Professional Documents

Culture Documents

103 Jamnagar

Uploaded by

seehariOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

103 Jamnagar

Uploaded by

seehariCopyright:

Available Formats

Reliance Ports and Terminals Limited Jamnagar Export Refinery Project

Client: Bechtel France Owner Reliance Port & Terminal LTD Period: 2006 Owner: 2006-2008

Reliance Jamnagar Marine Terminal is situated in the Gulf of Kutch, State of Gujarat, I India, about 35 km west of the town of Jamnagar. The Marine Terminal was inaugurated in 1999, to serve the worlds lar largest grass roots refinery, having a capacity of 33 MMTPA. In 2006, after eight years of successful service, Reliance Industries Limited (RIL) has planned to increase the crude ed processing capacity of the refinery from 33 MMTPA to finery 64.6 MMTPA, as part of the Jamn Jamnagar Export Refinery Project (JERP). The aim of this is to maximising processing units and pr production of refined petroleum products as wel as addiwell tional petrochemical products for the export markets. The increase in capacity required an increase in the number of import and export lines and rea reallocation of some of the existing ones. To implement these changes there were also a requirement to modify the existing trestle stru plement structures and sleepers both onshore and offshore, and the construction of new structures. The marine facility for the existing refinery comprises of 2 SPMs for crude oil import and 4 Tanker rude Berths A, B, C and D for exporting products and a seawater intake facility for cooling water requir or water requirements. In addition the marine facility also includes a Ro-Ro facility and unloading platforms for handling he cility Project construction cargo. The product pipelines from the existing Jamnagar rom refinery were routed from Marine Tank Farm (MTF) re to Land Fall Point (LFP) on onshore RCC sleepers and steel frames. These then travel on pile supported RCC pile caps and steel frames along 1400 m l long shore link between LFP and Zero P Point (the interface point between the Shore-Link and the Approach Link Trestle). From the Zero Point (shore line) the existing crude and product pipelines were supported on lines 60 m span structural steel Approach T tural Trestle beams having total length of 3600m. These existing Approach Trestle beam were supported on steel Mono-pile structures socketed in hard restle beams pile rock for desired pile capacity. The lines run on the Approach Trestle up to the Knuckle and then along the Jetty Trestle to the Berths or the existing riser platform. In order to meet the cargo handling requirements for crude import and product export from the new o JERP, the marine facility needed an expansion by the addition of a crude import SPM and two product export SPMs. The additional product pipelines to the export SPMs will be routed thr through the existing facilities to the New Riser Platform at the end of the Jetty T ser Trestle.

Project main requirement was to take care that Tanker Berths A, B, C & D would be fully operational during construction of the new facilities. TECON has developed the multi disciplinary engineering, on behalf of Bechtel France, for the following disciplines: Electrical Instrumentation and Control Systems Safety and Loss Prevention Material Engineering Mechanical Piping Process Structural

The services developed were the following: a) Detailed design of the new lines from the MTF to the LFP b) Detailed design of the new lines from the LFP to the New Riser Platform or existing Berths c) Detailed design pf new lines from LFP to Y-Point via the Take-Off Point. d) Detailed civil/structural design of the additional level of piperack from LFP to the Zero Point e) Civil/structural design of modification to Approach and Jetty Trestles, Berth Heads and existing Riser Platform. f) Detailed design of new loading arm installation including associated facilities

g) Detailed design of new Riser Platform h) Detailed design of Auxiliary Mooring near Berth A i) j) Detailed design of new pig launcher area adjacent to existing pig launchers Detailed design of new piperack between MTF and LFP

k) Detailed design of infill areas from the LFP to the Take-off Point along the side of the haul road l) Detailed design of cause way from Take-Off Point to Y-Point

You might also like

- Machines, Tools and Methods of Automobile ManufactureFrom EverandMachines, Tools and Methods of Automobile ManufactureRating: 4 out of 5 stars4/5 (1)

- IRCON's approach for developing Santragachi & Shalimar stations on South Eastern RailwayDocument36 pagesIRCON's approach for developing Santragachi & Shalimar stations on South Eastern RailwayHitesh Khanna100% (3)

- Crude Oil ProductionDocument7 pagesCrude Oil Productionumer shafiqueNo ratings yet

- 1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerFrom Everand1001 Mechanical Facts Made Easy - A Handbook Of Simple Mechanical Knowledge For Everyone Interested In The Work Of The EngineerNo ratings yet

- Air BP - Recent New Projects v3Document15 pagesAir BP - Recent New Projects v3PedroNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- 6785 PDFDocument5 pages6785 PDFSandip SurNo ratings yet

- Draft NIT For Conducting Pre-Vendor Meet For Dust Suppression System For Goleti CHP, BPA AreaDocument16 pagesDraft NIT For Conducting Pre-Vendor Meet For Dust Suppression System For Goleti CHP, BPA AreakalaiNo ratings yet

- 06 FEED Development - Onshore and OffshoreDocument2 pages06 FEED Development - Onshore and Offshorezdq02No ratings yet

- Refineria de Cartagena (Reficar) Refinery Expansion - Hydrocarbons TechnologyDocument3 pagesRefineria de Cartagena (Reficar) Refinery Expansion - Hydrocarbons TechnologyGjorgeluisNo ratings yet

- Brega Petroleum Marketing Company PRQ Tobrouk terminalDocument3 pagesBrega Petroleum Marketing Company PRQ Tobrouk terminalHedi Ben MohamedNo ratings yet

- Grateful Thanks to SCCL ManagementDocument17 pagesGrateful Thanks to SCCL ManagementluckyNo ratings yet

- Bharat Petroleum Corporation Limited LPG Bottling Plant, CSIDC, Vill. Khapri Tehsil - Tilda, RaipurDocument17 pagesBharat Petroleum Corporation Limited LPG Bottling Plant, CSIDC, Vill. Khapri Tehsil - Tilda, RaipurKausik DewanNo ratings yet

- Const. Methodology Hirong HE ProjectDocument28 pagesConst. Methodology Hirong HE ProjectVaibhav JainNo ratings yet

- Uk Asset EtapDocument6 pagesUk Asset EtapJiaqing_189134182No ratings yet

- NTPC Vindhyachal Coal Handling Plant GalleryDocument3 pagesNTPC Vindhyachal Coal Handling Plant Gallerylaloo01No ratings yet

- Coal Terminals at PQADocument31 pagesCoal Terminals at PQAtariq azizNo ratings yet

- Otc19676 SurfDocument0 pagesOtc19676 SurfAnonymous OFP2ygPIdNo ratings yet

- Salpg VizagDocument10 pagesSalpg VizagmppurohitNo ratings yet

- Track Record AudexDocument11 pagesTrack Record AudexAndy Rahmadi HerlambangNo ratings yet

- Scope and SpecificationsDocument286 pagesScope and SpecificationsRam Narendra NathNo ratings yet

- Report 4Document3 pagesReport 4madherchodgroup1No ratings yet

- Environmental Review DocumentDocument10 pagesEnvironmental Review DocumentKroya HunNo ratings yet

- Archicture Design For Green HomesDocument4 pagesArchicture Design For Green HomessokarankumarNo ratings yet

- Used Power Plant Equipment For SaleDocument54 pagesUsed Power Plant Equipment For SaleR. Baker and Son All Industrial ServicesNo ratings yet

- Core Loc WaterfrontDocument12 pagesCore Loc WaterfrontricardoNo ratings yet

- Coal Terminal at Port QasimDocument31 pagesCoal Terminal at Port QasimTariq AzizNo ratings yet

- KPT Surging Ahead Carying Forward Its 125 Years HistoryDocument5 pagesKPT Surging Ahead Carying Forward Its 125 Years HistoryproshariqNo ratings yet

- Atrum Coal Investment Fact Sheet February 2012Document2 pagesAtrum Coal Investment Fact Sheet February 2012Game_BellNo ratings yet

- Tendernotice 4Document644 pagesTendernotice 4mayank bhardwajNo ratings yet

- Sabah - Sarawak Gas Pipeliene Project BackgroundDocument4 pagesSabah - Sarawak Gas Pipeliene Project BackgroundAnkit Kumar0% (1)

- GBS and LNG Tank Design for Adriatic LNG TerminalDocument29 pagesGBS and LNG Tank Design for Adriatic LNG TerminalthawdarNo ratings yet

- Scope of Work-BAMDocument21 pagesScope of Work-BAMShabeer Shaarim Abdul Jabbar100% (1)

- Weekly Activity Report 13-01-2024 To 19-01-2024Document5 pagesWeekly Activity Report 13-01-2024 To 19-01-2024أسامه محمد عونNo ratings yet

- BP Executive - Summary - English - Final - BPCL - 11102018Document18 pagesBP Executive - Summary - English - Final - BPCL - 11102018ANIL KUMARNo ratings yet

- To Abg Shipyard: 1.1 About The Training OrganizationDocument26 pagesTo Abg Shipyard: 1.1 About The Training Organizationavis_in2000No ratings yet

- Schedule B "Scope of Service": 1. GeneralDocument13 pagesSchedule B "Scope of Service": 1. Generalali tareenNo ratings yet

