Professional Documents

Culture Documents

Ds100-4-Eng (Mut2200el+mut2500el)

Uploaded by

sar_tpgitOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ds100-4-Eng (Mut2200el+mut2500el)

Uploaded by

sar_tpgitCopyright:

Available Formats

dg: www.oryana.com.

ar

Electromagnetic flowmeters

NEW

Sensors MUT 2200 EL / MUT 2500 EL

DS100-4-ENG

1/14

Sensors MUT 2200 EL / MUT 2500 EL

MUT 2200 EL / MUT 2500 EL sensors represent the state of the art of EUROMAG INTERNATIONAL production for water cycle

and process applications. The new structure for the generation of the magnetic field, the innovative route of the signal

generated by the electrodes, provide a sensor with an extremely wide measurement range:

EL= Extended Linearity.

This new sensors series follows the successful tradition of the MUT 2200 / MUT 2500, introducing a measurement range of

more than 1:1000 without linearization software. These kinds of performances allow very accurate measures on a wide flow

rate range and to count lower flow rates that, before, would have been reset because of the effect of the converters cut off.

This flanged sensors series bases its operation on the Faraday Principle, by which a conductor crossing a magnetic field

generates a potential perpendicularly orientated to the same field. In this case the flow tube made in stainless steel AISI 304 is

equipped with carbon or stainless steel flanges, two coils are installed on the top and inferior part; the magnetic field,

generated by the electric current crossing the coil, induces in the electrodes a difference in the potential proportional to the

flow rate. With the aim of measuring such potential of very low values, the interior of the flow tube is electrically insulated,

thus the process liquid is no longer in contact neither with the material of the flow tube nor with that of the flange.The

converter used generates the current supplying the coil, acquires the electrodes difference of potential, process the signal to

calculate the flowrate and administers the communication with the exterior. The entire sensor, when installed in the separate

version, has a degree of protection IP 68 suitable for a permanent immersion in water up to a depth of 1.5m thanks to a

welded plate structure containing the coil and the electrodes.

1. Body and flange

4. Coupling and connecting to sensor

The flange and the sensor external surface are acrylic painted. This

MUT 2200 EL / MUT 2500 EL sensors may be coupled with any

treatment gives the sensor an excellent resistance to water, even in

EUROMAG converters (see Table 5). In the separate version the

permanent immersion. When special ambient conditions require it,

sensor is connected to the converter by means of a cable whose

the MUT 2000 EL / MUT 2500 EL may be supplied in stainless steel,

length depends on the liquid conductivity; the maximum length not

flange included (see Table 2).

exceeding 100 metres as shown in Figure 1. If these sensors are

inserted in a plastic or lined pipe line, they require the use of two

grounding rings of the liquid, which are inserted between the flange

and the counter flange or the installation of the grounding electrode.

An empty pipe device is also available .

2. Internal lining

The standard internal insulating lining is in PTFE for diameters from

ND 15 to ND 50, in hard rubber (ebonite for food) for diameters of

more than ND 50. On request, the sensors may be supplied coated

with PTFE with diameters of more than ND 50. The temperature of

5. Choice of diameter

the liquid to be measured is limited by the kind of internal lining

used. (see Table 4).

When choosing the diameter we advice keeping at the full scale flow

rate, a liquid velocity of at least 23 m/s. The maximum acceptable

velocity is of 10 m/s. Figure 3 provides the flow rate for each ND

(nominal diameter) according to the liquid velocity.

3. Electrodes

The standard electrodes are in Hastelloy C and, therefore, guarantee

a wide compatibility with the process liquids, if required, they may

be supplied in the materials shown in Table 3.

2/14

6. Maximum temperature of the liquid

Maximum length of cables according to the liquid conductivity

120

shown in Table 4. In the compact version instead, the maximum

100

temperature allowed depends on the ambient temperature. This is

due to the required cooling of the electronics. The maximum liquid

temperature allowed for the compact version should be 80C.

Maximum length of cables (m)

In the separate version the maximum liquid temperature allowed is

80

60

40

20

0

0

50

100

150

200

250

300

Conductivity ( us/cm )

7. Calibration and maximum error

figure 1

MUT 2200 EL / MUT 2500 EL sensors belong to the reference Group

B1 (ISO 11631). Each sensor is calibrated by a hydraulic bench

Standard diameters

equipped with a reference weighting system and SIT certified. The

uncertainty of the measure is equal to 0.2% of the read flowrate

millimeters (mm)

15

20

25

value when the velocity of the liquid is more than 0.2 m/s. The

inches ( " )

1/2"

3/4"

1"

millimeters (mm)

100

125

150

200

inches ( " )

4"

5"

6"

8"

millimeters (mm)

450

500

600

inches ( " )

18"

20"

24"

repeatability of the measure is in the order of 0.1%

8. Reference standards

The EUROMAG magnetic meters are marked CE and are

manufactured according to the following standards:

* CEI EN 61010-1

* EN 50081 - 1

* UNI EN ISO 6817

* EN 50082 - 1

* 2006/95/CE, 93/68 (LVD)

* EN 1434

* 2004/98/CE, 92/31 (EMC)

50

65

80

2"

2.1/2"

3"

250

300

350

400

10"

12"

14"

16"

700

800

900

1000

1200

28"

32"

36"

40"

48"

2000

32

40

1.1/4" 1.1/2"

millimeters (mm) 1300

1400

1500

1600

1700

1800

inches ( " )

56"

60"

64"

68"

72"

52"

80"

table 1

Flow tube materials

On request, MUT 2200 EL and MUT 2500 EL sensors can be provided

with certification ATEX II 2 GD EEx mb IIC T4 U.

