Professional Documents

Culture Documents

Roof and Wall Leaflet

Uploaded by

cosineCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Roof and Wall Leaflet

Uploaded by

cosineCopyright:

Available Formats

Wall Profile N&K 10

Fixing

Roof & Wall

Claddings

For typical installations the following methods

would be adopted:

Type: & 10/1092

Overall width 1160mm

Roof

0

Pitches under 10 - end lap of min. 230mm.

0

Pitches over 10 - end lap of min. 150mm.

Cover width 1092mm

End laps should occur over purlins.

The bottom of the sheet should project

a minimum 60mm over the purlin.

A minimum of 3 fixings per sheet per purlin

should be used, except at the ends of sheets

where there could be a fixing every valley.

0mm

- 23

150

Roof and Wall Claddings were develop to provide

an attractive appearance, good stsructural

performance and ease of installation.

The main features can be summarised as follows:

1. Available in any trasportable length.

2. Suitable for double skin site construction.

3. Profiles can be arrange vertically

or horizontally.

4. Manufactured from prepainted

galvanised steel - available

in a variety of colours

and finishes.

Self drilling and tapping

screw q 6.3mm 25mm long

Side lap fixing should begin approximately

150mm from the end of the sheet

and be spaced at intervals of about 450mm.

10

156 pitch

20

136

30

126

Type: & 10/936

Wall

End laps should be at least 100mm.

Side lap fixings should begin approximately

150mm from the end of the sheet

and be spaced at intervals of about 500mm.

Fixing to steel Supports

0mm

- 23

150

Overall width 1005mm

Cover width 936mm

Self drilling and tapping

screw q 6.3mm 40mm long

Self drilling and tapping

screw q 5.3mm 20mm long

Side lap

Fixing to timber Supports

10

Fixing position for N&K 33

156 pitch

20

136

30

126

Note: According to Code of Practice for the use of profiled sheet for Roof and Wall Cladding on buildings, Part 1. (revision of BS 5427)

GERI INDUSTRIAL ESTATE

P.O.BOX 12665 - 2251 NICOSIA - CYPRUS

T: +357 22 482 000, F: +357 22 485 380, E: nkm@cytanet.com.cy

www.nkmetal.com.cy

EsTaBlisHEd 1977

Roof Profile N&K 33

Wall Profile N&K 33

side lap detail

Cover Width 1000mm

side lap detail

Cover Width 1000mm

Ridge & Eaves Details

250

33

150

33

200 pitch

28

172

85

115

200 pitch

Material and Section Properties

Load Tables

Material

Thickness

m.m.

The load tables are calculated in accordance with the European

Recommendations for Steel Construction-ECCS TC7 and also

with regard to 8.5.5950 requirements.

The loads shown in the Tables hove been produced by dividing

the Ultimate load. by a Safety Factor of 1.5.

Materiol Yield Strength used in the Design Calculations is

Z2 210N/mm2

Weight

per metre

kgs.

Small Flange

in Compression

Ixx

Zxx

cm3

cm4

Large Flange

in Compression

Ixx

Zxx

cm3

cm4

0.50

4.907

9.050

4.062

5.499

3.163

0.60

5.888

11.399

5.155

7.232

4.278

0.70

6.869

13.609

6.160

9.101

5.529

0.80

7.850

15.748

7.117

11.092

6.914

0.90

8.832

17.861

8.055

13.198

8.433

1.00

9.813

19.962

8.984

15.412

10.089

28

172

85

Ridge Details (Case No.1)

115

Material and Section Properties

Load Tables

Material

Thickness

m.m.

The load tables are calculated in accordance with the European

Recommendations for Steel Construction-ECCS TC7 and also

with regard to 8.5.5950 requirements.

The loads shown in the Tables hove been produced by dividing

the Ultimate load. by a Safety Factor of 1.5.

Materiol Yield Strength used in the Design Calculations is

Z2 210N/mm2

Weight

per metre

kgs.

Small Flange

in Compression

Ixx

Zxx

cm3

cm4

Large Flange

in Compression

Ixx

Zxx

cm3

cm4

0.50

4.907

9.050

4.062

5.499

0.60

5.888

11.399

5.155

7.232

3.163

4.278

0.70

6.869

13.609

6.160

9.101

5.529

0.80

7.850

15.748

7.117

11.092

6.914

0.90

8.832

17.861

8.055

13.198

8.433

1.00

9.813

19.962

8.984

15.412

10.089

200

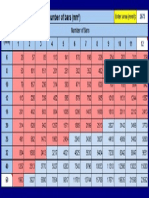

Applied Loads in KN/m2

DEFLECTION L/200

Self weight has been

taken into account

Applied Loads in KN/m2

Downward Loads

Wind Uplift

Purlin Spacing mm

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

Single Span

DEFLECTION L/150

Self weight has been

taken into account

Side Pressure

Side Suction

Purlin Spacing mm

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

Ridge Details (Case No.2)

