Professional Documents

Culture Documents

Project Cycle

Uploaded by

mind2008Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Cycle

Uploaded by

mind2008Copyright:

Available Formats

PROJECT CYCLE

PREPARATION IMPLEMENTATION

PLANNING

COMMISSIONING GESTATION CONSOLIDATION

PLANNING PREPARATION

TECHNOLOGY SELECTION COST BENEFIT FEASIBILITY - DETAILED PROJECT DESIGN & ENGINEERING SCHEDULING CONTRACTING & PURCHASE

IMPLEMENTATION

- CONSTRUCTION PERT CHART CONTINGENCY PLANS MATCHING DIFFERENT PROJECTS

THE PROJECT MANAGER `S ROLE ENDS NOT ONLY WHEN THE PROJECT IS COMPLETED WITHOUT ANY TIME & COST OVERRUN BUT ALSO ONLY WHEN THE RATED PRODUCTION & TECHNOECONOMICS ENVISAGED ARE ATTAINED.

AT SENIOR LEVEL

ORIENT THINKING AND ACTIONS

PROJECT COMPLETION

PROJECT COST

PRODUCTION

PROFIT

PRODUCTIVITY

PROFITABILITY

COMPLETE BUSINESS MANAGER

CONTENTS OF A PROJECT PLAN

The overall Project Plan will consist of the following detailed Plans compiled by the appropriate Departments. ~ PROJECT ENGINEERING PLAN ~ PROJECT ORGANISATION ~ OPERATIONAL PLAN ~ COMMERCIAL PLAN ~ PERSONNEL PLAN ~ MASTER BUDJET ~ CONTRACT POLICY ~ TIME ESTIMATE FOR MAIN ACTIVITIES ~ FINANCIAL EVALUATION

OH

PROJECT PLANNING

THE PROJECT ENGINEERING PLAN

The Project Engineering plan will provide sufficient precise description of the facilities to be constructed so that design (specification writing) and procurement can proceed. THE PLAN SHOULD CONSIST OF:~ DETAILS OF TECHNOLOGY ~ MATERIAL FLOW CHARTS ~SITE PLAN ~ PROCESS SPECIFICATION ~ PROCESS CONTROL SYSTEMS ~QUALITY CONTROL SYSTEMS ~INFORMATION SYSTEMS ~ ENVIRONMENTAL CONTROL ~ SERVICE REQUIREMENTS i.e. WATER, STEAM, COMPRESSED AIR, ~ SITE PREPARATION

OH 2 PROJECT PLANNING

THE PROJECT ORGANISATION

STRUCTURE

Organization chart with names of Senior Managers. i.e. Project Manager, Project Engineer,ProductionManager. Main functions engaged in the project Levels of Authority and areas of responsibility.

USE OF CONSULTANTS

The chosen consultants The role of the consultants

LOCATION OF PROJECT STAFF

Off site On site

PROJECT REVIEW AND CONTROL

System for control of : COST TIME TECHNICAL PERFORMANCE Schedule of regular meetings and reports

OH 3 PROJECT PLANNING

THE OPERATIONAL PLAN

OPERATING STANDARDS OF PERFORMANCE . MANPOWER LEVELS . SPEED OF WORKING . YIELD . QUALITY . DELAYS PRODUCTION,MAINTENANCE . ENERGY CONSUMPTION . ENVIRONMENTAL CONDITIONS . COMPARISION WITH OTHER PLANTS NATIONAL,INTERNATIONAL OPERATING AND MANAGEMENT SYSTEMS .SYSTEMS AND PROCEDURES TO MEET THE ABOVE STANDARDS, ~Production planning systems ~Quality Control Systems ~Maintenance Systems ~Operating and Maintenance Practices MATERIAL FLOW CONTROL SYSTEMS ~SETTING AND CONTROLLING STOCK LEVELS FOR ~ Raw Materials ~Work in progress ~Finished Goods PERSONNEL This is a prime responsibility of Operations Management and is carried out with the Personnel Department. This will be dealt with under the Personnel Plan. CHANGES TO EXISTING PLANT ~IMPACT OF THE NEW PLANT ON EXISTING PLANT OH 4 PROJECT PLANNING