AISI 304 (Inox)

9. Applications

Flanges materials

The sensors of the family MUT 2200 EL / MUT 2500 EL are suitable

Carbon Steel Painted (std)

for any application of on-line mensuration. These sensors are

AISI 304 (Inox)

typically used in the mensure of potable o reflow water, industrial

AISI 316 (Inox)

table 2

waste water, industrial process liquids, mud and concretes.

Available electrodes

Hastelloy C (std)

Hastelloy B

Titanium

Tantalum

Platinum

table 3

3/14

Internal lining - Liquid temperature

Internal lining

Liquid temperature

PTFE

Standard -40 /+140C (up to +180 on request)

EBANITE FOR FOOD

-40C / +80C

table 4

General characteristics of Sensor MUT2200 EL / MUT 2500 EL

Available diameters

15

20

25

1/2"

3/4"

1"

32

40

450

500

600

700

800

900

1000

1200

1300

1400

1500

18"

20"

24"

28"

32"

36"

40"

48"

52"

56"

60"

1.1/4" 1.1/2"

50

65

80

100

125

150

200

250

300

350

400

2"

2.1/2"

3"

4"

5"

6"

8"

10"

12"

14"

16"

1600

1700

1800

2000

64"

68"

72"

80"

Standard flanged connections

UNI2223

ANSI 150

Flanged connections on request

BS45404

AWWA

Standard operation pressure [1]

ANSI 300

DIN2501

ISO7005

KS

16 bar

Degree of protection

IP68 continuous immersion at 1,5 m (IEC 529)

Converters compatibility

MC 106 A

MC 106 B

MC 308

Dimensions

MC 308 C

MC 108

See figure 2

Parts in contact with the liquid [2]

PTFE

Ebonite for food stuff

Electrical connections

Cableglands PG 11 + terminal box + sealing resin

table 5

[1] On request up to 150 bar

[2] Others on request.

Fig. 2 - Overall dimensions.

