Professional Documents

Culture Documents

BS EN 25817 Level B

Uploaded by

Mohammed NazeerOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BS EN 25817 Level B

Uploaded by

Mohammed NazeerCopyright:

Available Formats

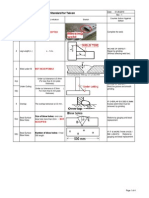

SURFACE IMPERFECTION 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 Crack Crater Crack Surface Pore End Crater Pipe Lack of Fusion (Incomplete Fusion) Incomplete

Root Penetration Continous undercut Intermittent undercut Shrinkage Groove t = 0.5 to 3 mm Shrinkage Groove t > 3 mm Excess Weld Metal Excessive convexity (Fillet weld) Excess Penetration t = 0.5 to 3 mm Excess Penetration t > 3 mm Incorrect weld toe Overlap Sagging incompletely filled grove t = 0.5 to 3 mm Sagging incompletely filled grove t > 3 mm Burn through Excessive asymmetry of Fillet Weld (excessive unequal length) Root concavity t = 0.5 to 3 mm Root concavity t > 3 mm Root Porosity Poor Restart Insufficient throat thickness Excessive throat thickness Stray arc Spatter

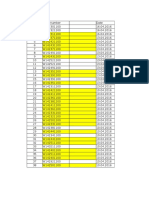

BS EN 25817 Level B Not permitted Not permitted Not permitted Not permitted Not permitted Not permitted Not permitted h 0.05t, but max. 0.5 mm Not permitted Short imperfection h 0.05t, but max. 0.5 mm h 1 mm + 0.1 b , but max. 5 mm h 1 mm + 0.1 b , but max. 3 mm h 1 mm + 0.1 b h 1 mm + 0.2 b , but max. 3 mm a 150 Not permitted Not permitted Short imperfection h 0.05t, but max. 0.5 mm Not permitted

h 1.5 mm + 0.15 a Not permitted Short imperfection h 0.05t, but max. 0.5 mm Not permitted Not permitted Not permitted h 1 mm + 0.15 a, but max. 3 mm Not permitted Accepteance sepends on application

ASME SEC IX

0.05t, but max. 0.5 mm

rt imperfection h 0.05t, but max. 0.5 mm 1 mm + 0.1 b , but max. h 1.5 mm + 0.15 a 5 mm 1 mm + 0.1 b , but max. 3 mm

1 mm + 0.2 b , but max. 3 mm

rt imperfection h 0.05t, but max. 0.5 mm

rt imperfection h 0.05t, but max. 0.5 mm

1 mm + 0.15 a, but max. 3 mm

epteance sepends on application

You might also like

- Limits For Imperfections ISO 5817Document2 pagesLimits For Imperfections ISO 5817tudorteuNo ratings yet

- Weld Imperfection Examination StandardDocument4 pagesWeld Imperfection Examination StandardMohd Akmal ShafieNo ratings yet

- Line Pipe Is (Tolerance)Document4 pagesLine Pipe Is (Tolerance)Mani MaranNo ratings yet

- Quality Level BDocument17 pagesQuality Level BUgonnaNo ratings yet

- Hot TolDocument2 pagesHot Toljdsa123No ratings yet

- Quality Level CDocument17 pagesQuality Level CUgonnaNo ratings yet

- ASTM-530 ToleranceDocument1 pageASTM-530 TolerancesasmayaNo ratings yet

- Welding and piping inspection criteriaDocument1 pageWelding and piping inspection criteriaAdisak Aumpiem0% (1)

- ASME Section VIII radiographic weld acceptance standardsDocument2 pagesASME Section VIII radiographic weld acceptance standardsAkhtarcmti1342No ratings yet

- Weld Acceptance CriteriaDocument14 pagesWeld Acceptance Criteria0502raviNo ratings yet