Single Span

0.50

Dead+Super

Uplift

4.50

3.59

3.12

2.50

2.29

1.60

1.72

1.08

1.21

0.76

0.88

0.55

0.66

0.42

0.51

0.32

0.40

0.25

0.32

0.20

0.26

0.17

0.50

Pressure

Suction

3.54

4.55

2.46

3.16

1.81

2.32

1.38

1.78

0.99

1.40

0.72

1.14

0.54

0.89

0.42

0.69

0.33

0.54

0.26

0.43

0.21

0.35

0.60

Dead+Super

Uplift

5.72

4.85

3.96

3.34

2.90

2.10

2.17

1.41

1.52

0.99

1.11

0.73

0.83

0.55

0.64

0.42

0.50

0.33

0.40

0.27

0.33

0.22

0.60

Pressure

Suction

4.79

5.77

3.33

4.01

2.44

2.95

1.85

2.26

1.30

1.78

0.95

1.44

0.71

1.12

0.55

0.87

0.43

0.68

0.35

0.55

0.28

0.44

0.70

Dead+Super

Uplift

6.83

6.26

4.73

4.19

3.47

2.65

2.59

1.78

1.82

1.25

1.32

0.91

0.99

0.69

0.76

0.53

0.60

0.42

0.48

0.34

0.39

0.27

0.70

Pressure

Suction

6.19

6.90

4.30

4.79

3.16

3.52

2.33

2.70

1.64

2.13

1.19

1.72

0.90

1.34

0.69

1.03

0.54

0.81

0.44

0.65

0.35

0.53

0.80

Dead+Super

Uplift

7.89

7.82

5.47

5.11

4.01

3.22

3.00

2.16

2.10

1.52

1.53

1.11

1.15

0.84

0.88

0.65

0.69

0.51

0.56

0.41

0.45

0.33

0.80

Pressure

Suction

7.74

7.97

5.38

5.54

3.95

4.07

2.84

3.11

2.00

2.46

1.46

1.99

1.09

1.55

0.84

1.20

0.66

0.94

0.53

0.75

0.43

0.61

0.90

Dead+Super

Uplift

8.94

9.53

6.19

6.07

4.54

3.83

3.40

2.57

2.39

1.81

1.74

1.32

1.30

0.99

1.00

0.77

0.79

0.60

0.63

0.48

0.51

0.39

0.90

Pressure

Suction

9.44

9.02

6.56

6.27

4.82

4.60

3.38

3.52

2.38

2.78

1.73

2.26

1.30

1.76

1.00

1.36

0.79

1.07

0.63

0.85

0.51

0.69

1.00

Dead+Super

Uplift

9.97

11.40

6.91

7.09

5.07

4.47

3.80

3.00

2.67

2.11

1.94

1.54

1.46

1.16

1.12

0.89

0.88

0.70

0.70

0.57

0.57

0.46

1.00

Pressure

Suction

11.30

10.06

7.85

6.99

5.77

5.13

3.95

3.93

2.77

3.11

2.02

2.52

1.52

1.97

1.17

1.52

0.92

1.19

0.74

0.95

0.60

0.78

0.50

Dead+Super

Uplift

4.38

5.73

3.04

3.99

2.22

2.65

1.70

1.78

1.34

1.25

1.08

0.91

0.89

0.69

0.75

0.53

0.64

0.42

0.53

0.33

0.43

0.27

0.50

Pressure

Suction

5.69

4.43

3.95

3.08

2.90

2.26

2.22

1.73

1.65

1.37

1.20

1.11

0.90

0.91

0.70

0.77

0.55

0.66

0.44

0.56

0.36

0.49

0.60

Dead+Super

Uplift

5.93

7.27

4.11

5.06

3.01

3.49

2.30

2.34

1.82

1.65

1.47

1.20

1.21

0.90

1.02

0.70

0.84

0.55

0.67

0.44

0.55

0.36

0.60

Pressure

Suction

7.22

5.99

5.01

4.16

3.68

3.06

2.82

2.34

2.17

1.85

1.58

1.50

1.19

1.24

0.92

1.04

0.72

0.89

0.58

0.76

0.47

0.67

0.70

Dead+Super

Uplift

7.67

8.69

5.32

6.05

3.90

4.39

2.98

2.94

2.35

2.07

1.90

1.51

1.57

1.14

1.28

0.88

1.01

0.69

0.81

0.55

0.65

0.45

0.70

Pressure

Suction

8.62

7.74

5.99

5.38

4.40

3.95

3.37

3.02

2.66

2.39

1.99

1.94

1.50

1.60

1.15

1.34

0.91

1.15

0.73

0.99

0.59

0.86

0.80

Dead+Super

Uplift

9.60

10.04

6.66

6.98

4.88

5.14

3.73

3.58

2.94

2.52

2.38

1.84

1.93

1.38

1.48

1.07

1.16

0.84

0.93

0.67

0.76

0.55

0.80

Pressure

Suction

9.96

9.68

6.92

6.72

5.08

4.94

3.89

3.78

3.08

2.99

2.43

2.42

1.82

2.00

1.40

1.68

1.10

1.43

0.88

1.23

0.72

1.02

0.90

Dead+Super

Uplift

11.72

11.36

8.13

7.90

5.96

5.82

4.56

4.26

3.60

3.00

2.91

2.19

2.18

1.64

1.68

1.27

1.32

1.00

1.06

0.80

0.86

0.65

0.90

Pressure

Suction

11.28

11.81

7.83

8.20

5.75

6.02

4.41

4.61

3.48

3.34

2.82

2.95

2.17

2.44

1.67

2.05

1.31

1.75

1.05

1.42

0.86

1.16

1.00

Dead+Super

Uplift

14.03

12.67

9.73

8.81

7.14

6.49

5.46

4.97

4.31

3.50

3.25

2.55

2.44

1.92

1.88

1.48

1.48

1.17

1.18

0.93

0.96

0.76

1.00

Pressure

Suction

12.58

14.12

8.73

9.81

6.42

7.21

4.91

5.52

3.88

4.36

3.14

3.53

2.53

2.92

1.95

2.45

1.53

1.99

1.23

1.59

1.00

1.29

Multi Span

Eaves Details

Multi Span

Ridge & Eaves Metal Filler

Roof Profile N&K 33

Wall Profile N&K 33

side lap detail

Cover Width 1000mm

side lap detail

Cover Width 1000mm

Ridge & Eaves Details

250

33

150

33

200 pitch

28

172

85

115

200 pitch

Material and Section Properties

Load Tables

Material

Thickness

m.m.

The load tables are calculated in accordance with the European

Recommendations for Steel Construction-ECCS TC7 and also

with regard to 8.5.5950 requirements.

The loads shown in the Tables hove been produced by dividing

the Ultimate load. by a Safety Factor of 1.5.

Materiol Yield Strength used in the Design Calculations is

Z2 210N/mm2

Weight

per metre

kgs.

