Professional Documents

Culture Documents

Arroz Fatty Acids Ethyl Esters From Rice Bran Oil...

Arroz Fatty Acids Ethyl Esters From Rice Bran Oil...

Uploaded by

Nguyễn Đình PhongOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Arroz Fatty Acids Ethyl Esters From Rice Bran Oil...

Arroz Fatty Acids Ethyl Esters From Rice Bran Oil...

Uploaded by

Nguyễn Đình PhongCopyright:

Available Formats

Fatty acids ethyl esters from rice bran oil by in-situ esterification as a biodiesel fuel

Sevil Ozgl-Ycel* a , Selma Trkaya Istanbul Technical University, Chemical and Metallurgical Faculty, Chemical Engineering Department, 80626 Maslak- Istanbul, TURKEY Fax: 90 212 285 2925; yucels@itu.edu.tr

Fatty acids esters are known to be good alternative fuels(biodiesel). Due to the economic reasons, the use of cheap materials as substrats for biodiesel is being preferred. In this case, rice bran oil, which can not to be evaluated as an edible oil, is an interesting substrat. In-situ esterification of high-acidity rice bran oil with ethanol and sulfuric acid catalyst was investigated.The effects of free fatty acid (FFA) contents of rice bran oil and ethanol concentration on in-situ esterification were investigated and compositions of produced ethyl esters due to the conditions were determined. Research Objectives Fatty acid monoesters produced by esterification of fatty acids with monohydroxy compounds are fatty chemicals widely used in industry due to their lubricating and softening properties[1]. Additionally, methyl and ethyl esters of these fatty acids are recently being used in diesel fuels are renewable and clean energy sources. Producing ethyl ester rather than methyl ester is of considerable interest because it allows production of an entirely agricultural fuel, and the extra carbon brought by ethanol molecule slightly increases the heat and the cetane number?2?. However, because monoesters of vegetable oils are more expensive than corresponding petroleum products, cheaper raw materials are being searched. Therefore, in this study the use of rice bran oil, agricultural waste material that can not be evaluated as an edible oil in the country, in the production of ethyl esters was investigated. Rice bran which is obtained as a by-product in the milling of brown rice kernel to yield the familiar white rice, has an oil content that varies from 12 to 23 %, depending on variety of rice and degree of milling?3,4?. Oil extracted from bran may have low or high acidity, depending on the conditions and duration of storage. The rapid increase of free fatty acids (FFA) in the bran after milling has been recognized as a serious problem for rice bran industries. The principal cause of oil deterioration in the bran during storage is the activity of the lipase enzyme in the presence of moisture. For this reason only 6,5% world rice bran oil potential is evaluated as edible and the rest for industrial product purposes. In-situ Esterification Ethyl ester production carried out from fats and oils by alkaline-catalyzed interesterification(ethanolysis) or by direct esterification of inexpensive fatty acids using acidic catalyst. While the esterification of fatty acids is fast in acidic media, the fast esterification of triglicerides is performed in alkali media. So, the esterification of high-acidity oils such as rice bran oil, presents production problem due to their high contents of free fatty acids(FFA), mono- and diglicerides. For this reason, rapid and efficient conversion of high acidity oils to ethyl esters by onestep is not practical. In this study, the production of fatty acids monoesters of rice bran oil by in-situ esterificatio n method was investigated. In this method, the oil was not extracted from the seed and reacted with the alcohol with acid catalyst. The extraction and monoester production occured simultaneously. In-situ esterification method is preferred to conventional methods, not only one-step esterification of high acidity oils but also provides pure products[5,6,7]. Conclusion In this study, in-situ esterification of rice bran oil with ethanol(96%) was investigated using sulfuric acid. The effect of FFA content of rice bran oil and ethanol concentration on the yield and purity of obtained esters was investigated. The results showed that the ethyl ester content of products changed considerably with the FFA content of rice bran oil. The ester content of product increase from 36,6% to 78% with increasing the FFA content of oil from 14.5% to 81.0, respectively. Similarly, it was also observed that high amount of the esters products obtained from rice bran oils containing high FFA.

In the second part of the study, in-situ esterification experiments were conducted with 99.1% ethanol and these results were compared with 96% ethanol. It was seen that the increasing of ethanol concentration resulted in significant increasement in the yield of esters from low-acidity bran oils, i.e., the ester yield increased about 20% when the rice bran oil, having 14% FFA was treated with 99.1% ethanol. However, bran oils with high FFA contents used in the esterification reaction 99.1% ethanol did not effect practically the yield of ester. As a conclusion, production of ethyl esters from a cheap raw material such as rice bran oil by in-situ esterification method would increase the importance of these esters as a clean and alternative energy source. References ?1? Meffret A., Technical Uses of Fatty Acid Esters, J.Am.Oil Chem.Soc., 1984, 61, p.255-258. 427- 432. ?2? Fillieres L., Benjelloun-Mlayah, B. Delmas, M., Ethanolysis of Rapeseed Oil: Quantitation of Ethyl Esters, Mono-Di-, and Triglycerides and Glycerol by High-Performance Size-Exclusion Chromatography, J.Am.Oil Chem.Soc., 1995, 72, p.427- 432. ?3? Gupta,H.P., Rice Bran Offers in Indian Oil Source. J. Am. Oil Chem.Soc., 1989, 66, p. 620-623. ?4? Saunders R.M., Rice Bran Composition and Potential Food Uses, Food Reviews International, 1986, 1, p.465-495. ?5? Ozgl, S. Trkay, S., In-situ Esterification of Rice Bran Oil with Methanol and Ethanol, J.Am.Oil Chem.Soc., 1993, 70, p.145-147. ?6? Kildiran, G. Ycel, S.O.. Trkay, S., In-situ Acoholysis of Soybean Oil, J.Am.Oil Chem.Soc., 1996, 73, p.223-225. ?7? Harrington, K.J., D'Arcy-Evans, C., A Comparison of Conventional and In-Situ Methods of Transesterification of Seed Oil from a Series of Sunflower, J.Am.Oil Chem.Soc., 1985, 62, p.10091013.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Mas and e PDFDocument5 pagesMas and e PDFtulasi saladiNo ratings yet

- Ifra 50th Amendment (Att 03) - Index of Ifra Standards June 30 2021Document11 pagesIfra 50th Amendment (Att 03) - Index of Ifra Standards June 30 2021Carlos Gonzalez CastroNo ratings yet

- Class XII: Chemistry Chapter 12: Aldehydes, Ketones and Carboxylic Acids Top ConceptsDocument15 pagesClass XII: Chemistry Chapter 12: Aldehydes, Ketones and Carboxylic Acids Top ConceptsAshaNo ratings yet

- Arndt-Eistert Synthesis (Wolf Rearrangement) : O CH N N RC O OH R C O CL CH N 2 - Diazoketone R C O CH NNDocument54 pagesArndt-Eistert Synthesis (Wolf Rearrangement) : O CH N N RC O OH R C O CL CH N 2 - Diazoketone R C O CH NNJosephine TorresNo ratings yet

- 9701 Chemistry Data Booklet Specimen 2016Document20 pages9701 Chemistry Data Booklet Specimen 2016rosestrikesNo ratings yet

- Nov 2020 QPDocument20 pagesNov 2020 QPmarcoscervantes006No ratings yet

- Alcohols, Diols, and ThiolsDocument3 pagesAlcohols, Diols, and ThiolsJeremy A. Baker100% (1)

- Answers To Exam-Style Questions: Module 1 (Page 68)Document2 pagesAnswers To Exam-Style Questions: Module 1 (Page 68)Milana AndrewNo ratings yet

- Katowice Entrance ExamDocument8 pagesKatowice Entrance Examnathaaaa0% (1)

- Biochem Lec Midterm TransDocument18 pagesBiochem Lec Midterm TransAndrea Jersey BuluranNo ratings yet

- Carboxylic Acids, Esters, and Other Acid Derivatives: Test BankDocument14 pagesCarboxylic Acids, Esters, and Other Acid Derivatives: Test BankAda VessaliusNo ratings yet

