BulosNo ratings yet

- QMC001 01 GBDocument16 pagesQMC001 01 GBsansagithNo ratings yet

- Beacon Flixborough PDFDocument1 pageBeacon Flixborough PDFjargiaNo ratings yet

- Unidentified Thermal Expansion Hazard Causes Oil Spill To Secondary Containment - ToolboxDocument4 pagesUnidentified Thermal Expansion Hazard Causes Oil Spill To Secondary Containment - ToolboxchemjesuNo ratings yet

- Chemical Engineering 12 2012Document70 pagesChemical Engineering 12 2012Leonardo Ramos100% (1)

- Mccall Diesel Motor Works Case StudyDocument14 pagesMccall Diesel Motor Works Case StudyKimberlyConde100% (2)

- Section No.: 7 / Title: Condition Based MaintenanceDocument5 pagesSection No.: 7 / Title: Condition Based Maintenancekrishna_14893No ratings yet

- Operator’S Guide to Rotating Equipment: An Introduction to Rotating Equipment Construction, Operating Principles, Troubleshooting, and Best PracticesFrom EverandOperator’S Guide to Rotating Equipment: An Introduction to Rotating Equipment Construction, Operating Principles, Troubleshooting, and Best PracticesRating: 5 out of 5 stars5/5 (3)

- Lean To WeldingDocument10 pagesLean To Weldingkarthiks12008658No ratings yet

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- An Introduction To The Concept of Double Jeopardy in Process SafetyDocument4 pagesAn Introduction To The Concept of Double Jeopardy in Process SafetyAnonymous a4Jwz14WNo ratings yet

- Don't Do This!: SafetyDocument8 pagesDon't Do This!: SafetyJohn AnthoniNo ratings yet

- An Engineer S Guide To MocDocument5 pagesAn Engineer S Guide To MocAnonymous 1XHScfCI100% (1)

- OMNIWELD Applying Kaizen To Welding OperationsDocument6 pagesOMNIWELD Applying Kaizen To Welding OperationsClaudia MmsNo ratings yet

- HSSE Alert - BP Refinery Explosion Incident - March 23rdDocument4 pagesHSSE Alert - BP Refinery Explosion Incident - March 23rdOsedebamen Irabor100% (1)

- Mechanical Engineering Failures The Role of ReliabilityDocument15 pagesMechanical Engineering Failures The Role of ReliabilityAbdulrahman AlkhowaiterNo ratings yet

- Are Your PMs Working For or Against YouDocument4 pagesAre Your PMs Working For or Against Yousrjsk1No ratings yet

- A Procedure For Lube Oil FlushingDocument9 pagesA Procedure For Lube Oil FlushingBrosGeeNo ratings yet

- Joe Bell Maintenance ArticleDocument5 pagesJoe Bell Maintenance ArticlemadodandembeNo ratings yet

- CCC White Paper - Knowledge in Control - Sep - 2014Document4 pagesCCC White Paper - Knowledge in Control - Sep - 2014Pedro MunizNo ratings yet

- Safety Engineering ExamDocument4 pagesSafety Engineering ExamAel Xander Loresco50% (2)

- PSE Alert - VCE Incident - BP RefineryDocument4 pagesPSE Alert - VCE Incident - BP RefineryOsedebamen IraborNo ratings yet

- Longxi Machinery Works - Mar 4Document1 pageLongxi Machinery Works - Mar 4Liby SantosNo ratings yet

- Gas Lift ThesisDocument8 pagesGas Lift Thesisfjbr4n2n100% (2)

- December 2016 - Intl.Document208 pagesDecember 2016 - Intl.Karem Jeanette Saenz Bernal100% (1)

- HPHT Cementing GuidelinesDocument15 pagesHPHT Cementing Guidelineshamora33100% (4)

- Calibracion de Valvulas D399Document82 pagesCalibracion de Valvulas D399Reynol Rivas80% (5)

- How to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsFrom EverandHow to Rebuild & Modify Ford C4 & C6 Automatic TransmissionsRating: 5 out of 5 stars5/5 (5)

