Professional Documents

Culture Documents

Hints For Feeder QM46

Uploaded by

Daniela AndriaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hints For Feeder QM46

Uploaded by

Daniela AndriaCopyright:

Available Formats

PREPRESS

PRESS

POSTPRESS

Printmaster QM 46-1/-2

Hints for the feeder

Printmaster QM 46-1/-2

Printmaster QM 46-1/-2 The Feeder In this brochure we would like to give you several hints for the settings of the feeder and the paper run. Heidelberg has collected results from several test runs and experiences from the field about handling and settings for different stocks.

Scheme Drawing Adjusting possibilities of a QM 46 Feeder This scheme drawing shows the QM 46 operator the position of each adjustment element of the feeder.

Printmaster QM 46-1/-2

Paper Qualtity Preparing the production process The values specified in this information only apply to conditioned paper. There are influences like paper dampness, grain direction of the paper, humidity or static charges in the paper which may require to change the settings. The recommended speeds for 40-80 g/m2 paper is up to 6,000 sheets/h, and 8,000 sheets/h for paper above 80 g/m2. Paper quality For portrait presses like the Printmaster QM 46 model range, the graining direction of paper up to 170 g/m2 should be the same as the feeding direction (short grain). When printing thicker material the grain direction should be parallel to the cylinder shaft (long grain). Stocks cut to end format may have tolerances in size. In order to prevent feeding or register problems caused by these tolerances and to guarantee true to register printing and an optimized paper run we recommend an angle cut or four side cut of the paper.

Sheet feeding direction When printing paper of a length between 14 an 34 cm it is recommended to feed the longer side of the paper. Tilting Feed Table Benefit This tilting feed table for Printmaster QM 46 is a favourably priced alternative for conventional envelope feeders. Its compact an simple design makes the production of difficult stocks more profitable. Information sheet Printmaster QM 46 Helpful hints for the feeder This information sheet should be kept close to the press as it is a summary of all settings. The operator no longer needs to check the operation manual for this information. Further interesting information about Printmaster QM 46 at www.heidelberg.com.

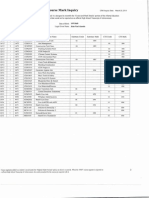

Paper run settings

40 g 70 g Pile height Scale on blower bar Sheet arrival Position pointer Suction air Position control knob Blast air Position control knob Corner blowers Lateral sheet separation blower Rear edge blowers Position of front wiper strip Pull rod Starting point Pressing power O-seal on the pull rod Lateral pile guide rail Spring Middle mark or deeper 2 Tolerance +2/-1 7 Tolerance +1/-0,5 1,5 Tolerance +2/-0,5 no only if required 45 to the rear no maximum protrusion late minimum Spring touches the pile lightly >70 g 120 g Middle mark or 2 mm higher 2 Tolerance +2/-2 6 Tolerance +1,5/-0,5 4,5 Tolerance +2/-1 no only if required 45 to the rear no maximum protrusion late minimum Spring touches the pile lightly >120 g 170 g Centre middle and upper line or higher 1 Tolerance +2/-1 7 Tolerance +1,5/-1 7 Tolerance +2/-1 no only if required 45 to the rear to 90 to the pile yes maximum to half protrusion early minimum Spring touches the pile lightly >170 g Top line or slightly lower 0 Tolerance +2/-1 8 Tolerance +2/-1 8 Tolerance +2/-1 no only if required no yes minimum protrusion early 1/2 maximum 2 Spring presses lightly against the pile

You might also like

- Horizon BQ 470 1Document8 pagesHorizon BQ 470 1Javier Martinez Cañal0% (1)

- Horizon - BQ 470 1 PDFDocument8 pagesHorizon - BQ 470 1 PDFWael Samir YousefNo ratings yet

- Ideal GuilotineDocument48 pagesIdeal GuilotineGeorgi Velkov100% (1)

