Professional Documents

Culture Documents

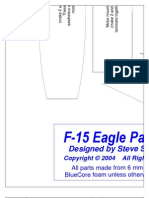

F-15 Park Jet Plans (Parts Templates Non-Tiled) Rev C

Uploaded by

Finu Bv0 ratings0% found this document useful (0 votes)

27 views1 pageOriginal Title

F-15 Park Jet Plans %28Parts Templates Non-Tiled%29 Rev C

Copyright

© Attribution Non-Commercial (BY-NC)

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

27 views1 pageF-15 Park Jet Plans (Parts Templates Non-Tiled) Rev C

Uploaded by

Finu BvCopyright:

Attribution Non-Commercial (BY-NC)

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Canopy

(make 11 and laminate together)

Aft Fuselage Sides with Vertical Tails

(make 2)

3/8" foam strips (2 layers)

F-2

F-3 F-1

F-4

0.75" x 0.75" 1/64" ply

doublers on inboard side

(drill 3/16" hole for pivot

bearing tubes)

Cut hole for access

to radio compartment

Make 2 from 1/4" sq. balsa

Glue 3/8" x 7" strip of foam here to support fuselage top piece

Aft Fuselage Bottom

(make 1)

Cut to fit motor

Turtledeck Sides (make 2)

3/8" foam strip

3/8" foam strip

Turtledeck Top

(make 1 and trim to fit)

Wing

(make 1)

Cut slot to fit wing spar

Cut to fit servo

Forward Fuselage Sides

(make 2)

Aft Fuselage Top

(make 1)

Cut to fit motor

OPTIONAL: Internal support

for launch pylon (make 1)

3/8" foam strips (2 layers)

2

4

0

Scale in inches

2 4

Side fairings for launch pylon

Sand to an airfoiled shape (make 2)

OPTIONAL: Launch pylon

(make 1 from 1/8" lite-ply)

Wing strakes/inlet top

(make 1)

Forward Fuselage Bottom (make 1)

Nosecone top view template

(trace outline on top of nosecone

to assist in carving it to shape)

B

e

v

e

l

t

h

is

a

r

e

a

Forward inlet tops

(make 2)

Flaperon and rudder control horns

(make from 1/32" plywood)

B

e

v

e

l

t

h

is

a

r

e

a

Exhaust nozzle

sides (make 2

mirror image)

Inboard inlet sides

(make 2)

Inlet diverter/spacer

(make 2 from 3 mm

Depron or 1/8" balsa)

Nosecone

(make 11 and

laminate together)

T

o

p

f

w

d

f

u

s

e

la

g

e

(

t

r

im

t

o

f

it

)

F-15 Eagle Park Jet

Designed by Steve Shumate

All parts made from 6 mm Depron or

BlueCore foam unless otherwise specified

Copyright 2004 All Rights Reserved

Stabilators

(make 2)

Cut slot to fit stabilator pivot

Mounting hole for stabilator servo

(cut to fit servo very tightly)

Motor mount

(make 2 and

laminate together)

0.75" x 0.75" 1/64" ply doublers each side

(drill 3/16" hole for pivot bearing tubes)

Bulkhead F-3

(make 1)

Bulkhead F-1

(make 1)

Bulkhead F-2

(make 1)

Bulkhead F-4

(make 1)

O

P

T

I

O

N

A

L

:

A

f

t

e

n

g

in

e

f

a

ir

in

g

s

(

m

a

k

e

2

)

You might also like

- 2000 Chevy Suburban Body Repair ManualDocument37 pages2000 Chevy Suburban Body Repair Manualwhunt001No ratings yet

- Panel Saw PlanDocument11 pagesPanel Saw Plankarim100% (1)

- Ing Swin Gar M 1/8" Lite-PlyDocument1 pageIng Swin Gar M 1/8" Lite-Plymam73100% (1)

