Professional Documents

Culture Documents

717SM02

Uploaded by

hdlozanoaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

717SM02

Uploaded by

hdlozanoaCopyright:

Available Formats

2.

SOFTWARE STRUCTURE AND TIMING CHART

2-1 (1)

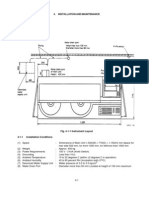

Data Processing Fundamental Measurement The fundamental measurement with this analyzer is as shown in Fig. 2-1-1. After measurement of the water blank and addition of the 1st reagent, the absorbance is measured for 50 points at intervals of about 12 seconds over a 10-minute period, and data processing is made using the value from which the water blank value has been subtracted. The actual timing to be used for the absorbance differs with the analytical method.

Fig. 2-1-1 Fundamental Measurement

2-1

(2)

Whole Reaction Process Photometry Figure 2-1-2 shows the photometric monitoring sequence of the whole reaction process in the Model 717 analyzer. After measurement of water blank, the first reagent (R1) is added to each sample. Then, for ten minutes, absorbance of reaction solution is measured repetitively every 12 seconds. That is, photometric measurement is repeated 50 times for ten minutes as indicated below. The user can select arbitrary photometric (absorbance) points from these 50 points to meet the particular purpose of test.

Fig. 2-1-2 Reaction Time Course

Table 2-1-1 Photometric Points and Elapsed Time

Photome Point 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 Elapsed Time (sec) 0.00 11.87 23.74 35.60 47.47 59.34 71.21 83.08 94.95 106.81 118.68 130.55 142.42 154.29 166.16 178.02 189.89 11.87 Time Interval (sec) Approx. 11.87 Photome Point 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 Elapsed Time (sec) 201.76 213.63 225.50 237.37 249.23 261.10 272.97 282.86 294.72 306.59 318.46 330.33 342.20 354.07 365.93 377.80 389.67 11.87 11.87 9.89 11.87 Time Interval (sec) 11.87 Photome Point 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 Elapsed Time (sec) 401.54 413.41 425.28 437.14 449.01 460.88 472.75 484.62 496.49 508.35 520.22 532.09 543.96 555.83 567.70 579.56 11.87 Time Interval (sec) 11.87

2-2

2-1-1

Absorbance Measurement

ADC-error data alarm is added when ADC value was not acquired at even one point among all photometric points. ADC Control (a) ADC Calibration 1) Calibration Formula

Fig. 2-1-3 ADC Calibration

Activity X can be calculated by the formula below according to measured ADC count Y with reference to the above figure. X = (b-a)/(B-A) (Y - (Ab-Ba)/(b - a)) a and b values become as listed below in photometric assay and ISE measurement.

Activity Photometric assay 10 mm-converted absorbance X 10??-4 Abs Electromotive force mV

a (2 V)

b (6 V)

10 V

0V

8333

25,000 b (8 V)

41,667

ISE measuremen

+150 -150

+250

-250

Fig. 2-1-4 Abs vs. ADC Value Comparison

2-3

2)

Integral Time and Allowable Error of Calibration Voltage ADC Count Photometric assay: ISE assay: 16 bits, full, 7.2 msec 16 bits, full, 3.6 msec

ADC count for each calibration voltage lies within the following range. Photometric assay: 2 V ...................................... 6189 to 10,315 6 V ...................................... 13,946 to 23,244 ISE assay: 2 V....................................... 12,377 to 20,629 8 V....................................... 35.650 to 59,416 ADC CALIB alarm is issued when each output ADC value exceeds the above range upon ADC calibration.

(b)

ADC Error Check ADC error alarm occurs if the number of ADC starts does not match that of acquired ADC values.

2-1-2 (a)

Temperature Measurement Temperature ADC 1) 2) Integral Time Set at 1.8 msec. Calibration Formula Temperature 100 = 1600Y/(B-A) + (800B-2400A)/(B-A) A ................ ADC count for calibration voltage 2 V B ................ ADC count for calibration voltage 6 V Y................. Measured ADC count 3) Calibration Error Temperature ADC calibration error alarm is generated when the output ADC count for each calibration voltage is not within the following range. 2 V.................................... 6189 to 10,315 6 V.................................... 13,946 to 23,244 4) Temperature ADC Error Alarm is issued when temperature ADC cannot terminate.