- Mercedes V 220 2015 Owners ManualDocument360 pagesMercedes V 220 2015 Owners ManualMusaHamzic100% (1)

- Prinect Metadimension Manual UsoDocument2 pagesPrinect Metadimension Manual UsohdzsNo ratings yet

- Ideal 4850-95 EPDocument20 pagesIdeal 4850-95 EPPrintalias CórdobaNo ratings yet

- Preps 6.1 PrinergyGuide enDocument18 pagesPreps 6.1 PrinergyGuide enWilliam MendozaNo ratings yet

- Prinect Signa Station - Install ENDocument28 pagesPrinect Signa Station - Install ENAndrés Febres-CorderoNo ratings yet

- MC 8Document46 pagesMC 8Christian Marcelo VallejosNo ratings yet

- Software Product Description: (Version 17.00.409)Document28 pagesSoftware Product Description: (Version 17.00.409)Ricardo AquinoNo ratings yet

- Heidelberg FlyerDocument66 pagesHeidelberg Flyergayan12001No ratings yet

- Processor-Grafmac-maintain - 32+45+53CDN - 20080923A-KSDocument26 pagesProcessor-Grafmac-maintain - 32+45+53CDN - 20080923A-KSalejandro100% (1)

- Duplo DB-200 Instruction Manual Perfect Binding DB-200Document18 pagesDuplo DB-200 Instruction Manual Perfect Binding DB-200Javier Rivera100% (1)

- CPT Press Web-SeptemberDocument39 pagesCPT Press Web-SeptemberAnonymous B7H9JXnbNo ratings yet

- RobatecDocument130 pagesRobatecbk158124No ratings yet

- En Prinect Quick StartDocument138 pagesEn Prinect Quick StartOmarŻelaya100% (1)

- Sj745exe y Sj645exDocument187 pagesSj745exe y Sj645exfefotroncitoNo ratings yet

- Xc540e PDFDocument239 pagesXc540e PDFMana FiúzaNo ratings yet

- Conversor CC Gefran - TPD32 92 enDocument480 pagesConversor CC Gefran - TPD32 92 enBarbozma100% (1)

- Roland ErrorsDocument9 pagesRoland ErrorsBryanHumphriesNo ratings yet

- Digifold Operators Manual Issue 11Document42 pagesDigifold Operators Manual Issue 11SARyan0% (1)

- Fastback-20 ServiceManual VCDocument124 pagesFastback-20 ServiceManual VCLars Notlev100% (1)

- Seiko IP 6600 Plotter Service ManualDocument361 pagesSeiko IP 6600 Plotter Service Manualwcualumni0% (1)

- Xerox D95/D110/D125/D136 Copier/Printer: System Administration GuideDocument250 pagesXerox D95/D110/D125/D136 Copier/Printer: System Administration GuideKaimook CopierNo ratings yet

- 52di Esm-2Document109 pages52di Esm-2Vance IbzNo ratings yet

- Vutek UltraVU 5300 ManualDocument250 pagesVutek UltraVU 5300 ManualGeorge Scurtu100% (2)

- VersaUV White Gloss Guide PDFDocument76 pagesVersaUV White Gloss Guide PDFJosé Alarcón PalomarNo ratings yet

- Special Equipment: Service Training MechanikDocument16 pagesSpecial Equipment: Service Training Mechanikfroilan ochoa100% (1)

- Enthrone 29Document6 pagesEnthrone 29Adam Muhamad AliNo ratings yet

- 1 Preface: 1.1 Notes For The ReaderDocument14 pages1 Preface: 1.1 Notes For The ReaderDaniel GureanuNo ratings yet

- Error List PS 5000 / PS 6000 Technical InformationDocument53 pagesError List PS 5000 / PS 6000 Technical InformationAlexNo ratings yet

- Burny 2.5 PlusDocument398 pagesBurny 2.5 PlusGiannis Psarakis100% (1)

- Service Notes: Confi DentialDocument235 pagesService Notes: Confi DentialFranklin TejedaNo ratings yet

