Professional Documents

Culture Documents

Edasd

Uploaded by

mayukhguha1988Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Edasd

Uploaded by

mayukhguha1988Copyright:

Available Formats

GRUNDFO S

WHITE PAPER

Specific Speed

by Steve Wilson

he term specific speed is much misunderstood in the pump industry, yet terms that arise from specific speed discussions are used without full knowledge of the implications. A basic understanding of specific speed is necessary and helpful in pump selection and analysis and in discussions of impeller types. This paper is by no means intended as a complete discourse on specific speed, but rather a basic overview. For the interested, further study should be made.

Note on the Statement, and Calculation of Specific Speed: NS of a pump is calculated using BEP of the pump at full diameter. On multi-stage pumps, NS is computed for the first stage only. If asked specifically by a customer for the NS of a pump being proposed, NS should be calculated using the proposed pumps BEP at the proposed diameter.

DEFINITION OF SPECIFIC SPEED

Specific speed is the speed in RPM at which a given impeller would operate if reduced (or increased) proportionally in size so as to deliver a capacity of one GPM at a head of one foot. By itself, this seems meaningless, but taken into the bigger picture, the specific speed (NS) becomes a dimensionless number that describes the hydraulic features of a pump, and more specifically of a pumps impeller(s). Designers use specific speed, coupled with modeling laws and other tools such as the affinity laws to fix curve shape, predict theoretical efficiencies, HPs, etc..

SPECIFIC SPEED BASICS

The specific speed is largely related to the impeller discharge angle, relative to the inlet. Pumps in which the discharge of the impeller is directly radial to the suction; that is, where the flow transitions rapidly from one plane to the other, have a low specific speed and are called radial vaned or radial flow impellers. The N S will be in the neighborhood of from 500 to 1700. These pumps will usually exhibit a low flow to head ratio. At the other end of the scale, the fluid will be discharged from the impeller along the same axis as it enters. These impellers (or propellers) have high specific speeds, generally above 9000, and are referred to as axial flow impellers (or propellers) and have a high flow to head ratio. Between these two extremes fall: Mixed Flow Impellers, with an NS range of from around 4000 to 9000 begin to transition away from the suction axis, but discharge between the axial and radial angles, and generally exhibit a high flow to moderate head ratio. Francis Vaned Impellers, between mixed and radial flow, with NS values from around 1700 to 4000. Francis vaned impellers are frequently discussed in the industry, and are simply impellers which have vanes curvature such that the transition from the inlet axis to radial axis is completed more gradually.

SPECIFIC SPEED FORMULA

The formula for specific speed is simplified as: NS = RPM x GPM.5 H.75 or NS = NQ H3/4

Where: NS = Specific Speed RPM = Speed in revolutions per minute GPM = US Gallons Per Minute H = Head in feet N = RPM Q = GPM

SPECIFIC SPEED

GRUNDFOS WHITE PAPER | 2

Ns 1 50 0

10 0 0

20 0 0

rise as flow increases. High specific speed pumps (propellers and mixed flow) exhibit dropping HP characteristics: The HP requirement is highest at shutoff and decreases as flow increases. (Care must be taken in running or testing high NS pumps at shutoff to assure motor HP is not overloaded.) Francis vaned impellers again fall in between these two extremes, with power curves that rise from shutoff but flatten out as flow increases. Figure 2 gives a graphic illustration of the relative curve shapes for both HQ and Power.

30 0 0

50 0 0

300 HEAD % OF NORMAL

10 0 0 0

HEAD CAPACITY CURVES

200 5

4 6 3 2 1

Figure 1. Impellers of various specific speed design

100

Figure 1 illustrates the general appearance of impellers of various specific speed designs, with inlet being at the bottom.

0

1 2 3 4 5 6 5 1 2 3 4 5 6

SPECIFIC SPEED AND THE PUMP CURVE

The specific speed of the pump will determine the general (theoretical) curve slope, from shutoff to runout. Low specific speed impellers will exhibit flat head curves and high specific speed pumps will exhibit steeper curves. (Remember that specific speed is taken for a single stage only. Many multi-stage pumps exhibit steep curves when all stages are shown together, but have a low NS.

4 3 2 1

BRAKE HORSEPOWER CAPACITY CURVES

50 100 CAPACITY - % OF NORMAL SPECIFIC SPEED CURVE

15

Figure 2. HQ and BHP curves for various specific speeds

SPECIFIC SPEED AND POWER REQUIREMENTS

Just as pumps with low NS values have low HQ curves, their power requirements will continue to

SPECIFIC SPEED

GRUNDFOS WHITE PAPER | 3

SPECIFIC SPEED AND EFFICIENCY

The impact of specific speed on theoretical efficiency has been well studied and verified by testing. Both Karassik, in the Pump Handbook (page 2.203) and Lobanoff, in Centrifugal Pumps: Design and Application (pages 15-18) reveal the results of the studies: Pumps with specific speeds from 2000-3500 (Francis Vane Impellers) will exhibit the highest efficiencies in theory and in test. Of course, as discussed in the High and Broad Band Efficiency paper, pump construction and configuration will cause differences between theoretical and actual results. Further, it is not practical or possible to utilize the same range of specific speeds for all desired conditions of service or installations.