- Tecumseh Engine Parts Manual HH60 105106FDocument8 pagesTecumseh Engine Parts Manual HH60 105106FRyan PelletierNo ratings yet

- Fokker DR1 Plans (Parts Templates Non-Tiled)Document1 pageFokker DR1 Plans (Parts Templates Non-Tiled)mam73No ratings yet

- Hurricane Construction ManualDocument111 pagesHurricane Construction ManualJorge José Figueiredo SiqueiraNo ratings yet

- Knockdown Shooting BenchDocument7 pagesKnockdown Shooting Benchpaddyfritz100% (2)

- T-38 Park Jet Plans (Assembly Drawing)Document2 pagesT-38 Park Jet Plans (Assembly Drawing)souheil_souNo ratings yet

- T-38 Park Jet Plans (Parts Templates Tiled)Document15 pagesT-38 Park Jet Plans (Parts Templates Tiled)Iruel Street NewNo ratings yet

- Oil Drum ForgesDocument42 pagesOil Drum ForgesMegan AndrewsNo ratings yet

- Plans: Anel AWDocument11 pagesPlans: Anel AWElysita Macedo SalvadorNo ratings yet

- T-38 Park Jet Plans (Parts Templates Tiled) BETA2Document16 pagesT-38 Park Jet Plans (Parts Templates Tiled) BETA2Emerson URNo ratings yet

- 4 X 4 Off RoaderDocument6 pages4 X 4 Off Roaderhulusi67No ratings yet

- 8A Thickness SanderDocument15 pages8A Thickness SanderAulia Haq Aqoby100% (1)

- Morris Mustang P 51Document2 pagesMorris Mustang P 51Emerson URNo ratings yet

- Fokker DR1 Plans (Parts Templates Tiled)Document25 pagesFokker DR1 Plans (Parts Templates Tiled)mam73No ratings yet

- WW1 Sopwith Triplane N5912Document6 pagesWW1 Sopwith Triplane N5912hawkeye11100% (6)

- A Homebuilt Threshing Machine For Small HoldersDocument62 pagesA Homebuilt Threshing Machine For Small HoldersJaremy Scott Golightly100% (1)

- 84 - Cutting Diagrams - Classic Cabinet-Base WorkbenchDocument5 pages84 - Cutting Diagrams - Classic Cabinet-Base WorkbenchGsmHelpNo ratings yet

- Gripen Park Jet Parts Template TiledDocument16 pagesGripen Park Jet Parts Template TiledZRomulus73No ratings yet

- Building Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeFrom EverandBuilding Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeNo ratings yet

- F-15 Park Jet Plans (Parts Templates Scaled 150 Tiled)Document42 pagesF-15 Park Jet Plans (Parts Templates Scaled 150 Tiled)donlynNo ratings yet

- Su-37 Park Jet Plans (Parts Templates Tiled)Document28 pagesSu-37 Park Jet Plans (Parts Templates Tiled)colo0% (1)

- F-22 Park Jet (Parts Templates Scaled 120 Tiled)Document28 pagesF-22 Park Jet (Parts Templates Scaled 120 Tiled)Ronald Cardenas GNo ratings yet

- Sukhoi Su 26Document4 pagesSukhoi Su 26Jesùs AlfaroNo ratings yet

- Polaris Parts Templates (Tiled)Document20 pagesPolaris Parts Templates (Tiled)Leandro AlvarengaNo ratings yet

- Gripen200 A4Document64 pagesGripen200 A4vscribNo ratings yet

- F-18 Park Jet (Part Templates Tiled) Rev ADocument16 pagesF-18 Park Jet (Part Templates Tiled) Rev ApapacoolNo ratings yet

- Su-37 Plans PT1 A0Document1 pageSu-37 Plans PT1 A0Leonardo VillarroelNo ratings yet

- T-38 Park Jet Plans (Parts Templates 120 Scaled)Document25 pagesT-38 Park Jet Plans (Parts Templates 120 Scaled)vscribNo ratings yet