- Internship Presentation MPCLDocument44 pagesInternship Presentation MPCLAli HassanNo ratings yet

- Nepean Conveyors Projects CapabilityDocument13 pagesNepean Conveyors Projects CapabilityFelipe RibeiroNo ratings yet

- CV. (Khalil Khan) UpdatedDocument3 pagesCV. (Khalil Khan) UpdatedKhalil KhanNo ratings yet

- Rand 7408Document108 pagesRand 7408Shahid KhurshidNo ratings yet

- Case Hsinta CoalYardDocument1 pageCase Hsinta CoalYardAmit BhaduriNo ratings yet

- Ghanas Jubilee Gas Export Pipeline ProjectDocument26 pagesGhanas Jubilee Gas Export Pipeline ProjectEbenezer Amoah-Kyei100% (3)

- SojitzDocument8 pagesSojitzPratik GuptaNo ratings yet

- ATTCO BrochureDocument40 pagesATTCO BrochurePERICOGARCANo ratings yet

- Technical Challenge of Quator Gas LNG ProjectDocument10 pagesTechnical Challenge of Quator Gas LNG ProjectthawdarNo ratings yet

- APGENCODocument18 pagesAPGENCOVenky PragadaNo ratings yet

- PUBLIC JOINT STOCK COMPANY "SHIPYARD ZALIVDocument21 pagesPUBLIC JOINT STOCK COMPANY "SHIPYARD ZALIViulika202No ratings yet

- Rotork Controls The Flow at Thames Water's Flagship Project: Also in This Issue..Document16 pagesRotork Controls The Flow at Thames Water's Flagship Project: Also in This Issue..Iñaki EseberriNo ratings yet

- AmritsarDocument6 pagesAmritsarprjiviNo ratings yet

- Penstock Erection Procedure - SUHEPDocument7 pagesPenstock Erection Procedure - SUHEPPrasanta MallaNo ratings yet

- PenstockDocument8 pagesPenstockJoe Mari CapaNo ratings yet

- Commissioning and Start-Up of QAFCO 5 and 6: Ali Abdi JamaDocument14 pagesCommissioning and Start-Up of QAFCO 5 and 6: Ali Abdi JamaGrootNo ratings yet

- Maintaining Energy Storage With Hot WorkDocument101 pagesMaintaining Energy Storage With Hot WorkParaZzzitNo ratings yet

- Onshore Pipelines OverviewDocument43 pagesOnshore Pipelines OverviewRa Kish P100% (1)

- Appendix 1 - Project Developments: HGCP Layout Typical WellpadDocument41 pagesAppendix 1 - Project Developments: HGCP Layout Typical WellpadRaduNo ratings yet

- Trans Load Facility OverviewDocument8 pagesTrans Load Facility OverviewBrad PritchardNo ratings yet

- Actual ReportDocument73 pagesActual ReportEzio3511No ratings yet

- ERGON POWER S A C - Company Overview - November 2013Document66 pagesERGON POWER S A C - Company Overview - November 2013Henry LévanoNo ratings yet

- Andreas Dracoulis - Haynes and BooneDocument15 pagesAndreas Dracoulis - Haynes and BooneJoão Mendonça SantosNo ratings yet

- TOTAL FIBONACCI TRADING TRADE SETUPSDocument12 pagesTOTAL FIBONACCI TRADING TRADE SETUPSChandler BingNo ratings yet

- Proposed Project Execution Baseline Schedule Rev BDocument1 pageProposed Project Execution Baseline Schedule Rev BseehariNo ratings yet

- KPMG Law - Legal Guideline For Offshore Project Contracts PDFDocument24 pagesKPMG Law - Legal Guideline For Offshore Project Contracts PDFseehari100% (1)

- Pre-Comm Sow Sogtrev0Document10 pagesPre-Comm Sow Sogtrev0seehariNo ratings yet

- 20jan15raymondflood FourierDocument40 pages20jan15raymondflood FourierseehariNo ratings yet

- Snagit 13 - CaptureDocument71 pagesSnagit 13 - CaptureseehariNo ratings yet

- PJT-PDP-TLM-733 Project Document & Drawing NumberingDocument19 pagesPJT-PDP-TLM-733 Project Document & Drawing NumberingseehariNo ratings yet

- Numbering SystemDocument8 pagesNumbering SystemseehariNo ratings yet

- Charter Party PDFDocument149 pagesCharter Party PDFseehariNo ratings yet

- 48'' Pipeline Shore Approach Reportpdf PDFDocument22 pages48'' Pipeline Shore Approach Reportpdf PDFvpandya1981100% (2)

- Operations Department Procedure Manual: by byDocument29 pagesOperations Department Procedure Manual: by byseehariNo ratings yet

- Harmonic Analysis: Chapter TenDocument40 pagesHarmonic Analysis: Chapter TenKishore Chandrasekhar PatnaikNo ratings yet

- Google book search project to digitize public domain textsDocument232 pagesGoogle book search project to digitize public domain textsseehariNo ratings yet

- Diagramma Della Verita by GalilieoDocument11 pagesDiagramma Della Verita by Galilieopremnaryans50% (2)

- Volume Average ExponentialDocument9 pagesVolume Average ExponentialrentacuraNo ratings yet

- Trading The MACDDocument24 pagesTrading The MACDemirav283% (6)

- Trading The MACDDocument24 pagesTrading The MACDemirav283% (6)

- Intro To Ortho ProjectionDocument22 pagesIntro To Ortho ProjectionseehariNo ratings yet

- TEPZZ 7Z - A T: European Patent ApplicationDocument39 pagesTEPZZ 7Z - A T: European Patent ApplicationseehariNo ratings yet

- Alt Fuel PropertiesDocument3 pagesAlt Fuel PropertiesseehariNo ratings yet

- Pasavento Instructions For Zup Pattern IndicatorDocument13 pagesPasavento Instructions For Zup Pattern IndicatormleefxNo ratings yet

- Motion Um002 en PDocument280 pagesMotion Um002 en PseehariNo ratings yet

- Creating A Frame Title BlockDocument2 pagesCreating A Frame Title BlockseehariNo ratings yet

- M.tech - Credit SystemDocument16 pagesM.tech - Credit SystemRamesh BammankattiNo ratings yet

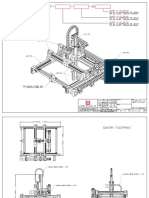

- HBG 25 Gantry Robot PrintDocument1 pageHBG 25 Gantry Robot PrintseehariNo ratings yet

- 2nd Internal Question Papers For Electrical and ElectronicsDocument1 page2nd Internal Question Papers For Electrical and ElectronicsseehariNo ratings yet

- .B.E.-B.Tech - VTUDocument8 pages.B.E.-B.Tech - VTUyamaha640No ratings yet

- MCS R6Y DrawingDocument4 pagesMCS R6Y DrawingseehariNo ratings yet

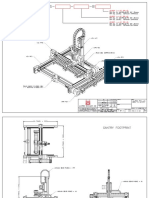

- MCS R6S Belt Z DrawingDocument4 pagesMCS R6S Belt Z DrawingseehariNo ratings yet

- Manual TransmissionDocument19 pagesManual TransmissionPaklong Azham100% (1)

- Model Ship To Ship Transfer Operations PlanDocument47 pagesModel Ship To Ship Transfer Operations PlanAnkit VyasNo ratings yet

- 3crisplant Ps Crisbag 08Document4 pages3crisplant Ps Crisbag 08Catalin AlexandruNo ratings yet

- Parts Manual: Serial Number RangeDocument283 pagesParts Manual: Serial Number RangekuangyongserviceNo ratings yet

- New Final ProjectDocument20 pagesNew Final ProjectShashank gowdaNo ratings yet

- Neacsu George Lorrymer MR 04jul Otp AmsDocument2 pagesNeacsu George Lorrymer MR 04jul Otp Amstania_liliana2004No ratings yet

- Shipbuilding Industry in IndiaDocument6 pagesShipbuilding Industry in IndiaHrushikesh. ParulekarNo ratings yet

- Transit Signal Priority Optimization For Urban TraDocument12 pagesTransit Signal Priority Optimization For Urban TraSimona NicoletaNo ratings yet

- Bmssa - Marc - S1 - Stud - M2 - Multiple Nuclei Theory - (Vidya, Likith, Renuka)Document12 pagesBmssa - Marc - S1 - Stud - M2 - Multiple Nuclei Theory - (Vidya, Likith, Renuka)YogeshNo ratings yet

- Manual Issue-2 - NewDocument96 pagesManual Issue-2 - NewGiuro Kralev80% (5)

- View 1121Document1 pageView 1121Akhmad Ridlo FauziNo ratings yet

- GMSL CNG EquipmentDocument23 pagesGMSL CNG EquipmentbaskorohelambangNo ratings yet

- Bel Geddes ProfileDocument7 pagesBel Geddes ProfileLewis PuntonNo ratings yet

- 01 - Highway Planning in IndiaDocument22 pages01 - Highway Planning in IndiaSanket MistryNo ratings yet