104

60

= =

D5

J

S

126

35.5

53.5

No. 2

M20x1.5

Earthing point

M5

L4

= =

DN

N holes S on D6

Only for DN > 400

4/14

MUT 2200 EL Separate PN10

L4

MUT 2200 EL Separate PN16

DN

D5

D6

DN

D5

D6

15

84

200

0

-3

114.5

65

14

168

15

84

200

L4

0

-3

114.5

65

14

168

20

84

200

0

-3

114.5

75

14

168

20

84

200

0

-3

114.5

75

14

168

25

64

200

0

-3

104.5

85

14

158

25

64

200

0

-3

104.5

85

14

158

111

100

18

164.5

32

77

200

0

-3

111

100

18

164.5

113.5

110

18

167

40

82

200

0

-3

113.5

110

18

167

121.5

125

18

175

129.5

145

18

183

32

77

200

0

-3

40

82

200

0

-3

121.5

125

18

175

50

98

200

0

-3

129.5

145

18

183

65

114

200

0

-3

50

98

200

0

-3

65

114

200

0

-3

136

160

18

189.5

80

127

200

0

-3

136

160

18

189.5

148.5

180

18

202

100

152

250

0

-3

148.5

180

18

202

80

127

200

0

-3

100

152

250

0

-3

161.5

210

18

215

125

178

250

0

-3

161.5

210

18

215

175.5

240

22

229

150

206

300

0

-3

175.5

240

22

229

125

178

250

0

-3

150

206

300

0

-3

201

295

22

254.5

200

257

350

0

-3

201

295

12

22

254.5

228

350

12

22

281.5

250

311

450

0

-5

228

355

12

25

281.5

200

257

350

0

-3

250

311

450

0

-5

253.5

400

12

22

307

300

362

500

0

-5

253.5

410

12

25

307

269.5

460

16

22

323

350

394

550

0

-5

269.5

470

16

25

323

600

0

-5

294.5

525

16

30

348

300

362

500

0

-5

350

394

550

0

-5

600

0

-5

400

444

294.5

515

16

25

348

400

444

table 6

MUT 2500 EL Separate PN10

DN

D5

L4

MUT 2500 EL Separate PN16

J

450

519

450

0

-7

500

570

500

0

-9

table 8

D6

DN

D5

332

565

20

25

385.5

450

519

357.5

620

20

25

411

500

570

L4

D6

450

0

-7

332

585

20

30

385.5

500

0

-9

357.5

605

20

33

411

413.5

770

20

36

467

464

840

24

36

517.5

600

682

600

0

-9

413.5

725

20

30

467

600

682

600

0

-9

700

783

700

0

-9

464

840

24

30

517.5

700

783

700

0

-9

800

885

800

0

-9

515

950

24

33

568.5

800

885

800

0

-9

515

950

24

39

568.5

900

0

-15

570.5

1050

28

33

624

900

996

900

0

-15

570.5

1050

28

39

624

621.5

1160

28

36

675

1000

1098

1000

0

-15

621.5

1170

28

42

675

728.5

1380

32

39

782

1200

1312

1200

0

-15

728.5

1390

32

48

782

828.5

1590

36

48

882

880.5

900

996

1000

1098

1000

0

-15

1200

1312

1200

0

-15

828.5

880.5

1400

1512

1400

0

-15

1500

1616

1500

0

-15

1590

36

42

882

1400

1512

1400

0

-15

934

1500

1616

1500

0

-15

934

1600

1712

1600

0

-15

928.5

1820

40

48

982

1600

1712

1600

0

-15

928.5

1820

40

56

982

1800

1922

1800

0

-15

1033.5

2020

44

48

1087

1800

1922

1800

0

-15

1033.5

2020

44

56

1087

2000

2122

2000

0

-15

1133.5

2230

48

48

1187

2000

2122

2000

0

-15

1133.5

2230

48

62

table 7

1187

table 9

5/14

MUT 2200 EL Separate PN25

DN

D5

L4

MUT 2200 EL Separate PN40

J

15

84

200

0

-3

20

84

200

0

-3

D6

DN

D5

114.5

65

14

168

15

84

114.5

75

14

168

20

84

L4

D6

200

0

-3

114.5

65

14

168

200

0

-3

114.5

75

14

168

25

64

200

0

-3

104.5

85

14

158

25

64

200

0

-3

104.5

85

14

158

32

77

200

0

-3

111

100

18

164.5

32

77

200

0

-3

111

100

18

164.5

40

82

200

0

-3

113.5

110

18

167

40

82

200

0

-3

113.5

110

18

167

200

0

-3

121.5

125

18

175

50

98

200

0

-3

121.5

125

18

175

50

98

65

114

200

0

-3

129.5

145

18

183

65

114

200

0

-3

129.5

145

18

183

80

127

200

0

-3

136

160

18

189.5

80

127

200

0

-3

136

160

18

189.5

100

152

250

0

-3

148.5

190

22

202

100

152

250

0

-3

148.5

190

22

202

250

0

-3

161.5

220

25

215

125

178

250

0

-3

161.5

220

25

215

175.5

250

25

229

201

320

12

30

254.5

125

178

150

206

300

0

-3

175.5

250

25

229

150

206

300

0

-3

200

257

350

0

-3

201

310

12

25

254.5

200

257

350

0

-3

250

311

450

0

-5

228

370

12

30

281.5

250

311

450

0

-5

228

385

12

33

281.5

500

0

-5

253.5

430

16

30

307

300

362

500

0

-5

253.5

450

16

33

307

269.5

490

16

33

323

350

394

550

0

-5

269.5

510

16

36

323

294.5

550

16

36

348

400

444

600

0

-5

294.5

585

16

39

348

300

362

350

394

550

0

-5

400

444

600

0

-5

table 10

MUT 2500 EL Separate PN25

DN

D5

L4

MUT 2500 EL Separate PN40

J

450

519

450

0

-7

500

570

500

0

-9

D6

DN

D5

332

600

20

36

385.5

450

519

357.5

660

20

36

411

500

570

L4

D6

450

0

-7

332

610

20

39

385.5

500

0

-9

357.5

670

20

42

411

413.5

795

20

48

467

464

900

24

48

517.5

600

682

600

0

-9

413.5

770

20

39

467

600

682

600

0

-9

700

783

700

0

-9

464

875

24

42

517.5

700

783

700

0

-9

800

885

800

0

-9

515

990

24

48

568.5

800

885

800

0

-9

515

568.5

900

996

900

0

-15

570.5

1090

28

48

624

900

996

900

0

-15

570.5

624

621.5

728.5

675

1000

1098

1000

0

-15

621.5

675

782

1200

1312

1200

0

-15

728.5

782

1512

1400

0

-15

828.5

882

1616

1500

0

-15

880.5

934

1000

1098

1000

0

-15

1200

1312

1200

0

-15

828.5

882

1400

880.5

934

1500

1400

1512

1400

0

-15

1500

1616

1500

0

-15

1210

28

56

1600

1712

1600

0

-15

928.5

982

1600

1712

1600

0

-15

928.5

982

1800

1922

1800

0

-15

1033.5

1087

1800

1922

1800

0

-15

1033.5

1087

2000

2122

2000

0

-15

1133.5

1187

2000

2122

2000

0

-15

1133.5

table 11

6/14

table 12

1187

table 13

MUT 2200 EL Separate ANSI 300

MUT 2200 EL Separate ANSI 150

DN

D5

L4

15

84

200

0

-3

20

84

200

0

-3

D6

DN

D5

114.5

60.3

16

168

15

84

114.5

69.8

16

168

20

84

L4

D6

200

0

-3

114.5

66.7

16

168

200

