Professional Documents

Culture Documents

FM 200

Uploaded by

Mani KumarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FM 200

Uploaded by

Mani KumarCopyright:

Available Formats

FM-200

Features

TM

Engineered System Nozzles

, , 1, 1, 1, 2 Inch Sizes 180 and 360 Discharge Options Large Area Coverage Capability Aluminum Construction Listed, FM Approved, ULC Listed NYMEA approved, CSFM approved

180 Nozzle Description

The FM-200TM engineered system nozzles are designed to provide rapid and thorough mixing of FM-200TM with the air in the protected space and to provide coverage for a large area. Standard nozzles are made of aluminum. Engineered system nozzles are made in five pipe sizes: ", ", 1", 1", 1" and 2". All sizes have both 180 and 360 discharge patterns available. All nozzles, both 180 and 360, have eight hole patterns. For hung ceiling application, the 360 nozzle is recommended and should be mounted the maximum distance below the ceiling to minimize the effect on the ceiling tiles. It is also recommended that the tiles be secured in place by the liberal use of special clips which are made for this purpose.

360 Nozzle

Ordering Information

Engineer and Architect Specifications

The nozzles shall be of 180 or 360 discharge pattern type and made of aluminum. They shall be marked with the Siemens Building Technologies, Inc. Fire Safety Division part number. The nozzles shall have a standard female pipe thread for attachment to the discharge piping. Nozzles shall be spaced in accordance with the instructions in the engineered system design manual and as required by the UL listing or FM approval.

CATALOG NUMBER

6021

Hazard Area and Nozzle Placement Design Criteria

Nozzles - are available in both 180 and 360 discharge patterns. The 180 sidewall nozzle is designed for installation along the end of zones of the hazard, with discharge directed away from the end of zone on which it is installed. The 360 nozzle is designed to be installed in the center of the area being protected. All nozzles must be installed in a vertical (pendant) position with the nozzle facing either down or up. Nozzles must be installed with orifices 6" 2" (15cm 5cm) below ceiling. 180 nozzles must be located 12" 2" (30 cm 5cm) away from side wall. Ceiling Height - The maximum ceiling height when using FM-200TM nozzles (both 180 and 360) is 16 feet (36.6 meters). Area Coverage - Both 180 and 360 nozzles were tested for maximum area coverage using a 40 ft. wide by 40 ft. long (12.2m x 12.2m) enclosure. Based on these parameters, the maximum area coverage for each nozzle is described as a straight line distance from the nozzle to the farthest corner of the protected space. The max area coverage per nozzle is 40x40 = 1600ft2.

D D = 44.7' D = 14.6m

D D = 28.28' D = 9.27m 40'

40'

40' 180 Nozzle

40' 360 Nozzle

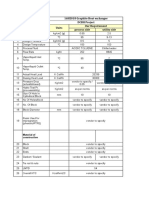

FM-200 Engineered Nozzle Numbering System

Nozzle Part Number

Example: CPYEN-3-.2610 3/4 Pipe threads: 180 degree type nozzle drilled to 0.2610 size orifice

Nozzle Flow Path

180 Degree Side Wall

360 Degree Cental

180 Degree Side Wall

360 Degree Cental

Ordering Information

Part numbers will be generated by the FM-200 Fire Suppression System Design Software Tool. An example is below.

Typical output from FM200 Flow Program.

Siemens Building Technologies Fire Safety

Fire Safety 8 Fernwood Road Florham Park, NJ 07932 Tel: (973) 593-2600 FAX: (973) 593-6670 Website: www.sbt.siemens.com/fis

4/03 5M SFS-IG Printed in U.S.A.