(b)

Temperature Measurement Incubation Bath in End Point Assay 1) Temperature is measured every 1.5 seconds, and an average of 4 measured temperatures is indicated on OPERATION MONITOR screen. 2) Overheat alarm occurs when temperature rises beyond 39C. 3) Temperature alarm is issued if the current temperature is out of a range of 25/30/37C 0.5C. 2-4

2-1-3

Original Absorbance Measurement

(1)

Functions Absorbances at all measuring points are output. Concentrations and serum indexes are also output. Routine or stat samples are subjected. New channels can be added only for serum indexes. No channel is added to test-to-test correction or isozyme P. Key-in Procedure Enter YES for the ORIGINAL ABS of the START CONDITIONS screen, and then depress the START key. Operation Same as routine operation.

(2)

(3)

2-1-4 (1)

Photometer Check Function Water blank absorbance is measured with the photometer. Key-in Procedure Enter START for the PHOTOMETER CHECK shown in the START CONDITIONS screen. Operation 1) The cells having numbers 119 and 1 are rinsed, and then water for blank is added to them. 2) The absorbances of water blanks contained in cells 119 and 1 are measured at 12 wavelengths. Upon completion of the measurements, the absorbances measured at the respective wavelengths are averaged. The average value is then separated into ADCs for main wavelength measurement and sub wavelength measurement, which are then printed out together with the data acquired through the preceding measurement. The data acquired through the current measurement are written into a floppy disk.

(2)

(3)

3)

Note: If the STOP key is depressed, or STOP alarm is issued during the above operation, the system stops the rest of the operation. In this case, the measurement results will not be written into a floppy disk.

2-5

2-2

Status Transition Matrix

<Operation>

Fig. 2-2-1

Status Transition Diagram Status Transition

5 6 7 Keys Remarks 8 9 10 11

Table 2-2-1

No Event 1 2 Alarm S.STOP Status Name E. STOP STOP Mechanism Liquid Level Sensor 7 7 3 4

No.

START

S.STOP

STOP

STARTT/M T/M UP JOB (MECHA.) (OPER.)

Auto STOP

1 2 3 4 5 6 7 8 9 10 11

Initialize Standby Parameter check Reset Sampling Operation Auto stop Key stop Sampling stop Restart enabled Restart disabled

11 11 11 11 11 11 11 11 11 11 -

2 10 10 10 10 10 10 -

9 9 9 9 -

3 5 5 -

7 -

10 10 10 10 10 2 2

12 -

13 -

14 -

2 4 5 6 8 8 10 10 2 2 The STOP key is ineffective during air purge. The STOP key is ineffective under mechanism reset or water exchange condition. Rinsing of sampling probe Rinsing of sampling probe

Stop Emergency stop

12

Start-up job

11

13

T/M (mechanism)

11

14 Notes:

T/M (operation) 1. Start-up job 2. T/M (mechanism) 3. T/M (operation)

11 : : :

Air purge, WASH, photometer check, ISE priming Sampling mechanism, disk mechanism, reagent pipetting. stirrer mechanism, reset, water exchange, cell blank, probe adjustment, bar-code reader Parameter read/write, precision check, memory check, log-out, floppy disk utility, printer check

2-6

2-3

Major Functions

2-3-1

Reaction disk

The reaction disk is capable of accommodating 120 cells.

Reaction disk rotation: Half turn plus one cell per six seconds Under condition that the cell #N is at the position #P on reaction disk: (1) For reaction disk position #P, the following equations can be established. Next cell number = (N + 61) mod 120 Preceding cell number = (N + 59) mod 120 (2) For cell #N, the following equations can be established. Next position number = (P + 59) mod 120 Preceding position number = (P + 61) mod 120

Fig. 2-3-1

Reaction Disk Operation Sequence 2-7

2-3-2

Serum Sampling

(1)

Sample Pipetting The kind, sequence no., position no., ID no. and channel no. of a sample under sampling are indicated on OPERATION MONITOR screen.

<Sample Pipetting Sequence>

Fig. 2-3-2

Sample Pipetting Diagram

(a)

Operation of Sample Disk Operates only when a sample is switched over to the next one. Rotates to nearest intermediate point and then to a new sample position when sample position is changed from the outer to inner row. Rotates up to a required position in the directioon in which rotational distance is shorter.