- Thickness Tolerance of API 5L ASTM A53 EN10219 StandardDocument2 pagesThickness Tolerance of API 5L ASTM A53 EN10219 StandardhungNo ratings yet

- Acceptance Criteria for Pipe WeldsDocument2 pagesAcceptance Criteria for Pipe WeldsMichael CovillNo ratings yet

- Polyethylene Pipes WeldingDocument5 pagesPolyethylene Pipes WeldinglfpachecoNo ratings yet

- BS en ISO 5817 2014 Welding. Fusion-Welded Joints (Beam Welding Excluded) - Quality Levels For Imperfections Ref OnlyDocument20 pagesBS en ISO 5817 2014 Welding. Fusion-Welded Joints (Beam Welding Excluded) - Quality Levels For Imperfections Ref Onlyshaggeruk86% (7)

- ASTM A108 TolerancesDocument9 pagesASTM A108 TolerancesJosh ByronNo ratings yet

- Pipe TolerancesDocument1 pagePipe TolerancesKotu KotNo ratings yet

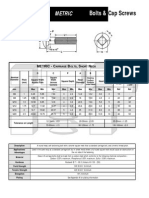

- Metric Carriage ShortneckDocument1 pageMetric Carriage ShortneckStefan StereaNo ratings yet

- Welding Standard Tolerances GuideDocument2 pagesWelding Standard Tolerances GuidewahyuNo ratings yet

- BS EN ISO 5817 2014 Welding. Fusion-Welded Joints (Beam Welding Excluded) - Quality Levels For ImperfectionsDocument18 pagesBS EN ISO 5817 2014 Welding. Fusion-Welded Joints (Beam Welding Excluded) - Quality Levels For ImperfectionsIan WNo ratings yet

- Tds Yieh 6082 Profile SheetDocument6 pagesTds Yieh 6082 Profile SheetRonnalyn TorresNo ratings yet

- ASTM A709-04aDocument1 pageASTM A709-04aSoowhan JungNo ratings yet

- Penthor 964: External StandardDocument2 pagesPenthor 964: External StandardAnjani kumarNo ratings yet

- Jis G4051Document7 pagesJis G4051tnchsgNo ratings yet

- NDT-Acceptance Various CodesDocument17 pagesNDT-Acceptance Various CodesShanmuga NavaneethanNo ratings yet

- ISO 5817 - Welds Acceptance CriteriaDocument45 pagesISO 5817 - Welds Acceptance Criteriaaravindan77% (22)

- Tamano de Catetos - Aws D1.1 PDFDocument1 pageTamano de Catetos - Aws D1.1 PDFAngelTinocoNo ratings yet

- 2tr-Fe Engine MechanicalDocument4 pages2tr-Fe Engine MechanicalPaul Velásquez71% (17)

- H Beam STDDocument2 pagesH Beam STDPamungkasNo ratings yet

- Radiographictesting Acceptance Standard Asme Section ViiiDocument1 pageRadiographictesting Acceptance Standard Asme Section ViiiAkhtarcmti1342No ratings yet

- ASME SEC VIII DIV-1 RT CriteriaDocument4 pagesASME SEC VIII DIV-1 RT CriteriaBALA CHANDAR M100% (1)

- Subject: Design: CHD: Client:: One-WayDocument3 pagesSubject: Design: CHD: Client:: One-WayIlmtalabNo ratings yet

- Bulb Flats Dimensions GuideDocument11 pagesBulb Flats Dimensions GuideMd. Rafique HassanNo ratings yet

- Reaming ToleranceDocument2 pagesReaming Tolerancetanha56313955100% (1)

- En 1090 2 Ex3 PDFDocument1 pageEn 1090 2 Ex3 PDFlai nguyenNo ratings yet

- c85 Spring Steel SheetDocument3 pagesc85 Spring Steel SheetariNo ratings yet

- Metric Hex Bolts ISO 4014Document2 pagesMetric Hex Bolts ISO 4014sroenschNo ratings yet