Fire Safety 2 Kenview Boulevard Brampton, Ontario Canada L6T 5E4 Tel: (905) 799-9937 FAX: (905) 799-9858

April 2003

Supersedes sheet dated 1/03

You might also like

- 93 Deg Chrome Finish,: 1/2" NPT Quick ResponseDocument20 pages93 Deg Chrome Finish,: 1/2" NPT Quick ResponserajaNo ratings yet

- Aurora Pump 6-491-12aDocument28 pagesAurora Pump 6-491-12ajuan yenqueNo ratings yet

- Technical Data: Model VFC Foam ChambersDocument8 pagesTechnical Data: Model VFC Foam Chambersrusli bahtiarNo ratings yet

- N2 (Ig-100) Gas Fire Suppression Systems: NFPA 2001: Standard On Clean Agent Fire Extinguishing SystemDocument8 pagesN2 (Ig-100) Gas Fire Suppression Systems: NFPA 2001: Standard On Clean Agent Fire Extinguishing SystemNattapong NatNo ratings yet

- Calculation of Invert LevelsDocument15 pagesCalculation of Invert LevelsUsama ChatthaNo ratings yet

- Flow-Switch-RapidropDocument4 pagesFlow-Switch-RapidropNOMANNo ratings yet

- Safety Engineering: 1-1/2" BS 336 MaleDocument12 pagesSafety Engineering: 1-1/2" BS 336 Malewalid kawsarNo ratings yet

- 481 & 483 Flow CurvesDocument64 pages481 & 483 Flow CurvesHermantoro W. Pradana100% (1)

- MainDrain SP1062 SP103x SP1030AV PDFDocument1 pageMainDrain SP1062 SP103x SP1030AV PDFAndrea Devky Kresna100% (1)

- Tips of Fountain Design Part 2 - 3 - Blog of Fountain Design and Water ShowsDocument2 pagesTips of Fountain Design Part 2 - 3 - Blog of Fountain Design and Water ShowsAnh Đức NguyễnNo ratings yet

- 750GPM@15 Bar-Vt-Soft Start PDFDocument113 pages750GPM@15 Bar-Vt-Soft Start PDFSajjadNo ratings yet

- Nfpa EseDocument3 pagesNfpa EseAlejandro ArroyaveNo ratings yet

- FESCO Fire PumpsDocument24 pagesFESCO Fire PumpsZeeshan HameedNo ratings yet

- Bases Detector NOTIFIER B501Document2 pagesBases Detector NOTIFIER B501Tai KucingNo ratings yet

- Fire FightDocument4 pagesFire Fightkiran raghukiranNo ratings yet

- Photoelectric Smoke Detectors Mir-338 Series: FeaturesDocument2 pagesPhotoelectric Smoke Detectors Mir-338 Series: FeaturesCesar MuñozNo ratings yet

- Kidde ECS and ECS-500 Part Number List For Nozzle Used With Novec 1230 K-45-2165 AADocument14 pagesKidde ECS and ECS-500 Part Number List For Nozzle Used With Novec 1230 K-45-2165 AAelias rangelNo ratings yet

- E - FM-200 Flow CalcDocument33 pagesE - FM-200 Flow CalcfereszaNo ratings yet

- Coal Conveyor Protection-Ih153es Ir Ember DetectorDocument72 pagesCoal Conveyor Protection-Ih153es Ir Ember DetectorShanmuganathan ShanNo ratings yet

- Landing-Valve - NaffcoDocument2 pagesLanding-Valve - NaffcoNOMAN100% (2)

- IG-100 CalculationDocument6 pagesIG-100 CalculationNA PauleNo ratings yet

- Fivalco CatalogDocument34 pagesFivalco CatalogsimonsecurityNo ratings yet

- Water Treatment CatalogueDocument12 pagesWater Treatment CatalogueJim TsikasNo ratings yet

- Lock Shield Valve: FeaturesDocument1 pageLock Shield Valve: FeaturesAymen AyedNo ratings yet

- Selection, Installation and Maintenance of Automatic Fire Detection and Alarm System - Code of PracticeDocument21 pagesSelection, Installation and Maintenance of Automatic Fire Detection and Alarm System - Code of Practiceabhirami91No ratings yet