Small Flange

in Compression

Ixx

Zxx

cm3

cm4

Large Flange

in Compression

Ixx

Zxx

cm3

cm4

0.50

4.907

9.050

4.062

5.499

3.163

0.60

5.888

11.399

5.155

7.232

4.278

0.70

6.869

13.609

6.160

9.101

5.529

0.80

7.850

15.748

7.117

11.092

6.914

0.90

8.832

17.861

8.055

13.198

8.433

1.00

9.813

19.962

8.984

15.412

10.089

28

172

85

Ridge Details (Case No.1)

115

Material and Section Properties

Load Tables

Material

Thickness

m.m.

The load tables are calculated in accordance with the European

Recommendations for Steel Construction-ECCS TC7 and also

with regard to 8.5.5950 requirements.

The loads shown in the Tables hove been produced by dividing

the Ultimate load. by a Safety Factor of 1.5.

Materiol Yield Strength used in the Design Calculations is

Z2 210N/mm2

Weight

per metre

kgs.

Small Flange

in Compression

Ixx

Zxx

cm3

cm4

Large Flange

in Compression

Ixx

Zxx

cm3

cm4

0.50

4.907

9.050

4.062

5.499

0.60

5.888

11.399

5.155

7.232

3.163

4.278

0.70

6.869

13.609

6.160

9.101

5.529

0.80

7.850

15.748

7.117

11.092

6.914

0.90

8.832

17.861

8.055

13.198

8.433

1.00

9.813

19.962

8.984

15.412

10.089

200

Applied Loads in KN/m2

DEFLECTION L/200

Self weight has been

taken into account

Applied Loads in KN/m2

Downward Loads

Wind Uplift

Purlin Spacing mm

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

Single Span

DEFLECTION L/150

Self weight has been

taken into account

Side Pressure

Side Suction

Purlin Spacing mm

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

Ridge Details (Case No.2)