(b)

Operation of Sample Probe and Syringe Preliminary washing The inside and outside of sample probe are washed only when sampling was not performed in the previous cycle. Aspiration Air is sucked and dummy is aspirated only at the first sampling of a sample. Discharge

Determined by SAMPLE VOLUME entry via CHEMISTRY PARAMETER screen. Washing Only at the final sampling of a sample, dummy and air are discharged, and inside and outside of sample probe are washed.

2-8

(c)

Processing upon Completion of Sampling Calibration NO appears for START UP CALIB. on START CONDITIONS screen. Recalibration NO apears for CALIB. (RERUN) on START CONDITIONS screen. Stat sample Sample data are erased from STAT screen. Routine sample The next sample no. appears for START SAMPLE NO. on START CONDITIONS screen. Rerun sample Same as for routine sample only in RERUN ONLY mode.

(d)

Measure against Abnormality Although the sample probe goes down in order to aspirate a sample, it will not go down and SAMPLING PROBE (4-8) alarm will occur if water drops have adhered between the liquid level sensor and the tip of sample probe. If no sample is placed where the sample probe goes down for aspirating a sample, a warning for indicating the absence of sample is added to data.

2-3-3

Reagent Sampling

(1)

Reagent Pipetting

<Reagent Pipetting Sequence>

Fig. 2-3-3 Reagent Pipetting Diagram 2-9

(a)

(b)

(c)

(d)

Operation of Reagent Disk Operates when channel is switched. Rotates up to a required position in the direction in which rotational distance is shorter. Operation of Reagent Probe and Syringe The volume of pipetted reagent is determined by REAGENT VOLUME entry on CHEMISTRY PARAMETER screen. When diluent volume is entered for DILUTION on CHEMISTRY PARAMETER screen, over the rinsing bath, the plunger in the syringe lowers in response to each dilution volume below, and flushing is performed so that the reagent probe is filled with water up to its leading end. Then reagents are aspirated in each specified volume, and water (of the dilution volume) and sample are discharged into the cell. R1 dilution volume ....................................................................... 0 to 350 l R2 dilution volume ....................................................................... 0 to 350 l Display of Remaining Reagent After a reagent is aspirated, its remaining volume is calculated and indicated on REAGENT VOLUME CHECK screen. This indication is given in volumetric steps for the number of samples, and the first digit (1 to 9 samples) is truncated. The following formulas are employed for calculating the remaining volume. 1) In case water drops have not adhered between the liquid level sensor and the tip of the reagent probe when the probe lowers to aspirate a reagent: Without Reagent Dilution: Remaining reagent volume = (Remaining pulses upon lowering of reagent probe) (Lowering distance per pulse) (Bottom area of reagent bottle)/(Pipetted reagent volume + Dummy reagent volume) With Reagent Dilution Remaining reagent volume = (Remaining pulses upon lowering of reagent probe) (Lowering distance per pulse) (Bottom area of reagent bottle)/(Pipetted reagent volume) 2) In case water drops have adhered to the liquid level sensor on the same occasion as above: Remaining reagent volume = (Remaining volume just after previous aspiration)-1 Measure against Abnormality STOP alarm occurs for 3 consecutive detections of water drops adhering to the liquid level sensor upon lowering of the reagent probe for aspirating a reagent. For up to 2 detections, the reagent is aspirated with reference to the previous pulse rate. On this occasion the alarm is not recorded. Instead, it is entered as a retry in the alarm log. Note, however, that analysis stops when an abnormality is detected at the first aspiration. An alarm for indicating the absence of a reagent is added to data when no reagent is accessed by the reagent probe which has lowered in order to aspirate the reagent. When reagent becomes inadequate for 10 samples, REAGENT SHORT alarm occurs.

2-10

2-3-4 (1)

Rinsing of Cell Cell Rinsing Sequence

Fig. 2-3-4 Cell Rinsing Operation 2-3-5 (1) Stirrer and Photometric Measurement Stirrer Sequence

Fig. 2-3-5 Stirring Operation (2) Photometric Sequence

Fig. 2-3-6 Photometric Operation 1) 2) A total of 61 cells are measured for 4.1 seconds while the reaction disk rotates. One cell is measured 54 times repetitively. If an ADC attempt is unsuccessful during measurements repeated 54 times, the unsuccessful data is cleared to zero and the ADC alarm is indicated.

