Professional Documents

Culture Documents

Tapering Corner Whatnot Shelf: Project 16912EZ

Tapering Corner Whatnot Shelf: Project 16912EZ

Uploaded by

agustinrubio7946Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tapering Corner Whatnot Shelf: Project 16912EZ

Tapering Corner Whatnot Shelf: Project 16912EZ

Uploaded by

agustinrubio7946Copyright:

Available Formats

Project 16912EZ:

Tapering Corner Whatnot Shelf

While the tapering structure of this pine corner shelf poses a challenge, youll have no problem putting the piece together once you understand its angular construction.

Corner Shelf Materials List

Part A B C D E F G H I J K L M N O P Q R Description Side (upper) Back Back Support Top Top Shelf Middle Shelf Lower Shelf Bottom Side (lower) Front Valance Molding Drawer Side Drawer Back Drawer Bottom Drawer Front Drawer Guide Knob Size 3/4" x 2" x 22" 1/4" x 8" x 26-5/8" 3/4" x 2-1/2" x 26-5/8" see Table 1 see Table 1 see Table 1 see Table 1 see Table 1 3/4" x 2" x 4" 3/4" x 2-1/4" x 4" 3/8" x 3" x 7-1/2" 1/4" x 1/4" round 1/4" x 4" x 4-1/2" 1/4" x 4" x 5-3/4" 1/4" x 4-1/4" x 5-3/4" 3/4" x 4" x 6" 1/8" x 3/4" x 4-1/4" see Figure 11 Number Required 2 2 1 1 1 1 1 1 2 2 1 12 in. 2 1 1 1 3 1

Corner Shelf Complete Schematic

Corner Shelf Instructions

Step 1: Cut the Two Sides (A) and Two Back Pieces (B) 1. Cut the two side pine pieces (A) according to the specified dimensions. 2. Use the dado-head to cut the shelf grooves and ends at a 6-degree angle on both side pieces (A) (see Figure 1). 3. Choose the wood from which you would like to cut the back pieces (B): scrap wall paneling or 1/4" plywood are two possibilities. 4. Measure the actual thickness of the wood for the back pieces (B). 5. Make a rabbet the thickness of the back pieces x 3/8" along the back edges of the side pieces (A) (see Figure 2) to accept the back pieces (B). 6. Cut the two back pieces according to the specified dimensions.

Figure 1: Side Pieces (A) Detailed Layout

Figure 2: Side Pieces (A) Rabbet

Step 2: Cut the Back Support (C) 1. Cut the back support (C) according to the specified dimensions. 2. Mark the back support (C) according to the dado layout in Figure 3. 3. Use the dado-head to cut the dadoes. 4. Reset the dado-head to equal the thickness of the back pieces (B). 5. Incline the blade to 45 degrees. 6. Make the 1/2" cut to accept the back pieces (B) (see Figure 4). 7. Set the blade at 45 degrees again. 8. Rip the waste away from the back support (C) (see Figure 5). 9. Rip the waste away.

Figure 4: Making the 1/2" Cut in the Back Support (C) to Accept the Back Pieces (B)

Figure 5: Trimming the Back Support (C) Waste

Figure 3: Back Support (C) Dado Layout

Step 3: Cut the Shelves 1. Cut the top piece (D), top shelf (E), middle shelf (F), lower shelf (G) and bottom piece (H) to the shape shown in Figure 6 using the dimensions listed in Table 1. NOTE: The bottom piece (H) has the same front and side profile as the bottom shelf, BUT extends under the back support (C). 2. Notch the lower shelf (G) to fit around the back pieces (B).

Figure 6: Shape of Top Piece (D), Shelves (E, F, G, and Bottom Piece (H)

Table 1. Top Piece (D), Shelves (E, F, G,) and Bottom Piece Dimensions

A Top (D) Top Shelf (E) Middle Shelf (F) Lower Shelf (G) Bottom (H) 8-1/2" 7-5/16" 8-3/8" 10-5/8" 10-5/8" B 2-1/2" 2" 2" 2-1/4" 2-1/4" C 7-3/4" 6-3/8" 7-1/8" 8-5/8" 9" D 1" 1-1/8" 1-1/8" 1-1/8" 1"

Step 4: Cut the Lower Sides (I) and Front Parts (J) 1. Cut the lower sides (I) according to the specified dimensions. 2. Make a rabbet the thickness of the back pieces x 3/8" along the back edges of the lower sides (I) (see Figure 7) to accept the back pieces (B). 3. Miter the front edges of the lower sides (I) at 22-1/2 degrees to meet the front parts (J) (see Figure 8). 4. Cut the front parts (J) according to the specified dimensions. 5. Miter the outside edges of the front parts (J) at 22-1/2 degrees to meet the lower sides (I) (see Figure 8).