- Visual Inspection Acceptance CriteriaDocument2 pagesVisual Inspection Acceptance CriteriaJohn TerryNo ratings yet

- A500 Spec PDFDocument2 pagesA500 Spec PDFUgur SenNo ratings yet

- A500 Spec SheetDocument2 pagesA500 Spec SheetMikku KattaNo ratings yet

- ASTM A312 2014 Specification For Seamless and Welded Austenitic Stainless Steel Pipe PDFDocument4 pagesASTM A312 2014 Specification For Seamless and Welded Austenitic Stainless Steel Pipe PDFanon_295291420No ratings yet

- TWI Training CSWIP 3.1 PlateDocument8 pagesTWI Training CSWIP 3.1 PlateSepthian DS100% (2)

- Weld Defect Acceptance Criteria by CodesDocument17 pagesWeld Defect Acceptance Criteria by CodesMidhun K Chandrabose96% (24)

- Product Style OgiDocument2 pagesProduct Style OgiarianaseriNo ratings yet

- Pipe Dimension and Wall Thickness Testing RequirementsDocument1 pagePipe Dimension and Wall Thickness Testing RequirementsJèfrì PìnémNo ratings yet

- Datasheet Spring Steel Strip 1Document3 pagesDatasheet Spring Steel Strip 1vaishu1502100% (1)

- Comparison of Steel GradesDocument3 pagesComparison of Steel GradesUsama AhmedNo ratings yet

- Welding Standard Ver1Document4 pagesWelding Standard Ver1Sowmen ChakrobortyNo ratings yet

- Sieve-Tray Tower Design and Operation PrinciplesDocument61 pagesSieve-Tray Tower Design and Operation PrinciplesM.H vafaeiNo ratings yet

- WSG (KR) - ASME - BPEDocument35 pagesWSG (KR) - ASME - BPEThomas C. Lane100% (1)

- Linotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeFrom EverandLinotype Manual: Giving Detailed Instructions of the Proper Adjustment and Care of the LinotypeNo ratings yet

- U.S. ALLOY CO. Superflow Brazing Selection ChartDocument1 pageU.S. ALLOY CO. Superflow Brazing Selection ChartMohammed NazeerNo ratings yet

- Book 1Document2 pagesBook 1Mohammed NazeerNo ratings yet

- Tank RT Status in Length BasisDocument4 pagesTank RT Status in Length BasisMohammed NazeerNo ratings yet

- Opper Alloy No. Temper Astm B111 C44300 Hsn70-1 O61 Astm B111 C68700 Hai77-2 Astm B111 C70600 Bf210-1-1 O61 H55 Astm B111 C71500 Bfe30-1-1 O61 Hr55Document8 pagesOpper Alloy No. Temper Astm B111 C44300 Hsn70-1 O61 Astm B111 C68700 Hai77-2 Astm B111 C70600 Bf210-1-1 O61 H55 Astm B111 C71500 Bfe30-1-1 O61 Hr55Mohammed NazeerNo ratings yet

- Opper Alloy No. Temper Astm B111 C44300 Hsn70-1 O61 Astm B111 C68700 Hai77-2 Astm B111 C70600 Bf210-1-1 O61 H55 Astm B111 C71500 Bfe30-1-1 O61 Hr55Document8 pagesOpper Alloy No. Temper Astm B111 C44300 Hsn70-1 O61 Astm B111 C68700 Hai77-2 Astm B111 C70600 Bf210-1-1 O61 H55 Astm B111 C71500 Bfe30-1-1 O61 Hr55Mohammed NazeerNo ratings yet

- Tank Thick DetailsDocument16 pagesTank Thick DetailsMohammed NazeerNo ratings yet

- Interpretations 24 B31.3Document13 pagesInterpretations 24 B31.3jensdcvNo ratings yet