CONCLUSION

Understanding specific speed in general is helpful in understanding curve shape, horsepower requirements, efficiency, and pump design. It is a basic tool of the pump designer. Understanding the physical and hydraulic natures of flow paths of different (or similar) NS values can be a valuable tool in assessing both proposed and existing installations.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Mini-Lab - Topology SheetsDocument15 pagesMini-Lab - Topology Sheetsmayukhguha1988No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Mini-Lab - Student GuideDocument14 pagesMini-Lab - Student GuideDiego Fernando Solis H100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 7Document2 pages7mayukhguha1988No ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Belt Filter Press TBEDocument2 pagesBelt Filter Press TBEmayukhguha1988No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Cs Dimenions Large FlangesDocument7 pagesCs Dimenions Large Flangesmayukhguha1988No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

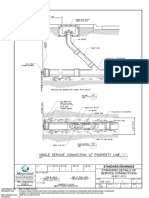

- Standard Details of Service Connections: PMD - EngineeringDocument1 pageStandard Details of Service Connections: PMD - Engineeringmayukhguha1988No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 2.11.1 Blowers Data Sheet Including Performance CurveDocument4 pages2.11.1 Blowers Data Sheet Including Performance Curvemayukhguha1988No ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Design Calculation Sheet: 1-AbbreviationsDocument3 pagesDesign Calculation Sheet: 1-Abbreviationsmayukhguha1988No ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Cavitation 160908025745Document76 pagesCavitation 160908025745bilal almelegyNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Review and Actions ArisingDocument1 pageReview and Actions Arisingmayukhguha1988No ratings yet

- General Guidelines InsulationDocument56 pagesGeneral Guidelines InsulationPadmanaban SoundirarajanNo ratings yet

- Product Sheet IPF 03 2017Document2 pagesProduct Sheet IPF 03 2017mayukhguha1988No ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

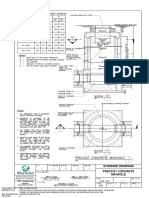

- Standard Details of Deep Precast Conc. Manhole W/ 1 Intermediate PlatformDocument1 pageStandard Details of Deep Precast Conc. Manhole W/ 1 Intermediate Platformmayukhguha1988No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Equalization Tank BOM Sht. 8 of 10)Document1 pageEqualization Tank BOM Sht. 8 of 10)mayukhguha1988No ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

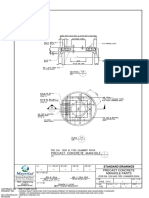

- Precast Concrete Manhole Parts: PMD - EngineeringDocument1 pagePrecast Concrete Manhole Parts: PMD - Engineeringmayukhguha1988No ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- 40.1000 Del - 705Document1 page40.1000 Del - 705mayukhguha1988No ratings yet

- Precast Concrete Manhole Parts: PMD - EngineeringDocument1 pagePrecast Concrete Manhole Parts: PMD - Engineeringmayukhguha1988No ratings yet

- 40.1000 Del - 706Document1 page40.1000 Del - 706mayukhguha1988No ratings yet

- Precast Concrete Manhole: PMD - EngineeringDocument1 pagePrecast Concrete Manhole: PMD - Engineeringmayukhguha1988No ratings yet

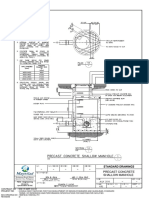

- Precast Concrete Shallow Manhole: PMD - EngineeringDocument1 pagePrecast Concrete Shallow Manhole: PMD - Engineeringmayukhguha1988No ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 1000-GS-8009 e 0Document39 pages1000-GS-8009 e 0mayukhguha1988No ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- MR for Submersible Pumps CoordinationDocument2 pagesMR for Submersible Pumps Coordinationmayukhguha1988No ratings yet

- General Guidelines InsulationDocument56 pagesGeneral Guidelines InsulationPadmanaban SoundirarajanNo ratings yet

- SCADA Desktop-Industrial TypeDocument1 pageSCADA Desktop-Industrial Typemayukhguha1988No ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- 58-0100 FRP - Process - Vessels PDFDocument20 pages58-0100 FRP - Process - Vessels PDFmayukhguha1988No ratings yet

- Pressure Vessel Design CalcDocument1 pagePressure Vessel Design Calcmayukhguha1988No ratings yet

