Professional Documents

Culture Documents

MANICA BOARDS and DOORS Tawanda Report On Boiler Final

Uploaded by

Robin BushuOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MANICA BOARDS and DOORS Tawanda Report On Boiler Final

Uploaded by

Robin BushuCopyright:

Available Formats

MANICA BOARDS AND DOORS (MBD) Pvt Ltd

To: Cc: From: Date: Mr. G. T. Zindove Mr. S Mukwamba, Mr. Saungweme, Mr. C Nyamugure Mr. Tawanda Bushu (Chemical and Processing System Engineering Attach). 7 February 2012

REF: REPORT ON THE BOILER

1.0 INTRODUCTION A boiler is a heat exchanger that converts chemical energy in fuel to heat energy under controlled conditions, for the purpose of generating steam. The boiler section is one of the sections of critical importance in the fiber board production as its operations affect the whole process of fibreboard manufacture. The main objective of the boiler section is to provide a steady and constant supply of steam at all times. All this has to happen within the statutes and parameters that govern the operation of boilers.

2.0 THE BOILER AND ITS SUPPORTIVE ANCILLARY SYSTEMS.

Fig1.1 boiler and its ancillary systems.

Fig 1.1 shows what goes into the boiler and what comes out and it is imperative that each aspect of that system is working in order.

2.1 BOILER. The type of boiler used at MBD is a Composite Boiler. It consists of a fire-tube boiler and a John Thompson Chaingrate Stoker (Stoker). A fire-tube boiler is a type of boiler in which hot gases from a fire pass through one or more tubes running through a sealed container of water. The heat of the gases is transferred through the walls of the tubes by thermal conduction, heating the water and ultimately creating steam. The heat source is inside a furnace or in this case it is the John Thompson Chaingrate Stoker that has to be kept permanently surrounded by the water in order to maintain the temperature of the heating surface just below boiling point. (Specifications of boiler found in appendix)

2.2 AIR SUPPLY Air is drawn in by forced draft fans (FD) which blow onto the feed stocker which will be carrying burning coal. The volume of feed air is controlled by (FD) dampers but the speed of the inlet air is constant. Secondary (FD) fans also blow onto the stocker to assist in the combustion of coal. The heated air is then drawn by a large Induced fan (ID) into fire tubes on the second section of the boiler. The hot air which in this case is now called flue gas is further drawn into a grit arrester which in practice is a centrifugal separator to separate grit from the flue gases. The grit is then collected at the bottom section and the lighter gases then goes into the chimney where they are discharged into the atmosphere.

2.3 BOILER WATER SUPPLY AND PURIFICATION SYSTEM. 2.3.1 INTRODUCTION The water supply system must achieve the following. Constant supply of safe make up water for the boiler. Prevention of corrosion from taking place at all cost or at list keeping it at the lowest possible level. Prevention of formation of scale and scum in the boiler.

The system is represented by the flow chart shown below. The water used in the Boiler at MBD is sourced from the Mutare City Council. The water is first stored in reservoir tanks then pumped to storage tanks through pipes with strainers to remove suspended solids in the water. This is the first operation of boiler water treatment. From the storage tanks water is pumped to the water softeners. From the softeners, water is pumped to 2 treated water storage tanks. Water from these treated water tanks is fed to the de aerator were it is scrubbed off the dissolved oxygen in water. Water from the de-aerator is the again treated with dosing chemicals from the dosing plant en-route to the boiler where steam is generated in a composite boiler.

Key: A main reservoir B storage tanks (2) C, D softeners E, F storage tanks G dosing tank H, I de-aerator water pumps (2) J de-aerator

K, L feed water pumps (2) M boiler Fig 1.2 flow chart showing feed water system.

2.3.2 WATER TREATMENT

At (MBD) the chemical laboratory department is the one responsible for caring out all the tests and analysis of the boiler water. The water is supposed to be tested on two hour intervals .In the event that there is a large deviation from the normal average then tests are carried out on hourly interval and a corrective measure is taken in each case until the anomaly is rectified. Boiler water has certain specifications that it should meet for it to be used in the boiler.

Table 1.1 boiler water specifications BOILER WATER TOTAL HARDNESS(TH) TOTAL DISOLVED SUBSTANCES(TDS) Ph PHOSPATE SULPHATE CHLORIDE OH IRON More than 10.5 30-90ppm 30-90ppm 800ppm 250-600ppm 0-5ppm 2000-3000ppm SPECIFICATIONS NIL

These measurements are critical for the operations of a boiler. Below the different aspects that are found in water are defined and how they might affect our boiler.

2.3.2.1 DISSOLVED SOLIDS These are substances that will dissolve in water. The principal ones are the carbonates and sulphates of calcium and magnesium, Effects: 1. Scale-forming when heated which reducing heat transfer and the effectiveness of the boiler it can also causing over heating of pipes and eventually the pipes end up bursting.

2.

Forming and scum formation which can lead to carry overs, damaging of the steam pipes by water hammers and lowering the steam quality by producing wet steam.