- Fire DRY HydrantsDocument4 pagesFire DRY HydrantsAbdullah RamadanNo ratings yet

- Pressure Regulators For 200/300 Bar Inert Gas SystemsDocument4 pagesPressure Regulators For 200/300 Bar Inert Gas SystemsDiego Martinez ConteiroNo ratings yet

- Mechanical Drawings: S O L Properties DevelopmentDocument17 pagesMechanical Drawings: S O L Properties DevelopmentArun UdayabhanuNo ratings yet

- Justification of Rates S. No. Description Qty. Unit Unit Rate (RS.) in FigureDocument6 pagesJustification of Rates S. No. Description Qty. Unit Unit Rate (RS.) in Figurekiran raghukiranNo ratings yet

- Piping Isometrics CPF Area Cpf2 Process Area - Drawing IndexDocument12 pagesPiping Isometrics CPF Area Cpf2 Process Area - Drawing IndexWnava CrisNo ratings yet

- 1729Document52 pages1729praj24083302No ratings yet

- Cla-Val: Fire Protection Pressure Relief ValveDocument2 pagesCla-Val: Fire Protection Pressure Relief ValveShoaib AhmedNo ratings yet

- Key Maintenance SwitchDocument4 pagesKey Maintenance SwitchkuraimundNo ratings yet

- Fan Coil Units (DX-COIL With Heat Pump) : High WallDocument9 pagesFan Coil Units (DX-COIL With Heat Pump) : High WallSTANDARD EDUCATION ACADEMY M.E.P CENTERNo ratings yet

- Tyco Water Curtain NozzleDocument2 pagesTyco Water Curtain NozzlejonejackrousseauNo ratings yet

- Cable TakeoffDocument14 pagesCable TakeoffRudivic LumainNo ratings yet

- Extcat FM200!Document15 pagesExtcat FM200!asifaliabid100% (1)

- Fire Extinguisher Design Procedure General Design Criteria Floor Basis Travel BasisDocument3 pagesFire Extinguisher Design Procedure General Design Criteria Floor Basis Travel Basistribhuvan ShankarNo ratings yet

- DESCRIPTIONS Garbage ChuteDocument12 pagesDESCRIPTIONS Garbage ChuteYasser Fathy AlyNo ratings yet

- LPCB Approved: Dry Pillar Fire HydrantsDocument6 pagesLPCB Approved: Dry Pillar Fire HydrantsZahir KhiraNo ratings yet

- Sprinkler System ComponentsDocument68 pagesSprinkler System Componentsjosediaz141No ratings yet

- KFS ECS FM-200 Software ManualDocument62 pagesKFS ECS FM-200 Software Manualgalandar1356No ratings yet

- Fire Alarm Telephones - PDF - Edwards UTCFS PDFDocument4 pagesFire Alarm Telephones - PDF - Edwards UTCFS PDFjhon bayonaNo ratings yet

- Novec Hazard Room CalcDocument8 pagesNovec Hazard Room Calckarim3samirNo ratings yet

- GW SprinklersDocument18 pagesGW SprinklersmajdirossrossNo ratings yet

- 200/300 BAR INERT GAS Fire Suppression Systems: JUNE 2017Document7 pages200/300 BAR INERT GAS Fire Suppression Systems: JUNE 2017Amir Hossein SaberNo ratings yet

- Direct Steam Injection HumidifierDocument41 pagesDirect Steam Injection Humidifierسامح الجاسم100% (1)

- 200622-Fcu & Refrigerant Pipe & Insulation SizeDocument1 page200622-Fcu & Refrigerant Pipe & Insulation Sizegukan rajNo ratings yet

- Rxco2 DatasheetDocument15 pagesRxco2 DatasheetBadr groupNo ratings yet

- Fire Fighting Pumps: FeaturesDocument3 pagesFire Fighting Pumps: FeaturesReyza Prasetyo100% (1)

- BOQ Format - Fire Pro PDFDocument6 pagesBOQ Format - Fire Pro PDFKurama BasketNo ratings yet