(3)

Others The R1 and R2 stirring operations are not independent of each other. Therefore, when either R1 or R2 is discharged, both R1 and R2 are stirred. 2-11

2-4 2-4-1 (1)

Floppy Disk Functions Specifications of Data Disk General FD is a double density type (256 bytes/sector) for all tracks of front and rear sides and is formatted. By copying via FD UTILITY on MAINTENANCE screen, copied FD track 0 is formatted on both sides with 256 bytes 26 sectors.

(2)

Data Disk Configuration

2-12

(3)

Result Data File (a) Configuration of Routine and Rerun Sample Result Data File

(b)

Contents of Routine and Rerun Sample Result Data Unless otherwise specified, information recorded as data is binary data. 1) Sample Measurement Code

Note: Becomes 0 by data clear. 2-13

2)

Results

Offset byte

0 Sample information 16 (Do not use) 62 Routine alarm codes 108 Routine sample results 292 Routine result presence codes 338 Comment data 378 (Do not use) 446 Rerun alarm codes 492 Rerun results 676 Rerun result presence codes 722 (no use) 76

i)

Sample Information

Offset S00 S01 S03 S04 S05

Byte 1 2 1 1 11

Description Sample type Sample number Disk number Position number ID number

Remarks Routine, rerun: 1 (Stat: 2) Routine, rerun: 1 to 1000 (Stat: 1 to 100) Routine, rerun: 0 to 9 (Stat: 0) Routine, rerun: 1 to 60 (Stat: 1 to 7) ASCII code

2-14

ii)

Alarm Code

iii)

Result

iv)

Result Presence Code

v)

Comment Data

40-byte ASCII code

2-15

(c)

Data Alarm Codes

0 S00 No alarm

1 ADC abnormal

7 Reaction limit over (all points)

Cell blank Sample Reagent Absorbanc Linearity abnormal insufficien insufficien over abnormal (8 points or less) Linearity abnormal (9 points more) Prozone error (no use)

S08

Reaction limit over (only 1 point OK) (no use) ISE noise

Reaction limit over (only 2, 3 points OK)

S10 S18

(no use)

ISE level abnormal

(no use)

Panic Cross-tests value over correction error

S20

Cross-tests correction impossible error (no use) (no use) (no use)

(no use)

S28 S30 S38

2-16

(d)

Real Number Expression

<Example>

Value 1.0 4.0 -1.0 3.0 -3.0 0.5 0.25 0

(e)

Real Number Expression (in bit data) 00 00 00 01 00 00 00 11 10 00 00 01 00 00 00 10 10 00 00 10 00 00 00 00 01 11 11 11 00 00 00 00 10 00 00 00 10 00 00 00 10 00 00 00 11 00 00 00 11 00 00 00 10 00 00 00 10 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

Configuration of Stat Sample Result Data File

2-17

(f)

Contents of Stat Sample Result Data Unless otherwise specified, information recorded as data is binary data. 1) Sample Measurement Code

Note: 2) Results

Becomes 0 by data clear.

(4)

Special Copy SPECIAL COPY of FD UTILITY on MAINTENANCE screen copies track 1 and subsequent excluding track 0 of FD.

2-18

2-4-2

Floppy Disk Structure

717 FD CONTENT Shown below are the disk contents for check SUM in execution of FD CHECK on the MAINTENANCE screen. (1) DATA DISK 1. NORMDF 2. 3. 4. 5. RERUNDF EMEGDF

: : :

CALIBOF : COMTRCDF :

Measured result of routine sample, 46 tests for each sample, 1000 samples Measured result of rerun sample, 46 tests for each sample, 1000 samples Measured result of stat sample, 46 tests for each sample, 100 samples Measured result of calibration Communication trace data, test selection information and result, for 160 minutes

(2)

SYSTEM DISK 1. DALMDF 2. CALMDF 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. CUMLQCDF CLBTRCDF PARAM1 PARAM2 REAGVOL CALIB ISECALIB INDEXBLK RBLKLEVL CELBLANK TSNORM TSCSTD

: : : : : : : : : : : : : :

PHOTDF : COMMONPF

Daily alarm data, 8 alarms and 8 retries for each cycle, 999 cyles Cumulative alarm data, 20 alarms and 20 retries for each day, 256 days Cumulative QC data, 31 days 6 controls 43 tests Calibration trace data Analytical parameter Analytical parameter Remaining reagent volume Calibration result for end-point assay Calibration result for ISE assay Serum index blank value Reagent blank level Result of cell blank measurement Test selection for routine and rerun samples, 1000 samples Test selection for calibration and control samples (3 types of calibration samples plus 6 control samples) Photometer data

37. 38.