Single Span

0.50

Dead+Super

Uplift

4.50

3.59

3.12

2.50

2.29

1.60

1.72

1.08

1.21

0.76

0.88

0.55

0.66

0.42

0.51

0.32

0.40

0.25

0.32

0.20

0.26

0.17

0.50

Pressure

Suction

3.54

4.55

2.46

3.16

1.81

2.32

1.38

1.78

0.99

1.40

0.72

1.14

0.54

0.89

0.42

0.69

0.33

0.54

0.26

0.43

0.21

0.35

0.60

Dead+Super

Uplift

5.72

4.85

3.96

3.34

2.90

2.10

2.17

1.41

1.52

0.99

1.11

0.73

0.83

0.55

0.64

0.42

0.50

0.33

0.40

0.27

0.33

0.22

0.60

Pressure

Suction

4.79

5.77

3.33

4.01

2.44

2.95

1.85

2.26

1.30

1.78

0.95

1.44

0.71

1.12

0.55

0.87

0.43

0.68

0.35

0.55

0.28

0.44

0.70

Dead+Super

Uplift

6.83

6.26

4.73

4.19

3.47

2.65

2.59

1.78

1.82

1.25

1.32

0.91

0.99

0.69

0.76

0.53

0.60

0.42

0.48

0.34

0.39

0.27

0.70

Pressure

Suction

6.19

6.90

4.30

4.79

3.16

3.52

2.33

2.70

1.64

2.13

1.19

1.72

0.90

1.34

0.69

1.03

0.54

0.81

0.44

0.65

0.35

0.53

0.80

Dead+Super

Uplift

7.89

7.82

5.47

5.11

4.01

3.22

3.00

2.16

2.10

1.52

1.53

1.11

1.15

0.84

0.88

0.65

0.69

0.51

0.56

0.41

0.45

0.33

0.80

Pressure

Suction

7.74

7.97

5.38

5.54

3.95

4.07

2.84

3.11

2.00

2.46

1.46

1.99

1.09

1.55

0.84

1.20

0.66

0.94

0.53

0.75

0.43

0.61

0.90

Dead+Super

Uplift

8.94

9.53

6.19

6.07

4.54

3.83

3.40

2.57

2.39

1.81

1.74

1.32

1.30

0.99

1.00

0.77

0.79

0.60

0.63

0.48

0.51

0.39

0.90

Pressure

Suction

9.44

9.02

6.56

6.27

4.82

4.60

3.38

3.52

2.38

2.78

1.73

2.26

1.30

1.76

1.00

1.36

0.79

1.07

0.63

0.85

0.51

0.69

1.00

Dead+Super

Uplift

9.97

11.40

6.91

7.09

5.07

4.47

3.80

3.00

2.67

2.11

1.94

1.54

1.46

1.16

1.12

0.89

0.88

0.70

0.70

0.57

0.57

0.46

1.00

Pressure

Suction

11.30

10.06

7.85

6.99

5.77

5.13

3.95

3.93

2.77

3.11

2.02

2.52

1.52

1.97

1.17

1.52

0.92

1.19

0.74

0.95

0.60

0.78

0.50

Dead+Super

Uplift

4.38

5.73

3.04

3.99

2.22

2.65

1.70

1.78

1.34

1.25

1.08

0.91

0.89

0.69

0.75

0.53

0.64

0.42

0.53

0.33

0.43

0.27

0.50

Pressure

Suction

5.69

4.43

3.95

3.08

2.90

2.26

2.22

1.73

1.65

1.37

1.20

1.11

0.90

0.91

0.70

0.77

0.55

0.66

0.44

0.56

0.36

0.49

0.60

Dead+Super

Uplift

5.93

7.27

4.11

5.06

3.01

3.49

2.30

2.34

1.82

1.65

1.47

1.20

1.21

0.90

1.02

0.70

0.84

0.55

0.67

0.44

0.55

0.36

0.60

Pressure

Suction

7.22

5.99

5.01

4.16

3.68

3.06

2.82

2.34

2.17

1.85

1.58

1.50

1.19

1.24

0.92

1.04

0.72

0.89

0.58

0.76

0.47

0.67

0.70

Dead+Super

Uplift

7.67

8.69

5.32

6.05

3.90

4.39

2.98

2.94

2.35

2.07

1.90

1.51

1.57

1.14

1.28

0.88

1.01

0.69

0.81

0.55

0.65

0.45

0.70

Pressure

Suction

8.62

7.74

5.99

5.38

4.40

3.95

3.37

3.02

2.66

2.39

1.99

1.94

1.50

1.60

1.15

1.34

0.91

1.15

0.73

0.99

0.59

0.86

0.80

Dead+Super

Uplift

9.60

10.04

6.66

6.98

4.88

5.14

3.73

3.58

2.94

2.52

2.38

1.84

1.93

1.38

1.48

1.07

1.16

0.84

0.93

0.67

0.76

0.55

0.80

Pressure

Suction

9.96

9.68

6.92

6.72

5.08

4.94

3.89

3.78

3.08

2.99

2.43

2.42

1.82

2.00

1.40

1.68

1.10

1.43

0.88

1.23

0.72

1.02

0.90

Dead+Super

Uplift

11.72

11.36

8.13

7.90

5.96

5.82

4.56

4.26

3.60

3.00

2.91

2.19

2.18

1.64

1.68

1.27

1.32

1.00

1.06

0.80

0.86

0.65

0.90

Pressure

Suction

11.28

11.81

7.83

8.20

5.75

6.02

4.41

4.61

3.48

3.34

2.82

2.95

2.17

2.44

1.67

2.05

1.31

1.75

1.05

1.42

0.86

1.16

1.00

Dead+Super

Uplift

14.03

12.67

9.73

8.81

7.14

6.49

5.46

4.97

4.31

3.50

3.25

2.55

2.44

1.92

1.88

1.48

1.48

1.17

1.18

0.93

0.96

0.76

1.00

Pressure

Suction

12.58

14.12

8.73

9.81

6.42

7.21

4.91

5.52

3.88

4.36

3.14

3.53

2.53

2.92

1.95

2.45

1.53

1.99

1.23

1.59

1.00

1.29

Multi Span

Eaves Details

Multi Span

Ridge & Eaves Metal Filler

Roof Profile N&K 33

Wall Profile N&K 33

side lap detail

Cover Width 1000mm

side lap detail

Cover Width 1000mm

Ridge & Eaves Details

250

33

150

33

200 pitch

28

172

85

115

200 pitch

Material and Section Properties

Load Tables

Material

Thickness

m.m.

The load tables are calculated in accordance with the European

Recommendations for Steel Construction-ECCS TC7 and also

with regard to 8.5.5950 requirements.

The loads shown in the Tables hove been produced by dividing

the Ultimate load. by a Safety Factor of 1.5.

Materiol Yield Strength used in the Design Calculations is

Z2 210N/mm2

Weight

per metre

kgs.

Small Flange

in Compression

Ixx

Zxx

cm3

cm4

Large Flange

in Compression

Ixx

Zxx

cm3

cm4

0.50

4.907

9.050

4.062

5.499

3.163

0.60

5.888

11.399

5.155

7.232

4.278

0.70

6.869

13.609

6.160

9.101

5.529

0.80

7.850

15.748

7.117

11.092

6.914

0.90

8.832

17.861

8.055

13.198

8.433

1.00

9.813

19.962

8.984

15.412

10.089

28

172

85

Ridge Details (Case No.1)

115

Material and Section Properties

Load Tables

Material

Thickness

m.m.

The load tables are calculated in accordance with the European

Recommendations for Steel Construction-ECCS TC7 and also

with regard to 8.5.5950 requirements.

The loads shown in the Tables hove been produced by dividing

the Ultimate load. by a Safety Factor of 1.5.

Materiol Yield Strength used in the Design Calculations is

Z2 210N/mm2

Weight

per metre

kgs.

Small Flange

in Compression

Ixx

Zxx

cm3

cm4

Large Flange

in Compression

Ixx

Zxx

cm3

cm4

0.50

4.907

9.050

4.062

5.499

0.60

5.888

11.399

5.155

7.232

3.163

4.278

0.70

6.869

13.609

6.160

9.101

5.529

0.80

7.850

15.748

7.117

11.092

6.914

0.90

8.832

17.861

8.055

13.198

8.433

1.00

9.813

19.962

8.984

15.412

10.089

200

Applied Loads in KN/m2

DEFLECTION L/200

Self weight has been

taken into account

Applied Loads in KN/m2

Downward Loads

Wind Uplift

Purlin Spacing mm

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

Single Span

DEFLECTION L/150

Self weight has been

taken into account

Side Pressure

Side Suction

Purlin Spacing mm

1000

1200

1400

1600

1800

2000

2200

2400

2600

2800

3000

Ridge Details (Case No.2)