- مواصفات التكييفDocument54 pagesمواصفات التكييفoth369No ratings yet

- Airport PlumbingDocument11 pagesAirport Plumbingquanghai1301No ratings yet

- Outside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesDocument42 pagesOutside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesayaNo ratings yet

- QCDD BP GuidelinesDocument6 pagesQCDD BP Guidelines남광연0% (1)

- Kelani Cable - ArmouredDocument1 pageKelani Cable - Armouredsukiraj Rasalingam50% (2)

- Hydrant Stand Post (Double) : Technical Data SheetDocument2 pagesHydrant Stand Post (Double) : Technical Data SheetshabahatNo ratings yet

- FM-200 Engineered Nozzles IV.1.03.01Document2 pagesFM-200 Engineered Nozzles IV.1.03.01Sergio Diaz PereiraNo ratings yet

- FM-200 Engineered Nozzles IV.1.03.01Document2 pagesFM-200 Engineered Nozzles IV.1.03.01hdrNo ratings yet

- BOQUILLASDocument2 pagesBOQUILLASEDUARDONo ratings yet

- GT-I8000 UM SEA Eng Rev.1.1 091112Document166 pagesGT-I8000 UM SEA Eng Rev.1.1 091112Mani KumarNo ratings yet

- Rare Yoga Part 3Document13 pagesRare Yoga Part 3VikasNo ratings yet

- Protection For High Voltage TransfromersDocument4 pagesProtection For High Voltage TransfromersMani KumarNo ratings yet

- Protection of Flammabel Liquid Storage RoomsDocument4 pagesProtection of Flammabel Liquid Storage RoomsMani KumarNo ratings yet

- Pipenet InstallationDocument11 pagesPipenet InstallationMani Kumar0% (1)

- FM 200Document4 pagesFM 200Mani KumarNo ratings yet

- Hindu TraditionsDocument119 pagesHindu TraditionsMohana Sundaram Ma Ni100% (8)

- Hindu Temples SculpturesDocument237 pagesHindu Temples SculpturesjayanthinthanNo ratings yet

- Engine Exhaust Flow Rate CalculationDocument8 pagesEngine Exhaust Flow Rate CalculationMani Kumar50% (2)

- Definition ErminologyDocument2 pagesDefinition ErminologyMani KumarNo ratings yet

- Antenna QuestionDocument1 pageAntenna QuestionMani KumarNo ratings yet

- Fire PumpDocument8 pagesFire PumpMani KumarNo ratings yet

- Introduction To Fire Pump Operations - Chapter 7Document44 pagesIntroduction To Fire Pump Operations - Chapter 7HenryG.MontenegroHo-SangNo ratings yet

- Hayagriva SahasranaamamDocument71 pagesHayagriva Sahasranaamamajiva_rts33% (3)

- Engine Exhaust Flow Rate CalculationDocument8 pagesEngine Exhaust Flow Rate CalculationMani Kumar50% (2)

- Nema Design Code For MotorsDocument8 pagesNema Design Code For MotorsMani KumarNo ratings yet

- API 650 Tank Nozzle Stand OutDocument8 pagesAPI 650 Tank Nozzle Stand OutmadodandembeNo ratings yet

- SPB Pocket Plus User ManualDocument22 pagesSPB Pocket Plus User ManualMani KumarNo ratings yet

- Cavitation in ValvesDocument6 pagesCavitation in ValvesMani KumarNo ratings yet

- Automatic Air Release ValveDocument2 pagesAutomatic Air Release ValveMani KumarNo ratings yet

- TM 9-792 M21 AMMUNITION TRAILERDocument128 pagesTM 9-792 M21 AMMUNITION TRAILERAdvocate100% (1)

- Netbackup UsefulDocument56 pagesNetbackup Usefuldnyan123No ratings yet

- Growth of Escherichia Coli in A 5 Litre Batch Fermentation VesselDocument15 pagesGrowth of Escherichia Coli in A 5 Litre Batch Fermentation VesselAs'ad Mughal100% (2)