OPTIONPF

Programs

Comments on samples; 1000 routine sample, 100 stat samples

COMMENT

2-19

2-5 Timing Charts 2-5-1 Main Function Timing Chart

2-20

2-5-2 Maintenance Pro. (Reset) Time Chart

2-21

2-5-3

Maintenance Pro. (Inc. Water Exchange) Time Chart

2-22

2-5-4

Maintenance Pro. (Cell Blank)

Note: Data is printed out immediately after measurement of each cell.

2-23

2-5-5 Maintenance Pro. (Cells) Time Chart (1/2)

2-24

2-5-5

Maintenance Pro. (Cells) Time Chart (E/2)

2-25

2-5-6

Maintenance Pro. (Air Purge) Time Chart

2-26

2-5-7

Maintenance Pro. (Photometer Check) Time Chart

2-27

2-5-8

Maintenance Pro. (Disk) Time Chart

2-28

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- IRS Manual 2014 PDFDocument651 pagesIRS Manual 2014 PDFTiggle Madalene100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- CSEC Information Technology SummaryDocument6 pagesCSEC Information Technology SummaryAnonymous hWHYwX6No ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Cs Online Test Sify 1500 Questions MCQDocument110 pagesCs Online Test Sify 1500 Questions MCQcsjournal70% (10)

- A+ - Computer TechnicianDocument568 pagesA+ - Computer Technicianfluxcountry100% (3)

- Syst 917 PDFDocument462 pagesSyst 917 PDFCorina StanculescuNo ratings yet

- Storage Concepts Storing and Managing Digital DataDocument345 pagesStorage Concepts Storing and Managing Digital DataKomma Ravi VarmaNo ratings yet

- 2X812 Student Exercise Guide PDFDocument126 pages2X812 Student Exercise Guide PDFBenNo ratings yet

- Quarter 1 - PCODocument73 pagesQuarter 1 - PCOGlezelBayubay100% (1)

- CD Ruby Operator Manual 08H5602Document714 pagesCD Ruby Operator Manual 08H5602hdlozanoa91% (11)

- Hitachi 917 Analyzer - User ManualDocument406 pagesHitachi 917 Analyzer - User Manualmylove2804100% (1)

- CHAPTER 1 - Overview 1.1 Overview 1-2: Roche/Hitachi 912 Analyzer Tutorial Guide V1.2Document8 pagesCHAPTER 1 - Overview 1.1 Overview 1-2: Roche/Hitachi 912 Analyzer Tutorial Guide V1.2hdlozanoaNo ratings yet

- H912 Tut Guide Chapter 3Document102 pagesH912 Tut Guide Chapter 3hdlozanoaNo ratings yet

- H912 Tut Guide Chapter 1Document14 pagesH912 Tut Guide Chapter 1hdlozanoaNo ratings yet

- H912 Tut Guide Chapter 2Document58 pagesH912 Tut Guide Chapter 2hdlozanoaNo ratings yet

- Roche/Hitachi 912 Analyzer Tutorial Guide V1.2Document2 pagesRoche/Hitachi 912 Analyzer Tutorial Guide V1.2hdlozanoaNo ratings yet

- Janus ADocument36 pagesJanus Ay1y2z3No ratings yet

- AVL 9180 Operator ManualDocument178 pagesAVL 9180 Operator ManualhdlozanoaNo ratings yet

- Citadel Operator GuideDocument60 pagesCitadel Operator GuidePatricia Mendoza100% (1)

- Modular Pre Analytics OP Manual EVO System 05334837001 PDFDocument367 pagesModular Pre Analytics OP Manual EVO System 05334837001 PDFhdlozanoaNo ratings yet

- Installation and MaintenanceDocument47 pagesInstallation and MaintenancehdlozanoaNo ratings yet

- Leica rm2155 Manual PDFDocument54 pagesLeica rm2155 Manual PDFhdlozanoaNo ratings yet

- Urisys 2400 Host Interface Document vs.1 2002 11675000Document23 pagesUrisys 2400 Host Interface Document vs.1 2002 11675000hdlozanoaNo ratings yet