Single Span

0.50

Dead+Super

Uplift

4.50

3.59

3.12

2.50

2.29

1.60

1.72

1.08

1.21

0.76

0.88

0.55

0.66

0.42

0.51

0.32

0.40

0.25

0.32

0.20

0.26

0.17

0.50

Pressure

Suction

3.54

4.55

2.46

3.16

1.81

2.32

1.38

1.78

0.99

1.40

0.72

1.14

0.54

0.89

0.42

0.69

0.33

0.54

0.26

0.43

0.21

0.35

0.60

Dead+Super

Uplift

5.72

4.85

3.96

3.34

2.90

2.10

2.17

1.41

1.52

0.99

1.11

0.73

0.83

0.55

0.64

0.42

0.50

0.33

0.40

0.27

0.33

0.22

0.60

Pressure

Suction

4.79

5.77

3.33

4.01

2.44

2.95

1.85

2.26

1.30

1.78

0.95

1.44

0.71

1.12

0.55

0.87

0.43

0.68

0.35

0.55

0.28

0.44

0.70

Dead+Super

Uplift

6.83

6.26

4.73

4.19

3.47

2.65

2.59

1.78

1.82

1.25

1.32

0.91

0.99

0.69

0.76

0.53

0.60

0.42

0.48

0.34

0.39

0.27

0.70

Pressure

Suction

6.19

6.90

4.30

4.79

3.16

3.52

2.33

2.70

1.64

2.13

1.19

1.72

0.90

1.34

0.69

1.03

0.54

0.81

0.44

0.65

0.35

0.53

0.80

Dead+Super

Uplift

7.89

7.82

5.47

5.11

4.01

3.22

3.00

2.16

2.10

1.52

1.53

1.11

1.15

0.84

0.88

0.65

0.69

0.51

0.56

0.41

0.45

0.33

0.80

Pressure

Suction

7.74

7.97

5.38

5.54

3.95

4.07

2.84

3.11

2.00

2.46

1.46

1.99

1.09

1.55

0.84

1.20

0.66

0.94

0.53

0.75

0.43

0.61

0.90

Dead+Super

Uplift

8.94

9.53

6.19

6.07

4.54

3.83

3.40

2.57

2.39

1.81

1.74

1.32

1.30

0.99

1.00

0.77

0.79

0.60

0.63

0.48

0.51

0.39

0.90

Pressure

Suction

9.44

9.02

6.56

6.27

4.82

4.60

3.38

3.52

2.38

2.78

1.73

2.26

1.30

1.76

1.00

1.36

0.79

1.07

0.63

0.85

0.51

0.69

1.00

Dead+Super

Uplift

9.97

11.40

6.91

7.09

5.07

4.47

3.80

3.00

2.67

2.11

1.94

1.54

1.46

1.16

1.12

0.89

0.88

0.70

0.70

0.57

0.57

0.46

1.00

Pressure

Suction

11.30

10.06

7.85

6.99

5.77

5.13

3.95

3.93

2.77

3.11

2.02

2.52

1.52

1.97

1.17

1.52

0.92

1.19

0.74

0.95

0.60

0.78

0.50

Dead+Super

Uplift

4.38

5.73

3.04

3.99

2.22

2.65

1.70

1.78

1.34

1.25

1.08

0.91

0.89

0.69

0.75

0.53

0.64

0.42

0.53

0.33

0.43

0.27

0.50

Pressure

Suction

5.69

4.43

3.95

3.08

2.90

2.26

2.22

1.73

1.65

1.37

1.20

1.11

0.90

0.91

0.70

0.77

0.55

0.66

0.44

0.56

0.36

0.49

0.60

Dead+Super

Uplift

5.93

7.27

4.11

5.06

3.01

3.49

2.30

2.34

1.82

1.65

1.47

1.20

1.21

0.90

1.02

0.70

0.84

0.55

0.67

0.44

0.55

0.36

0.60

Pressure

Suction

7.22

5.99

5.01

4.16

3.68

3.06

2.82

2.34

2.17

1.85

1.58

1.50

1.19

1.24

0.92

1.04

0.72

0.89

0.58

0.76

0.47

0.67

0.70

Dead+Super

Uplift

7.67

8.69

5.32

6.05

3.90

4.39

2.98

2.94

2.35

2.07

1.90

1.51

1.57

1.14

1.28

0.88

1.01

0.69

0.81

0.55

0.65

0.45

0.70

Pressure

Suction

8.62

7.74

5.99

5.38

4.40

3.95

3.37

3.02

2.66

2.39

1.99

1.94

1.50

1.60

1.15

1.34

0.91

1.15

0.73

0.99

0.59

0.86

0.80

Dead+Super

Uplift

9.60

10.04

6.66

6.98

4.88

5.14

3.73

3.58

2.94

2.52

2.38

1.84

1.93

1.38

1.48

1.07

1.16

0.84

0.93

0.67

0.76

0.55

0.80

Pressure

Suction

9.96

9.68

6.92

6.72

5.08

4.94

3.89

3.78

3.08

2.99

2.43

2.42

1.82

2.00

1.40

1.68

1.10

1.43

0.88

1.23

0.72

1.02

0.90

Dead+Super

Uplift

11.72

11.36

8.13

7.90

5.96

5.82

4.56

4.26

3.60

3.00

2.91

2.19

2.18

1.64

1.68

1.27

1.32

1.00

1.06

0.80

0.86

0.65

0.90

Pressure

Suction

11.28

11.81

7.83

8.20

5.75

6.02

4.41

4.61

3.48

3.34

2.82

2.95

2.17

2.44

1.67

2.05

1.31

1.75

1.05

1.42

0.86

1.16

1.00

Dead+Super

Uplift

14.03

12.67

9.73

8.81

7.14

6.49

5.46

4.97

4.31

3.50

3.25

2.55

2.44

1.92

1.88

1.48

1.48

1.17

1.18

0.93

0.96

0.76

1.00

Pressure

Suction

12.58

14.12

8.73

9.81

6.42

7.21

4.91

5.52

3.88

4.36

3.14

3.53

2.53

2.92

1.95

2.45

1.53

1.99

1.23

1.59

1.00

1.29

Multi Span

Eaves Details

Multi Span

Ridge & Eaves Metal Filler

Wall Profile N&K 10

Fixing

Roof & Wall

Claddings

For typical installations the following methods

would be adopted:

Type: & 10/1092

Overall width 1160mm

Roof

0

Pitches under 10 - end lap of min. 230mm.

0

Pitches over 10 - end lap of min. 150mm.

Cover width 1092mm

End laps should occur over purlins.

The bottom of the sheet should project

a minimum 60mm over the purlin.

A minimum of 3 fixings per sheet per purlin

should be used, except at the ends of sheets

where there could be a fixing every valley.

0mm

- 23

150

Roof and Wall Claddings were develop to provide

an attractive appearance, good stsructural

performance and ease of installation.

The main features can be summarised as follows:

1. Available in any trasportable length.

2. Suitable for double skin site construction.

3. Profiles can be arrange vertically

or horizontally.

4. Manufactured from prepainted

galvanised steel - available

in a variety of colours

and finishes.

Self drilling and tapping

screw q 6.3mm 25mm long

Side lap fixing should begin approximately

150mm from the end of the sheet

and be spaced at intervals of about 450mm.

10

156 pitch

20

136

30

126

Type: & 10/936

Wall

End laps should be at least 100mm.