- NTCC Sourabh ShuklaDocument29 pagesNTCC Sourabh ShuklaSourav ShuklaNo ratings yet

- CQV #2 Like-For-Like Change ProblemsDocument7 pagesCQV #2 Like-For-Like Change Problemswindli2012No ratings yet

- Accident Avoiding of Punching Machine ReportDocument31 pagesAccident Avoiding of Punching Machine ReportpramodassNo ratings yet

- Validating and Testing A Fluid Bed System - Part 2Document2 pagesValidating and Testing A Fluid Bed System - Part 2Donig FermanianNo ratings yet

- Effects From Changes May Take Years To AppearDocument1 pageEffects From Changes May Take Years To AppearukrtiNo ratings yet

- Diesel Generator Overhauling Procedure-21-22 Best PracticeDocument15 pagesDiesel Generator Overhauling Procedure-21-22 Best PracticeMarcos Fernandez100% (2)

- Centrifugal Pump MaintenanceDocument32 pagesCentrifugal Pump MaintenancemersiumNo ratings yet

- Toyota PDFDocument8 pagesToyota PDFOHNo ratings yet

- Reduce Shutdowns and Fulfill Production Goals: Compressor Health MonitoringDocument4 pagesReduce Shutdowns and Fulfill Production Goals: Compressor Health Monitoringpeach5No ratings yet

- Mohd Khairul Azmi - PM - TUGASANDocument6 pagesMohd Khairul Azmi - PM - TUGASANSyafiz NawawiNo ratings yet

- Don't Start That Motor!Document7 pagesDon't Start That Motor!Tobias OliveiraNo ratings yet

- PROCESS SAFETY&Mdash 1 - Gas Conditioning Failures Show Need For Design Scrutiny - Oil & Gas JournalDocument6 pagesPROCESS SAFETY&Mdash 1 - Gas Conditioning Failures Show Need For Design Scrutiny - Oil & Gas JournalcsNo ratings yet

- About UsDocument35 pagesAbout Us9897856218No ratings yet

- Process Engineering Solutions To Mechanical FailuresDocument10 pagesProcess Engineering Solutions To Mechanical FailuresfendynovapamelaNo ratings yet

- Ajuste y DiagnosticoDocument79 pagesAjuste y Diagnosticojulio cesarNo ratings yet

- Analysis of Breakdown and Imp in PM On 1000ton Hyd PressDocument10 pagesAnalysis of Breakdown and Imp in PM On 1000ton Hyd PressSundar Kumar Vasantha GovindarajuluNo ratings yet

- 2002 07 Beacon English 0Document1 page2002 07 Beacon English 0Eslam HusseinNo ratings yet

- ch14 SchultheisDocument0 pagesch14 Schultheissatya_chagantiNo ratings yet

- 5 Steps Before Making An Air Compressor Purchase DecisionDocument40 pages5 Steps Before Making An Air Compressor Purchase DecisionIsmail AliNo ratings yet

- Guide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingFrom EverandGuide for Asset Integrity Managers: A Comprehensive Guide to Strategies, Practices and BenchmarkingNo ratings yet

- Group 6 - Wheatco LTD and Chemco LTD (B)Document3 pagesGroup 6 - Wheatco LTD and Chemco LTD (B)Belly Satrio Wiwoho0% (3)

- CAST Practicum v2Document33 pagesCAST Practicum v2tin2huynhNo ratings yet

- Vanaken AbsDocument5 pagesVanaken AbsGul sher BalochNo ratings yet

- Injection Actuation Pressure - Test: TroubleshootingDocument19 pagesInjection Actuation Pressure - Test: TroubleshootingMbahdiro KolenxNo ratings yet

- 10 Rules For Condition Monitoring.Document8 pages10 Rules For Condition Monitoring.Zegera MgendiNo ratings yet

- BP Texas Oil RefineryDocument21 pagesBP Texas Oil Refinerymuhammad saifullahNo ratings yet

- Management of Change: Did You Know?Document1 pageManagement of Change: Did You Know?baaziz2015No ratings yet