- 717SM08Document44 pages717SM08hdlozanoaNo ratings yet

- MODEL 717 Automatic AnalyzerDocument1 pageMODEL 717 Automatic AnalyzerhdlozanoaNo ratings yet

- 717SM11Document14 pages717SM11hdlozanoaNo ratings yet

- 12-1 AC Line Circuit DiagramDocument21 pages12-1 AC Line Circuit DiagramhdlozanoaNo ratings yet

- 717 SMTPDocument1 page717 SMTPhdlozanoaNo ratings yet

- 717SM06Document27 pages717SM06hdlozanoaNo ratings yet

- 717SM07Document34 pages717SM07hdlozanoaNo ratings yet

- 717SM05Document13 pages717SM05hdlozanoaNo ratings yet

- 717SM10Document48 pages717SM10hdlozanoaNo ratings yet

- Sensor Locations and Wire Cross Reference ListDocument11 pagesSensor Locations and Wire Cross Reference ListhdlozanoaNo ratings yet

- 717SM03Document37 pages717SM03hdlozanoaNo ratings yet

- Structure and SpecificationsDocument4 pagesStructure and SpecificationshdlozanoaNo ratings yet

- Slide 07Document100 pagesSlide 07phong haiNo ratings yet

- (EyeMax) User Manual 5.1.4.0Document144 pages(EyeMax) User Manual 5.1.4.0chrispyrytgmailcomNo ratings yet

- CompTIA A+Document36 pagesCompTIA A+John Rey Goh100% (1)

- Computer Systems Servicing 1: ST STDocument2 pagesComputer Systems Servicing 1: ST STJuren Andrew NievesNo ratings yet

- Computer Question Bank: Objective QuestionsDocument8 pagesComputer Question Bank: Objective QuestionsrashmiameNo ratings yet

- Head Actuator: Gabriel MbuguaDocument6 pagesHead Actuator: Gabriel MbuguaGaby MbuguaNo ratings yet

- Itc 102 Module 1Document7 pagesItc 102 Module 1Lehd OnlaoNo ratings yet

- Award BIOS Setup Program: Rom Pci / Isa Bios (2A69Jc39) Cmos Setup Utility Award Software, IncDocument24 pagesAward BIOS Setup Program: Rom Pci / Isa Bios (2A69Jc39) Cmos Setup Utility Award Software, IncTushar VaskarNo ratings yet

- G10M1Document6 pagesG10M1Chris TallaNo ratings yet

- Obilor Computer LiteracyDocument31 pagesObilor Computer LiteracybenobilorNo ratings yet

- Manual Ga-p55-Ud3l (Us3l) - (TPM) v2.0Document112 pagesManual Ga-p55-Ud3l (Us3l) - (TPM) v2.0snobic9379No ratings yet

- Fujitsu Rx300 s6 ManualDocument130 pagesFujitsu Rx300 s6 ManualEnsign Budi HandokoNo ratings yet

- STB CommandDocument41 pagesSTB CommandAnh Quân BùiNo ratings yet

- What Is A Hard Disk DriveDocument19 pagesWhat Is A Hard Disk DriveGladis PulanNo ratings yet

- Abc It1Document159 pagesAbc It1m ganeshNo ratings yet

- Disk ManagementDocument124 pagesDisk ManagementnewaplokNo ratings yet

- DS-7108HI-S Series Net DVR User ManualDocument75 pagesDS-7108HI-S Series Net DVR User ManualCristian ȚîrleaNo ratings yet

- 4th Computer Hardware ServicingDocument24 pages4th Computer Hardware ServicingShabby Gay Malala TroganiNo ratings yet

- Samsung SFD321B 070103Document31 pagesSamsung SFD321B 070103Joshua Castro RiveraNo ratings yet

- DFSort Tuning GuideDocument112 pagesDFSort Tuning GuidejagaNo ratings yet

- Lesson 2Document3 pagesLesson 2api-249203258No ratings yet

- Chapter-2 Innovations & Inventions in Computer Science & Engineering/ Information Technology CST-156Document33 pagesChapter-2 Innovations & Inventions in Computer Science & Engineering/ Information Technology CST-156Mohit BihaniNo ratings yet

- OSG202 - Chap 4 - File SystemDocument56 pagesOSG202 - Chap 4 - File SystemMinh Tuấn NguyễnNo ratings yet