THE COMMERCIAL PLAN

THIS PLAN WILL SET OUT THE COMMERCIAL JUSTIFICATION FOR THE PROJECT. IT SHOULD INCLUDE:DEMAND NATIONAL AND INTERNATIONAL DEMAND SUBSTITUTION OF IMPORTS POSSIBLE EXPORTS FORECASTS OF NATURE OF DEMAND e.g. Size of Order Size of Product ASSUMPTIONS AND EVIDENCE

PRICES FORECASTS OF PRICES FOR HOME AND EXPORTS FORECASTS OF PRICES OF COMPETING MATERIALS ASSUMPTIONS AND EVIDENCE

TERMS AND CONDITIONS OF SALE SPECIAL SALES DISCOUNTS CREDIT TERMS

DISTRIBUTION NUMBER AND LOCATION OF CUSTOMERS METHODS OF DISTRIBUTION Transport Stockyards or Direct to Main Users

OH 5 PROJECT PLANNING

IMPACT ON OTHER PRODUCTS OR PLANTS

THE PERSONNEL PLAN

THE PLAN WILL BE DRAWN UP IN CONJUNCTION WITH THE OPERATIONS DEPARTMENT. IT SHOULD INCLUDE: MANAGEMENT REQUIREMENTS ORGANISATION STRUCTURE AND DEPARTMENTAL BOUNDARIES ANTICIPATED PROBLEMS OF FILLING KEY ROLES PRODUCTION OPERATIVE REQUIREMENTS WORKING PRACTICES FORECAST OF CATEGORIES AND NUMBERS WAGES OF KEY WORKERS ASSESSMENT OF AVAILABILITY CONSTRUCTION OPERATIVES INDICATION OF AVAILABILITY OF CONSTRUCTION WORKERS FACILITIES (ACCOMODATION, TRANSPORT,MEDICAL etc.) TRAINING ASSESSMENT OF TRAINING AND RETRAINING NEEDS TRAINING STRATEGY AND PLAN INDICATION OF TRAINING PROGRAMMES, RANGE AND NUMBER REDEPLOYMENT IMPACT ON EMPLOYMENT AT OTHER PLANTS

OH 6

PROJECT PLANNING

THE MASTER BUDGET

THE MASTER BUDGET SHOWS THE LATEST ESTIMATES OF COSTS FOR ALL ITEMS AND SERVICES TO BE PURCHASED

IT IS ITEMISED UNDER THE FOLLOWING HEADINGS:1. 2. 3. 4. 5. 6. 7. 8. AREAS OF RESPONSIBILITY OF EACH PRINCIPLE MANAGER CATEGORY OF EXPENDITURE e.g. Foundations, structure, Plant CONTRACT CONTRACTOR OTHER COSTS NOT ALLOCATED TO SPECIFIC ITEMS CONTINGENCIES ALLOCATED TO EACH OF THE ABOVE HEADINGS ALLOWANCE FOR INFLATION ALLOCATED TO EACH FORECAST CASH FLOW IN CONJUNCTION WITH TIME ESTIMATES THE MASTER BUDGET PROVIDES THE STANDARD AGAINST WHICH COST IS CONTROLLED

OH 7

PROJECT PLANNING

THE PURPOSE OF A PROJECT PLAN

1. 2. 3. 4. 5. 6.

PROVIDES A BUSINESS APPROACH TO THE PROJECT ENSURES ALL ASPECTS OF THE PROJECT ARE CONSIDERED REDUCES THE RISK OF MAJOR BLUNDERS PROVIDES THE BEST SOLUTION ENSURES DEPARTMENTS WORK TOGETHER FORCES EARLY DECISIONS ON THE WAY IN WHICH THE PROJECT WILL BE MANAGED