Figure 7: Lower Sides (I) Rabbet

Figure 8: Mitering the Lower Sides (I) and Front Parts (J)

Step 5: Assemble 1. Test assemble the parts that you have cut so far. 2. Adjust any parts that do not fit properly. 3. Use glue and brads to make the final assemble. Step 6: Cut and Fit the Valance (K) 1. Select a 3/8" x 3-1/4" x 6" piece of stock. 2. Set the table saw at a 6-degree tilt. 3. Rip along the top edge of the stock to create the valances (K) final 3" width (see Figure 9). 4. Hold the valance (K) in place on the case. 5. Mark for the two side cuts. NOTE: You MUST make the side cuts at 47 degrees, as opposed to the 45-degree cut that you would make if the sides were NOT inclined inward.

Figure 9: Valance Layout

6. 7. 8. 9. 10. 11.

Make the two side cuts. Refer to the grid pattern in Figure 9 to lay out the valance profile. Band saw the valance profile. Use glue and brads to mount the completed valance (K) to the case. Miter the quarter-round molding (L) as needed. Apply the molding (L) to the valance (K), side pieces (A), and back pieces (B) with glue and small brads. NOTE: Because the quarter-round molding (L) is small, you do NOT need to adjust it further to make it comply with the taper.

Step 7: Make the Drawer 1. Cut the drawer parts (M, N, O, and P) according to the specified numbers and dimensions. 2. Use standard rabbeted drawer construction techniques to complete the edges of the drawer parts (M, N, and P). 3. Use the table saw to bevel the drawer front (P) (see Figure 10). NOTE: The blade height at a 10-degree angle is 1-1/8". 4. Use glue and small brads to assemble the completed drawer parts (M, N, O, and P). 5. Cut the drawer guides (Q) according to the specified numbers and dimensions. 6. Mount two of the drawer guides (Q) to the drawer bottom (O) (see complete schematic for correct placement). Figure 10: Drawer Front Bevel

7. Mount the third drawer guide (Q) to the center of the case bottom (see complete schematic for correct placement). 8. Place a turned knob (R) or a porcelain knob 1" in diameter in the drawer front (P) to complete the drawer (see Figure 11).

Figure 11: Drawer Knob Placement

Step 8: Stain and Finish to Suit These plans were originally published in Volume 11, Issue 6 of The Woodworkers Journal (Nov./Dec. 1987, pages 54-56).

You might also like

- Quick and Easy Router TableDocument5 pagesQuick and Easy Router TableNebojša Jovanov100% (1)

- Recipe Box: Project 15193EZDocument5 pagesRecipe Box: Project 15193EZBSulli100% (1)

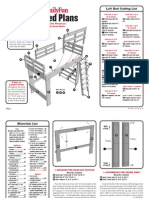

- Loft Bed PlansDocument6 pagesLoft Bed PlansDarryl Lashambe100% (2)

- Adirondack PlansDocument5 pagesAdirondack PlansDebbie Mack100% (2)

- Craftman Wood ChestDocument5 pagesCraftman Wood ChestIsidro CM100% (1)

- Ingerie Resser LAN: PlansDocument10 pagesIngerie Resser LAN: PlansGsmHelpNo ratings yet

- Tambour Topped BoxDocument7 pagesTambour Topped BoxTed MooreNo ratings yet

- Panel Saw PlanDocument11 pagesPanel Saw Plankarim100% (1)

- Workshop Tote Box: Project 20466EZDocument3 pagesWorkshop Tote Box: Project 20466EZBSulli100% (1)

- Country Curio Clock: Project 12231EZDocument7 pagesCountry Curio Clock: Project 12231EZBSulliNo ratings yet

- Writing Desk: Project 13586EZDocument7 pagesWriting Desk: Project 13586EZBSulliNo ratings yet

- U-Bild: Linen ClosetDocument6 pagesU-Bild: Linen ClosetEmilian BalutaNo ratings yet

- Stacking Desk Tray: Project 19874EZDocument4 pagesStacking Desk Tray: Project 19874EZBSulliNo ratings yet

