Professional Documents

Culture Documents

2009 SDPlate 2.1-2 45in PT PS Concrete Beams

Uploaded by

andreilupuOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

2009 SDPlate 2.1-2 45in PT PS Concrete Beams

Uploaded by

andreilupuCopyright:

Available Formats

STATE

FEDERAL PROJECT NO.

SHEET

TOTAL SHEETS

N. J.

8"

Interior Beam

8" min. Fascia Beam O See Note 7 NO. MARK SIZE Stirrups adjacent to 8" X 3"

4"

C L Span

(D) Beam Symmetrical about C L Span

STRUCTURE NO.

opening shall be skewed.

SCHEDULE OF MILD STEEL REINFORCEMENT

LENGTH TYPE A B

C

STRUCTURE NAME

D 4-"

C L Beam (D)

R1 #16 #16 8-3" 1 4"

(D) C L Sole Plate

C L Diaphragm

R2

3-3"

6"

6"

5"

1-1"

1 #16

2 2-8" (D)

8-0"

Bearing Line

(D)

R3 R4 R5

4 2 #16

11-0"

8"

6-6"

8"

1-6"

5"

1-4"

GENERAL NOTES

HALF PLAN

(D) (D) L/6 L/6

L/6

C L Diaphragm

1. DESIGN SPECIFICATIONS

A 2

4-9" 1-6" 4-9"

(D) The AASHTO LRFD Bridge Design Specifications, with current interims, as

D (D)

#16-R1 @ (D) and #16-R2 @ (D) 10" #16-R1 and #16-R2 @ (D) 1-6" #16-R1 and #16-R2 @ (D) #16-R1 and #16-R2 @ (D) (D)

modified by Section 3 of the NJDOT Design Manual for Bridges and Structures.

R6

R7

(D) #16

14-0"

(D)

2

STR

6-6"

1-0"

6-6"

2. LIVE LOAD

HL-93 or NJDOT Permit Vehicle, whichever governs.

A " Lifting hook (Plain Bars)

0"

0"

3. PRESTRESSING STEEL

0"

0"

2 (D) R4 2-#16-R7 0"

1 (D) R6

CORROSION PROTECTED BARS (REFER TO SECTION 26 OF THIS MANUAL FOR TYPES OF NOTE:

6"

The pretensioning strands shall be " dia. or 0.6" dia., 7-wire uncoated

CORROSION PROTECTED REINFORCEMENT STEEL THAT CAN BE USED)

steel strands conforming to current AASHTO M203 Grade 270 and shall be

low relaxation strands. Each strand shall be given an initial tension of DEBONDED STRAIGHT STRANDS

0.75 fs x As

as specified in applicable sections of the PCI Design Handbook

Double pick-up threaded inserts as approved by the Engineer (see detail)

8" X 3" Opening for concrete

Double pick-up threaded inserts

MAY BE UTILIZED AS AN ALTERNATE Distance to hold down point (D)

TO DRAPED STRANDS. ONE PIECE

- Precast and Prestressed Concrete. Any change in the system of prestressing

A MAXIMUM OF 8 STRANDS STIRRUPS MAY BE UTILIZED AS AN

ALTERNATE TO TWO PIECE STIRRUPS.

must be accompanied by complete calculations for approval by the Engineer.

CGS

diaphragm (See note 7)

PER ROW MAY BE PLACED

4. CONCRETE DESIGN STRESSES

IN THE BOTTOM FLANGE.

1-4"

(D) Design compressive strength (fc)

psi, class

concrete,

10"

#16-R5 Sole plate (See detail)

(D) Compressive strength at prestress (fci) =

#16-R3

psi.

5. CONCRETE

3"

#16-R3 (in pairs) @ (D) #16-R3 (in pairs) @ (D) (to match R1 and R2 bars)

B

#16-R3 (in pairs) @ (D)

#16-R5

All

exposed corners shall be chamfered " or rounded to " radius.

Angles of intersection between webs and flanges shall be rounded to not

(to match R1

#16-R3 (in pairs) @ (D)

and R2 bars) L/2

(to match R1

and R2 bars) Tie minimum of 3 strands

to Bolster 2" min.

less than " radius. Top surface of beams shall be roughened to the

satisfaction of the Engineer. At approximate time of initial set all laitance

shall be removed with a stiff wire brush.

6. SOLE PLATES C L Bearing

HALF ELEVATION

C L Beam

" 3"

" 1-4" 1-4" Typ.

1" (Typ.)

4" to C L strand 4 Straps, 1" X" X 1-11", or "

3"

Support

Cost of Sole Plates shall

be included in price bid for Prestressed

Bolsters 8- " end welded studs, 6" high

Concrete Beams. Sole Plates shall

be galvanized as per Specifications.