- F-15 Park Jet Plans Assembly Drawing TiledDocument2 pagesF-15 Park Jet Plans Assembly Drawing TiledNestor Omar AmbesiNo ratings yet

- F-15 Park Jet Plans (Parts Templates Tiled)Document18 pagesF-15 Park Jet Plans (Parts Templates Tiled)EricsonNo ratings yet

- T-38 Park Jet Plans (Parts Templates Tiled 60 Scaled)Document6 pagesT-38 Park Jet Plans (Parts Templates Tiled 60 Scaled)vscribNo ratings yet

- SE5a eDocument3 pagesSE5a eairsoft doença100% (1)

- SU-47 Parts 6mm DepronDocument19 pagesSU-47 Parts 6mm DepronrevolverasNo ratings yet

- Air Tool Station: Materials & HardwareDocument2 pagesAir Tool Station: Materials & HardwareflerziNo ratings yet

- MTD Model 146S845H788 (Tmo 3399006) (1996) Parts ListDocument24 pagesMTD Model 146S845H788 (Tmo 3399006) (1996) Parts ListdgroffwaNo ratings yet

- Catabourne 12" (Nominal) Catapult Glider: Designed by Ted Horsey (Bournemouth Club)Document2 pagesCatabourne 12" (Nominal) Catapult Glider: Designed by Ted Horsey (Bournemouth Club)Bosko LacimicNo ratings yet

- Sigrc 74 Kadetlt 25Document34 pagesSigrc 74 Kadetlt 25carlosulloa100% (1)

- 86 - Cutting Diagram - Table Saw Thickness SanderDocument1 page86 - Cutting Diagram - Table Saw Thickness SanderAdam HemsleyNo ratings yet

- Srx4 Srx6 TableDocument1 pageSrx4 Srx6 TableRolando Antonio TroncosoNo ratings yet

- Flaglor Scooter Buildguide v3Document11 pagesFlaglor Scooter Buildguide v3Isyna AriefNo ratings yet

- References and Parts ListDocument3 pagesReferences and Parts ListybouriniNo ratings yet

- Spitfire MK - Xiv/Xix: Two Wheel Retract SystemDocument8 pagesSpitfire MK - Xiv/Xix: Two Wheel Retract Systemall4scaleNo ratings yet

- NP-A2S: Service Bulletin CopierDocument3 pagesNP-A2S: Service Bulletin CopierAmer RafiqueNo ratings yet

- Allsport Ez-Go TXT Flip Seat InstructionsDocument14 pagesAllsport Ez-Go TXT Flip Seat InstructionsCaleb LoweryNo ratings yet

- Chests - Blanket Chest PDFDocument3 pagesChests - Blanket Chest PDFAleksandar NikolicNo ratings yet

- By Graham Smith: Top View RudderDocument1 pageBy Graham Smith: Top View RudderSergio De Manuel GálvezNo ratings yet

- 32 Ford Final Pattern PDFDocument1 page32 Ford Final Pattern PDFMarian VoicuNo ratings yet

- F-14 Park Jet (Assembly Drawing)Document2 pagesF-14 Park Jet (Assembly Drawing)John MondoNo ratings yet

- Xpag BoltsDocument9 pagesXpag BoltsNakkolopNo ratings yet

- 2010 FSAE Design Spec Sheet: Car No. SchoolDocument3 pages2010 FSAE Design Spec Sheet: Car No. SchoolOswaldo BorjasNo ratings yet

- 99paa13364 Ghostsii Ewb Spec 2014 New.1Document1 page99paa13364 Ghostsii Ewb Spec 2014 New.1sdfhsdkfhksNo ratings yet

- Tecumseh Model Hm80 155128e Parts ListDocument11 pagesTecumseh Model Hm80 155128e Parts ListAndy TuranskyNo ratings yet