- Welding BrassDocument5 pagesWelding BrassMohammed NazeerNo ratings yet

- Plate Chemical Analysis ValueDocument6 pagesPlate Chemical Analysis ValueMohammed NazeerNo ratings yet

- Kpi RfiDocument1 pageKpi RfiMohammed NazeerNo ratings yet

- CS - PQR Qualification Schedule - Rev.00Document4 pagesCS - PQR Qualification Schedule - Rev.00Mohammed NazeerNo ratings yet

- Opper Alloy No. Temper Astm B111 C44300 Hsn70-1 O61 Astm B111 C68700 Hai77-2 Astm B111 C70600 Bf210-1-1 O61 H55 Astm B111 C71500 Bfe30-1-1 O61 Hr55Document8 pagesOpper Alloy No. Temper Astm B111 C44300 Hsn70-1 O61 Astm B111 C68700 Hai77-2 Astm B111 C70600 Bf210-1-1 O61 H55 Astm B111 C71500 Bfe30-1-1 O61 Hr55Mohammed NazeerNo ratings yet

- Userguide en SONY SBH52Document14 pagesUserguide en SONY SBH52PaspargiliusNo ratings yet

- Sliver Defects On Low Carbon Steels, Cold Rolled StripsDocument5 pagesSliver Defects On Low Carbon Steels, Cold Rolled StripsMohammed NazeerNo ratings yet

- Weld Defects and DiscontinuitiesDocument78 pagesWeld Defects and DiscontinuitiesGilbert MendozaNo ratings yet

- 6GR WPS PQRDocument15 pages6GR WPS PQRMohammed NazeerNo ratings yet

- Weld Joint Geometry and Weld Symbols: Parts of A Weld Joint Welding Technology Lee Co. ATC Graphics Compliments of AWSDocument9 pagesWeld Joint Geometry and Weld Symbols: Parts of A Weld Joint Welding Technology Lee Co. ATC Graphics Compliments of AWSMohammed NazeerNo ratings yet

- Child NamesDocument34 pagesChild NamesMohammed NazeerNo ratings yet

- Javeed CVDocument3 pagesJaveed CVMohammed NazeerNo ratings yet

- Userguide en SONY SBH52Document14 pagesUserguide en SONY SBH52PaspargiliusNo ratings yet

- Acceptance - Standards Visual TestingDocument1 pageAcceptance - Standards Visual TestingAhmed GomaaNo ratings yet

- 0395 WPQT Programme 070 Rev 0Document1 page0395 WPQT Programme 070 Rev 0Mohammed NazeerNo ratings yet

- ASME SECTION IX INTERPRETATIONSDocument77 pagesASME SECTION IX INTERPRETATIONSहेमंत कुमार मीणाNo ratings yet

- Cwi Fun 1Document7 pagesCwi Fun 1Amirtha Thiyagaraajan Alagesan100% (1)

- Finish WRDocument2 pagesFinish WRTejinder KumarNo ratings yet

- Annex C: EN1504 and Other European Standards Relevant To Concrete Repair and ProtectionDocument12 pagesAnnex C: EN1504 and Other European Standards Relevant To Concrete Repair and ProtectionLjiljana MiskovicNo ratings yet

- PETA SEBARAN REKOMENDASI PENGANGKUTAN LIMBAH B3Document118 pagesPETA SEBARAN REKOMENDASI PENGANGKUTAN LIMBAH B3Dimas Dwi Ivandri 2No ratings yet

- Floor DiaphragmDocument24 pagesFloor DiaphragmChristian LeobreraNo ratings yet

- Steel BS 5950Document26 pagesSteel BS 5950Rodain NajjarNo ratings yet

- Design Recommendations for Screw Machine ProductsDocument23 pagesDesign Recommendations for Screw Machine Productsashwin josephNo ratings yet

- Evalene HDPE Grade SlateDocument1 pageEvalene HDPE Grade Slatepalani.djpNo ratings yet