2.3.2.2 SUSPENDED SOLIDS These are substances that exist in water as suspended particles. They are usually mineral, or organic in origin. These substances are not generally a problem as they can be filtered out. In the case of (MDB) strainers are inserted along the pipe lines to trap all suspended solids before the feed water goes into the boiler. Effects: 1. The effects of suspended solids are the same to those of dissolved solid with the addition that they damage control valves and heat exchange systems

2.3.2.3 DISSOLVED GASES Oxygen and carbon dioxide can be readily dissolved by water. Effects: 1. These gases are aggressive instigators of corrosion. According to the design at (MBD) the amount of oxygen going into the boiler is supposed to be substantially reduced by the de-aerator.

2.3.2.4 SCUM FORMING SUBSTANCES These are mineral impurities that foam or scum. One example is soda in the form of a carbonate, chloride, or sulphate. Effects: 1. Scum can cause carry-over of suspended solids which has the same negative effects as those of suspended solids. 2.3.2.5 HARDNESS Water is referred to as being either 'hard' or 'soft'. Hard water contains scale-forming impurities while soft water contains little or none. Hardness is caused by the presence of the mineral salts of calcium and magnesium and it is these same minerals that encourage the formation of scale. There are two common classifications of hardness: 1. Alkaline hardness (also known as temporary hardness) - Calcium and magnesium bicarbonates are responsible for alkaline hardness. The salts dissolve in water to form an alkaline solution. When heat is applied, they decompose to release carbon dioxide and soft scale or sludge. Alkaline or temporary hardness.

2. Non-alkaline hardness and carbonates (also known as permanent hardness) - This is also due to the presence of the salts of calcium and magnesium but in the form of sulphates and chlorides. These precipitate out of solution, due to their reduced solubility as the temperature rises, and form hard scale, which is difficult to remove. The purpose of the softener is to remove this hardness. In addition, the presence of silica in boiler water can also lead to hard scale, which can react with calcium and magnesium salts to form silicates which can severely inhibit heat transfer across the fire tubes and cause them to overheat.

2.3.2.6 TOTAL HARDNESS Total hardness is not to be classified as a type of hardness, but as the sum of concentrations of calcium and magnesium ions present when these are both expressed as CaCO3. If the water is alkaline, a proportion of this hardness, equal in magnitude to the total alkalinity and also expressed as CaCO3, is considered as alkaline hardness, and the remainder as non-alkaline hardness

\ 2.3.2.7 NON-SCALE FORMING SALTS Non-hardness salts, such as sodium salts are also present, and are far more soluble than the salts of calcium or magnesium and will not generally form scale on the surfaces of a boiler

2.3.2.8 pH VALUE This is a numerical value representing the potential hydrogen content of water - which is a measure of the acidic or alkaline nature of the water. Acids and alkalis have the effect of increasing the conductivity of water above that of a neutral sample. For example, a sample of water with a pH value of 12 will have a higher conductivity than a sample that has a pH value of 7.Effects: 1. If the pH value is low then the feed water will be highly corrosive and can not be tolerated. 2. If pH is high say its 13 then it cause corrosion again in the form of crack corrosion.

It is therefore very crucial to make sure that the water is treated so as to avoid the above mentioned problems. To achieve the above specifications water from the city council goes through a number of stages so as to meet the above stages. The water is suppose to firstly pass through softeners to reduce its hardness but currently the water softeners are not working, this is then followed by deaeration by a de-aerator which is functioning and lastly trough chemical treatment.

2.4 WATER SOFTENING At MBD water softening was achieved by using resin softeners to remove hardness of water. Hard water has high concentrations of Ca2+ and Mg2+ ions in form of salts that encourage the formation of scale (fouling). Technical specifications of softeners found in appendix.Water flows into the softener from the top making a fine spray on top of the resins. The magnesium and calcium ions in the water are adsorbed on the surface of the resin and sodium ions are released into the water. In principal this is basically the softening process. The softening action continues until the ion exchange material contains no more sodium which can be exchanged for calcium and magnesium.

After 24 hours the resins becomes saturated with impurities and needs to be regenerated. The regeneration takes place in four stages that are given below. The whole regeneration process takes an average of 1 hour 30 minutes. Backwash stage This is the first stage in the regeneration process. Water enters the softener in a reverse direction all the impurities that are trapped in the softener are washed out buy this reverse flow into the drain Sodium injection Brine which is sodium chloride solution is pumped into the softener. Sodium ions are adsorbed on the surface of the resin at the same time magnesium and calcium ions are discharged into solution the solution. This is preferential adsorption. During this stage no water enters the softener. Fast rinse Water enters the softener in the normal way and the calcium and magnesium ions in the solution are then washed out into the drain. Slow rinse. This time water enter into the softener with a very slow rate all the calcium and magnesium ions are then washed away and the softener is now ready for use .MBD had two softeners so that during the regeneration of one softener the other softener will be working but at present none is functioning.

From the softeners the water goes to the water storage tanks. The storage tanks have a glass water level indicator and must be kept full at all times. In the storage tank EDITA is added as an ant-scelent. From the storage tanks water goes into the de- aerator.