0

-3

114.5

82.5

19

168

25

64

200

0

-3

104.5

79.4

15.9

158

25

64

200

0

-3

104.5

88.9

19

158

32

77

200

0

-3

111

88.9

15.9

164.5

32

77

200

0

-3

111

98.4

19

164.5

40

82

200

0

-3

113.5

98.4

15.9

167

40

82

200

0

-3

113.5

114.3

22.2

167

200

0

-3

121.5

120.6

19

175

50

98

200

0

-3

121.5

127

19

175

50

98

65

114

200

0

-3

129.5

139.7

19

183

65

114

200

0

-3

129.5

149.2

22.2

183

80

127

200

0

-3

136

152.4

19

189.5

80

127

200

0

-3

136

168.3

22.2

189.5

100

152

250

0

-3

148.5

190.5

19

202

100

152

250

0

-3

148.5

200

22.2

202

250

0

-3

161.5

215.9

22.2

215

125

178

250

0

-3

161.5

234.9

22.2

215

175.5

269.9

12

22.2

229

201

330.2

12

25.4

254.5

125

178

150

206

300

0

-3

175.5

241.3

22.2

229

150

206

300

0

-3

200

257

350

0

-3

201

298.4

22.2

254.5

200

257

350

0

-3

250

311

450

0

-5

228

361.9

12

25.4

281.5

250

311

450

0

-5

228

387.3

16

28.6

281.5

500

0

-5

253.5

431.8

12

25.5

307

300

362

500

0

-5

253.5

450.8

16

31.7

307

269.5

476.2

12

28.6

323

350

394

550

0

-5

269.5

514.3

20

31.7

323

294.5

539.7

16

28.6

348

400

444

600

0

-5

294.5

571.5

20

34.9

348

300

362

350

394

550

0

-5

400

444

600

0

-5

table 14

MUT 2500 EL Separate ANSI 300

MUT 2500 EL Separate ANSI 150

DN

D5

L4

450

519

450

0

-7

500

570

500

0

-9

table 16

D6

DN

D5

332

577.6

16

31.7

385.5

450

519

357.5

635

20

31.7

411

500

570

L4

D6

450

0

-7

332

628.6

24

34.9

385.5

500

0

-9

357.5

685.8

24

34.9

411

413.5

812.8

24

41.3

467

464

939.8

28

44.5

517.5

600

682

600

0

-9

413.5

749.3

20

34.9

467

600

682

600

0

-9

700

783

700

0

-9

464

863.6

28

35

517.5

700

783

700

0

-9

800

885

800

0

-9

515

977.9

28

41

568.5

800

885

800

0

-9

515

1054.1

28

50.8

568.5

900

0

-15

570.5

1085.9

32

41

624

900

996

900

0

-15

570.5

1168.4

32

53.8

624

621.5

1200

36

41

675

1000

1098

1000

0

-15

621.5

1155.7

32

44.5

675

728.5

1422.4

44

41

782

1200

1312

1200 -150

728.5

1371.6

32

50.8

782

0

-15

828.5

1600.2

28

60.5

882

880.5

1701.8

32

60.5

934

900

996

1000

1098

1000

0

-15

1200

1312

1200

0

-15

828.5

1651

48

47.8

882

1400

1512

1400

880.5

1760

52

47.8

934

1500

1616

1500 -150

0

-15

1400

1512

1400

0

-15

1500

1616

1500

0

-15

1600

1712

1600

0

-15

928.5

982

1600

1712

1600

928.5

982

1800

1922

1800

0

-15

1033.5

1087

1800

1922

1800 -150

1033.5

1087

2000

2122

2000

0

-15

1133.5

1187

2000

2122

2000 -150

1133.5

table 15

1187

table 17

7/14

Fig. 3 - MUT 2200 EL / MUT 2500 EL Compact - Converter MC 106 Horizontal ABS Case

MUT 2500 EL

MUT 2200 EL

142

H1

66

158

8/14

DN

H1

25

93

159

32

99.5

165.5

40

102

168

50

110

176

65

118

184

80

124.5

190.5

100

137

203

125

150

216

150

164

230

200

189.5

255.5

250

216.5

282.5

300

242

308

350

258

324

400

283

349

450

320.5

386.5

500

346

412

600

402

468

700

452.5

518.5

800

503.5

569.5

900

559

625

1000

610

676

1200

717

783

1400

818

883

1500

869

935

1600

917

983

1800

1022

1088

2000

1122

1188

table 18

Fig. 4 - MUT 2200 EL / MUT 2500 EL Compact - Converter MC 308 Horizontal ABS Case

MUT 2200 EL

222

H1

99.5

MUT 2500 EL

149

DN

H1

25

93

192.5

32

99.5

199

40

102

201.5

50

110

209.5

65

118

217.5

80

124.5

224

100

137

236.5

125

150

249.5

150

164

263.5

200

189.5

289

250

216.5

316

300

242

341.5

350

258

357.5

400

283

382.5

450

320.5

420

500

346

445.5

600

402

501.5

700

452.5

552

800

503.5

603

900

559

658.5

1000

610

709.5

1200

717

816.5

1400

817

916.5

1500

869

968.5

1600

917

1016.5

1800

1022

1121.5

2000

1122

1221.5

table 19

9/14

Fig. 5 - MUT 2200 EL / MUT 2500 EL Compact - Converter MC 308 Vertical ABS Case

154

149

107.5

12

H1

222

46.5

10/14

H1

DN

H1

25

105

327

450

332.5

554.5

32

111.5

333.5

500

358

580

40

114

336

600

414

636

50

122

344

700

464.5

686.5

65

130

352

800

515.5

737.5

80

136.5

358.5

900

571

793

100

149

371

1000

622

844

125

162

384

1200

729

951

MUT 2500 EL

MUT 2200 EL

DN

150

176

398

1400

829

1051

200

201.5

423.5

1500

881

1103

250

228.5

450.5

1600

929

1151

300

254

476

1800

1034

1256

350

270

492

2000

1134

1356

400

295

517

table 20

Fig. 6 - MUT 2200 EL / MUT 2500 EL Compact - Converter MC 108 / 308 Vertical Alluminium Case

169.5

46.5

123

DN

H1

DN

H1

25

103

358

450

330.5

585.5

32

109.5

364.5

500

356

611

40

112

367

600

412

667

50

120

375

700

462.5

717.5

65

128

383

800

513.5

768.5

80

134.5

389.5

100

147

402

900

569

824

1000

620

875

125

160

415

150

174

429

1200

727

982

1400

827

1082

200

199.5

250

226.5

454.5

1500

879

1134

481.5

1600

927

1182

300

350

252

507

1800

1032

1287

268

523

2000

1132

1387

400

293

548

MUT 2500 EL

MUT 2200 EL

10

H1

255

176

table 21

11/14

Fig. 7 - MUT 2200 EL / MUT 2500 EL Compact - Converter MC 308 C

63.5

117

MC 308 C

52

H1

183

67.5

www.euromag.it

MUT 2200 EL

POSSIBLE ROTATION

SUPERIOR VIEW

MUT 2500 EL

175

DN

H1

25

32

215

32

38.5

221.5

40

41

224

50

49

232

65

57

240

80

63.5

246.5

100

76

259

125

89

272

150

103

286

200

128.5

311.5

250

155.5

338.5

300

181

364

350

197

380

400

222

405

450

259.5

442.5

500

285

468

600

341

524

700

391.5

574.5

800

442.5

625.5

900

498

681

1000

549

732

1200

656

839

1400

756

939

1500

808

991

1600

856

1039

1800

961

1144

2000

1061

1244

table 22

DN

12/14

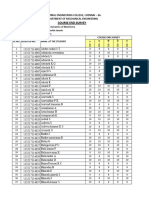

Flowrate Table (Blue values are preferable)