- 16 - Chapter 8 PDFDocument60 pages16 - Chapter 8 PDFJavier Martinez CañalNo ratings yet

- SM SX 52 Manual 2Document20 pagesSM SX 52 Manual 2Ali HussnainNo ratings yet

- Becker Brochure PDFDocument20 pagesBecker Brochure PDFMiraNo ratings yet

- 4995A ICS BrochureDocument8 pages4995A ICS BrochureGerardo BernardoNo ratings yet

- OKI MAnualDocument1,267 pagesOKI MAnualdragojevicdejanNo ratings yet

- Discrete Flat No-Leads DFN Package PosterDocument1 pageDiscrete Flat No-Leads DFN Package Posterbbxload319No ratings yet

- WWW Rollersales ComDocument4 pagesWWW Rollersales ComleonelcoolNo ratings yet

- Heidelberg SM 102-4p 25731Document2 pagesHeidelberg SM 102-4p 25731karimNo ratings yet

- Drystar 2000 Smcd102 2003-2005 Eng DemoDocument30 pagesDrystar 2000 Smcd102 2003-2005 Eng DemoAlejandro SotoNo ratings yet

- As InfoDocument308 pagesAs InfoFlashPTNo ratings yet

- Gronhi YK1800 Service ManualDocument73 pagesGronhi YK1800 Service ManualJohn HardenNo ratings yet

- HD 42Document11 pagesHD 42Resimasc GonzálezNo ratings yet

- 2012 Own and BT in Parts GBPDocument51 pages2012 Own and BT in Parts GBPabed sabbaghNo ratings yet

- Manuals and SchemesDocument8 pagesManuals and SchemesRishi jain0% (1)

- 52di Esm-1Document116 pages52di Esm-1Vance IbzNo ratings yet

- Two-Color Small Offset Press: WarningDocument568 pagesTwo-Color Small Offset Press: WarningSachin NerkarNo ratings yet

- Triumph 6660 Parts ListDocument18 pagesTriumph 6660 Parts ListD_moneyNo ratings yet

- Prinect Signa Station - Install enDocument41 pagesPrinect Signa Station - Install enRogelio Jr. AustriaNo ratings yet

- S5100 OperatorsManual S5100-E4 EnglishDocument105 pagesS5100 OperatorsManual S5100-E4 EnglishJacob B ChackoNo ratings yet

- PT-R8600 Electric Circuit Diagram: G.AppendicesDocument81 pagesPT-R8600 Electric Circuit Diagram: G.AppendicesBenjamin100% (1)

- Oce Windows Printer Driver Installation Guide PDFDocument156 pagesOce Windows Printer Driver Installation Guide PDFLoraine Lipalam JuanitasNo ratings yet

- Epson Stylus Pro 7890/9890: User'S GuideDocument224 pagesEpson Stylus Pro 7890/9890: User'S GuideTayyab GillaniNo ratings yet

- Guia Soporte de Producto Pro 8200EX - 8200S - 8210S - 8220S PDFDocument69 pagesGuia Soporte de Producto Pro 8200EX - 8200S - 8210S - 8220S PDFcaratulinNo ratings yet

- Klipper Pressure AdvanceDocument4 pagesKlipper Pressure AdvanceenriquecourtadepNo ratings yet

- Sugar IndustryDocument12 pagesSugar IndustrybenjieducutNo ratings yet

- Norgren PressureRegulatorDocument3 pagesNorgren PressureRegulatormreichenNo ratings yet

- M7E01 TechData 01Document10 pagesM7E01 TechData 01lexeberu100% (1)

- Analysis of Rates (Nh-15 Barmer - Sanchor)Document118 pagesAnalysis of Rates (Nh-15 Barmer - Sanchor)rahulchauhan7869No ratings yet

- Tangerine - Breakfast Set Menu Wef 16 Dec UpdatedDocument3 pagesTangerine - Breakfast Set Menu Wef 16 Dec Updateddeveloper louNo ratings yet