OH 8

PROJECT PLANNING

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Self DevelopmentDocument15 pagesSelf Developmentmind2008100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Role of F.line Managers-MT (T)Document5 pagesRole of F.line Managers-MT (T)mind2008No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Project CycleDocument10 pagesProject Cyclemind2008No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Operation Manual CS6 GasDocument17 pagesOperation Manual CS6 Gasmind2008No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Good Morning: I Have Never Met A Man So Ignorant That I Couldn't Learn Something From HimDocument7 pagesGood Morning: I Have Never Met A Man So Ignorant That I Couldn't Learn Something From Himmind2008No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Organisational Excellence and Team Work (H)Document7 pagesOrganisational Excellence and Team Work (H)mind2008No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- SND - Effective SupervisionDocument54 pagesSND - Effective Supervisionmind2008No ratings yet

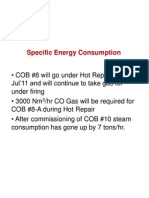

- Specific EnergyDocument1 pageSpecific Energymind2008No ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Planning and OrganizingDocument7 pagesPlanning and Organizingmind2008No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Team Building Skills LeadershipDocument84 pagesTeam Building Skills Leadershipmind2008No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Specific PowerDocument1 pageSpecific Powermind2008No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Organisational Sustainabilty Through Inclusive GrowthDocument44 pagesOrganisational Sustainabilty Through Inclusive Growthmind2008No ratings yet

- Understanding How Teams WorkDocument22 pagesUnderstanding How Teams Workmind2008No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- SND - Men Are From MarsDocument10 pagesSND - Men Are From Marsmind2008No ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team Work (Modified)Document30 pagesTeam Work (Modified)mind2008No ratings yet

- TeAm DevelopmentDocument28 pagesTeAm Developmentmind2008No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- SKPTQP TRGDocument33 pagesSKPTQP TRGmind2008No ratings yet

- Transformational Leadership (ST - Xaviers)Document23 pagesTransformational Leadership (ST - Xaviers)mind2008No ratings yet

- New Rabbit and Tortoise StoryDocument31 pagesNew Rabbit and Tortoise StoryAbd Rahman IbrahimNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Understanding ChangeDocument32 pagesUnderstanding Changemind2008100% (1)

- The StructureDocument5 pagesThe Structuremind2008No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- What's EmotionsDocument9 pagesWhat's Emotionsmind2008No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Practice of MentoringDocument27 pagesThe Practice of Mentoringmind2008No ratings yet

- University Educational System in The USADocument21 pagesUniversity Educational System in The USAmind2008No ratings yet

- Transformational Leadership: Manager To Leader A Paradigm ShiftDocument23 pagesTransformational Leadership: Manager To Leader A Paradigm Shiftmind2008No ratings yet

- Transformational Leadership: Manager To Leader A Paradigm ShiftDocument20 pagesTransformational Leadership: Manager To Leader A Paradigm Shiftmind2008No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Why MentoringDocument26 pagesWhy Mentoringmind2008No ratings yet

- Transformational Leadership: Manager To Leader A Paradigm ShiftDocument25 pagesTransformational Leadership: Manager To Leader A Paradigm Shiftmind2008No ratings yet

- Anup Kumar 9 Jan, 2010Document29 pagesAnup Kumar 9 Jan, 2010mind2008No ratings yet

- Good Morning: I Have Never Met A Man So Ignorant That I Couldn't Learn Something From HimDocument7 pagesGood Morning: I Have Never Met A Man So Ignorant That I Couldn't Learn Something From Himmind2008No ratings yet

- Plan Procurement ManagementDocument24 pagesPlan Procurement Managementsherif9ahmed9sabriNo ratings yet

- Break-Even Analysis Guide for ManagersDocument8 pagesBreak-Even Analysis Guide for ManagersParamartha BanerjeeNo ratings yet

- The Role of Financial System in The EconomyDocument15 pagesThe Role of Financial System in The Economymubarek100% (2)

- RyanAir Stakeholder AnalysisDocument2 pagesRyanAir Stakeholder AnalysisVishal Chaudhari100% (1)

- Key ProblemsDocument2 pagesKey Problemsnino laoshvili0% (1)

- Marketing Research on Spacewood's Customer EfficiencyDocument21 pagesMarketing Research on Spacewood's Customer EfficiencydacchuNo ratings yet