- EZStoolDocument4 pagesEZStoolBSulliNo ratings yet

- U-Bild: China SideboardDocument8 pagesU-Bild: China SideboardEmilian BalutaNo ratings yet

- Dresser PlanDocument11 pagesDresser PlanGsmHelpNo ratings yet

- Early American Step Table: Project 18321EZDocument4 pagesEarly American Step Table: Project 18321EZBSulliNo ratings yet

- Plans: Anel AWDocument11 pagesPlans: Anel AWElysita Macedo SalvadorNo ratings yet

- Porch Swing: Project 16258EZDocument5 pagesPorch Swing: Project 16258EZBSulli100% (1)

- How To Build An Adjustable SawhorseDocument15 pagesHow To Build An Adjustable SawhorseMad Cow100% (1)

- Z3083 CurlymapledesktoporganizerDocument0 pagesZ3083 Curlymapledesktoporganizerroose1No ratings yet

- Chest of Drawers: Project 11819EZDocument7 pagesChest of Drawers: Project 11819EZBSulli100% (1)

- Blanketchest PlanDocument15 pagesBlanketchest PlanGuillermo WeylandNo ratings yet

- Pot Plant StandDocument5 pagesPot Plant Standhjholden100% (1)

- Router Bit Box: Project 20261EZDocument6 pagesRouter Bit Box: Project 20261EZBSulliNo ratings yet

- Shop Workstation: Project 20569EZDocument3 pagesShop Workstation: Project 20569EZBSulliNo ratings yet

- Wall-Hung Telephone Cabinet: Project 11257EZDocument6 pagesWall-Hung Telephone Cabinet: Project 11257EZBSulli100% (1)

- Wall-Hung Telephone Cabinet: Project 11257EZDocument6 pagesWall-Hung Telephone Cabinet: Project 11257EZBSulli100% (1)

- Drill Press Table (X-Y)Document15 pagesDrill Press Table (X-Y)RickNo ratings yet

- Trestle Table and Benches: Project 18444EZDocument5 pagesTrestle Table and Benches: Project 18444EZAndre GaioNo ratings yet

- Cabinet CDDocument5 pagesCabinet CDbehnamin_rahmaniNo ratings yet

- Veneered End Table: Project 17901EZDocument4 pagesVeneered End Table: Project 17901EZBSulliNo ratings yet

- Veneered End Table: Project 17901EZDocument4 pagesVeneered End Table: Project 17901EZBSulliNo ratings yet

- Rolling Toy: Project 19376EZDocument3 pagesRolling Toy: Project 19376EZBSulliNo ratings yet

- DIY Writing DeskDocument7 pagesDIY Writing DeskStephen MooreNo ratings yet

- Wooden Coat Hanger: Project 16474EZDocument3 pagesWooden Coat Hanger: Project 16474EZBSulliNo ratings yet

- Supra 650-750 62-11155 PDFDocument92 pagesSupra 650-750 62-11155 PDFjosh100% (4)

- Country Bench: Project 10307EZDocument8 pagesCountry Bench: Project 10307EZBSulliNo ratings yet

- Pine Cabinet: Project 11142EZDocument5 pagesPine Cabinet: Project 11142EZBSulliNo ratings yet

- U-Bild: Bathroom CabinetDocument7 pagesU-Bild: Bathroom CabinetEmilian BalutaNo ratings yet

- Mantel Clock: © 2012 August Home Publishing CoDocument9 pagesMantel Clock: © 2012 August Home Publishing CoEsequiel Yakueczik100% (1)

- Record and Tape Cabinet: Project 11185EZDocument8 pagesRecord and Tape Cabinet: Project 11185EZBSulliNo ratings yet

- Record and Tape Cabinet: Project 11185EZDocument8 pagesRecord and Tape Cabinet: Project 11185EZBSulliNo ratings yet

- Advanced Drilling Practices - Casing Design PDFDocument92 pagesAdvanced Drilling Practices - Casing Design PDFAnonymous H9n5g3aaCE100% (1)

- Shop Storage PlanDocument7 pagesShop Storage Planiforeman100% (1)

- Design Approval Checklist 2nd Rev.Document3 pagesDesign Approval Checklist 2nd Rev.Daric Tesfaye0% (1)

- Woodworking Plans - Hope ChestDocument6 pagesWoodworking Plans - Hope ChestAhmet Aydogan100% (1)