2.5 THE DE-AERATOR De-aeration is based on two scientific principles. The first principle can be described by Henry's Law. Henry's Law asserts that gas solubility in a solution decreases as the gas partial pressure above the solution decreases. The second scientific principle that governs de-aeration is the relationship between gas solubility and temperature. Easily explained, gas

solubility in a solution decreases as the temperature of the solution rises and approaches saturation temperature. A de-aerator utilizes both of these natural processes to remove dissolved oxygen, carbon dioxide, and other non-condensable gases from boiler feedwater. This process can be classified as a unit operation called scrubbing. The feedwater is sprayed in thin films into a steam atmosphere allowing it to become quickly heated to saturation. Spraying feedwater in thin films increases the surface area of the liquid in contact with the steam, which, in turn, provides more rapid oxygen removal and lower gas concentrations. This process reduces the solubility of all dissolved gases and removes it from the feedwater. The liberated gases are then vented from the de-aerator. The de-aerator saves two purposes 1. To remove dissolved gases in the boiler feed water. 2. To raise the temperature of the feed water to a temperature of about 750 C Reasons: Dissolved gases lead to corrosion of the boiler. Dissolve gasses can accumulate in the steam section of the boiler forming bubbles. To avoid heat stress in the boiler so as to avoid thermal stress failure in the boiler. To increases solubility of dosing chemicals. To save energy during steam production since the water will be at elevated temperatures already.

The de-aerator that is being used uses scrubbing mechanism. The diagram below shows how this process works

Water from the storage tanks is pumped into the de-aerator. The de-aerator has a control valve and a pressure gauge to regulate the rate at which the water goes into the de-aerator so that flooding or wiping will not take place in the boiler. The feed water enters the deaerator in the form a fine spray on top of the tray and flows down onto the trays where it comes in contact with the steam which will be rising through the perforated trays. The steam will strip the water of dissolved gases as it rises. Heat exchange also takes place between the steam and the water resulting in an increase in the temperature of the water as a result the solubility of dissolved gases decrees and the water gives up the dissolved gases. The water then accumulates in the water storage section where a further heating occurs to a temperature of about 80oC. From the de-aerator the water is then pumped in the boiler by boiler feed pumps. Before it is pumped dosing chemicals are introduced between the deaerator and the feed pumps.This conditioning the water is then feed into boiler

2.6 DOSING CHEMICALS Three chemicals are dosed online into the feed water. One is for scale and deposit control, the other one for oxygen corrosion control and the last one is a pH booster. scale and deposit control To control this, a phosphate based treatment (chematron 155) is used. Chematron 155 is synergistic blend of organic and inorganic scale inhibitors.

10

Oxygen corrosion control The oxygen scavenger used has sulphite as the active component. pH buster Caustic Soda is used as the pH buster

These chemicals are feed into the feed water stream by an adjustable pump which regulates the rate at which these chemicals are feed into the feed water.

2.7 CONTROL SYSTEM 2.6.1 BOILER CONTROL SYSTEM The boiler has a control system that regulates it operations. The system has gauges that self regulate according to set points. (Copy of boiler control system attached) Water level The boiler has a self regulating system that controls the amount of water in the boiler as per set range of set points set by the operator. It also has a gauge known as the mobri switch that gives an alarm when the water level reaches a critical low level. It also operates within a range of set points set by the designer. If it reaches the lower set point it automatically shuts the boiler off. The main feed water modulating control valve is an electro pneumatic control valve which actuates level into pneumatics. It opens when the level is below the lower value set point and closes when the level goes above the upper set parameter. The system has a bypass in case of failer of modulating valve which can be used during repairs to the valve Pressure control The boiler has a valve that regulates the pressure within design set points. This gauge shuts off the ID fans when pressure reaches the upper set point. The pressure release valves are design feature for failure of the pressure control valves. It also controls the amount of heart that goes through to the shells reducing the amount of steam generated and thus controlling pressure.

Flow control

11

The boiler has a valve that controls flow rate as per designed parameters. The feeder pipe has a designed capacity of nominal flow 16.5t.h and a maximum flow of 20.0t.h.

Combined control system The above control systems are connected altogether in controlling the boiler. The main objective of a combined control system is to for them to complement one another in case one fails the other can regulate the system.

2.6.2 DE-AERATOR CONTROL SYSTEM The de-aerator has a control system that regulates its operations. The system has gauges that self regulate according to set points. (Copy of boiler control system attached) Water control. It has an electro pneumatic control valve which controls the level of water in the deaerator within two set points. It opens when the level goes below the lower limit and closes when it passes the upper limit. There is also a bypass system which is used in case the valve malfunctions.

It also has an over flow valve that opens when the water level surpasses the upper set value of level and closes when it reaches the lower limit. It compliments the level control valve.

Steam control The de-aerator has a pressure electro pneumatic pressure control valve which maintains the pressure in the de-aerator within given set. There is also a bypass system which is used in case the valve malfunctions.