Side lap fixings should begin approximately

150mm from the end of the sheet

and be spaced at intervals of about 500mm.

Fixing to steel Supports

0mm

- 23

150

Overall width 1005mm

Cover width 936mm

Self drilling and tapping

screw q 6.3mm 40mm long

Self drilling and tapping

screw q 5.3mm 20mm long

Side lap

Fixing to timber Supports

10

Fixing position for N&K 33

156 pitch

20

136

30

126

Note: According to Code of Practice for the use of profiled sheet for Roof and Wall Cladding on buildings, Part 1. (revision of BS 5427)

GERI INDUSTRIAL ESTATE

P.O.BOX 12665 - 2251 NICOSIA - CYPRUS

T: +357 22 482 000, F: +357 22 485 380, E: nkm@cytanet.com.cy

www.nkmetal.com.cy

EsTaBlisHEd 1977

Wall Profile N&K 10

Fixing

Roof & Wall

Claddings

For typical installations the following methods

would be adopted:

Type: & 10/1092

Overall width 1160mm

Roof

0

Pitches under 10 - end lap of min. 230mm.

0

Pitches over 10 - end lap of min. 150mm.

Cover width 1092mm

End laps should occur over purlins.

The bottom of the sheet should project

a minimum 60mm over the purlin.

A minimum of 3 fixings per sheet per purlin

should be used, except at the ends of sheets

where there could be a fixing every valley.

0mm

- 23

150

Roof and Wall Claddings were develop to provide

an attractive appearance, good stsructural

performance and ease of installation.

The main features can be summarised as follows:

1. Available in any trasportable length.

2. Suitable for double skin site construction.

3. Profiles can be arrange vertically

or horizontally.

4. Manufactured from prepainted

galvanised steel - available

in a variety of colours

and finishes.

Self drilling and tapping

screw q 6.3mm 25mm long

Side lap fixing should begin approximately

150mm from the end of the sheet

and be spaced at intervals of about 450mm.

10

156 pitch

20

136

30

126

Type: & 10/936

Wall

End laps should be at least 100mm.

Side lap fixings should begin approximately

150mm from the end of the sheet

and be spaced at intervals of about 500mm.

Fixing to steel Supports

0mm

- 23

150

Overall width 1005mm

Cover width 936mm

Self drilling and tapping

screw q 6.3mm 40mm long

Self drilling and tapping

screw q 5.3mm 20mm long

Side lap

Fixing to timber Supports

10

Fixing position for N&K 33

156 pitch

20

136

30

126

Note: According to Code of Practice for the use of profiled sheet for Roof and Wall Cladding on buildings, Part 1. (revision of BS 5427)

GERI INDUSTRIAL ESTATE

P.O.BOX 12665 - 2251 NICOSIA - CYPRUS

T: +357 22 482 000, F: +357 22 485 380, E: nkm@cytanet.com.cy

www.nkmetal.com.cy

EsTaBlisHEd 1977

You might also like

- KS1000 RW Panel UK Roof Poduct Data SheetDocument6 pagesKS1000 RW Panel UK Roof Poduct Data SheetThe Lone GunmanNo ratings yet

- Topdek 700 Concealed Clip RoofingDocument16 pagesTopdek 700 Concealed Clip RoofingctaciutNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Ancon - Stainless Steel SectionsDocument10 pagesAncon - Stainless Steel SectionspiotrnowakNo ratings yet

- Stramit Monoclad: Product Technical ManualDocument8 pagesStramit Monoclad: Product Technical Manualchillerz69No ratings yet

- Multideck 60-V2: - Concrete Volume SavingsDocument18 pagesMultideck 60-V2: - Concrete Volume Savingsdexterbox1No ratings yet

- Z PurlinsDocument27 pagesZ Purlinsmassive85No ratings yet

- Roofing and Wall Cladding Performance GuideDocument4 pagesRoofing and Wall Cladding Performance GuideAndrea GibsonNo ratings yet

- BQ AsramaDocument50 pagesBQ AsramaAreja Siti80% (15)

- Steel Sheet Piles GuideDocument4 pagesSteel Sheet Piles Guidevinaysa18gmailcomNo ratings yet

- 02Document23 pages02chibssa alemayehuNo ratings yet

- Reinforced Concrete Column DesignDocument18 pagesReinforced Concrete Column DesignGeorge LazarNo ratings yet

- Alustar (Perfis & Secções)Document49 pagesAlustar (Perfis & Secções)Jeovani DanielNo ratings yet

- Lysaght OptimaDocument8 pagesLysaght OptimaAgung PriambodhoNo ratings yet

- Hollow Core DesignDocument15 pagesHollow Core DesignMelinda Gordon100% (1)

- Gratings BrochureDocument22 pagesGratings BrochureN P Srinivasarao100% (2)

- Arcelor - Catalog Cu Palplanse Metalice - 2Document16 pagesArcelor - Catalog Cu Palplanse Metalice - 2S. Marius100% (1)

- Technical Characteristics and Reference Standards: Zintek® in The Building IndustryDocument2 pagesTechnical Characteristics and Reference Standards: Zintek® in The Building Industryapi-112807037No ratings yet

- Fireproof Insulated Metal Wall PanelDocument2 pagesFireproof Insulated Metal Wall Panelliviu_dovaNo ratings yet

- Comparision Between WPB 160x30.44kg (300 Mpa) and SC 152x37Document1 pageComparision Between WPB 160x30.44kg (300 Mpa) and SC 152x37renu.messagesNo ratings yet

- Technical Data Sheet for Knauf Board CeilingsDocument28 pagesTechnical Data Sheet for Knauf Board CeilingsAmin ChhipaNo ratings yet

- Comax 1000Document2 pagesComax 1000hitendra_gkNo ratings yet

- Chapter 3 Datasheets Roof PanelsDocument16 pagesChapter 3 Datasheets Roof PanelsMladen BilincNo ratings yet

- Cold Bridging in Rainscreen Cladding SystemDocument5 pagesCold Bridging in Rainscreen Cladding SystemStephenNo ratings yet

