Professional Documents

Culture Documents

Lifting Beams Stop Log

Uploaded by

elfe710Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Lifting Beams Stop Log

Uploaded by

elfe710Copyright:

Available Formats

Lifting Beams Stop Log

TREBLE R FABRICATIONS

UNIT 42 CROSSGATE ROAD PARK FARM INDUSTRIAL ESTATE REDDITCH WORCS B987SN

.tel 01527 503 303 fax 01527 503 325 web www.treblerfabrications.co.uk

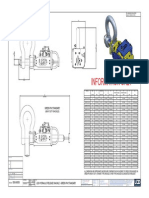

STOPLOG LIFTING BEAMS

All Stoplogs subject to size require lowering and removal and the requirement / need for aSemi-Automatic Lifting Beam is the ideal solution. Following the procedure below this isstraight forward.

OPERATING PROCEDURETO LIFT LOGS

1) LOWER BEAM USING SLING (NOT TREBLE R FABRICATIONS SUPPLY)2) LIFT BEAM WITH LOG

TO DISENGAGE

1) LOWER BEAM TO REST ON LOG2) PULL ON NYLON ROPE VERTICALLY TO DISENGAGE

3)

LIFT BEAM WHILST HOOKS ARE DISENGAGED

CLEANING

BEAM MUST BE CLEANED AND DEGREASED.

STORAGE

BEAM TO BE STORED UPRIGHT ON A RACK TO AVOID DAMAGE TO HOOKS.BEAM IS TESTED WITH SWL 300 Kg (PROOF LOAD 600 Kg.

Subject to width of Beam, weight of Beam, weight of log the SWL will be greaterthan 300 Kg. This can be determined and re-sized on a particular application

S T O P L O G L I F T I N G BE A M S

http://www.scribd.com/doc/74240131/Lifting-Beams-Stop-Log (1 of 3)2012-05-04 $ 3:42:35

Lifting Beams Stop Log

Stoplog Lifting Beam

Stoplog Lifting Beam

See Dimensional DrawingA = WidthB = A + 104C = A

-

540D = C + 113

*

E = C + 290

*

* These

http://www.scribd.com/doc/74240131/Lifting-Beams-Stop-Log (2 of 3)2012-05-04 $ 3:42:35

Lifting Beams Stop Log

dimensions are approx.

http://www.scribd.com/doc/74240131/Lifting-Beams-Stop-Log (3 of 3)2012-05-04 $ 3:42:35

You might also like

- Lifting Beams Stop LogDocument4 pagesLifting Beams Stop LogkhalidcosmosNo ratings yet

- Deco Heavy Duty Adjustable Anchors Sales SheetsDocument2 pagesDeco Heavy Duty Adjustable Anchors Sales SheetsPete SwiftNo ratings yet

- Hollow Structural Sections Column Load TablesDocument128 pagesHollow Structural Sections Column Load TablesPedro PereiraNo ratings yet

- Kuenz TRCMDocument9 pagesKuenz TRCMklcy1987No ratings yet

- Rolltec Coupler BrochureDocument4 pagesRolltec Coupler BrochureMohammad Aasimuddin100% (1)

- 20kl 4compartment Petrol Tanker SpecDocument3 pages20kl 4compartment Petrol Tanker SpecPido VillaruelNo ratings yet

- Green Pin Standard Hydraulic ShackleDocument1 pageGreen Pin Standard Hydraulic ShackleAthox QhurienNo ratings yet

- Is 2645 2003 PDFDocument16 pagesIs 2645 2003 PDFlittle gloryNo ratings yet

- Welcome To The Institute For Timber Construction-South Africa Itc-SaDocument75 pagesWelcome To The Institute For Timber Construction-South Africa Itc-SaMclyb GumbieNo ratings yet

- Ricci ClamshellDocument12 pagesRicci ClamshellEmily MartiniNo ratings yet

- ABB CatalogueDocument6 pagesABB CatalogueNavneet SinghNo ratings yet

- Universal BeamDocument17 pagesUniversal BeamHazwan AzamanNo ratings yet

- OSHA 1926.1053 Subpart X LaddersDocument2 pagesOSHA 1926.1053 Subpart X LaddersEmmanNo ratings yet

- Russel Metals Grating PDFDocument51 pagesRussel Metals Grating PDFtylerlhsmithNo ratings yet

- 45 Degree Cone MethodDocument3 pages45 Degree Cone Methodundf25No ratings yet

- Intake BOQDocument2 pagesIntake BOQKrishna RaoNo ratings yet

- Piling Codes of Practice in Southern AfricaDocument7 pagesPiling Codes of Practice in Southern AfricaMfanelo MbanjwaNo ratings yet

- Stop LogsDocument1 pageStop LogsiculasiNo ratings yet

- BH HydrobinDocument1 pageBH HydrobinHari Devender AnchooriNo ratings yet

- Welcome To E-Z-Slab 2001Document18 pagesWelcome To E-Z-Slab 2001dakotaaaNo ratings yet

- Din 471 Ext CirclipsDocument5 pagesDin 471 Ext Circlipschaitanya_kumar_13No ratings yet

- PD Lab 8CE4-22Document32 pagesPD Lab 8CE4-22tech hubNo ratings yet

- NEC CHAPTER 3 QUIZ With AnswersDocument20 pagesNEC CHAPTER 3 QUIZ With AnswersAbdul RaheemNo ratings yet