DN

VELOCITY [m/s]

0,05

25

88,36

l/h

0,14

m3/h

0,23

m3/h

0,35

m3/h

65

0,60

m3/h

32

40

MUT 2200 EL

50

883,57

5

l/h

1,45

m3/h

2,26

m3/h

3,53

m3/h

5,97

m3/h

8.835,73

10

l/h

17.671,46

l/h

14,48

m3/h

28,95 m3/h

22,62

m3/h

45,24 m3/h

35,34

m3/h

70,69 m3/h

59,73

m3/h

119,46 m3/h

80

0,90 m3/h

9,05 m3/h

90,48 m3/h

180,96 m3/h

100

1,41 m3/h

14,14 m3/h

141,37 m3/h

282,74 m3/h

125

2,21 m3/h

22,09 m3/h

220,89 m3/h

441,79 m3/h

150

3,18 m3/h

31,81 m3/h

318,09 m3/h

636,17 m3/h

200

5,65

m3/h

56,55

m3/h

565,49

m3/h

1.130,97 m3/h

8,84

m3/h

88,36

m3/h

883,57

m3/h

1.767,15 m3/h

12,72

m3/h

127,23

m3/h

1.272,35

m3/h

2.544,69 m3/h

350

17,32

m3/h

173,18

m3/h

1.731,80

m3/h

3.463,61 m3/h

400

22,62 m3/h

226,19 m3/h

2.261,95 m3/h

4.523,89 m3/h

450

28,63 m3/h

286,28 m3/h

2.862,78 m3/h

5.725,55 m3/h

500

35,34 m3/h

353,43 m3/h

3.534,29 m3/h

7.068,58 m3/h

550

42,76 m3/h

427,65 m3/h

4.276,49 m3/h

8.552,99 m3/h

600

50,89

m3/h

508,94

m3/h

5.089,38

m3/h

10.178,76 m3/h

59,73

m3/h

597,30

m3/h

5.972,95

m3/h

11.945,91 m3/h

69,27

m3/h

692,72

m3/h

6.927,21

m3/h

13.854,42 m3/h

79,52

m3/h

795,22

m3/h

7.952,16

m3/h

15.904,31 m3/h

250

300

650

700

MUT 2500 EL

0,5

750

800

90,48 m3/h

904,78 m3/h

9.047,79 m3/h

18.095,57 m3/h

900

114,51 m3/h

1.145,11 m3/h

11.451,11 m3/h

22.902,21 m3/h

1000

141,37 m3/h

1.413,72 m3/h

14.137,17 m3/h

28.274,33 m3/h

1200

203,58 m3/h

2.035,75 m3/h

20.357,52 m3/h

40.715,04 m3/h

1300

238,92

m3/h

2.389,18

m3/h

23.891,81

m3/h

47.783,62 m3/h

277,09

m3/h

2.770,88

m3/h

27.708,85

m3/h

55.417,69 m3/h

318,09

m3/h

3.180,86

m3/h

31.808,63

m3/h

63.617,25 m3/h

1600

361,91

m3/h

3.619,11

m3/h

36.191,15

m3/h

72.382,29 m3/h

1700

408,56 m3/h

4.085,64 m3/h

40.856,41 m3/h

81.712,82 m3/h

1800

458,04 m3/h

4.580,44 m3/h

45.804,42 m3/h

91.608,84 m3/h

2000

565,49 m3/h

5.654,87 m3/h

56.548,67 m3/h

113.097,34 m3/h

1400

1500

table 23

13/14

14/14

The data shown in this catalogue are subject to modification without prior notice.

EUROMAG INTERNATIONAL srl

35035 Mestrino (Padova) Via Torino, 3 Italy

Tel. +39 049 9005064 Fax +39 049 9007764

www.euromag.com

You might also like

- Flujometro 6 Inch MUT2200EL V2 1805Document12 pagesFlujometro 6 Inch MUT2200EL V2 1805jorge jacomeNo ratings yet

- Hall-Effect Sensors: Theory and ApplicationFrom EverandHall-Effect Sensors: Theory and ApplicationRating: 5 out of 5 stars5/5 (1)

- Data Sheet For MUT2200 MC608Document8 pagesData Sheet For MUT2200 MC608Camila DezanNo ratings yet

- S103C E - Magnetici Flowmter CH2200 - 2500 Flanged PipeDocument7 pagesS103C E - Magnetici Flowmter CH2200 - 2500 Flanged PipeAdam SamyNo ratings yet

- Power Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageFrom EverandPower Electronics Applied to Industrial Systems and Transports: Volume 5: Measurement Circuits, Safeguards and Energy StorageNo ratings yet

- MC608 ManualDocument12 pagesMC608 Manualn_zeinounNo ratings yet

- ABB - FXE4000 - Medidor EletromagneticoDocument48 pagesABB - FXE4000 - Medidor Eletromagneticoalex_julieneNo ratings yet