2.8 STEAM GENERATION

12

Hot gases from a fire pass through one or more tubes first running through a sealed container of water. The heat of the gases is transferred through the walls of the tubes by thermal conduction, heating the water and ultimately creating steam. The heat source is inside a furnace or in this case it is the John Thompson Triumph Chaingrate Stoker that has to be kept permanently surrounded by the water in order to maintain the temperature of the heating surface just below boiling point. With the aid of the ID fan the flue gas moves to the shell side of the boiler where it travels through 2 tube passes transferring heat by convection to the surrounding water creating steam

2.9 STEAM USES 1. Pre-heating the de-aerator 2. Source of energy during pressing 3. Pre-treatment of the chips before defibration process 4. Source of energy during defibration process 5. Heat water at the accumulator

2.10

HEAT GENERATION

Coal is used as source of fuel in the stoker and it is washed pear size currently sourced from Hwange. Washed peas coal is used and an average consumption of 1200tonnes/month. From the stoker hopper coal is laid onto the Chaingrate which is rotating at a preselected speed. The Chaingrate then transfers the cola into the boiler via the guillotine door which regulates the fuel bed thickness. After passing under the guillotine door the coal is heated by radiation from the hot refractory ignition arc. Release of volatiles constituents of coal commences at about 1500C. The volatiles mix with the air supplied by the FD fans and burn above the fuel bed. The burning volatiles heat the ignition arc and radiate directly onto the oncoming fuel and supplement the effect of the arc. A step in the arc increases turbulence in the ignition zone. This promotes mixing of the volatiles and the air, increasing flame temperature and so improving the overall effect of the system. The coke formed in the ignition arc the move s into the furnace arc where burns through a

13

high temperature oxidizing atmosphere leaving a layer of ash on the chain grate. The coal burns according to the following equation

C + O2 CO2 + heat The heat produced is of importance and is quantified by equation Q=UAdT Where Q A dT U is the heat transferred per unit time, the area available for the flow of heat, the difference in temperature between the flame and the boiling water, and is known as the overall heat transfer coefficient (W/m2 K).

Heat is either transferred by conduction to the water tubes surrounding the stoker or by convection and radiation to the fire tubes of the boiler For conduction: Q= kA(T1-T2)/x Where: k is the thermal conductivity of the material. x wall of thickness T1 and T2 Temperatures of stoker inside and outside walls respectively [3]

For convection (forced convection): Q= hA(T1-T2) Where: k is the thermal conductivity of the material. x wall of thickness T1 and T2 Temperatures of stoker inside and outside walls respectively [4]

The heated water will then produce steam and the amount of heat can be quantified by:

14

Q = mCpdT Where: m Cp dT mass flow rate of top up water (Kg/s) specific heat capacity of water temperature rise of top up water

[5]

The following energy balance equation will then apply assuming that there are no further energy losses. Ms hfg = Q = m Cp dT Where: Ms = mean steam consumption rate (Kg/s) hfg = specific enthalpy of evaporation of steam (kJ/Kg) Q = mean heat transfer rate (kW) [6]

Heat is also lost in a number of ways and these have effects on thermal efficiency of the boiler.Boiler efficiency simply relates energy output to energy input, usually in percentage terms:

Boiler efficiency, in the simplest terms, represents the difference between the energy input and energy output. The following design issues should be considered during a boiler efficiency evaluation. 1. Number of boiler passes. The number of boiler passes simply represents the number of times the hot combustion gas travels across the boiler (heat exchanger). A boiler with two passes provides two opportunities for the hot gasses to exchange heat to the water in the boiler. A 4-pass unit provides four opportunities for heat transfer. The stack temperature of a 4-pass boiler will be lower than the stack temperature of a similar size 2- or 3-pass boiler operating under similar conditions. 2. Repeatable air/ fuel control 15

The efficiency of the boiler depends on the ability of the burner to provide the proper air to fuel mixture throughout the firing rate, day in and day out, without the need for complex set-up or adjustments. Many burner designs can deliver the required air-to-fuel mix with enough time provided to adjust the burner or for a single test period. 3. Combustion Efficiency Combustion efficiency is an indication of the burners ability to burn fuel. The amount of unburned fuel and excess air in the exhaust are used to assess a burners combustion efficiency. Burners resulting in low levels of unburned fuel while operating at low excess air levels are considered efficient. 4. Thermal Efficiency Thermal efficiency is a measure of the effectiveness of the heat exchanger of the boiler. It measures the ability of the exchanger to transfer heat from the combustion process to the water or steam in the boiler. Because thermal efficiency is solely a measurement of the effectiveness of the heat exchanger of the boiler, it does not account for radiation and convection losses due to the boilers shell, water column, or other components. Since thermal efficiency does not account for radiation and convection losses, it is not a true indication of the boilers fuel usage and should not be used in economic evaluations. 5. Fuel-To-Steam Efficiency Fuel-to-steam efficiency is a measure of the overall efficiency of the boiler. It accounts for the effectiveness of the heat exchanger as well as the radiation and convection losses. It is an indication of the true boiler efficiency and should be the efficiency used in economic evaluations. when dealing with fuel to steam efficiency

2.11

HEAT LOSSES Heat losses due to unburned carbon Size of the coal, fired in boiler should be controlled. For example for sticker fired coal, it should not be more than 20 mm. Proper amount of excess air should be supplied to the boiler. Boiler should not be overloaded.

16

Homogenous mixing of air and fuel should be maintained.

Heat losses due to formation of carbon monoxide Excess air should not be less than 60%. Air should be entered with higher turbulence so that each carbon atom comes in contact with oxygen atoms. Ratio of Actual air to theoretical air should be more than 1.3. Heat losses due to moisture in the fired coal Proper storage of coal should be done. (Especially in rainy season). Coal preheating

2.12

HEALTH AND SAFETY

The boiler is both the source of energy for most unit operations in fibreboard production as well as a source of indirect and direct risk. The operations of the boiler are guided by the law The Factories and Works Act 14:08/1996 Regulations that include

1. RGN 279 of 1976 (Boilers). 2. RGN 303/1976 (Pressure vessels). It is the best interest of the company that these regulations are followed for the safety of the operator and the boiler itself.

2.13

FINDINGS Water analysis The primary objective of the boiler is to supply steam to the production line, this supply if primarily affected by things such as boiler efficiency and the efficiency is affected a number of things and boiler water is one of them. Boiler water samples were taken for a number of days to analyze the effect of the boiler water to the boiler. MONDAY

property

TUESDAY SW 6.2 14 ST 6.6 24 BW 9.2 700 DW 7.0 22 FW 6.8 20 SW 6.6 20 ST 6.7 22 BW DW 9.9 84 8.1 89

FW 6.4

pH

conductivity 26

17

TDS TH Ca H CL Sulphite PH

18 17 6

22 11

16 20

540 ND

14 ND NA

14 20 11

14 9 10

18 23 4

580 ND

62 ND NA

84 11 30 WENESDAY FW SW ST 6.69 20 20 9 5 84 35 31 7 BW DW FW

70 9 20 THURDAY SW ST BW DW

pH

7.73 7.90 20 20 9 2

10.65 9.15 900 540 34 14 20 14 6 5 20 14 7 7 20 18 7 6 67 40 34 920 580 26 62 10 4

conductivity 20 TDS TH Ca H CL Sulphite OH 18 9 6

A close analysis of these results will help us appreciate the effects of the water top the boiler. The main are of concern is hardness, as the softeners are not working. The results of the city council water show that it is not hard water as total hardness is fairly low, lucky for us. Analysis of the feed water and the softeners water produces relatively the same results.

The pH is generally within the parameters playing around alkalinity which is good for the boiler. The next other thing very important is the sulphite concentration in the boiler water; a low concentration would mean that little oxygen was removed from the boiler water resulting in the corrosion of the shells. The results show that this was happening on monday and tuesday with a corrective measure being taken the day after. The major issue that was highlighted was the boiler operators were conducting blow downs before the chemicals added to counter this effect had worked.

18

It can be said that the dosing chemicals are achieving their desired objective and it can be highlighted by the results above

Boiler operations Boiler operations have deviated from their designed operations. Control mechanisms that were put in pace to make boiler operations safe and within desirable parameters are no longer functional. The majority of the valves on the boiler and the de-aerator are not functioning properly. Shear pins that seem to be so little to the running of the boiler and which by design must be made of brass were changed and steel ones were put in place. They have caused a lot of damage in the running of the chain grate.

The boiler and steam flow should be almost closed a closed system with a little of make up water but currently make up water is now the major source of water being used. This shows us that the piping system is now in bad shape as it is loosing a lot of stem and water which in turn increase the operational costs.

Redundant equipment It was observed that the redundant equipment is no longer in the designed specifications resulting in unnecessary stoppages due to failer of some of the equipment. Below is a list of the design specification of the equipment.

Boiler 1 Storage tank pumps

Design 1running, 1 standby

current 1running, no standby

De-aerator feed water pumps

1running, 1 standby

I running, 1 standby

Feed water pumps

1running, 1 standby

I running, no standby

4 5

softeners Dosing pumps

1running, 1 standby 1running, 1 standby

No running I running, no stand by

19

Analysis of coal used at MBD Coal used at MBD comes from a different places and an analysis of the coal used for the past two years was done. Analysis of the results was done (see copy of the results attached). It can be said that the ideal coal for use in the burner should have low sulpher contents which are good for the boiler and the atmosphere, high volatile content which release sufficient heat energy to ignite the coal, and an average moisture content as it helps to limit segregation. It can be seen that at times the buying of the coal is done not paying much attention to the previous records of which coal is best for boiler.

Soot blowing. Soot blowing was condemned, as the boiler is not producing dry steam which is a cause of concern. Removing of soot is now done during plant shut downs.

2.14

RECOMMENDATION Control system repair needs to be restored. It is imperative that the boiler and deaerator control systems be functional. This not only reduces pressure on the operator but also on the system as a whole. All valves on the boiler and de-aerator need to be repaired. Redundant equipment need to maintain as per designed specifications so as to reduce dead time. New softeners need to be bought and installed to further reduce the effects of hardness on the boiler. Finding the perfect coal with the right constituents is a bit difficult but blending two typical coals is recommended for example Hwange coal and sengwa coal. Hwange coal is typical low moisture, high sulphur, high volatile content coal and low ash fusion temperature, with sengwa being a low sulphur, moderately to high moisture content, high volatile content but high ash fusion temperature. Blending the two colas produces excellent results as the shortfalls of the other are complimented by

20

the other. Blending enables Hwange coal to burn to ash reducing clinkage and significantly reducing costs. Proper maintenance of the boiler needs to be done as this can reduce future operational costs which at times can even result in the whole boiler being replaced. It needs to be investigated why the boiler is producing wet steam.

2.15

APPENDIX Boiler specifications Type Manufacturers Working pressure Design efficiency Size Type of fuel Firing methods Draught plant Water tube and Fire tube Cochrane engineering 32 bars 75% Capacity output 20 tones per hour Coal (washed peas) chain grate stroker ID and FD draughts

De-aerator specifications Model Storage volume Outlet capacity Operating pressure Design pressure Outlet temperature Heating steam volume Heating steam pressure Heating steam temperature Chematron T.6 3700 kg normal operation 1 800-2 150 kg/hr 410 kPa 600 kPa 152 0C 1 200 kg/hr 2 900 kPa 233 0C

Softeners specifications MODEL AC 300 Aquamatic

21

Maximum working pressure Minimum working pressure Maximum softening flow Minimum softening flow Resins

550 kPa 250 kPa 12 m3/hr 1.5 m3/hr Ambelite IR12 sodium cations softening resins

Blow down

Blow down is the removal of water in the boiler. Feed water impurities, oxygen scavengers, caustic soda and other chemicals that are injected in the boiler form sludge in the boiler. If uncontrolled the sludge will cause foaming and carryover which is a threat to the piping system. Blow down is necessary to avoid total dissolved solids from exceeding 3500 mg/ l.

22

You might also like

- Working Guide to Petroleum and Natural Gas Production EngineeringFrom EverandWorking Guide to Petroleum and Natural Gas Production EngineeringRating: 5 out of 5 stars5/5 (2)

- Softening: Water TreatmentDocument20 pagesSoftening: Water Treatmentpkgarg_iitkgpNo ratings yet

- Boiler WaterDocument70 pagesBoiler WaterDarius DsouzaNo ratings yet

- Boiler TroublesDocument9 pagesBoiler TroublesMadhavanIce50% (2)

- Unit 1 - Water Technology: Engineering Chemistry Two Marks Question and AnswersDocument19 pagesUnit 1 - Water Technology: Engineering Chemistry Two Marks Question and Answers14567No ratings yet

- Power Plant Chemistry by Ramesh PDFDocument62 pagesPower Plant Chemistry by Ramesh PDFKomma Ramesh0% (1)

- Water ChemistryDocument13 pagesWater ChemistrynivasssvNo ratings yet

- Unit-I Water TechnologyDocument22 pagesUnit-I Water TechnologyManivannanVenkatesan100% (1)

- 17.4 Boiler and Feed-Water TreatmentDocument28 pages17.4 Boiler and Feed-Water Treatmentnomeacuerdo1No ratings yet

- 11.boiler Water ChemistryDocument9 pages11.boiler Water Chemistrykcp1986No ratings yet

- Power Plant ChemistryDocument136 pagesPower Plant ChemistryGajender Singh RajputNo ratings yet

- SBR ManualDocument27 pagesSBR ManualbjhamnaniNo ratings yet

- Water Treatment White PaperDocument20 pagesWater Treatment White PaperAlejandro Medina GómezNo ratings yet

- Physics Syllabus: GRADE 10 - 12Document79 pagesPhysics Syllabus: GRADE 10 - 12Mapalo Chirwa100% (4)

- Boiler System Chemical TreatmentDocument36 pagesBoiler System Chemical TreatmentNavaganesh Kannappen100% (1)

- Condensate Water Polishing SystemDocument257 pagesCondensate Water Polishing SystemHamza RaoNo ratings yet

- 16.1 Multiple-Choice Questions: Chapter 16 Carboxylic Acids and EstersDocument23 pages16.1 Multiple-Choice Questions: Chapter 16 Carboxylic Acids and EstersJames ChavezNo ratings yet

- Boiler-Water Treatment-Why, What and HowDocument7 pagesBoiler-Water Treatment-Why, What and How陳0鴻No ratings yet

- Calculation BFWDocument22 pagesCalculation BFWDavid Lambert100% (1)

- Boiler Treatment, Lecture 3Document75 pagesBoiler Treatment, Lecture 3Eisar Khan100% (1)

- Boiler Water TreatmentDocument5 pagesBoiler Water TreatmentUsamaNo ratings yet

- Handout BOILER FEED WATERDocument9 pagesHandout BOILER FEED WATERMuhammad Omar AzadNo ratings yet

- Boiler Water ConditioningDocument3 pagesBoiler Water ConditioningShahin AfrozNo ratings yet

- Boiler Water TreatmentDocument13 pagesBoiler Water TreatmentAisyah M YahyaNo ratings yet

- Boiler Feed Water CalculationDocument4 pagesBoiler Feed Water Calculationamit_kt1973No ratings yet

- Thermodynamic Relations - Applications - v44 - P4Document40 pagesThermodynamic Relations - Applications - v44 - P4Santiago Cardona ArroyaveNo ratings yet

- Unit I - Water Technology PDFDocument14 pagesUnit I - Water Technology PDFaashishNo ratings yet

- Ill Effects of Water in Steam GenerationDocument15 pagesIll Effects of Water in Steam GenerationCHARITHANo ratings yet

- 1 Water TechnologyDocument27 pages1 Water TechnologyB MohanNo ratings yet

- Water Treatment Plant-2Document98 pagesWater Treatment Plant-2Sai SwaroopNo ratings yet