- Calcul Des Structures Acier: Norme: Type D'AnalyseDocument2 pagesCalcul Des Structures Acier: Norme: Type D'AnalyseMouhi MouhaNo ratings yet

- Catálogo RULMECADocument308 pagesCatálogo RULMECArdgmaxiNo ratings yet

- Mitek 12kN Pile FixingDocument2 pagesMitek 12kN Pile FixingTuroyNo ratings yet

- Is 866 1957Document7 pagesIs 866 1957sarath6725No ratings yet

- 01 Plate Analysis Result Staad ProDocument1 page01 Plate Analysis Result Staad ProSunil NepalNo ratings yet

- Mould 99 Correct NoDocument2 pagesMould 99 Correct NonephembaniNo ratings yet

- Demacon West Rand Industrial Development Strategy July 20131Document63 pagesDemacon West Rand Industrial Development Strategy July 20131adiNo ratings yet

- Standard Details Public Works ConstructionDocument207 pagesStandard Details Public Works Constructionnido77No ratings yet

- Technical Specification Boomer WE3 C - 18 - 9851 2471 01c - Web - tcm820-1533277Document4 pagesTechnical Specification Boomer WE3 C - 18 - 9851 2471 01c - Web - tcm820-1533277Pedro Suárez VargasNo ratings yet

- Murray Roberts (Willy Cocquyt PR Eng 860106) Calculation Sheet Input SheetDocument23 pagesMurray Roberts (Willy Cocquyt PR Eng 860106) Calculation Sheet Input SheetMbalekelwa MpembeNo ratings yet

- Sor 2015 PWD (DWS) TripuraDocument406 pagesSor 2015 PWD (DWS) TripuraArup Debnath75% (8)

- Beam Bridge Ethereum Part Security AnalysisDocument9 pagesBeam Bridge Ethereum Part Security AnalysisBeamPrivacyNo ratings yet

- Sizes of Different Motor FramesDocument2 pagesSizes of Different Motor FramesVijay Raghavan0% (1)

- Live Load Distribution Factor CalculationsDocument5 pagesLive Load Distribution Factor CalculationsBunkun15No ratings yet

- Catalouge For Lenton CouplersDocument18 pagesCatalouge For Lenton Couplerss.skumar1No ratings yet

- Trashrack DesignDocument4 pagesTrashrack DesignpicottNo ratings yet

- Example: Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingDocument10 pagesExample: Calculation of Effective Section Properties For A Cold-Formed Lipped Channel Section in BendingVarga ZoranNo ratings yet

- Sor (SH&MDR) 2018 19Document959 pagesSor (SH&MDR) 2018 19Monjit GogoiNo ratings yet

- CC102 Construction Materials and Application (Dry N Wet Risers)Document30 pagesCC102 Construction Materials and Application (Dry N Wet Risers)Adron LimNo ratings yet

- Simply SupportedDocument9 pagesSimply Supportedpackya7191No ratings yet

- 2013 Wright Specifications CatalogDocument189 pages2013 Wright Specifications CatalogcenicercNo ratings yet

- Anclajes Red HeadDocument8 pagesAnclajes Red HeadLeonardo AvilaNo ratings yet

- Land Code (Amendment) Ordinance, 2018 and Land (Native Communal Title) Rules, 2019Document24 pagesLand Code (Amendment) Ordinance, 2018 and Land (Native Communal Title) Rules, 2019Polycarp Danson SigaiNo ratings yet

- KKKH3353 - Structural Steel Design - Design of Restrained BeamsDocument47 pagesKKKH3353 - Structural Steel Design - Design of Restrained BeamsZeyad Tareq Al SaroriNo ratings yet

- Step by Step Procedure For Concrete RepairDocument4 pagesStep by Step Procedure For Concrete RepairMdShahbazAhmedNo ratings yet

- Analysis of A Three Flight Free Standing Staircase 2Document9 pagesAnalysis of A Three Flight Free Standing Staircase 2walaywanNo ratings yet

- Maintenance and Inspection of BTH LiftersDocument8 pagesMaintenance and Inspection of BTH Liftersrpatel12No ratings yet

- Foundations BookletDocument5 pagesFoundations BookletForbes KambaNo ratings yet

- Estimate ManualDocument47 pagesEstimate ManualGerald YasonNo ratings yet

- Method Statement - 20 BridgesDocument109 pagesMethod Statement - 20 BridgesRohit Bali100% (5)

- Exterior Trim: Section: 9MDocument5 pagesExterior Trim: Section: 9MBlakess SpanNo ratings yet

- Sony HCD-ED1 Service ManualDocument46 pagesSony HCD-ED1 Service ManualnunoqueirozNo ratings yet

- Solder Wick (Desoldering Braid)Document3 pagesSolder Wick (Desoldering Braid)Ferdinand EstanislaoNo ratings yet

- Fluiteco CatalogoDocument84 pagesFluiteco CatalogoPablo FaldutiNo ratings yet

- Compressor Wash Skid Manual (Pages 1-14)Document14 pagesCompressor Wash Skid Manual (Pages 1-14)Anibal QuezadaNo ratings yet

- Method Statement 20 Bridges PDF FreeDocument109 pagesMethod Statement 20 Bridges PDF FreeThabiso MotalingoaneNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet