Professional Documents

Culture Documents

Racire Cooling Eng

Uploaded by

DrakooolaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Racire Cooling Eng

Uploaded by

DrakooolaCopyright:

Available Formats

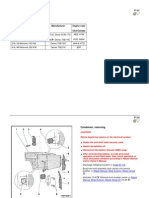

Engine BHW Cooling system components, removing and installing

Page 1 / 24

19 - 1

Cooling system components, removing and installing

Warning! When doing any repair work, especially in the engine compartment, pay attention to the following due to clearance issues: Route all the various lines (e.g. for fuel, hydraulics, EVAP system, coolant, refrigerant, brake fluid and vacuum lines and hoses) and electrical wiring so that the original positions are restored. Ensure sufficient clearance to all moving or hot components. Note: When the engine is warm the cooling system is under pressure. If necessary release pressure before beginning repair work. Hoses are secured with spring-type clips. In cases of repair only use spring-type clips.

The spring-type clip pliers VAS 5024A are recommended for installing spring-type clips. When installing coolant hoses, make sure they are free of stress and do not come into contact with other components (observe markings on coolant connections and hoses).

Cooling system components, removing and installing

Page 2 / 24

Perform leak test of cooling system using cooling system tester V.A.G 1274 , adapter V.A.G 1274/8 and adapter V.A.G 1274/9 . Cooling system components, body side system components, body side . Cooling system components, engine side system components, engine side . Draining and filling with coolant draining and filling . 19-1, Cooling 19-1, Cooling

19-1, Cooling system,

Coolant mixture ratios 19-1, Cooling system, draining and filling , Coolant, draining and filling.

Cooling system components, body side

Sealing lip For upper radiator

Cooling system components, removing and installing

Page 3 / 24

Securing pin Securing rubber Upper coolant hose From upper coolant pipe Item - 2 Secured to radiator with a retaining clip Ensure seated tightly Rubber washer Coolant Fan V7 Bolt Fan ring Is clipped into intake air elbow and secured with bolt 10 Nm Cap Check using cooling system tester V.A.G 1274 and adapter V.A.G 1274/9 Test pressure: 1.4...1.6 bar O-ring Replace if damaged 3 Nm Reservoir Perform leak test of cooling system using cooling system tester V.A.G 1274 and adapter V.A.G 1274/8 Coolant hose From upper coolant pipe

Cooling system components, removing and installing

Page 4 / 24

Item - 2 O-ring Check for secure seat Replace if damaged Lower coolant hose To housing for coolant thermostat Item - 17 Secured to radiator and thermostat housing with a retaining clip Ensure seated tightly Retaining clip Check for secure seat O-ring Replace if damaged Coolant Fan Control (FC) Thermal Switch F18 For electric fan Only vehicles with optional equipment Switch temperatures: 1. Speed on: 92 to 97 C, off: 84 to 91 C; 2. Speed on: 99 to 105 C, off: 91 to 98 C Connector For Coolant Fan Control (FC) thermal switch Locking bolt, 10 Nm Sealing lip For bottom of radiator

Cooling system components, removing and installing

Page 5 / 24

Drain plug Cooling system, draining and filling 19-1, Cooling system, draining and filling

Cooling system components, engine side

To upper radiator Item - 4 Upper coolant line Coolant hose To upper coolant reservoir Item - 14 -

Cooling system components, removing and installing

Page 6 / 24

O-ring Check for secure seat Replace Coolant hose Engine Coolant Temperature (ECT) Sensor G62 With Engine Coolant Temperature (ECT) Gauge Sensor G2 Retaining clip Check for secure seat O-ring Replace 10 Nm Connecting piece Only vehicles with optional equipment With glow plugs for coolant Coolant hose To heat exchanger Secured to connections with retaining clip Ensure seated tightly Connecting piece Coolant hose From heat exchanger Secured to lower coolant pipe with retaining clip Ensure seated tightly

Cooling system components, removing and installing

Page 7 / 24

Lower coolant line 15 Nm Coolant hose From lower radiator 16 Item -

Secured to radiator and thermostat housing with a retaining clip Ensure seated tightly Connecting piece For thermostat Coolant thermostat Removing and installing 19-1, Coolant thermostat, removing and installing Observe installed location 19-1, Coolant thermostat, removing and installing , Coolant thermostat, removing and installing Checking: Heat up thermostat in water Opening begins: approx. 85 C Ends: approx. 105 C

Opening lift: min. 7 mm 40 Nm Oil cooler Fan wheel For viscous fan clutch Viscous fan clutch, removing and installing 19-1, Viscous fan clutch, removing and installing

Cooling system components, removing and installing

Page 8 / 24

15 Nm Coolant pump Check for ease of movement Note installation position Removing and installing 19-1, Coolant pump, removing and installing 25 Nm

Cooling system, draining and filling

Special tools, testers and auxiliary items required Refractometer T10007

Cooling system components, removing and installing

Page 9 / 24

Drip tray V.A.G 1306 Spring-type clip pliers VAS 5024A Cooling system charge unit VAS 6096 Adapter V.A.G 1274/8 Torque wrench (5 to 50 Nm) V.A.G 1331

Special tools, testers and auxiliary items required

Adapter V.A.G 1274/10

Draining

Caution! When opening the expansion tank, hot steam may be released. Cover the cap with a rag and open very carefully. - Open cap on coolant expansion tank. - Remove sound insulation pan:

Repair Manual, Body Exterior, Repair Group 50, Sound insulation

Cooling system components, removing and installing

Page 10 / 24

- Pull coolant hose retaining clip - arrow - off downward and remove coolant hose from radiator.

- In addition, drain coolant from engine by disconnecting coolant hoses at oil cooler - arrows - . Note: Observe disposal regulations for coolant!

Filling

Note: Only use coolant additive G 12 according to TL "VW 774 F" . Distinguishing color: violet G 12 violet according to TL "VW 774 F" may be mixed with previous coolant additive G 12 red!

Cooling system components, removing and installing

Page 11 / 24

"G 12" and coolant additives marked in accordance with TL "VW 774 F" prevent frost and corrosion damage, scaling and also raise the boiling point of the coolant. For this reason the system must be filled all year round with frost and corrosion protection additives. Because of its high boiling point, the coolant improves engine reliability under heavy loads, particularly in countries with tropical climates. Protection against frost must be assured to about -25 C (in arctic climatic countries to about -35 C). The coolant concentration must not be reduced by adding water even in warmer seasons and in warmer countries. The coolant additive portion must be at least 40%. If for climatic reasons a greater frost protection is required, the amount of G 12 can be increased, but only up to 60% (frost protection to about -40 C), as otherwise frost protection is reduced again and cooling effectiveness is also reduced. Use only clean drinking water for mixing. If radiator, heat exchanger, cylinder head or cylinder head gasket is replaced, do not reuse old coolant. Recommended mixture ratios: Frost protection to -25 -35

1) The

Anti-freeze portion 40% 50%

G 12 1) 3.0 L 3.5 L

Water 1) 4.0 L 3.5 L

C C

quantity of coolant can vary depending upon the vehicle equipment. - Install lower coolant hose and secure. - Connect coolant hoses on oil cooler. With cooling system charge unit VAS 6096 :

Cooling system components, removing and installing

Page 12 / 24

- Screw adapter V.A.G 1274/8 onto expansion tank. - Fill coolant circuit using cooling system charge unit VAS 6096 . Operating instructions for cooling system charge unit VAS 6096 Without cooling system charge unit VAS 6096 :

- Screw adapter V.A.G 1274/8 on expansion tank and extend it using adapter for V.A.G 1274 tester V.A.G 1274/10 .

Cooling system components, removing and installing

Page 13 / 24

- Loosen coolant hose on heater core and pull back hose sufficiently so that bleed hole in coolant hose - arrow - is no longer covered by connecting piece. - Fill with coolant until it escapes from coolant hose bleeder hole. - Push coolant hose on connection and secure it. With and without cooling system charge unit VAS 6096 : - Close expansion tank. - Turn off heater controls. - Start engine and maintain an engine speed of about 2000 rpm for approx. 3 minutes. - Allow engine to run at idle speed until lower hose on radiator becomes hot. Caution! When opening the expansion tank, hot steam may be released. Cover the cap with a rag and open very carefully. - Check coolant level and top off if necessary. With engine at operating temperature, coolant level must be at max. marking. With engine cold, coolant level must be between min. and max. marking.

Radiator, removing and installing

Cooling system components, removing and installing

Page 14 / 24

Special tools, testers and auxiliary items required Refractometer T10007 Drip tray V.A.G 1306 Pliers for spring type clips VAS 5024 A Cooling system charge unit VAS 6096 Adapter V.A.G 1274/8 Torque wrench (5 to 50 Nm) V.A.G 1331

Cooling system components, removing and installing

Page 15 / 24

Special tools, testers and auxiliary items required

Adapter V.A.G 1274/10

Removing

- Drain coolant filling .

19-1, Cooling system, draining and

- Remove front bumper:

Repair Manual, Body Exterior, Repair Group 63, Assembly overview - front bumper - Pull off coolant hoses from radiator.

- Unbolt cooling coil for power steering fluid (arrows) and let hang free; Do not open hydraulic fluid circuit. - Remove upper radiator securing clips and remove radiator toward front. Vehicles with air conditioning - Observe additional information and removal work 19-1, Additional information and assembly work on vehicles with

Cooling system components, removing and installing

Page 16 / 24

air conditioning .

Installing

Installation is performed in the reverse order of removal, noting the following: - Fill with coolant filling . 19-1, Cooling system, draining and

- Check electrical connections and routing:

Repair Manual, Electrical Equipment, Repair Group 97, - Install front bumper

Repair Manual, Body Exterior, Repair Group 63, Assembly overview - front bumper

Additional information and assembly work on vehicles with air conditioning

Warning! The air conditioning refrigerant circuit must not be opened. Note: Do not bend or stretch lines or hoses as condenser and/or refrigerant lines/hoses may be damaged. - Remove retaining clamp(s) from refrigerant lines. - Unscrew condenser from radiator and pull forward as far as possible. - Secure condenser to body so that refrigerant lines/hoses are not stressed. - Pull radiator out between condenser and lock carrier.

Coolant pump, removing and installing

Cooling system components, removing and installing

Page 17 / 24

Special tools, testers and auxiliary items required Refractometer T10007 Drip tray V.A.G 1306 Pliers for spring type clips VAS 5024 A Cooling system charge unit VAS 6096 Adapter V.A.G 1274/8 Torque wrench (5 to 50 Nm) V.A.G 1331

Cooling system components, removing and installing

Page 18 / 24

Special tools, testers and auxiliary items required

Adapter V.A.G 1274/10

Removing

Note: Always replace gaskets and seals. - Bring lock carrier into service position.

Repair Manual, Body Exterior, Repair Group 50, Body front - Drain coolant filling . 19-1, Cooling system, draining and 13-1, Ribbed belt, removing and

- Remove ribbed belt installing

- Remove toothed belt 15-1, Toothed belt, removing, installing and tensioning .

- Remove bolts - 1 - of coolant pump - 2 - and carefully take

Cooling system components, removing and installing

Page 19 / 24

out coolant pump.

Installing

Installation is performed in the reverse order of removal, note the following:

- Soak new O-ring - 3 - with coolant and install. - Place coolant pump - 2 - into cylinder block and fasten bolts - 1 - to 15 Nm. Note: The sealing plug of the coolant pump faces downward. - Install toothed belt 15-1, Toothed belt, removing, installing and tensioning . - Install ribbed belt installing . - Refill with coolant filling . 13-1, Ribbed belt, removing and 19-1, Cooling system, draining and

Coolant thermostat, removing and installing

Cooling system components, removing and installing

Page 20 / 24

Special tools, testers and auxiliary items required Refractometer T10007 Drip tray V.A.G 1306 Pliers for spring type clips VAS 5024 A Cooling system charge unit VAS 6096 Adapter V.A.G 1274/8 Torque wrench (5 to 50 Nm) V.A.G 1331

Cooling system components, removing and installing

Page 21 / 24

Special tools, testers and auxiliary items required

Adapter V.A.G 1274/10

Removing

Note: Always replace gaskets and seals. - Drain coolant filling . 19-1, Cooling system, draining and

- Disconnect coolant hose from housing.

- Unscrew bolts - 1 - from housing - 2 - and remove with coolant thermostat - 4 - . - Turn coolant thermostat - 4 - 1 / 4 turn (90 remove it from housing - 2 - .

Installing

) left and

Installation is performed in the reverse order of removal, note the following:

Cooling system components, removing and installing

Page 22 / 24

- Moisten new O-ring - 3 - with coolant and install. - Insert coolant thermostat - 4 - into housing - 2 - and turn right 1 / 4 turn (90 ). Note: The clip of the thermostat must be positioned at approx. right angle. - Insert housing - 2 - with thermostat - 4 - into engine block. - Tighten bolts - 1 - : Torque specification 15 Nm - Fill with coolant filling . 19-1, Cooling system, draining and

Viscous fan clutch, removing and installing

Special tools, testers and auxiliary items required

Pin wrench 3212 Special tools, testers and auxiliary items required

Cooling system components, removing and installing

Page 23 / 24

Torque wrench (5 to 50 Nm) V.A.G 1331

Removing

- Bring lock carrier into service position.

Repair Manual, Body Exterior, Repair Group 50, Body front - Remove ribbed belt installing . 13-1, Ribbed belt, removing and

- Remove fan wheel from viscous fan clutch.

- Counterhold belt pulley for viscous fan clutch with pin wrench 3212 and unscrew from bracket with 8 mm hex socket wrench. - Remove belt pulley from viscous fan clutch.

Cooling system components, removing and installing

Page 24 / 24

Installing

Installation is performed in the reverse order of removal, note the following: - Tighten belt pulley to viscous fan clutch to 30 Nm. - Tighten viscous fan clutch to bracket to 45 Nm. - Tighten fan wheel to viscous fan clutch to 10 Nm. - Install ribbed belt installing . 13-1, Ribbed belt, removing and

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- SSP GBDocument75 pagesSSP GBDeanna VegaNo ratings yet

- b5 Loc Electr CompDocument12 pagesb5 Loc Electr CompAdam TylickiNo ratings yet

- Manual Clima PassatDocument48 pagesManual Clima PassatCatalin JianuNo ratings yet

- SSP 191 - VW Passat B5 '97 - Construction & OperationDocument47 pagesSSP 191 - VW Passat B5 '97 - Construction & OperationaleuzevaxNo ratings yet

- Manual Clima PassatDocument48 pagesManual Clima PassatCatalin JianuNo ratings yet

- b5 Dop SignDocument1 pageb5 Dop SignDrakooolaNo ratings yet

- Manual Climatronic b5Document61 pagesManual Climatronic b5Muraru Dan91% (11)

- BMW Error CodesDocument32 pagesBMW Error CodesSagr95% (44)

- b5 Ac Refrigerant Syst ServDocument29 pagesb5 Ac Refrigerant Syst ServTanee BoonmalertNo ratings yet

- PASSAT b5 Ac TroubleDocument18 pagesPASSAT b5 Ac TroublesafetNo ratings yet

- VW Passat B5 87-132 AC Refrigerant SysDocument9 pagesVW Passat B5 87-132 AC Refrigerant SysJosé Luis Ormeño100% (1)

- Caresheet For Vipera AmmodytesDocument3 pagesCaresheet For Vipera AmmodytesDrakooolaNo ratings yet

- b5 Ac Refrigerant Syst CapacitiesDocument5 pagesb5 Ac Refrigerant Syst CapacitiesDrakooolaNo ratings yet

- BMW Error CodesDocument32 pagesBMW Error CodesSagr95% (44)

- Rescue Cards For Passenger Cars Mercedes Benz - AMG - McLaren - Maybach - SmartDocument99 pagesRescue Cards For Passenger Cars Mercedes Benz - AMG - McLaren - Maybach - SmartDrakooolaNo ratings yet

- PalaDocument1 pagePalaDrakooolaNo ratings yet

- Raw Food Diva PDFDocument176 pagesRaw Food Diva PDFHerbert Berty DassingerNo ratings yet

- 53 Bevel Gear Support DrawDocument1 page53 Bevel Gear Support DrawFelipe KnorstNo ratings yet

- Building A SmokehouseDocument6 pagesBuilding A Smokehouseleecad77No ratings yet

- Tabla RulmentiDocument1 pageTabla RulmentiDrakooolaNo ratings yet

- Turbin ADocument1 pageTurbin ADrakooolaNo ratings yet

- 53 Bevel Gear Support DrawDocument1 page53 Bevel Gear Support DrawFelipe KnorstNo ratings yet

- Raising Japanese QuailDocument5 pagesRaising Japanese QuailJafar Khan100% (1)

- DiscDocument1 pageDiscDrakooolaNo ratings yet

- BratDocument1 pageBratDrakooolaNo ratings yet

- The Lost Journals of Nikola Tesla PDFDocument155 pagesThe Lost Journals of Nikola Tesla PDFJosé Guzmán ChumánNo ratings yet

- (Docauto - Uv.ro) 107 2006 ManualDocument83 pages(Docauto - Uv.ro) 107 2006 ManualDrakooolaNo ratings yet

- The Lost Journals of Nikola Tesla PDFDocument155 pagesThe Lost Journals of Nikola Tesla PDFJosé Guzmán ChumánNo ratings yet

- Rescue Cards For Passenger Cars Mercedes Benz - AMG - McLaren - Maybach - SmartDocument99 pagesRescue Cards For Passenger Cars Mercedes Benz - AMG - McLaren - Maybach - SmartDrakooolaNo ratings yet

- Opcom Read Security CodeDocument1 pageOpcom Read Security CodeAlex MusatNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hyundai D6GA Engine Mechanical SystemDocument97 pagesHyundai D6GA Engine Mechanical SystemBigfair HD7889% (27)

- Radiator RemovalDocument8 pagesRadiator RemovaliveyNo ratings yet

- 17 Samss 518Document20 pages17 Samss 518Mohamed H. ShedidNo ratings yet

- Bus Bid Sheet With Cross RefDocument56 pagesBus Bid Sheet With Cross ReftylerNo ratings yet

- HYSTER H3-0FT L177 Engine Spare PartsDocument85 pagesHYSTER H3-0FT L177 Engine Spare PartsMelwyn Fernandes100% (1)

- Worcester Greenstar 24i Operating InstructionsDocument32 pagesWorcester Greenstar 24i Operating InstructionsKaren SayalNo ratings yet

- Parts ManualDocument142 pagesParts ManualAlexandru AlistarhNo ratings yet

- IGNIS Uputstvo ENGDocument13 pagesIGNIS Uputstvo ENGVeronica WaltersNo ratings yet

- Worcester Greenstar Junior Instruction GuideDocument65 pagesWorcester Greenstar Junior Instruction GuidePeter ThomasNo ratings yet

- WIA WC30D Operator ManualDocument43 pagesWIA WC30D Operator Manualsoheil zamaniNo ratings yet

- CO - CoolingDocument43 pagesCO - CoolingOral McnarrinNo ratings yet

- Power Products 50Hz 650 - 3000 kVA)Document12 pagesPower Products 50Hz 650 - 3000 kVA)Jamal HabbasNo ratings yet

- Maintenance: ASU-600 SeriesDocument54 pagesMaintenance: ASU-600 SeriesMichael Maluenda Castillo100% (2)

- 3406C GENERATOR SET ENGINE CaterpillarDocument1 page3406C GENERATOR SET ENGINE CaterpillarAmazonas ManutençãoNo ratings yet

- Conditioning Laboratory Unit,: Computer Controlled Air With SCADA and PID ControlDocument17 pagesConditioning Laboratory Unit,: Computer Controlled Air With SCADA and PID ControlBeshir Heyru MohammedNo ratings yet

- MFL68026607 15 220603 04 Web EnglishDocument263 pagesMFL68026607 15 220603 04 Web Englishingrid apaqNo ratings yet

- Parts Manual: TRUCK MODEL: C20-33 (35) L SERIAL NUMBER: P232L-224 & Above 9644 KFDocument165 pagesParts Manual: TRUCK MODEL: C20-33 (35) L SERIAL NUMBER: P232L-224 & Above 9644 KFpaulo_gallina_2No ratings yet

- KITI FHK Technik 2015 Engl INT PDFDocument140 pagesKITI FHK Technik 2015 Engl INT PDFRO-AM-BDNo ratings yet

- Engine Performance Data at 1800 RPM: % KG/KWH LB/ BHP-H U.S. Gal/ Hour Liter/ Hour BHP KWMDocument3 pagesEngine Performance Data at 1800 RPM: % KG/KWH LB/ BHP-H U.S. Gal/ Hour Liter/ Hour BHP KWMazhan77No ratings yet

- Analysis of Maruti 800Document148 pagesAnalysis of Maruti 800Anup C67% (3)

- BMW B46TU Engine Technical TrainingDocument41 pagesBMW B46TU Engine Technical TrainingLauri MäkinenNo ratings yet

- Calculate Size of Exhaust Pipe-2Document33 pagesCalculate Size of Exhaust Pipe-2Mạnh Ngô Đức75% (4)

- Application of ThermodynamicsDocument5 pagesApplication of ThermodynamicsRonald McJollibeeNo ratings yet

- Pantera Dpi Hydraulic System: Original InstructionsDocument98 pagesPantera Dpi Hydraulic System: Original InstructionsLewis Nemananga100% (1)

- Cat C175-16: Diesel Generator SetsDocument5 pagesCat C175-16: Diesel Generator SetsMiriam GaboNo ratings yet

- Imi Ae06kDocument4 pagesImi Ae06kpawel ras100% (2)

- Event & Diagnostic Troubleshooting Guide v6Document18 pagesEvent & Diagnostic Troubleshooting Guide v6AliHabesNo ratings yet

- Engine Cooling SystemDocument28 pagesEngine Cooling SystemSagar Dadhich100% (1)

- Made in ST - Petersburg Official Export Directory of ST - Petersburg 2019 PDFDocument204 pagesMade in ST - Petersburg Official Export Directory of ST - Petersburg 2019 PDFkishoreNo ratings yet

- 24 MW HFO PlanDocument13 pages24 MW HFO PlanMuhammad Arga Sadhewa100% (1)