- El 2271 PDFDocument2 pagesEl 2271 PDFJavierbritosNo ratings yet

- Flomat EngDocument8 pagesFlomat Engalex.amaral9292No ratings yet

- Electromagnetic Flowmeter User Manual: SHM "Gives You Trust"Document22 pagesElectromagnetic Flowmeter User Manual: SHM "Gives You Trust"Rudi SetiawanNo ratings yet

- Krohne MenuDocument59 pagesKrohne Menueeng_nnabilNo ratings yet

- Crack VibDocument4 pagesCrack VibIshu VohraNo ratings yet

- HA IFC300 en 061121Document72 pagesHA IFC300 en 061121magolelNo ratings yet

- Analizador de Humedad BARTECDocument11 pagesAnalizador de Humedad BARTECFabian GomezNo ratings yet

- Caudal o MetroDocument20 pagesCaudal o MetropeskamasNo ratings yet

- 13dj3 In001 - en P PDFDocument16 pages13dj3 In001 - en P PDFΔημητρηςΣαρακυρουNo ratings yet

- Magnetic - Inductive Flowmeter Type PEM-1000 User'S ManualDocument25 pagesMagnetic - Inductive Flowmeter Type PEM-1000 User'S ManualKaler Soto PeraltaNo ratings yet

- Magnetic Flow Meter 1 - 6f9aDocument16 pagesMagnetic Flow Meter 1 - 6f9aSilvaACANo ratings yet

- Eurosonic 2000Document75 pagesEurosonic 2000Sandra Carr100% (1)

- F13125 4340 ACE3000 100 110 4pp Brochure - 5 PDFDocument4 pagesF13125 4340 ACE3000 100 110 4pp Brochure - 5 PDF94528809No ratings yet

- Modmag M-Series m5000 Product Data Sheet Mag-Ds-00175-EnDocument4 pagesModmag M-Series m5000 Product Data Sheet Mag-Ds-00175-EnNAHASALI11No ratings yet

- Electromagnetic Flowmeter Type MAGNETOFLOW™ M2000: DescriptionDocument4 pagesElectromagnetic Flowmeter Type MAGNETOFLOW™ M2000: DescriptionAlphatech1No ratings yet

- Omega Insertion Fmg-550Document3 pagesOmega Insertion Fmg-550savagedloveNo ratings yet

- SRI SensorDocument7 pagesSRI SensorArun GuptaNo ratings yet

- Indicador de Nivel MagneticoDocument6 pagesIndicador de Nivel MagneticoEdivan Laurindo FerreiraNo ratings yet

- Inductive SensorsDocument96 pagesInductive SensorsMoustapha SeyeNo ratings yet

- DS100 7 Eng Mut2200elDocument16 pagesDS100 7 Eng Mut2200elAhmed IsmailNo ratings yet

- ABB CoriolisMaster FCM2000Document68 pagesABB CoriolisMaster FCM20001234567890No ratings yet

- SCA-1 LPR Corrosion Rate Instrument ManualDocument33 pagesSCA-1 LPR Corrosion Rate Instrument ManualEdgar I RamirezNo ratings yet

- Addmas: "ADDMAS" Make Electro-Magnetic Flow MetersDocument22 pagesAddmas: "ADDMAS" Make Electro-Magnetic Flow Metersinfo -ADDMAS100% (1)

- 3300 Proximity Transducer System: DescriptionDocument18 pages3300 Proximity Transducer System: DescriptionSuvek KumarNo ratings yet

- 3300 XL 11mm Proximity Transducer System: DescriptionDocument21 pages3300 XL 11mm Proximity Transducer System: DescriptionOmer ZamanNo ratings yet

- Abb Flow Meter Mag WW 20Document16 pagesAbb Flow Meter Mag WW 20afsaltataNo ratings yet

- Probe MF-FDDocument4 pagesProbe MF-FDPramudita Johan IswaraNo ratings yet

- Euromag Mut2200el SensorDocument12 pagesEuromag Mut2200el Sensorn_zeinoun100% (1)

- DLMS Spec For Bulk MetersDocument36 pagesDLMS Spec For Bulk MetersSuresh UmadiNo ratings yet

- Product Data Sheet: M-Series® M5000Document4 pagesProduct Data Sheet: M-Series® M5000Carlos GilNo ratings yet

- FM and FMC Approved!: Model Ft2 Gas Mass Flowmeter & Temperature TransmitterDocument4 pagesFM and FMC Approved!: Model Ft2 Gas Mass Flowmeter & Temperature TransmitterMonica AguilarNo ratings yet

- CX-EMFM User manual of Electromagnetic flowmeter 电磁说明书 (2018新)Document29 pagesCX-EMFM User manual of Electromagnetic flowmeter 电磁说明书 (2018新)megsa saNo ratings yet

- MAG-DS-00493-EN M3000 Electromagnetic Flow Meter Product Data SheetDocument4 pagesMAG-DS-00493-EN M3000 Electromagnetic Flow Meter Product Data SheetSebastián Alexander Flores OroscoNo ratings yet

- ACE300 114/116 Series: Polyphase Electricity MetersDocument4 pagesACE300 114/116 Series: Polyphase Electricity Metersasnan22No ratings yet

- Submersible Liquid Level Transmitters Type LS-10, LH-10: ApplicationsDocument4 pagesSubmersible Liquid Level Transmitters Type LS-10, LH-10: ApplicationsDragos NojeaNo ratings yet

- Instruction For Installation and Maintenance - CT - ADocument12 pagesInstruction For Installation and Maintenance - CT - AcataconstantinNo ratings yet

- Electronic Flow SwitchDocument4 pagesElectronic Flow SwitchwilfredoNo ratings yet