- Fuzzy Multiple Criteria Decision-Making PDFDocument23 pagesFuzzy Multiple Criteria Decision-Making PDFMilan KolarevicNo ratings yet

- HFSS Radar Cross SectionDocument33 pagesHFSS Radar Cross SectionMohamad SalehNo ratings yet

- Bently PresentationDocument33 pagesBently PresentationWilliam Will Controle WoodwardNo ratings yet

- Building Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeFrom EverandBuilding Outdoor Furniture: Classic Deck, Patio & Garden Projects That Will Last a LifetimeNo ratings yet

- U-Bild: Three-Piece Bedroom SetDocument8 pagesU-Bild: Three-Piece Bedroom SetEmilian BalutaNo ratings yet

- Sony Cfd-s35cp Ver-1.1 SMDocument64 pagesSony Cfd-s35cp Ver-1.1 SMAndrei Cain100% (1)

- Leg Tapering Jig: Project 14585EZDocument5 pagesLeg Tapering Jig: Project 14585EZBSulliNo ratings yet

- Leg Tapering Jig: Project 14585EZDocument5 pagesLeg Tapering Jig: Project 14585EZBSulliNo ratings yet

- Double-Duty Shop Stool: It's All Plywood, and Only Uses A Half SheetDocument11 pagesDouble-Duty Shop Stool: It's All Plywood, and Only Uses A Half SheetDaniel Andres Montanares BustamanteNo ratings yet

- 4 X 4 Off RoaderDocument6 pages4 X 4 Off Roaderhulusi67100% (1)

- AW Extra - Double-Duty Shop StoolDocument15 pagesAW Extra - Double-Duty Shop StoolIlberto FortunaNo ratings yet

- BS 476-1 1953Document27 pagesBS 476-1 1953iask5275No ratings yet

- U-Bild: Lingerie ChestDocument7 pagesU-Bild: Lingerie ChestEmilian BalutaNo ratings yet

- Tool Box - Workshop ToolboxDocument6 pagesTool Box - Workshop ToolboxDaniel Lourenço100% (1)

- U-Bild: ArmoireDocument11 pagesU-Bild: ArmoireEmilian BalutaNo ratings yet

- Welding Complete - Compressed (199-402)Document204 pagesWelding Complete - Compressed (199-402)SergioNo ratings yet

- Child's Settle Table: Project 00000EZDocument5 pagesChild's Settle Table: Project 00000EZagustinrubio7946No ratings yet

- Timber Frame Bird House InstructionsDocument8 pagesTimber Frame Bird House InstructionsBobNo ratings yet

- Box Display BoxDocument6 pagesBox Display BoxMansur NuriNo ratings yet

- U-Bild: Child's ArmoireDocument6 pagesU-Bild: Child's ArmoireEmilian BalutaNo ratings yet

- Box of Shapes Toy: Project 18618EZDocument5 pagesBox of Shapes Toy: Project 18618EZBSulliNo ratings yet

- Green Wall Shelf Popular WoodworkingDocument21 pagesGreen Wall Shelf Popular WoodworkingAdnan HasanovicNo ratings yet

- U-Bild: Hope ChestDocument6 pagesU-Bild: Hope ChestEmilian BalutaNo ratings yet

- Major ProjectDocument5 pagesMajor ProjectGary LavoieNo ratings yet

- Book Case - AnniversaryDocument10 pagesBook Case - AnniversaryCris CondeNo ratings yet

- Book Case - Early American BookcaseDocument7 pagesBook Case - Early American BookcaseCris CondeNo ratings yet

- Drill Press Organizer: Project 20068EZDocument5 pagesDrill Press Organizer: Project 20068EZBSulli100% (1)

- U-Bild: Space-Saver WorkbenchDocument8 pagesU-Bild: Space-Saver WorkbenchEmilian BalutaNo ratings yet

- U-Bild: Curio TableDocument5 pagesU-Bild: Curio TableEmilian BalutaNo ratings yet

- Ez Shaker WashstandDocument7 pagesEz Shaker WashstandBrian-Patty SullivanNo ratings yet

- Rope Whipping SheetDocument6 pagesRope Whipping SheetBSulliNo ratings yet

- Shaker Single Drop Leaf TableDocument6 pagesShaker Single Drop Leaf TableLory Dena HeathNo ratings yet