7. DIAPHRAGMS

STRAND SUPPORT BOLSTER

For the angle

O between the center line of beam and center line

of diaphragms or bearings reference the Framing Plan. 6"

8. MILD STEEL REINFORCEMENT

2" 2" R=3"

6"

5" (typ.) 2 (D)-R4 7" 2 #16-R7 7" 4" 1"

5" (typ.)

Reinforcement bars shall conform to ASTM A615, Grade 60.

C

2" 9"

C

2"

3" 4"

Minimum clear cover shall be 1" unless otherwise noted.

1 (D)-R6

7" 4"

7"

Cost of furnishing and placing reinforcement steel shall be included in

4"

1-6"

4"

3" 3-1"

the price bid for Prestressed Concrete Beams.

(D) #16-R2

#16-R2 4" 1" cover (typ.), all 1" cover (typ.), all

9. For camber diagram see sheet No. B

4" #16-R1 3-9"

1-7"

BEAM NO.

SOLE PLATE

mild reinforcing steel

Y MIDSPAN

Y ENDS

NO. OF STRANDS

Weld " min

plain

bar to legs.

2"

mild reinforcing steel 7"

7"

#16-R1

(D)

8" X 3" for intermediate concrete diaphragm. #16-R3

3-9"

1-7"

2"

Double pick-up

7" threaded inserts (fascia beam shown) 3"

C L

1" 6" 6" 6"

Bottom of form

Support Bolster

4" C L Double pick-up threaded inserts, each side (interior beam shown)

(typ.)

9"

2"

#16-R3

5"

"

LIFTING HOOK (OR EQUAL)

10" 2"

shall have plastic coated leg ends or be Stainless Steel

3 - "

support

bolsters per row

spaced not greater

7"

(typ.)

1-4"

7"

2"

than 10-0" intervals.

(typ.)

10"

SECTION E-E

7"

7"

QUANTITIES

3"

PRESTRESSING STRANDS

6"

PRESTRESSING STRANDS

6" 4" to 1-10"

3"

PAY STANDARD

ITEM

ITEM

4" to

4" to C Lstrand 1-#16-R5

Drill " deep overtapped C strand L

holes in 1" thick Sole Plate

1-6"

Beam ends shall be plumb when grade is 2% and above before galvanizing to receive

NO.

NO.

DESCRIPTION

UNIT

CONTRACT

QUANTITY

C strand L 1-10"

(D)

PRETENSIONED PRESTRESSED CONCRETE BEAMS, 45"

L.F.

VIEW C-C

SECTION B-B MIDSPAN

" flat head cap screws.

1"

Grout after cutting strands Deck Joint

2"

END

1"

SECTION A-A

"

TYPICAL BEAM SECTIONS

NOTE: Y LOCATES CENTROID

Brg. line Brg. line C L Sole plate

D

See Note 7

8"

OF STEEL PRESTRESSING

GROUP.

1" min.

C L Sole Plate 8"

2"

4"

4"

C L Beam

Beam C L

C L Diaphragm

2" X 2", W1.2 X W1.2 galv. wire mesh.

2"

NOTE: OMIT THREADED INSERTS ON OUTSIDE FACE OF FASCIA BEAM

2"

Cut strands

" from ends of beams O See Note 7 1-4"

To be used when recess is made for a group of strands.

Note:

1" min.

Recess can be made for a single strand or a group of strands. See

alternate detail above.

1" Recess within

1" Mortar Protection

strand area

C L Beam

PLAN

1" thick compressible

1" min. nonabsorbent material to remain in beam

4"

Top of Beam

STANDARD DRAWING PLATE 2.1-2

NEW JERSEY DEPARTMENT OF TRANSPORTATION

D

C L Bearing

END ELEVATION

SECTION D-D

BUREAU OF STRUCTURAL ENGINEERING

GROUTED RECESS FOR STRAND

PLAN AT ABUTMENT

CONTROL SECTION

DES. BY DWN. BY EST. CHK. BY

CHK.

45" PRETENSIONED PRESTRESSED

JOB NO.

END OF BEAM ELEVATION

(D)

BY

AT BEAM ENDS

CONCRETE BEAMS

LOCATION PLAN OF THREADED INSERTS

BEAMS AT PIERS

ROUTE

SECTION

(D)

BDC04MB-01

BY

SPECS.

BY

SCALE :

NONE

BRIDGE

IN CHARGE OF

REVISION

BY

CKD

DATE

SHEET NO .