- Diesel Engine Care and Repair: A Captain's Quick GuideFrom EverandDiesel Engine Care and Repair: A Captain's Quick GuideRating: 5 out of 5 stars5/5 (1)

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- Beacon EnglishDocument1 pageBeacon EnglishHarshad SolankiNo ratings yet

- 2009 05 Mechanical IntegrityDocument1 page2009 05 Mechanical IntegrityHarshad SolankiNo ratings yet

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- Beacon HindiDocument1 pageBeacon HindiHarshad SolankiNo ratings yet

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- Beacon EnglishDocument1 pageBeacon EnglishselvajanarNo ratings yet

- Beacon GujaratiDocument1 pageBeacon GujaratiHarshad SolankiNo ratings yet

- 2009 01 Fire While Filling Portable ContainerDocument1 page2009 01 Fire While Filling Portable ContainerHarshad SolankiNo ratings yet

- 2009 03 Fatality Caused by Unloading The Wrong ChemicalDocument1 page2009 03 Fatality Caused by Unloading The Wrong ChemicalHarshad SolankiNo ratings yet

- 2008 09 Plant SecurityDocument1 page2008 09 Plant SecurityHarshad SolankiNo ratings yet

- 2009 04 Be PreparedDocument1 page2009 04 Be PreparedHarshad SolankiNo ratings yet

- Spill Containment BeaconDocument1 pageSpill Containment BeaconselvajanarNo ratings yet

- 2008 11 Laboratory Refrigerator ExplosionsDocument1 page2008 11 Laboratory Refrigerator ExplosionsHarshad SolankiNo ratings yet

- 2008-12-Beacon - Static Electric Discharge Causes Fire - December 2008Document1 page2008-12-Beacon - Static Electric Discharge Causes Fire - December 2008liveconnectionz282No ratings yet

- 2008 06 Halon Cylinder Becomes RocketDocument1 page2008 06 Halon Cylinder Becomes RocketHarshad SolankiNo ratings yet

- 2008 04 Gasoline Pipeline Damaged by Construction Causes FireDocument1 page2008 04 Gasoline Pipeline Damaged by Construction Causes FireHarshad SolankiNo ratings yet

- 2008 01 2007 Beacon Review - Remember The Lessons LearnedDocument1 page2008 01 2007 Beacon Review - Remember The Lessons LearnedHarshad SolankiNo ratings yet

- 2008 08 Beacon Measuring Process Safety PerformanceDocument1 page2008 08 Beacon Measuring Process Safety PerformanceHarshad SolankiNo ratings yet

- 2008 10 Ice Ruptures Causes FireDocument1 page2008 10 Ice Ruptures Causes FireHarshad SolankiNo ratings yet

- Dust Explosion 2008 05 BeaconDocument1 pageDust Explosion 2008 05 BeaconHaresh PatelNo ratings yet

- 2008 07 What Is Process SafetyDocument1 page2008 07 What Is Process SafetyHarshad SolankiNo ratings yet

- Oil Tank Fire Caused by Static Discharge: Sponsored by Ccps SupportersDocument1 pageOil Tank Fire Caused by Static Discharge: Sponsored by Ccps SupportersNarasimmaraj NagarajanNo ratings yet

- 2007 09 Hot Work PermitsDocument1 page2007 09 Hot Work PermitsHarshad SolankiNo ratings yet

- 2007 11 Cold Embrittlement and Thermal StressDocument1 page2007 11 Cold Embrittlement and Thermal StressHarshad SolankiNo ratings yet

- 2008 02 How Can You Use The BeaconDocument1 page2008 02 How Can You Use The BeaconHarshad SolankiNo ratings yet

- 2008 03 Do Your Shutoff Systems Actually WorkDocument1 page2008 03 Do Your Shutoff Systems Actually WorkHarshad SolankiNo ratings yet

- 2007 08 Hazards of Temporary Confined SpacesDocument1 page2007 08 Hazards of Temporary Confined SpacesHarshad SolankiNo ratings yet

- 2007 10 We Have LiftoffDocument1 page2007 10 We Have LiftoffHarshad SolankiNo ratings yet