- Workbench Helper: Project 20518EZDocument3 pagesWorkbench Helper: Project 20518EZBSulliNo ratings yet

- Project 18732EZDocument4 pagesProject 18732EZBSulliNo ratings yet

- Weather Station: Project 14445EZDocument4 pagesWeather Station: Project 14445EZBSulliNo ratings yet

- Carved Walking Stick: Project 16695EZDocument3 pagesCarved Walking Stick: Project 16695EZBSulli100% (2)

- Wooden Combs: Project 16483EZDocument3 pagesWooden Combs: Project 16483EZBSulliNo ratings yet

- EZTenon JigDocument3 pagesEZTenon JigBSulliNo ratings yet

- Valentine Box: Project 10766EZDocument5 pagesValentine Box: Project 10766EZBSulliNo ratings yet

- EZVeneer BraceletDocument3 pagesEZVeneer BraceletBSulliNo ratings yet

- EZTowelbar W Glass ShelfDocument2 pagesEZTowelbar W Glass ShelfBSulliNo ratings yet

- Shaker Sewing TableDocument21 pagesShaker Sewing TableFeng Shu jiNo ratings yet

- Box of Shapes Toy: Project 18618EZDocument5 pagesBox of Shapes Toy: Project 18618EZBSulliNo ratings yet

- EZSalad TongsDocument3 pagesEZSalad TongsBSulliNo ratings yet

- EZRouted BookendsDocument3 pagesEZRouted BookendsBSulliNo ratings yet

- Chapter: 3. Goodwill Methods of Valuation of GoodwillDocument12 pagesChapter: 3. Goodwill Methods of Valuation of GoodwillRizwan AkhtarNo ratings yet

- Mcast TutorialDocument70 pagesMcast TutorialMd.Showkat AlamgirNo ratings yet

- Chapter 9: Targeting Display AdvertisingDocument22 pagesChapter 9: Targeting Display AdvertisingBobanNo ratings yet

- Chapter-3-Large-Scale Path LossDocument87 pagesChapter-3-Large-Scale Path Losszimitaw yibekalNo ratings yet

- 4-Chloroacetanilide A011011001Document2 pages4-Chloroacetanilide A011011001bio88No ratings yet

- Electronics and Communication EngineeringDocument2 pagesElectronics and Communication EngineeringAnu MohapatraNo ratings yet

- Thin Walled PressureDocument10 pagesThin Walled PressureDon MatiasNo ratings yet

- PaintsCoatings - Catalogue - 2023 FormuleDocument19 pagesPaintsCoatings - Catalogue - 2023 FormuleAchour BouchefraNo ratings yet

- CouplingsDocument45 pagesCouplingsLaxminarsimhaswamy Konda50% (2)

- Electric Field HockeyDocument5 pagesElectric Field HockeyMartin Fco EncinasNo ratings yet

- Practical 1 - Solution PDFDocument8 pagesPractical 1 - Solution PDFaniruddhNo ratings yet

- Catalogo RTC-8050 IIDocument2 pagesCatalogo RTC-8050 IISara Sarmiento EcheverryNo ratings yet

- Canon Ir9070 Brochure PDFDocument2 pagesCanon Ir9070 Brochure PDFvijaiNo ratings yet

- Technical Article SSAB Structural Hollow Sections For Functional Design According To Eurocode3Document17 pagesTechnical Article SSAB Structural Hollow Sections For Functional Design According To Eurocode3sharunnizamNo ratings yet

- IR DROP Analysis: Avg AvgDocument7 pagesIR DROP Analysis: Avg AvghardeepNo ratings yet

- 3WA Air Circuit Breakers - Portfolio OverviewDocument2 pages3WA Air Circuit Breakers - Portfolio OverviewKiran KarthikNo ratings yet

- Math 1B03 2022 Spring TermDocument9 pagesMath 1B03 2022 Spring TermzeroNo ratings yet

- NetSim HelpDocument409 pagesNetSim Helppulkit_khandelwal21No ratings yet

- Baking 3Document21 pagesBaking 3rem evangelistaNo ratings yet

- Chapter - 04 Mips Assembly Data PathDocument137 pagesChapter - 04 Mips Assembly Data PathAbubakar sabirNo ratings yet

- MEC 100 CHAPTER 4 (Engineering Estimation & Approximation)Document50 pagesMEC 100 CHAPTER 4 (Engineering Estimation & Approximation)HaFiy HaZimNo ratings yet