- 1000-Pa-5502 e 2Document22 pages1000-Pa-5502 e 2mayukhguha1988No ratings yet

- Pump Control System Automation - KSBDocument76 pagesPump Control System Automation - KSBmask98No ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Fans Reference GuideDocument160 pagesFans Reference Guidekarthikraja21100% (13)

- Pump CalculationsDocument26 pagesPump Calculationsrumabiswas853100% (1)

- Plastic AnalysisDocument23 pagesPlastic AnalysisPraveen Kumar R100% (1)

- MSDS Canada - ZRC Galvilite Galvanizing Repair CompoundDocument6 pagesMSDS Canada - ZRC Galvilite Galvanizing Repair CompoundRaymond LalumiereNo ratings yet

- 32LC818 Lcd26v88amDocument53 pages32LC818 Lcd26v88amDaniel AvecillaNo ratings yet

- Hydraulic Arm RealDocument14 pagesHydraulic Arm RealVarun S RajanNo ratings yet

- CO2 Arc Welding ProcessDocument4 pagesCO2 Arc Welding ProcessHari krishnan100% (1)

- SUPPLY OF LABOR MATERIALS EQUIPMENT FOR STAINLESS STEEL TANKSDocument2 pagesSUPPLY OF LABOR MATERIALS EQUIPMENT FOR STAINLESS STEEL TANKSWilliam LimNo ratings yet

- Colby - Sapac BrochureDocument16 pagesColby - Sapac Brochureshogun billings100% (1)

- Simrit Cassette SealsDocument6 pagesSimrit Cassette SealsfahazumeeNo ratings yet

- Moulding Effects & DefectsDocument91 pagesMoulding Effects & Defectsrijoy p pNo ratings yet

- 13 SH Cutting Tools R11Document65 pages13 SH Cutting Tools R11Richard ZawNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- CH - Mass Transfer and Transport Phenomenon PDFDocument29 pagesCH - Mass Transfer and Transport Phenomenon PDFRaghul RockNo ratings yet

- Fluid Mechanics-I Lab ManualDocument28 pagesFluid Mechanics-I Lab Manualउमेश गावंडेNo ratings yet

- AIGOSTAR 300000HFA Panini Maker NoticeDocument9 pagesAIGOSTAR 300000HFA Panini Maker NoticeSYLVIENo ratings yet

- Heat Load Calculation IIDocument2 pagesHeat Load Calculation IIsiruslara6491No ratings yet

- Corporate Image enDocument8 pagesCorporate Image enDanfert PinedoNo ratings yet

- QB 5 - Basic NDT - LT QBDocument5 pagesQB 5 - Basic NDT - LT QBprabhakaran.SNo ratings yet

- Chemistry ProjectDocument16 pagesChemistry Projectgaganshishodia2No ratings yet

- Corrosion of Chrome PlatingDocument37 pagesCorrosion of Chrome PlatingdavideNo ratings yet

- Local Bodies 3Document19 pagesLocal Bodies 3umzzNo ratings yet

- T100 Thrusters PropellerDocument15 pagesT100 Thrusters PropellerNikhilkrishna NairNo ratings yet

- Lec-2 Structural Steel PropertiesDocument10 pagesLec-2 Structural Steel PropertiesRifat HasanNo ratings yet

- A Review On Rubber Compound Mixing in Banbury Mixer at Tire Industries-864 PDFDocument4 pagesA Review On Rubber Compound Mixing in Banbury Mixer at Tire Industries-864 PDFJin HernNo ratings yet

- Leaflet Uniswitch CBCDocument2 pagesLeaflet Uniswitch CBCFahmi CumiNo ratings yet

- Smart Axis Automatic Chasing Machine ManualDocument38 pagesSmart Axis Automatic Chasing Machine Manualvser19No ratings yet

- Velan PDFDocument40 pagesVelan PDFpablopasqualini18No ratings yet

- API RP505 Classfication SelectedDocument2 pagesAPI RP505 Classfication SelectedSing Yew LamNo ratings yet

- Cane Ite PDFDocument4 pagesCane Ite PDFJim HaigNo ratings yet

- Introduction Electrical MotorDocument36 pagesIntroduction Electrical MotorYajidNo ratings yet

- Recycling ConcreteDocument56 pagesRecycling ConcreteReshmita PallaNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialFrom EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNo ratings yet

- Shorting the Grid: The Hidden Fragility of Our Electric GridFrom EverandShorting the Grid: The Hidden Fragility of Our Electric GridRating: 4.5 out of 5 stars4.5/5 (2)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentFrom EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentRating: 4.5 out of 5 stars4.5/5 (21)

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyFrom EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNo ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesFrom EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesRating: 4.5 out of 5 stars4.5/5 (21)