- 1 AvometerDocument3 pages1 AvometerEman AlzarieyNo ratings yet

- Water Meter ActarisDocument4 pagesWater Meter ActarisNavneet SinghNo ratings yet

- 3000 SI Series 4-20ma Sensor/transmitter: User ManualDocument33 pages3000 SI Series 4-20ma Sensor/transmitter: User ManualBogdan NistorNo ratings yet

- Pressurization Equipment 370-383Document14 pagesPressurization Equipment 370-383Anonymous rMwYBU2Il1100% (1)

- 1.3.1. - Ficha Tecnica OpacimetroDocument9 pages1.3.1. - Ficha Tecnica OpacimetroDirector Tecnico SuplenteNo ratings yet

- Product CatalogueDocument146 pagesProduct CatalogueSkazemi7No ratings yet

- 4to20ma Digital Transmitter Toxic Alpha SenseDocument10 pages4to20ma Digital Transmitter Toxic Alpha SenseMara AjkaloNo ratings yet

- Yokogawa DY050Document43 pagesYokogawa DY050ares201216675No ratings yet

- Sem210 Series: Programmable In-Head Universal Temperature TransmitterDocument5 pagesSem210 Series: Programmable In-Head Universal Temperature TransmitterjhuskanovicNo ratings yet

- Flow Meter ManualDocument70 pagesFlow Meter Manualrommel duranNo ratings yet

- Field Devices - Analytical: Product SpecificationsDocument32 pagesField Devices - Analytical: Product Specificationssalmo83:18No ratings yet

- 699 Pressure Sensor PDFDocument5 pages699 Pressure Sensor PDFEnriqueQNo ratings yet

- ABB 10D1477 (Magnetic Flow Meter)Document6 pagesABB 10D1477 (Magnetic Flow Meter)1234567890No ratings yet

- Datasheet STUF 280T NewDocument6 pagesDatasheet STUF 280T NewboubressNo ratings yet

- B.E (Full Time) Degree End Semester Examinations, April / May 2011Document2 pagesB.E (Full Time) Degree End Semester Examinations, April / May 2011sar_tpgitNo ratings yet

- Frequently Asked QuestionsDocument2 pagesFrequently Asked QuestionskhumisoNo ratings yet

- ACCUMULATORS Part-A Question and AnswersDocument10 pagesACCUMULATORS Part-A Question and Answerssar_tpgitNo ratings yet

- Me2305 Ahp 2 Marks Q ADocument10 pagesMe2305 Ahp 2 Marks Q Asar_tpgitNo ratings yet

- What Are The Differences Between A Liquid and A Gas: Lecture 2-Properties of FluidsDocument2 pagesWhat Are The Differences Between A Liquid and A Gas: Lecture 2-Properties of FluidsMostafa SaadNo ratings yet

- 1.what Is A Fluid? What Are The Functions and Characteristics of Hydraulic FluidsDocument3 pages1.what Is A Fluid? What Are The Functions and Characteristics of Hydraulic FluidsjtorerocNo ratings yet

- COOLING AND DRYING OF COMPRESSED AIR Part-A Question and AnswersDocument1 pageCOOLING AND DRYING OF COMPRESSED AIR Part-A Question and Answerssar_tpgitNo ratings yet

- Frequently Asked QuestionsDocument1 pageFrequently Asked Questions666667No ratings yet

- UHV Handout 4-Harmony in The SocietyDocument6 pagesUHV Handout 4-Harmony in The SocietyIshika ChokshiNo ratings yet

- FAQ-Lecture 20 PDFDocument4 pagesFAQ-Lecture 20 PDFMarathyancha BaapNo ratings yet

- HYDRAULIC ACTUATORS Part-A Question and AnswersDocument3 pagesHYDRAULIC ACTUATORS Part-A Question and Answerssar_tpgitNo ratings yet

- FAQ-Lecture 24 To 26Document11 pagesFAQ-Lecture 24 To 26sandeepNo ratings yet

- Evaluation of Course End SurveyDocument4 pagesEvaluation of Course End Surveysar_tpgitNo ratings yet

- UHV Handout 2-Harmony in The Human BeingDocument11 pagesUHV Handout 2-Harmony in The Human Beingbvs957946No ratings yet

- Rr412205 Hydraulic and Pneumatic Control SystemsDocument4 pagesRr412205 Hydraulic and Pneumatic Control SystemsSrinivasa Rao GNo ratings yet

- CIM OutlineDocument11 pagesCIM Outlinesar_tpgitNo ratings yet

- Instructions To Candiates 12Document32 pagesInstructions To Candiates 12sat18373No ratings yet

- AC 08 C DOM 2018-2019 OddDocument1 pageAC 08 C DOM 2018-2019 Oddsar_tpgitNo ratings yet

- Syllabus Jan.2014 1Document38 pagesSyllabus Jan.2014 1sar_tpgitNo ratings yet

- Drafting and Computer-Aided Design 10-20-30 2000Document60 pagesDrafting and Computer-Aided Design 10-20-30 2000anjaiah_19945No ratings yet

- 202804Document24 pages202804sar_tpgitNo ratings yet

- Me 1403 - Computer Intergrated ManufacturingDocument5 pagesMe 1403 - Computer Intergrated Manufacturingsar_tpgitNo ratings yet

- Me 2402-Computer Integrated ManufacturingDocument2 pagesMe 2402-Computer Integrated ManufacturingdsathiyaNo ratings yet

- Practice Question Set On General Intelligence and Reasoning For SSC Recruitment Examination 2012Document15 pagesPractice Question Set On General Intelligence and Reasoning For SSC Recruitment Examination 2012Ashish TiwariNo ratings yet