OF

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- 2009 SDPlate 2.3-4 Standard INstallation of 6in FG Conduit Under HighwDocument1 page2009 SDPlate 2.3-4 Standard INstallation of 6in FG Conduit Under HighwandreilupuNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 2009 SDPlate 2.5-4 Wingwall Details For Integral AbutmentsDocument1 page2009 SDPlate 2.5-4 Wingwall Details For Integral AbutmentsandreilupuNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 2009 SDPlate 2.4-2 Noise Wall Barrier Foundation DetailsDocument1 page2009 SDPlate 2.4-2 Noise Wall Barrier Foundation DetailsandreilupuNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- 2009 SDPlate 2.1-4.Dgn 63in PT PS Concrete BeamsDocument1 page2009 SDPlate 2.1-4.Dgn 63in PT PS Concrete BeamsandreilupuNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Construction of The Eads BridgeDocument43 pagesConstruction of The Eads BridgeandreilupuNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- 2009 SDPlate 2.6-1 Wall 1 Sample Control Plan (Sheet 1)Document1 page2009 SDPlate 2.6-1 Wall 1 Sample Control Plan (Sheet 1)andreilupuNo ratings yet

- Donna Gawlik 2 PG Resume 2014Document2 pagesDonna Gawlik 2 PG Resume 2014api-244892096No ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Aer504 Lab ManualDocument50 pagesAer504 Lab Manualfloyd617No ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Fabric Ducting & Diffusers: Technical DataDocument32 pagesFabric Ducting & Diffusers: Technical DataruwangaroshalNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Capital Modular XC Functional 251109Document73 pagesCapital Modular XC Functional 251109Olimpiu Stoicuta100% (3)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Ps SecurityDocument27 pagesPs SecurityMaster RajaNo ratings yet

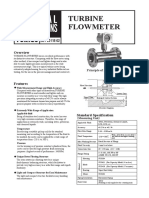

- Turbinemeter TurbineDocument11 pagesTurbinemeter TurbineMOSES EDWINNo ratings yet

- Summarizing A Research ArticleDocument3 pagesSummarizing A Research ArticleRahib JaskaniNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Robotic SensorsDocument21 pagesRobotic SensorsPawan SrivastavaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- 5a4b0 Compal LA-6072PDocument61 pages5a4b0 Compal LA-6072Pابراهيم السعيديNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Katalog LincolnaDocument612 pagesKatalog LincolnaHaris TrešnjoNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Report On Modal Analysis of A Hollow CylinderDocument2 pagesReport On Modal Analysis of A Hollow CylinderkbhattacNo ratings yet

- WT-805M Modbus Protocol V2.3Document16 pagesWT-805M Modbus Protocol V2.3Krishnakumar GanesanNo ratings yet

- 4601543493197ICC-ACOTEC Leaflet Edit FileDocument2 pages4601543493197ICC-ACOTEC Leaflet Edit FilesahanNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Autosys commands guideDocument39 pagesAutosys commands guidesantosh_panditpurNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Tis 0002 Timber DunnageDocument2 pagesTis 0002 Timber DunnageMustaffa HoodMusNo ratings yet

- Eclectic IqDocument17 pagesEclectic IqriyanNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Wordvice - EDITOR SAMPLE TEST - 20200526 (Edited Samples)Document6 pagesWordvice - EDITOR SAMPLE TEST - 20200526 (Edited Samples)wenelyn pinoNo ratings yet

- ConceptDocument162 pagesConceptzinab90No ratings yet

- M Tech SDM-Curriculum SyllabiDocument69 pagesM Tech SDM-Curriculum SyllabiDinesh AnbumaniNo ratings yet

- K. Jarrett - CountryDocument16 pagesK. Jarrett - Countrykasiula28111100% (2)

- Protege Transmission RebuildDocument29 pagesProtege Transmission RebuildBrody RivestNo ratings yet

- Death of Crypto King Nikolai Mushegian Fuels Conspiracy TheoriesDocument15 pagesDeath of Crypto King Nikolai Mushegian Fuels Conspiracy Theorieshans hansenNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Evolution of Cloud ComputingDocument3 pagesEvolution of Cloud ComputingVaishnavi ChockalingamNo ratings yet

- Projection types and viewsDocument4 pagesProjection types and viewsOscarArteagaNo ratings yet

- How Wireless WorksDocument123 pagesHow Wireless WorksAjay GargNo ratings yet

- X RayDocument3 pagesX RayjacksonNo ratings yet

- For AgentsDocument16 pagesFor AgentsPranesh GajendragadNo ratings yet

- HPCL Mumbai Refinery Radiography Job Hazard AnalysisDocument1 pageHPCL Mumbai Refinery Radiography Job Hazard AnalysisSiddharth RanaNo ratings yet

- Sample Apdf User InputDocument21 pagesSample Apdf User InputginjackNo ratings yet

- Untitled InstallDocument11 pagesUntitled InstalltestNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)