Professional Documents

Culture Documents

Waffle Slabs: Designed As Two-Way Slabs (Standard Moulds)

Waffle Slabs: Designed As Two-Way Slabs (Standard Moulds)

Uploaded by

Thành KCOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Waffle Slabs: Designed As Two-Way Slabs (Standard Moulds)

Waffle Slabs: Designed As Two-Way Slabs (Standard Moulds)

Uploaded by

Thành KCCopyright:

Available Formats

Waffle slabs

designed as two-way slabs (standard moulds)

Introducing voids to the soffit reduces dead weight and

these deeper, stiffer floors permit longer spans which are

economic for spans between 9 and 14 m. The saving of

materials tends to be offset by complication in site

operations.

span

Standard moulds are 225, 325 and 425 mm deep and are

used to make ribs 125 mm wide on a 900 mm grid.

Toppings are between 50 and 150 mm thick.

The chart and data assume surrounding and supporting

downstand beams, which should be subject to separate

consideration, and solid margins. Both waffles and

downstand beams complicate formwork.

ADVANTAGES

DISADVANTAGES

Medium to long spans

Lightweight

Profiles may be expressed architecturally, or used for

heat transfer

Higher formwork costs than for other slab systems

Slightly deeper members result in greater floor

heights

Slow. Difficult to prefabricate reinforcement

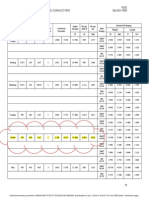

SPAN:DEPTH CHART

600

500

Multiple span

SLAB DEPTH, mm

400

300

200

7.2

8.1

9.0

9.9

10.8

11.7

12.6

13.5

KEY Characteristic imposed load (IL)

= 2.5 kN/m2

28

= 5.0 kN/m2

= 7.5 kN/m2

=10.0 kN/m2

14.4

SPAN, m

I N - S I T U

S L A B S

DESIGN ASSUMPTIONS

SUPPORTED BY

BEAMS in two orthogonal directions. Refer to beam charts and data to estimate sizes, etc.

DIMENSIONS

Square panels, minimum of two spans x two bays. Ribs 125 mm wide @ 900 mm cc.

Moulds 225, 325 or 425 mm deep. Topping 100 to 150 mm. Rib/solid intersection at 900 + 125/2 from

centreline of support.

REINFORCEMENT

Maximum bar sizes in ribs: 2T25B, 2T20T (in top of web) and R8 links. 25 mm allowed for A142 or A193 mesh

(@ 0.12%) in topping. 10% allowed for wastage and laps. fs may have been reduced.

LOADS

SDL of 1.50 kN/m2 (finishes etc) included. Ultimate loads to internal beams assume two adjacent corner

panels. Loads are applicable as a udl over 75% of the beams length. Self weight used accounts for 5:1 slope

to ribs, solid edges as described above and topping as inferred.

CONCRETE

C35, 24 kN/m3, 20 mm aggregate.

FIRE & DURABILITY

Fire resistance 1 hour; mild exposure.

DESIGN

Design based on corner panels. Single span (both ways) assumes torsional restraint.

SINGLE SPAN, m

7.2

8.1

9.0

9.9

10.8

11.7

12.6

THICKNESS, mm

IL = 2.5 kN/m2

IL = 5.0 kN/m2

IL = 7.5 kN/m2

IL = 10.0 kN/m2

325

325

325

325

325

325

350

375

350

365

425

425

375

425

440

470

435

470

525

540

525

535

565

kN/m

n/a (45)

n/a (58)

n/a (72)

n/a (89)

n/a (49)

n/a (68)

n/a (83)

n/a (99)

n/a (59)

n/a (76)

n/a (69)

ULTIMATE LOAD TO SUPPORTING BEAMS, INTERNAL (END),

IL = 2.5 kN/m2

n/a (29)

n/a (32)

n/a (38)

n/a (38)

n/a (43)

n/a (52)

IL = 5.0 kN/m2

IL = 7.5 kN/m2

n/a (48)

n/a (56)

n/a (64)

n/a (57)

n/a (69)

n/a (76)

IL = 10.0 kN/m2

REINFORCEMENT, kg/m2 (kg/m3)

8 (24)

IL = 2.5 kN/m2

11 (33)

IL = 5.0 kN/m2

IL = 7.5 kN/m2

15 (45)

19 (57)

IL = 10.0 kN/m2

12 (35)

18 (56)

19 (55)

20 (53)

15 (44)

20 (53)

16 (37)

20 (46)

19 (51)

17 (40)

21 (48)

22 (47)

18 (42)

21 (45)

20 (37)

23 (42)

16 (31)

22 (40)

21 (38)

13.5

14.4

MULTIPLE/TWO SPAN, m

7.2

8.1

9.0

9.9

10.8

11.7

12.6

13.5

14.4

THICKNESS, mm

IL = 2.5 kN/m2

IL = 5.0 kN/m2

IL = 7.5 kN/m2

IL = 10.0 kN/m2

325

325

325

325

325

325

325

325

325

325

325

325

325

325

335

350

350

350

375

425

425

425

425

450

450

450

475

525

525

525

535

575

565

565

kN/m

91 (32)

122 (43)

154 (54)

189 (66)

106 (37)

139 (49)

180 (63)

212 (74)

122 (43)

158 (55)

193 (68)

237 (83)

139 (49)

177 (62)

226 (79)

264 (93)

158 (56)

200 (70)

244 (86)

300 (105)

184 (65)

228 (80)

10 (32)

15 (46)

19 (58)

21 (59)

13 (37)

19 (55)

21 (55)

18 (43)

12 (27)

16 (37)

20 (48)

22 (50)

15 (32)

20 (44)

22 (47)

21 (41)

14 (27)

19 (36)

23 (43)

24 (42)

17 (30)

22 (39)

ULTIMATE LOAD TO SUPPORTING BEAMS, INTERNAL (END),

IL = 2.5 kN/m2

66 (23)

75 (26)

83 (29)

89 (31)

100 (35)

111 (39)

IL = 5.0 kN/m2

IL = 7.5 kN/m2

111 (39)

124 (44)

138 (49)

133 (47)

149 (52)

166 (58)

IL = 10.0 kN/m2

REINFORCEMENT, kg/m2 (kg/m3)

IL = 2.5 kN/m2

5 (16)

7 (21)

IL = 5.0 kN/m2

IL = 7.5 kN/m2

8 (26)

10 (31)

IL = 10.0 kN/m2

DESIGN NOTES

IL = 2.5 kN/m2

IL = 5.0 kN/m2

IL = 7.5 kN/m2

IL = 10.0 kN/m2

7 (20)

9 (26)

11 (33)

13 (40)

8 (25)

11 (34)

14 (44)

18 (55)

a = qk > 1.25 gk

ab

abe

abe

abe

e

abe

abe

b = qk > 5 kN/m2

e

e

e

abe

be

abe

abe

e = designed links may be required in ribs

e

e

e

e

e

e

e

e

be

be

be

abe

be

be

VARIATIONS TO DESIGN ASSUMPTIONS: differences in slab thickness for a characteristic imposed load (IL) of 5.0 kN/m2

Thickness, mm

Span, m

7.2

8.1

9.0

9.9

10.8

11.7

12.6

2 hrs fire, 115 topping

340

340

340

340

440

440

540

4 hrs 150 rib & topping

375

375

475

475

475

575

575

Moderate exposure

325

325

339

425

435

525

Severe exposure (C40)

325

325

345

425

440

535

Rectangular panels: economic thickness, mm

Long span, m

12.6

13.5

14.4

15.3

16.2

17.1

18.0

Short span = 9.0 m

325

325

325

325

325

325

325

Short span = 9.9 m

325

325

335

345

350

355

360

Short span = 10.8 m

355

365

375

425

425

425

425

Short span = 11.7 m

425

425

425

425

435

450

460

Short span = 12.6 m

450

450

455

475

525

525

525

Short span = 13.5 m

525

525

525

535

550

575

29

You might also like

- Troughed Slabs: (Ribbed Slabs With Integral Beams and Level Soffits, Troughed Flat Slabs, One-Way Joist Floors)Document2 pagesTroughed Slabs: (Ribbed Slabs With Integral Beams and Level Soffits, Troughed Flat Slabs, One-Way Joist Floors)renishkavukattNo ratings yet

- Composite Slab DesignDocument13 pagesComposite Slab Design_jesseca100% (2)

- Wall Calculation Example EC2Document15 pagesWall Calculation Example EC2Kristjan Igasta88% (8)

- Reinforced Concrete Buildings: Behavior and DesignFrom EverandReinforced Concrete Buildings: Behavior and DesignRating: 5 out of 5 stars5/5 (1)

- Ribbed SlabDocument2 pagesRibbed SlabsuhaimitmieNo ratings yet

- STEPOC 150dpiDocument6 pagesSTEPOC 150dpinick8081No ratings yet

- ECS478 CHAPTER 3-Flat SlabDocument40 pagesECS478 CHAPTER 3-Flat SlabAmron Abubakar0% (1)

- INSDAGDocument37 pagesINSDAGapi-3774289100% (2)

- Multideck 60-V2: - Concrete Volume SavingsDocument18 pagesMultideck 60-V2: - Concrete Volume Savingsdexterbox1No ratings yet

- ALC The Intelligent Building SystemDocument7 pagesALC The Intelligent Building SystemkucingmioewNo ratings yet

- Solar PV Panels The Best Option: Reliability ServiceDocument2 pagesSolar PV Panels The Best Option: Reliability ServicejprakashusNo ratings yet

- Unishield - Uniblend 5kvDocument2 pagesUnishield - Uniblend 5kvfmillan5018No ratings yet

- Hollow Core DesignDocument15 pagesHollow Core DesignMelinda Gordon100% (1)

- AQUAPANEL Cement Board Outdoor Datasheet 0817Document3 pagesAQUAPANEL Cement Board Outdoor Datasheet 0817xander1982No ratings yet

- Rawl R Kex 400 SpecDocument1 pageRawl R Kex 400 Speccromwell2000No ratings yet

- Long Span and Portal FramesDocument46 pagesLong Span and Portal FramesAdil ImtiazNo ratings yet