- 29 Oct. To 4 Nov. 211Document16 pages29 Oct. To 4 Nov. 211pratidinNo ratings yet

- Manual ArchicadDocument67 pagesManual ArchicadkhajaimadNo ratings yet

- Notes On Foam From SFPE HandbookDocument10 pagesNotes On Foam From SFPE HandbookkdsessionsNo ratings yet

- Pawan Kumar Dubey: ProfileDocument4 pagesPawan Kumar Dubey: Profilepawandubey9No ratings yet

- VMware VSphere Troubleshooting 5.5Document224 pagesVMware VSphere Troubleshooting 5.5Eugen-Florian NegruNo ratings yet

- Technology Architecture For NginX, postgreSQL, postgRESTDocument5 pagesTechnology Architecture For NginX, postgreSQL, postgRESTkarelvdwalt9366No ratings yet

- Linked List: Singly, Doubly and CircularDocument53 pagesLinked List: Singly, Doubly and CircularMia SamNo ratings yet

- B. Tech. Electrical and Electronics EngineeringDocument105 pagesB. Tech. Electrical and Electronics EngineeringKarthik NagarajanNo ratings yet

- LTS 3000 SpecificationDocument4 pagesLTS 3000 SpecificationMuhammad Nabil RoslanNo ratings yet

- BHTM445 Syllabus MW - Spring 2015-2016Document6 pagesBHTM445 Syllabus MW - Spring 2015-2016dangerousbabyNo ratings yet

- EL CID Stator Core TestDocument2 pagesEL CID Stator Core TestAnonymous CO7aaHrNo ratings yet

- Demographic Questions: Imagineh2O'S Water Energy Nexus Prize Competition Younoodle Registration QuestionsDocument3 pagesDemographic Questions: Imagineh2O'S Water Energy Nexus Prize Competition Younoodle Registration QuestionstmangatNo ratings yet

- After12th FinalDocument114 pagesAfter12th FinaltransendenceNo ratings yet

- Et154 PDFDocument6 pagesEt154 PDFbytecNo ratings yet

- Chapter 1 AnswersDocument3 pagesChapter 1 Answersdeerhntr22No ratings yet

- HartfordDocument7 pagesHartfordapi-443631703No ratings yet

- PowerMaxExpress V17 Eng User Guide D-303974 PDFDocument38 pagesPowerMaxExpress V17 Eng User Guide D-303974 PDFSretenNo ratings yet

- Altair EngineeringDocument11 pagesAltair EngineeringKarthikNo ratings yet

- Sairam OopsDocument103 pagesSairam OopsRakshit AshNo ratings yet

- Cansat2017 5235 CDR v02Document185 pagesCansat2017 5235 CDR v02tom2susanNo ratings yet

- About Indian Institute of Technology KanpurDocument54 pagesAbout Indian Institute of Technology KanpurPooja PundeerNo ratings yet

- Pressure Sensors - Nautilus: For Control Circuits, Type XML-F PresentationDocument11 pagesPressure Sensors - Nautilus: For Control Circuits, Type XML-F PresentationxzxNo ratings yet

- 16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideDocument2 pages16HE018 Graphite Heat Exchanger DCBH Project Sr. No. Particulars Units Our Requirement Process Side Utility SideBhaumik BhuvaNo ratings yet

- Company in India" DTDC Constantly Endeavours To Meet & Exceed Customers'Document7 pagesCompany in India" DTDC Constantly Endeavours To Meet & Exceed Customers'Vinod KumarNo ratings yet

- Truck Parking Areas 2009Document147 pagesTruck Parking Areas 2009IRUNo ratings yet

- Oscilloscope Lab Manual11Document16 pagesOscilloscope Lab Manual11DM RafiunNo ratings yet

- AcaDocument3 pagesAcasweetunannuNo ratings yet