- ResumeDocument3 pagesResumechavanshital855No ratings yet

- IoioDocument126 pagesIoioJbdc4 Ohsec50% (2)

- 3 HI-TRAC 100 HSWIM Data Collection and Pre-Selection System - TDCDocument52 pages3 HI-TRAC 100 HSWIM Data Collection and Pre-Selection System - TDCAda BaleaNo ratings yet

- Flight Itinerary for Bersales/Errelyn and Bersales/Zylen MissDocument1 pageFlight Itinerary for Bersales/Errelyn and Bersales/Zylen MissTantan Fortaleza Pingoy100% (1)

- Valley Mack: PlazaDocument36 pagesValley Mack: PlazaDasari PrabodhNo ratings yet

- Bryson Police ReportDocument33 pagesBryson Police ReportSGVNewsNo ratings yet

- Pacific Military Bases (1945)Document274 pagesPacific Military Bases (1945)CAP History Library100% (6)

- PLEM Design Methodology: StructureDocument4 pagesPLEM Design Methodology: StructureErik AlfiandyNo ratings yet

- Meritor Serie 160 164Document69 pagesMeritor Serie 160 164Manuel RojasNo ratings yet

- 01 Road Location SurveyDocument57 pages01 Road Location SurveyBilal Saif100% (1)

- MCJ 21 Cargo PaySlipDocument9 pagesMCJ 21 Cargo PaySlipyhanie punioNo ratings yet

- Regulation Test AnswersDocument9 pagesRegulation Test Answerskaitlyn bannisterNo ratings yet

- ETHIOPIAN AVIATION ACADEMY MPL TRAINING CURRICULUMDocument1,135 pagesETHIOPIAN AVIATION ACADEMY MPL TRAINING CURRICULUMsurafel amare100% (1)

- Technical Specifications: Hydraulic ExcavatorDocument12 pagesTechnical Specifications: Hydraulic ExcavatorArvind HarryNo ratings yet

- Sales BOMDocument6 pagesSales BOMAniruddha ChakrabortyNo ratings yet

- Import of Vehicles: Taxpayer's Facilitation GuideDocument12 pagesImport of Vehicles: Taxpayer's Facilitation GuideSami Ur RehmanNo ratings yet

- A Place of My Own: The Architecture of DaydreamsFrom EverandA Place of My Own: The Architecture of DaydreamsRating: 4 out of 5 stars4/5 (241)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseFrom EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseRating: 4.5 out of 5 stars4.5/5 (50)

- Building Construction Technology: A Useful Guide - Part 1From EverandBuilding Construction Technology: A Useful Guide - Part 1Rating: 4 out of 5 stars4/5 (3)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- An Architect's Guide to Construction: Tales from the Trenches Book 1From EverandAn Architect's Guide to Construction: Tales from the Trenches Book 1No ratings yet

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsFrom EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsRating: 4.5 out of 5 stars4.5/5 (6)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionFrom EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionRating: 4.5 out of 5 stars4.5/5 (3)

- The Laws of Thermodynamics: A Very Short IntroductionFrom EverandThe Laws of Thermodynamics: A Very Short IntroductionRating: 4.5 out of 5 stars4.5/5 (10)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedFrom EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedRating: 5 out of 5 stars5/5 (1)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseFrom EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseRating: 5 out of 5 stars5/5 (3)

- Introduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandIntroduction to Applied Thermodynamics: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 2.5 out of 5 stars2.5/5 (3)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionFrom EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionRating: 4.5 out of 5 stars4.5/5 (2)

- Control of Power Electronic Converters and Systems: Volume 1From EverandControl of Power Electronic Converters and Systems: Volume 1Rating: 5 out of 5 stars5/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Design of Foundations for Offshore Wind TurbinesFrom EverandDesign of Foundations for Offshore Wind TurbinesRating: 5 out of 5 stars5/5 (3)

- Engineering Critical Assessment (ECA) for Offshore Pipeline SystemsFrom EverandEngineering Critical Assessment (ECA) for Offshore Pipeline SystemsNo ratings yet

- Building Construction Technology: A Useful Guide - Part 2From EverandBuilding Construction Technology: A Useful Guide - Part 2Rating: 5 out of 5 stars5/5 (1)

- The E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItFrom EverandThe E-Myth Contractor: Why Most Contractors' Businesses Don't Work and What to Do About ItRating: 4 out of 5 stars4/5 (16)

- Quantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationFrom EverandQuantum Mechanics 4: Spin, Lasers, Pauli Exclusion & Barrier PenetrationRating: 1 out of 5 stars1/5 (1)

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsFrom EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)