- Boiler Blowdown and Refuse LossesDocument14 pagesBoiler Blowdown and Refuse LossesknsaravanaNo ratings yet

- UNIT-III ChemistryDocument12 pagesUNIT-III ChemistrySivaprasad GanjiNo ratings yet

- Boiler Water Treatment: Deposit ControlDocument5 pagesBoiler Water Treatment: Deposit ControlKrishna RayuduNo ratings yet

- Chapter 2: Water TreatmentDocument9 pagesChapter 2: Water TreatmentRavi DeshmukhNo ratings yet

- Water Technology: Main Sources of WaterDocument10 pagesWater Technology: Main Sources of WaterdeepaNo ratings yet

- Chemistry Unit 1Document10 pagesChemistry Unit 1Jannath FirdousNo ratings yet

- Water Technology 2015 2016 1Document86 pagesWater Technology 2015 2016 1Srinivas AkHilNo ratings yet

- 3.10 Water For The BoilerDocument12 pages3.10 Water For The BoilerJhonathan AlejandroNo ratings yet

- QADocument5 pagesQATejas Yadav100% (1)

- Chem Mod1Document10 pagesChem Mod1baritone.exhaustNo ratings yet

- Volume Increases 1,600 Times.: Furnace Boiler ProperDocument17 pagesVolume Increases 1,600 Times.: Furnace Boiler ProperAyush DeoreNo ratings yet

- Lecture 30 Boil WaterDocument4 pagesLecture 30 Boil WaterMuhammad AhmedNo ratings yet

- Water Technology: Boiler Feed Water: "It Is The Water Used in The Boilers (A Closed Vessel), Which Operates at DifferentDocument5 pagesWater Technology: Boiler Feed Water: "It Is The Water Used in The Boilers (A Closed Vessel), Which Operates at DifferentDency SanganiNo ratings yet

- Water Conditioning: by S.Umair Jarwar PakistanDocument4 pagesWater Conditioning: by S.Umair Jarwar PakistanS.Umair JarwarNo ratings yet

- Adobe Scan Apr 26, 2021Document11 pagesAdobe Scan Apr 26, 2021canusha820No ratings yet

- Boiler Water Treatment External PDFDocument4 pagesBoiler Water Treatment External PDFHadi AnsyahNo ratings yet

- Module V LecDocument21 pagesModule V LecAman John TuduNo ratings yet

- ManualDocument65 pagesManualAtul GargNo ratings yet

- Water Lecture-3: Water For Industrial Use Scale & SludgeDocument23 pagesWater Lecture-3: Water For Industrial Use Scale & Sludgesayan halderNo ratings yet

- Cy1104 - Engineering Chemistry: NameDocument21 pagesCy1104 - Engineering Chemistry: NameBeuna.No ratings yet

- Civildatas - Blogspot.in: Unit IDocument14 pagesCivildatas - Blogspot.in: Unit IVignesh VickieNo ratings yet

- Watertreatmentandanalysis 2Document19 pagesWatertreatmentandanalysis 2O MNo ratings yet

- Engineering ChemistryDocument87 pagesEngineering ChemistrylegendofrohithNo ratings yet

- Water Pre - Treatment Process (Water Packaging)Document6 pagesWater Pre - Treatment Process (Water Packaging)Abhishek GoraiNo ratings yet

- Water TreatDocument15 pagesWater TreatbjosufNo ratings yet

- 02-Effect of Water Impurities in BoilersDocument4 pages02-Effect of Water Impurities in BoilersBikas SahaNo ratings yet

- Boiler Feed WaterDocument4 pagesBoiler Feed Wateranghel_florin82No ratings yet

- 2001 - March - Boiler (Part 1)Document6 pages2001 - March - Boiler (Part 1)arunkumar23101No ratings yet

- Water and Its Treatment MaterialDocument14 pagesWater and Its Treatment MaterialSameer SamNo ratings yet

- Unit II Boiler Corrosion and Softening MethodsDocument13 pagesUnit II Boiler Corrosion and Softening MethodsMohit PawarNo ratings yet

- Unit-4 Water TechnologyDocument22 pagesUnit-4 Water TechnologymaheshkancherlajobNo ratings yet

- Wet Processing I Water PDFDocument7 pagesWet Processing I Water PDFkabir_ce06038No ratings yet

- Nanoporous Catalysts for Biomass ConversionFrom EverandNanoporous Catalysts for Biomass ConversionFeng-Shou XiaoNo ratings yet

- Pot n2Document18 pagesPot n2Robin BushuNo ratings yet

- UK Y12 Biology Cell Biology 1014 待美化Document21 pagesUK Y12 Biology Cell Biology 1014 待美化Robin Bushu100% (1)

- Why Study Cell Biology?Document38 pagesWhy Study Cell Biology?Ellen mae MNo ratings yet

- Eng Econ SlidesDocument34 pagesEng Econ Slidesاحمد عمر حديدNo ratings yet

- AAA Holiday Timetable Preliminary ClasesDocument10 pagesAAA Holiday Timetable Preliminary ClasesRobin BushuNo ratings yet

- 07 Chapter 1Document42 pages07 Chapter 1Robin BushuNo ratings yet

- 06 Boundary ConditionsDocument31 pages06 Boundary Conditionstolga_enes9949No ratings yet