- Marketing Aspects of a Proposed Body Massage and SpaDocument24 pagesMarketing Aspects of a Proposed Body Massage and SpaTokZhit50% (2)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- RevistaDocument92 pagesRevistaIgnacio MarinNo ratings yet

- RBVDocument3 pagesRBVSam Gitonga100% (1)

- RetailDocument67 pagesRetailretailer72No ratings yet

- Music IndustryDocument2 pagesMusic IndustryAlwynBaloCruz0% (1)

- Supply Chain Management: An International Journal: Article InformationDocument10 pagesSupply Chain Management: An International Journal: Article InformationEsthefany Galvez - F1 ServicesNo ratings yet

- Abstract vs Executive Summary: The Key DifferencesDocument2 pagesAbstract vs Executive Summary: The Key DifferencesVishal RamnarineNo ratings yet

- Risk Passage and Insurance in CIF and FOB ContractsDocument19 pagesRisk Passage and Insurance in CIF and FOB ContractsSumukh SharmaNo ratings yet

- My Bussiness PlanDocument9 pagesMy Bussiness PlanMasaba Denis Maden100% (1)

- Products Liability Policy Summary (35Document21 pagesProducts Liability Policy Summary (35Aman DivyaNo ratings yet

- Accounting For Home Office, Branch and AgencyDocument17 pagesAccounting For Home Office, Branch and AgencyTrace ReyesNo ratings yet

- VP Senior Director Integrated Marketing in New York City Resume Stephen McMasterDocument2 pagesVP Senior Director Integrated Marketing in New York City Resume Stephen McMasterStephenMcMasterNo ratings yet

- International Trade Law-SlidesDocument21 pagesInternational Trade Law-SlidesReshan Saranga WediwardanaNo ratings yet

- Marketing PlanDocument6 pagesMarketing PlanClaire M. LegaspiNo ratings yet

- Pre Sales Consultant Australia Epsilon DEP 05022009Document3 pagesPre Sales Consultant Australia Epsilon DEP 05022009samNo ratings yet

- Understanding The Startup Funding Game DraftDocument19 pagesUnderstanding The Startup Funding Game DraftkasmodiaNo ratings yet

- Levis Jeans - Satisfaction LevelsDocument30 pagesLevis Jeans - Satisfaction Levelsagoyal88No ratings yet

- 3 - Noynay Vs Citihomes Builder (MACEDA)Document7 pages3 - Noynay Vs Citihomes Builder (MACEDA)Sansa StarkNo ratings yet

- Stategic Mgt. Unit - 1Document33 pagesStategic Mgt. Unit - 1Kiran S RaoNo ratings yet

- HRM AssignmentDocument4 pagesHRM AssignmentJhankriti100% (1)

- Harley-Davidson Case Study Explores Strategy and Global ReachDocument11 pagesHarley-Davidson Case Study Explores Strategy and Global ReachBao Ngoc NguyenNo ratings yet

- Lavnotes Sales Civil Law: I. A. Definition of Sale - Art. 1458Document24 pagesLavnotes Sales Civil Law: I. A. Definition of Sale - Art. 1458Leizl Aldave VillapandoNo ratings yet

- Full Text 01Document50 pagesFull Text 01Adam KhaleelNo ratings yet

- Aptitude Booklet2Document25 pagesAptitude Booklet2Rahul DragoonNo ratings yet

- Waiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterFrom EverandWaiter Rant: Thanks for the Tip—Confessions of a Cynical WaiterRating: 3.5 out of 5 stars3.5/5 (487)

- The PARA Method: Simplify, Organize, and Master Your Digital LifeFrom EverandThe PARA Method: Simplify, Organize, and Master Your Digital LifeRating: 5 out of 5 stars5/5 (36)

- The United States of Beer: A Freewheeling History of the All-American DrinkFrom EverandThe United States of Beer: A Freewheeling History of the All-American DrinkRating: 4 out of 5 stars4/5 (7)

- Vulture Capitalism: Corporate Crimes, Backdoor Bailouts, and the Death of FreedomFrom EverandVulture Capitalism: Corporate Crimes, Backdoor Bailouts, and the Death of FreedomNo ratings yet