- TATA D159 Steel S320 PlainDocument1 pageTATA D159 Steel S320 Plainreviva1No ratings yet

- Cembrit Multi Force (FR) Building BoardsDocument12 pagesCembrit Multi Force (FR) Building BoardsVladoiu SorinNo ratings yet

- Isofire Roof 1000 PDFDocument2 pagesIsofire Roof 1000 PDFIon VasileNo ratings yet

- Long-Span Structural Systems OverviewDocument46 pagesLong-Span Structural Systems OverviewAdil ImtiazNo ratings yet

- Larssen U profile sheet pile specifications and applicationsDocument20 pagesLarssen U profile sheet pile specifications and applicationssiana herawatiNo ratings yet

- Design Calculations For Aluminium Profile-13794Document14 pagesDesign Calculations For Aluminium Profile-13794msiddiq175% (4)

- Components Overview - Brochures V11 I400003GBDocument80 pagesComponents Overview - Brochures V11 I400003GBKirsten HernandezNo ratings yet

- Sheetpile Catalogue NipponDocument20 pagesSheetpile Catalogue NipponTony Lai100% (1)

- AQUAPANEL Cement Board Outdoor Datasheet 0817Document3 pagesAQUAPANEL Cement Board Outdoor Datasheet 0817xander1982No ratings yet

- Bondor BondorPanel Insulated Walling Technical DataDocument2 pagesBondor BondorPanel Insulated Walling Technical DataSvan Dxi ArulNo ratings yet

- KLH SpecsDocument6 pagesKLH Specsbob burgerNo ratings yet

- En 1996-1-1 Reinforced Masonry Design Example 1: (Note: This Uses The Uk National Annex NDP Values)Document6 pagesEn 1996-1-1 Reinforced Masonry Design Example 1: (Note: This Uses The Uk National Annex NDP Values)Eduardo Martinez CaleroNo ratings yet

- Foil TecDocument4 pagesFoil TecgibboofunkNo ratings yet

- Steelway Brochure - Core-Products09Document20 pagesSteelway Brochure - Core-Products09Laura EddowesNo ratings yet

- Steel Sheet PilesDocument6 pagesSteel Sheet PilesavckumaraNo ratings yet

- Curtain Wall-Report REv 1-10-21Document11 pagesCurtain Wall-Report REv 1-10-21MuraleedharanNo ratings yet

- Cold Rolling MillDocument4 pagesCold Rolling MillArslan BohioNo ratings yet

- Acoustic CatalogDocument12 pagesAcoustic CatalogrohizatNo ratings yet

- Steel Cord - Vulcanized SpliceDocument16 pagesSteel Cord - Vulcanized Splicebogeyman666No ratings yet

- Euroclad Guide To Design and Installation of Trapezoidal SystemsDocument0 pagesEuroclad Guide To Design and Installation of Trapezoidal Systemsssss2345No ratings yet

- Assan Panel Walls RockwoolDocument5 pagesAssan Panel Walls RockwoolFlorin MatisNo ratings yet

- M50 enDocument338 pagesM50 entomwilkinsNo ratings yet

- STEEL ROOF TRUSS DESIGN FOR PETROL STATIONDocument22 pagesSTEEL ROOF TRUSS DESIGN FOR PETROL STATIONemuan vanessaNo ratings yet

- TP of RC Design, G7A PDFDocument31 pagesTP of RC Design, G7A PDFJulesNo ratings yet

- MIL-DTL-17-133E - Cables, Radio Frequency, Coaxial, 0.0865 Diameter, Semi Rigid, 50 OhmsDocument11 pagesMIL-DTL-17-133E - Cables, Radio Frequency, Coaxial, 0.0865 Diameter, Semi Rigid, 50 OhmsgamillosNo ratings yet

- Anchorage zone design and reinforcementDocument47 pagesAnchorage zone design and reinforcementbeeNo ratings yet

- Fisa Tehnica Volet Rectangular SystemAirDocument17 pagesFisa Tehnica Volet Rectangular SystemAiroelbergluisNo ratings yet

- Knauf CeilingsDocument32 pagesKnauf CeilingsSebastian BadilaNo ratings yet

- Alpha Ceiling Square DiffusersDocument6 pagesAlpha Ceiling Square DiffusersbhaveshbhoiNo ratings yet

- Valuated Bill of Quantities for Building Construction ProjectDocument191 pagesValuated Bill of Quantities for Building Construction ProjectcostemaraNo ratings yet

- Optimize airflow with adjustable double-row grillesDocument14 pagesOptimize airflow with adjustable double-row grillesAndreea DiaconuNo ratings yet

- Pull Out ForceDocument4 pagesPull Out ForceYap Tat MingNo ratings yet

- Part - D - 2010 PDFDocument10 pagesPart - D - 2010 PDFcosineNo ratings yet

- Blank Calculation SheetDocument1 pageBlank Calculation SheetcosineNo ratings yet

- Flash Cover InstallationDocument1 pageFlash Cover InstallationcosineNo ratings yet

- Wind Loads On Structures According To CYS EN 1991Document1 pageWind Loads On Structures According To CYS EN 1991cosineNo ratings yet

- Calculate the appropriate cooling capacityDocument1 pageCalculate the appropriate cooling capacitycosineNo ratings yet

- Ce CementDocument1 pageCe CementcosineNo ratings yet

- T 8164 Miele Control Panel PDFDocument1 pageT 8164 Miele Control Panel PDFcosineNo ratings yet

- T 8164 Miele Control Panel PDFDocument1 pageT 8164 Miele Control Panel PDFcosineNo ratings yet

- BR PDF Adr7 1999Document0 pagesBR PDF Adr7 1999TOOMACENo ratings yet

- Manhole Cover PlanDocument1 pageManhole Cover PlancosineNo ratings yet

- Gate Valve Side ElevationDocument1 pageGate Valve Side ElevationcosineNo ratings yet

- Gate Valve Front ElevationDocument1 pageGate Valve Front ElevationcosineNo ratings yet