- Post TreatmentDocument23 pagesPost TreatmentVishnu VardhanNo ratings yet

- B Esimating 10-22Document13 pagesB Esimating 10-22Mursaleen BawarNo ratings yet

- Dezurik Eccentric Plug Valves Pec Pef 12 3 Pec Eccentric Plug Valves Technical 12-00-1bDocument12 pagesDezurik Eccentric Plug Valves Pec Pef 12 3 Pec Eccentric Plug Valves Technical 12-00-1bOleg ShkolnikNo ratings yet

- House - Contract AgreementDocument5 pagesHouse - Contract Agreementshashikiran divateNo ratings yet

- Pre-Engineered Buildings PDFDocument21 pagesPre-Engineered Buildings PDFlakshmidileepNo ratings yet

- ARP 107-6001 Mitsubishi Torque SpecsDocument1 pageARP 107-6001 Mitsubishi Torque SpecsJohnTexeiraNo ratings yet

- Plastid RainDocument8 pagesPlastid Rainkkppkk1No ratings yet

- Use of Waste Plastic in Concrete Mixture As Aggregate ReplacementDocument4 pagesUse of Waste Plastic in Concrete Mixture As Aggregate ReplacementIJAERS JOURNALNo ratings yet

- Lecture 7 Portland CementDocument13 pagesLecture 7 Portland Cementsalil dubeyNo ratings yet

- Catalogue Indium CorporationDocument5 pagesCatalogue Indium CorporationPhilippe GuillemetNo ratings yet

- Additives: Civil Engineering Materials 267Document10 pagesAdditives: Civil Engineering Materials 267CalvinhaoweiNo ratings yet

- Effects of Sugarcane Bagasse Ash on Strength of ConcreteDocument61 pagesEffects of Sugarcane Bagasse Ash on Strength of ConcreteKaushiki KambojNo ratings yet

- Chapter 1 - Loading, Unloading, Carriage & Setting Out: Item No. Unit Rate (RS.) DescriptionDocument38 pagesChapter 1 - Loading, Unloading, Carriage & Setting Out: Item No. Unit Rate (RS.) DescriptionAbhijeet SahuNo ratings yet

- Lock Forming MachineDocument5 pagesLock Forming MachineIBRAHIM AL-SURAIHINo ratings yet

- STONE MASONRY RATESDocument13 pagesSTONE MASONRY RATESAkhlaq HussainNo ratings yet

- Alkali Aggregate Reaction, Alkali Carbonate Reaction and Pyrite AttackDocument3 pagesAlkali Aggregate Reaction, Alkali Carbonate Reaction and Pyrite AttackVasanthapragash NadarajhaNo ratings yet

- F 1789 - 04Document11 pagesF 1789 - 04LuisNo ratings yet

- ASME B31.3 Nonmetallic Piping Course Covers ThermoplasticsDocument26 pagesASME B31.3 Nonmetallic Piping Course Covers ThermoplasticsSutarto AbutamisNo ratings yet

- Bell Type Packoff: B & T Oilfield Products Wireline Product CatalogDocument5 pagesBell Type Packoff: B & T Oilfield Products Wireline Product CatalogaminoNo ratings yet

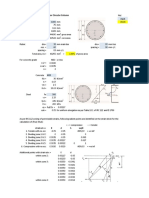

- Design PM Interaction Curve For Circular ColumnDocument3 pagesDesign PM Interaction Curve For Circular ColumnPoshan DhunganaNo ratings yet

- Hot Weather Concreting GuideDocument4 pagesHot Weather Concreting GuideHazem EmamNo ratings yet

- Power-Free Turbine Ventilator: Eagle Steel Roof Truss SystemDocument2 pagesPower-Free Turbine Ventilator: Eagle Steel Roof Truss SystemWeilong LokNo ratings yet

- SpecsDocument16 pagesSpecsLea Ann BellenNo ratings yet