- Methods For The Synthesis of Gem-Difluoromethylene CompoundsDocument65 pagesMethods For The Synthesis of Gem-Difluoromethylene CompoundsjohnyeapNo ratings yet

- Recent Advances in Methylation: A Guide For Selecting Methylation ReagentsDocument63 pagesRecent Advances in Methylation: A Guide For Selecting Methylation ReagentsTuyết MaiNo ratings yet

- Kinetic Study of Esterification ReactionDocument10 pagesKinetic Study of Esterification ReactionPuput Trisnayanti Inanto PutriNo ratings yet

- Molecular RearrangementsDocument9 pagesMolecular RearrangementsDhanaswamy Ilangeswaran67% (3)

- Compatibilidad Quimica StubbeDocument198 pagesCompatibilidad Quimica StubbeBase SistemasNo ratings yet

- Reaction Kinetics of The Catalytic Esterification of Citric Acid With EthanolDocument8 pagesReaction Kinetics of The Catalytic Esterification of Citric Acid With EthanolJason SanchezNo ratings yet

- 4 - Carboxylic Acids and Its Derivatives (Booklet-1)Document16 pages4 - Carboxylic Acids and Its Derivatives (Booklet-1)kraken monsterNo ratings yet

- United States Patent: (12) (10) Patent No.: US 7,528,272 B2Document18 pagesUnited States Patent: (12) (10) Patent No.: US 7,528,272 B2Alexander Franco CastrillonNo ratings yet

- Acid DerivativesDocument6 pagesAcid DerivativesAirome CorpuzNo ratings yet

- Chemistry Biodiversity - 2015 - Rios - Chemistry and Biology of The Genus Flourensia AsteraceaeDocument40 pagesChemistry Biodiversity - 2015 - Rios - Chemistry and Biology of The Genus Flourensia AsteraceaeGustavo CamposNo ratings yet

- The First Total Synthesis of - IngenolDocument3 pagesThe First Total Synthesis of - IngenolCabNo ratings yet

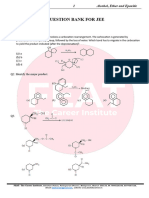

- Question Bank For Jee: Objective QuestionsDocument44 pagesQuestion Bank For Jee: Objective QuestionsYash KapoorNo ratings yet

- FOSFA Acceptable Previous Cargoes ListDocument3 pagesFOSFA Acceptable Previous Cargoes ListJorge GuevaraNo ratings yet

- Dke199 ch12Document40 pagesDke199 ch12qhqhqNo ratings yet

- Chemistry Pmc-1-36 (Paid) PaperDocument202 pagesChemistry Pmc-1-36 (Paid) PaperHaresh KumarNo ratings yet

- [Organic Process Research & Development 2012-Nov 30 Vol. 16 Iss. 12] Weiberth, Franz J._ Yu, Yong_ Subotkowski, Witold_ Pemberton, Cl - Demonstration on Pilot-Plant Scale of the Utility of 1,5,7-Triazabicyclo[4.4.0]Document3 pages[Organic Process Research & Development 2012-Nov 30 Vol. 16 Iss. 12] Weiberth, Franz J._ Yu, Yong_ Subotkowski, Witold_ Pemberton, Cl - Demonstration on Pilot-Plant Scale of the Utility of 1,5,7-Triazabicyclo[4.4.0]Эмилия МинисNo ratings yet

- Synthesis of Lactones and LactamsDocument1,093 pagesSynthesis of Lactones and LactamsnestorNo ratings yet

- OL Lab 9 Organic ChemistryDocument17 pagesOL Lab 9 Organic ChemistryHezekiah AtindaNo ratings yet

- Science Full Marks Term II PDFDocument232 pagesScience Full Marks Term II PDFMahavir Jain0% (2)

![[Organic Process Research & Development 2012-Nov 30 Vol. 16 Iss. 12] Weiberth, Franz J._ Yu, Yong_ Subotkowski, Witold_ Pemberton, Cl - Demonstration on Pilot-Plant Scale of the Utility of 1,5,7-Triazabicyclo[4.4.0]](https://imgv2-2-f.scribdassets.com/img/document/639410752/149x198/b3a17583da/1681910419?v=1)