- Steam TablesDocument6 pagesSteam TablesRichard Olawoyin100% (1)

- 07 Textile... (pp.221-225)Document5 pages07 Textile... (pp.221-225)sar_tpgitNo ratings yet

- Peek (Polyether Ether Ketone) : Basic Material For EngineeringDocument2 pagesPeek (Polyether Ether Ketone) : Basic Material For Engineeringsar_tpgitNo ratings yet

- Présentation Est Automatique. Votre Haut Paroles.: AllumezDocument23 pagesPrésentation Est Automatique. Votre Haut Paroles.: AllumezChe-che Mendoza OlivasNo ratings yet

- FMSEL 2.0: Fluid Control Research InstituteDocument9 pagesFMSEL 2.0: Fluid Control Research Institutecool_rdNo ratings yet

- Ismael AnabalonDocument35 pagesIsmael Anabalondnavarrete01No ratings yet

- BS Chemical EngineeringDocument110 pagesBS Chemical EngineeringhorasiusNo ratings yet

- Dairyprocess GuidebookDocument72 pagesDairyprocess GuidebookGraciela LacostaNo ratings yet

- Maya Gate QuestionDocument9 pagesMaya Gate QuestionGarv KumarNo ratings yet

- Preparation of Contaminated Test Coupons For The Evaluation of Cleaning AgentsDocument4 pagesPreparation of Contaminated Test Coupons For The Evaluation of Cleaning AgentsDavid Francisco Plata DuranNo ratings yet

- Fluoride Toxicity SeminarDocument27 pagesFluoride Toxicity SeminarNikhil BhandariNo ratings yet

- 04 Determining Molar Mass by FP DepressionDocument16 pages04 Determining Molar Mass by FP DepressionMuhammad IqbalNo ratings yet

- TFP330 10 2013Document4 pagesTFP330 10 2013Mihai CatalinNo ratings yet

- Annex Iv - Part 1 List of Colouring Agents Allowed For Use in Cosmetic ProductsDocument6 pagesAnnex Iv - Part 1 List of Colouring Agents Allowed For Use in Cosmetic Productstary_nuryanaNo ratings yet

- Chemical Food SafetyDocument297 pagesChemical Food SafetyqtrystNo ratings yet

- Cost Unit Februri 2017dddddddddddgDocument563 pagesCost Unit Februri 2017dddddddddddgHatlan RizalNo ratings yet

- Pulp and PaperDocument18 pagesPulp and PaperAbhishek AwasthiNo ratings yet

- Uniform Mechanical Code - 2009 Chapter 5Document34 pagesUniform Mechanical Code - 2009 Chapter 5memosplumbingNo ratings yet

- Xie Rehren 2009 Lead Silver Slag China BUMA VIDocument9 pagesXie Rehren 2009 Lead Silver Slag China BUMA VIth_rehrenNo ratings yet

- Market Survey On Copper PDFDocument210 pagesMarket Survey On Copper PDFmujib uddin siddiquiNo ratings yet

- Can Man Alter MarsDocument1 pageCan Man Alter MarsJan Gabriel Gimao100% (2)

- Cleaning and Care Instructions Marbond and SentecDocument12 pagesCleaning and Care Instructions Marbond and Sentecon onNo ratings yet

- Lecture 22-23-24 ChlorAlkali IndustryDocument83 pagesLecture 22-23-24 ChlorAlkali IndustryAnilKumar33% (3)

- Kinetics of The Partial Oxidation of MethanolDocument16 pagesKinetics of The Partial Oxidation of MethanolmagierezNo ratings yet

- Lecture 10a OptoelctronicsDocument33 pagesLecture 10a OptoelctronicsMegaHertz_92No ratings yet

- Variation QuestionDocument5 pagesVariation Questionanshul4clNo ratings yet

- ConcentrationExpresion QM Chp6Document38 pagesConcentrationExpresion QM Chp6theking12ion25% (4)

- Application of Hydrocolloids in The Beverage Industry - Dedi FardiazDocument35 pagesApplication of Hydrocolloids in The Beverage Industry - Dedi FardiazbanakhoiriNo ratings yet

- Effect of Heat Treatment On Microstructure and Mechanical Behaviours of 18ni-300 Maraging Steel Manufactured by Selective Laser MeltingDocument11 pagesEffect of Heat Treatment On Microstructure and Mechanical Behaviours of 18ni-300 Maraging Steel Manufactured by Selective Laser MeltingHasan TaşNo ratings yet

- Hesss LawDocument15 pagesHesss LawAriAnggoroNo ratings yet

- Dioscorea HispidaDocument9 pagesDioscorea HispidaHorcruxesNo ratings yet

- Robustness of The QAL2 Calibration EN14181 UncertaDocument10 pagesRobustness of The QAL2 Calibration EN14181 UncertaAnaibar TarikNo ratings yet

- Etheric MelaninDocument40 pagesEtheric MelaninAsar100% (1)

- Shubharambh Banquets HL - All Halls 26-5-2017Document5 pagesShubharambh Banquets HL - All Halls 26-5-2017calvin.bloodaxe4478No ratings yet

- ADVANTAGES. of Polymer Insulator PDFDocument1 pageADVANTAGES. of Polymer Insulator PDFviksoniNo ratings yet

- University of Chicago Press Fall 2009 Distributed TitlesFrom EverandUniversity of Chicago Press Fall 2009 Distributed TitlesRating: 1 out of 5 stars1/5 (1)

- University of Chicago Press Fall 2009 CatalogueFrom EverandUniversity of Chicago Press Fall 2009 CatalogueRating: 5 out of 5 stars5/5 (1)