- SASD Prac Probs 1 TensionDocument3 pagesSASD Prac Probs 1 TensionJia SingNo ratings yet

- Cavity ShaftwallDocument14 pagesCavity Shaftwallatac101No ratings yet

- 210 Assignment 4: 19113089 Nikhil KumarDocument13 pages210 Assignment 4: 19113089 Nikhil KumarNIKHIL KUMARNo ratings yet

- Lecture 5 FoundationsDocument30 pagesLecture 5 FoundationsCarel De JagerNo ratings yet

- Pad Foundation Design Example Eurocode 2Document30 pagesPad Foundation Design Example Eurocode 2mahalakshmiNo ratings yet

- MVLV Wire and CableDocument66 pagesMVLV Wire and CableMahmoud FawzyNo ratings yet

- Walkway Grating PDFDocument7 pagesWalkway Grating PDFGirinathNo ratings yet

- FarinDocument39 pagesFarinSuraj ApexNo ratings yet

- 3D-Dynamic Design For Reinforced Versus Prestress Concrete For Al-Huriya BuildingDocument36 pages3D-Dynamic Design For Reinforced Versus Prestress Concrete For Al-Huriya BuildingCahyadi SetiawanNo ratings yet

- 8WL3078_PI_76Document4 pages8WL3078_PI_76Soheil MoradiNo ratings yet

- Data Sheet C70 E 072011 02Document3 pagesData Sheet C70 E 072011 02Stefano BarbieriNo ratings yet

- NSB Ups BatteryDocument4 pagesNSB Ups BatteryLast Juan StandingNo ratings yet

- TERA Joint-Floor Joint System PDFDocument16 pagesTERA Joint-Floor Joint System PDFClaudioNo ratings yet

- En 1996-1-1 Reinforced Masonry Design Example 1: (Note: This Uses The Uk National Annex NDP Values)Document6 pagesEn 1996-1-1 Reinforced Masonry Design Example 1: (Note: This Uses The Uk National Annex NDP Values)Eduardo Martinez CaleroNo ratings yet

- R1 Solution 2013 PDFDocument7 pagesR1 Solution 2013 PDFkhayagskiNo ratings yet

- EG7005 STEEL DESIGN-BATCH 21-22: Lijose Jacob 2235791Document83 pagesEG7005 STEEL DESIGN-BATCH 21-22: Lijose Jacob 2235791lijosejacobNo ratings yet

- Steel Beam DesignDocument26 pagesSteel Beam DesignWazini D. Izani100% (1)

- Grid Coupling PDFDocument6 pagesGrid Coupling PDFsgupta_615796100% (1)

- Living Quarter LayoutDocument69 pagesLiving Quarter LayoutPhornlert WanaNo ratings yet

- Rafter Foundation CalculationsDocument8 pagesRafter Foundation CalculationstsapoutshisNo ratings yet

- Chapter 2: Analysis and Design of RC Slabs Per EbcsDocument45 pagesChapter 2: Analysis and Design of RC Slabs Per EbcsCaalaa Bashaa100% (5)

- Lecture 5 FoundationsDocument44 pagesLecture 5 Foundationsbeddows_sNo ratings yet

- IIT Indore CE 408: Foundation EngineeringDocument33 pagesIIT Indore CE 408: Foundation EngineeringChaitali PatilNo ratings yet

- Drake Conductor Refrence IEEE-524Document1 pageDrake Conductor Refrence IEEE-524SINU0607IITEEENo ratings yet

- The Advantages Includes The Following:: SimplicityDocument26 pagesThe Advantages Includes The Following:: SimplicityEbrahim ElnadyNo ratings yet

- High Quality CRA Solutions by Electroslag Process For Austenitic StainleDocument14 pagesHigh Quality CRA Solutions by Electroslag Process For Austenitic StainleMubeenNo ratings yet

- Design of A Modern High Rise Building in Abu-Dhabi (United Arab Emirates University) Graduation Project II Fall 2010Document50 pagesDesign of A Modern High Rise Building in Abu-Dhabi (United Arab Emirates University) Graduation Project II Fall 2010April Ingram100% (1)

- Analysis and Design of Flat Slab and Grid Slab and Their Cost ComparisonDocument5 pagesAnalysis and Design of Flat Slab and Grid Slab and Their Cost ComparisonjonnypremNo ratings yet

- Durai PPT Mini 2Document42 pagesDurai PPT Mini 2rexdindigulNo ratings yet

- NKT 12-42kv GB BsDocument54 pagesNKT 12-42kv GB BsvhgiaoNo ratings yet

- TDG 19 CLT DiaphragmsDocument6 pagesTDG 19 CLT DiaphragmsCarsonBakerNo ratings yet

- Roof and Wall LeafletDocument6 pagesRoof and Wall LeafletcosineNo ratings yet

- LG Bus Duct System: Leader in Electrics & AutomationDocument51 pagesLG Bus Duct System: Leader in Electrics & AutomationRajneesh KatochNo ratings yet

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsFrom EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNo ratings yet