- Gate Valve PlanDocument1 pageGate Valve PlancosineNo ratings yet

- Water Drain SectionDocument1 pageWater Drain SectioncosineNo ratings yet

- Manhole Cover Section 2Document1 pageManhole Cover Section 2cosineNo ratings yet

- Thrust BlockDocument1 pageThrust BlockcosineNo ratings yet

- Manhole Cover SectionDocument1 pageManhole Cover SectioncosineNo ratings yet

- 04 Alastair CoxDocument41 pages04 Alastair CoxcosineNo ratings yet

- Floor DrainDocument1 pageFloor DraincosineNo ratings yet

- WELDING PROCESS ABBREVIATIONSDocument1 pageWELDING PROCESS ABBREVIATIONSviluk0% (1)

- Rapid Visual Screening of Buildings For Potential Seismic HazardsDocument164 pagesRapid Visual Screening of Buildings For Potential Seismic HazardsPO Asselin100% (2)

- Calculate the appropriate cooling capacityDocument1 pageCalculate the appropriate cooling capacitycosineNo ratings yet

- Ratio of Cement and SandDocument1 pageRatio of Cement and SandcosineNo ratings yet

- Steel Area TableDocument1 pageSteel Area TablecosineNo ratings yet

- Roof and Wall LeafletDocument6 pagesRoof and Wall LeafletcosineNo ratings yet

- The Project ProgrammeDocument1 pageThe Project ProgrammecosineNo ratings yet

- Rapid Visual Screening of Buildings For Potential Seismic HazardsDocument164 pagesRapid Visual Screening of Buildings For Potential Seismic HazardsPO Asselin100% (2)

- WAP4410N Admin GuideDocument62 pagesWAP4410N Admin GuideLuis Reyes VenturaNo ratings yet

- Truss BDocument1 pageTruss BcosineNo ratings yet

- RR Rate Analysis 2Document1 pageRR Rate Analysis 2ansar700No ratings yet

- Manila ANCESTRAL HOUSESDocument15 pagesManila ANCESTRAL HOUSESGideon NavarroNo ratings yet

- Polypipe Underfloor HeatingDocument52 pagesPolypipe Underfloor HeatingAli MustafaNo ratings yet

- Plaster Render Paint and Coatings - Detail 2004Document111 pagesPlaster Render Paint and Coatings - Detail 2004HIRA100% (1)

- Plot Area For Psychiatric HospitalDocument12 pagesPlot Area For Psychiatric HospitalEsayase AsnakeNo ratings yet

- Weyerhauser TJ-9001Document19 pagesWeyerhauser TJ-9001Andrew PooleNo ratings yet

- Minerva College of ArchitectureDocument3 pagesMinerva College of ArchitectureROSHANI TIWARINo ratings yet

- COOLING COIL SELECTIONDocument7 pagesCOOLING COIL SELECTIONdheerajdorlikarNo ratings yet

- Concrete Floor ScreedDocument1 pageConcrete Floor ScreedQAQC GCCNo ratings yet

- Equlife Brochure Phase2Document15 pagesEqulife Brochure Phase2Hemant NebhaniNo ratings yet

- Philippine Vernacular Architecture: Pre-Hispanic EraDocument58 pagesPhilippine Vernacular Architecture: Pre-Hispanic EraKim TanNo ratings yet

- ECM 366 Assignment 1Document9 pagesECM 366 Assignment 1NORFITRIAH YAHYANo ratings yet

- Wellmade® HDPC Engineered Vinyl Plank/Tile Installation GuideDocument6 pagesWellmade® HDPC Engineered Vinyl Plank/Tile Installation GuidethomasmegargleNo ratings yet

- Schedule Breakdown for Grey Structure ConstructionDocument16 pagesSchedule Breakdown for Grey Structure Constructionaliengineer953No ratings yet

- Pre Engineered Steel BuildingsDocument25 pagesPre Engineered Steel BuildingsHari SankerNo ratings yet

- IStrucE Detailing Manual BS8110Document1 pageIStrucE Detailing Manual BS8110Thoong Yew Chan0% (1)

- Building Materials and Construction Seminar on Domes and VaultsDocument48 pagesBuilding Materials and Construction Seminar on Domes and Vaultsswaraj patilNo ratings yet

- Aluminum Sliding DoorsDocument20 pagesAluminum Sliding DoorsClovis BlairNo ratings yet

- Assign 3 Bridge Deck DesignDocument1 pageAssign 3 Bridge Deck DesignRodain NajjarNo ratings yet

- PH2 English 3 Soal Dan JawabanDocument3 pagesPH2 English 3 Soal Dan JawabanzainlarosNo ratings yet

- Pip Arc01015Document39 pagesPip Arc01015Ulises CastroNo ratings yet

- Broadview HotelDocument33 pagesBroadview HotelPreservationResearchNo ratings yet

- ABTS-II - 10 - Onkar Khaire - Auditorium DrawingDocument4 pagesABTS-II - 10 - Onkar Khaire - Auditorium DrawingPratik Shinde100% (1)

- rdb11 07Document18 pagesrdb11 07Mircea BobarNo ratings yet

- Ebrochure Tanakayu ChavaDocument18 pagesEbrochure Tanakayu ChavaandreNo ratings yet

- TABLE: Pier Forces Story Pier Load Case/Combo Location P V2 V3 T M2Document5 pagesTABLE: Pier Forces Story Pier Load Case/Combo Location P V2 V3 T M2Alexandru NastasieNo ratings yet

- Stone LintelDocument2 pagesStone LintelchrishoppepeNo ratings yet

- JVTDocument2 pagesJVTrabia banoNo ratings yet

- (Diaz, Hasan, Lu) RSMeans-Guided Approach To Detailed Cost EstimatingDocument10 pages(Diaz, Hasan, Lu) RSMeans-Guided Approach To Detailed Cost EstimatingCheesyPorkBellyNo ratings yet

- Tugas Bahasa Inggris Mbak IndahDocument3 pagesTugas Bahasa Inggris Mbak IndahNur WijayantoNo ratings yet