- Beer CombustionDocument33 pagesBeer CombustionRaveendhra IitrNo ratings yet

- Bio ReactorDocument22 pagesBio ReactorRobin BushuNo ratings yet

- 13 4 8alphaDocument3 pages13 4 8alphaAngela LimNo ratings yet

- 000383Document38 pages000383Robin BushuNo ratings yet

- Notification of Plant and Prescribed Equipment Design Advice DocumenDocument5 pagesNotification of Plant and Prescribed Equipment Design Advice DocumenRobin BushuNo ratings yet

- Coke Oven By-Product PlantDocument9 pagesCoke Oven By-Product PlantYudy TriyogaNo ratings yet

- Process Dynamics and Control Lecture 10Document33 pagesProcess Dynamics and Control Lecture 10Robin BushuNo ratings yet

- Theoretical Investigations of Structural, Spectroscopic and Electron Collision Data of AcetoneDocument21 pagesTheoretical Investigations of Structural, Spectroscopic and Electron Collision Data of AcetoneVinayak SavarkarNo ratings yet

- Explain The Role of Thioglycollic Acid in The Limit Test of IronDocument2 pagesExplain The Role of Thioglycollic Acid in The Limit Test of IronAnkita UpadhyayNo ratings yet

- Calculation of Pure and Mixture Physical PropertiesDocument11 pagesCalculation of Pure and Mixture Physical Propertiessocial peopleNo ratings yet

- Physics 715 HW 3Document18 pagesPhysics 715 HW 3Juan Manuel Orozco HenaoNo ratings yet

- Hladnjaca DefrostingDocument6 pagesHladnjaca DefrostingDzana KadricNo ratings yet

- Sensors Evaluation 2019 Oct 19 (19) - DOC#NDL:NDA:DGA:ON:072002 PDFDocument1 pageSensors Evaluation 2019 Oct 19 (19) - DOC#NDL:NDA:DGA:ON:072002 PDFDivyansh KohliNo ratings yet

- C184 E037bDocument48 pagesC184 E037bNeyda Flores VasquezNo ratings yet

- UhhghghhgjDocument2 pagesUhhghghhgjDivyansh SinghNo ratings yet

- Physics HL p2Document415 pagesPhysics HL p22025snehithNo ratings yet

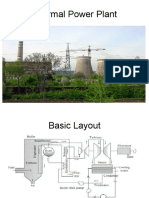

- Thermal Power PlantDocument29 pagesThermal Power Plantshamna AbdullaNo ratings yet

- Atomic ModelsDocument13 pagesAtomic Modelsmax mishraNo ratings yet

- RADIOIMMUNOASSAYDocument4 pagesRADIOIMMUNOASSAYJansen MunioNo ratings yet

- Simulation of Kaduna Refining and Petrochemical Company (KRPC) Crude Distillation Unit (CDU I) Using HysysDocument7 pagesSimulation of Kaduna Refining and Petrochemical Company (KRPC) Crude Distillation Unit (CDU I) Using HysysAdhityaEkoBagusNo ratings yet

- BSC Grade System Pt. Ravishankar Shukla University PDFDocument66 pagesBSC Grade System Pt. Ravishankar Shukla University PDFparmeshwar singhNo ratings yet

- Lab 3heatengine PhysicDocument3 pagesLab 3heatengine Physicapi-263500375No ratings yet

- Synthesis and Characterization of Nano Banana Fibre Reinforced Polymer Nano CompositesDocument133 pagesSynthesis and Characterization of Nano Banana Fibre Reinforced Polymer Nano CompositesBoopathi RajaNo ratings yet

- Cambridge IGCSE™: Chemistry 0620/52Document8 pagesCambridge IGCSE™: Chemistry 0620/52Sridharan VijayalakshmiNo ratings yet

- Steam Generation - Distribution 2023Document64 pagesSteam Generation - Distribution 2023Aaqil cassimNo ratings yet

- Constants and ConversionsDocument21 pagesConstants and ConversionsJulia Jaffa ChavezNo ratings yet

- SF6 Abatement in A Packed Bed Plasma Reactor: Role of Zirconia Size and Optimization Using RSMDocument12 pagesSF6 Abatement in A Packed Bed Plasma Reactor: Role of Zirconia Size and Optimization Using RSMClaudia TrujilloNo ratings yet

- Lecture 23: Introduction To Valence Bond TheoryDocument18 pagesLecture 23: Introduction To Valence Bond TheoryElectro_LiteNo ratings yet

- Phase Behavior of CO2-nC10 and CO2-nC16Document13 pagesPhase Behavior of CO2-nC10 and CO2-nC16ashkanscribdNo ratings yet

- Cyanide Generation, Corrosion, Treatment, and Discharge at A Petroleum RefineryDocument19 pagesCyanide Generation, Corrosion, Treatment, and Discharge at A Petroleum Refinery陳冠宏No ratings yet

- MSC Project1Document5 pagesMSC Project1Raef kobeissiNo ratings yet

- 9science 9 Force and Laws of MotionDocument27 pages9science 9 Force and Laws of MotionMohammed AadilNo ratings yet

- Toluene BenzeneDocument20 pagesToluene BenzeneZarin ZahurinNo ratings yet