- Research FinalDocument55 pagesResearch Finalkieferdem071908No ratings yet

- The Mooring Pattern Study For Q-Flex Type LNG Carriers Scheduled For Berthing at Ege Gaz Aliaga LNG TerminalDocument6 pagesThe Mooring Pattern Study For Q-Flex Type LNG Carriers Scheduled For Berthing at Ege Gaz Aliaga LNG TerminalMahad Abdi100% (1)

- Lady in The House, Her Responsibilities & Ambitions: Amrita DuhanDocument7 pagesLady in The House, Her Responsibilities & Ambitions: Amrita DuhanFitness FableNo ratings yet

- ADocument54 pagesActyvteNo ratings yet

- 2Document8 pages2Eduardo Antonio Comaru Gouveia75% (4)

- Derma Notes 22pages. DR - Vishwa Medical CoachingDocument23 pagesDerma Notes 22pages. DR - Vishwa Medical CoachingΝίκος ΣυρίγοςNo ratings yet

- Borges, The SouthDocument4 pagesBorges, The Southdanielg233100% (1)

- 2201 IntGCSE (9-1) Subject Grade Boundaries V1Document4 pages2201 IntGCSE (9-1) Subject Grade Boundaries V1Fariha RahmanNo ratings yet

- Volvo BL 71 ManualDocument280 pagesVolvo BL 71 ManualAlberto G.D.100% (2)

- Trina 440W Vertex-S+ DatasheetDocument2 pagesTrina 440W Vertex-S+ DatasheetBrad MannNo ratings yet

- The Linguistic Colonialism of EnglishDocument4 pagesThe Linguistic Colonialism of EnglishAdriana MirandaNo ratings yet

- G10 Lesson2 DLPDocument13 pagesG10 Lesson2 DLPAngeles, Mark Allen CNo ratings yet

- W.C. Hicks Appliances: Client Name SKU Item Name Delivery Price Total DueDocument2 pagesW.C. Hicks Appliances: Client Name SKU Item Name Delivery Price Total DueParth PatelNo ratings yet

- SP-Chapter 14 PresentationDocument83 pagesSP-Chapter 14 PresentationLoiDa FloresNo ratings yet

- Toh736 - 84000 The Dharani of Parnasavari PDFDocument24 pagesToh736 - 84000 The Dharani of Parnasavari PDFJames LeeNo ratings yet

- Loctite 586 PDFDocument9 pagesLoctite 586 PDForihimieNo ratings yet

- Assessment of Embodied Carbon Emissions For Building Construc - 2016 - Energy AnDocument11 pagesAssessment of Embodied Carbon Emissions For Building Construc - 2016 - Energy Any4smaniNo ratings yet

- Evidence Prove DiscriminationDocument5 pagesEvidence Prove DiscriminationRenzo JimenezNo ratings yet

- Pediatrics: The Journal ofDocument11 pagesPediatrics: The Journal ofRohini TondaNo ratings yet

- OM CommandCenter OI SEP09 enDocument30 pagesOM CommandCenter OI SEP09 enGabriely MuriloNo ratings yet

- Img 20150510 0001Document2 pagesImg 20150510 0001api-284663984No ratings yet

- Plastic Properties HandbookDocument15 pagesPlastic Properties HandbookguilloteARGNo ratings yet

- Multinational MarketingDocument11 pagesMultinational MarketingraghavelluruNo ratings yet

- Literature Review Template DownloadDocument4 pagesLiterature Review Template Downloadaflsigfek100% (1)

- A P P E N D I X Powers of Ten and Scientific NotationDocument5 pagesA P P E N D I X Powers of Ten and Scientific NotationAnthony BensonNo ratings yet

- Jul - Dec 09Document8 pagesJul - Dec 09dmaizulNo ratings yet

- D25KS Sanvick PDFDocument4 pagesD25KS Sanvick PDFJiménez Manuel100% (1)