Summary

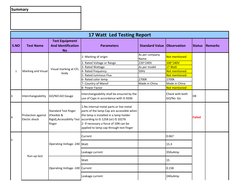

17 Watt Led Testing Report

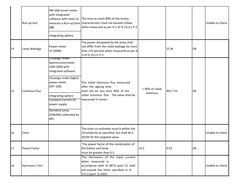

S.NO Test Name Test Equipment And Identification No Parameters

1- Marking of origin 2- Rated Voltage or Range 3- Rated Wattage Visual marking at CFL Marking and Visual 4- Rated frequency body 5- Rated luminous Flux 6- Rated color temp 7- Country of Manuf 8- Power Factor Interchangeability GO/NO-GO Gauge Interchangeability shall be ensured by the use of Caps in accordance with IS 9206

Standard Value Observation

As per company Name 220~240V As per model 50Hz 2700K Made in China Not mentioned 100~240V 17 Watt Not mentioned Not mentioned 2700K Made in China Not mentioned Check with both GO/No Go

Status Remarks

OK

1.No internal metal parts or live metal Standard Test finger parts of the lamp Cap are accessible when Protection against (Flexible & the lamp is installed in a lamp holder Electic shock Rigid),Accessibility Test according to IS 1258 (or) IS 10276 finger 2- If necessary a force of 10N can be applied to lamp cap through test finger Current 0.067 15.3 350uAmp 15 0.158 240uAmp

Failed

Operating Voltage -240 Watt Leakage current Run-up test Watt Operating Voltage -100 Current Leakage current

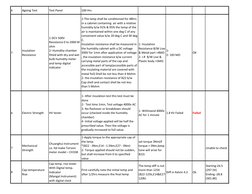

Ageing Test

Test Panel

100 Hrs

Insulation Resistance

1-The lamp shall be conditioned for 48hrs in a cabinet containing air with a relative humidity b/w 91% & 95% the temp of the air is maintained within one deg C of any convenient value b/w 20 deg C and 30 deg 1-DCV 500V C. Resistance 0 to 2000 M Insulation resistance shall be measured in ohm the humidity cabinet with a DC voltage 2- Humidity chamber 500V for 1min after application of voltage fitted with dry and wet , the insulation resistance b/w current bulb humidity meter carrying metal parts of the cap and and temp digital accessible part of lamp(accessible parts of indicator the insulating material are covered with metal foil) Shall be not less than 4 Mohm 2- the insulation resistance of B22 b/w Cap shell and contact shell be not less than 5 Mohm

1- Insulation Resistance B/W Live 1& Metal part >4M 2- 183 M 2- I.R B/W Live & Plastic body >5M

OK

Electric Strength

HV tester

1- After insulation test this test must be done 2- Test time 1min, Test voltage 4000v AC 3- No flashover or breakdown should 1- Withstand 4000v occur (checked inside the humidity 1.8 KV Failed AC for 1 minute chamber) 4- Initial voltage applied will be half the prescribed value. Then the voltage is gradually increased to full value.

Failed

Mechanical Strength

1-Apply torque to the appropriate cap of the lamp Chuanghui Instrument *(B22 - 3Nm,E14 - 1.5Nm,E27 - 3Nm) co. ltd make Torsion 2- Torque applied should not be sudden, meter model CH338 but shall increase from 0 to specified value Cap temp. rise tester With Digital temp. Indicator (Mangal Instrument) with digital clock

set torque 3Nm(If torque > 3Nm,beep tone will arise for B22)

Unable to check

Cap temperature Rise

First carefully note the initial temp and after 1/2hrs measure the final temp

The temp diff is not more than 125K Diff in Kelvin 4.3 (B22-125k,E14&E27120k)

Ok

Starting-24.5 (297.5K) Ending -28.8 (301.8K)

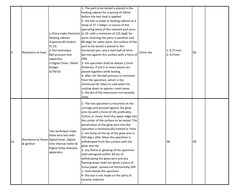

1- The part to be tested is placed in the heating cabinet for a period of 10min before the test load is applied 2- the test is made in heating cabinet at a temp of 27 +-5deg C in excess of the operating temp of the relevant part acco. 1-China make Electrical to 10. with a minimum of 125 degC for Heating cabinet parts retaining live parts in position and (Capacity 40 holder) 80 degC for other parts. the surface of the TC-01 part to be tested is placed in the 2-Test technique horizontal pos. and a steel ball of 5mm Resistance to heat >2mm dia Ball pressure test dia rest against this surface with a force of apparatus 20N 3-Digital Timer (Multi 3- the specimen shall be atleast 2.5mm Range) thickness, if not 2 or more pieces are A/TM-01 placed together while testing. 4- after 1hr the ball pressure is removed from the specimen, which is the immersed for 10sec in cold water for cooling down to approx. room temp. 5- the dia of the impression not exceeds 2mm 1- The test specimen is mounted on the carriage and pressed against the glow wire tip with a force of 1N, preferably 15mm, or more, from the upper edge into the center of the surface to be tested. The penetration of the glow wire into the specimen is mechanically limited to 7mm 2- the temp of the tip of the glow wire is 650 deg c after 30sec the specimen is withdrawed from the contact with the glow wire tip 3- any flame or glowing of the specimen shall extinguish within 30 sec of withdrawing the glow wire and any flaming drops shall not ignite a piece of tissue paper, spread out horizontally 200 +- 5mm below the specimen 4- the test is not made on the parts of ceramic material.

1- 0.75 mm 2- 0.9 mm

Ok

10

Test technique make Glow wire test with Resistance to flame Digital timer ,Digital & ignition time interval meter & Digital temp indicator apparatus

Ok

OK

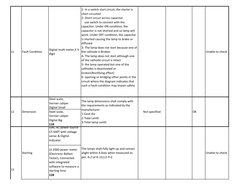

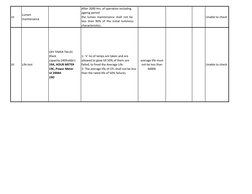

�11

Fault Condition

1- In a switch start circuit, the starter is short circuited 2- Short circuit across capacitor use switch to connect with the capacitor. Under ON condition, the capacitor is not shorted and so lamp will work. Under OFF condition, the capacitor is shorted causing the lamp to brake or diffused 3- The lamp does not start because one of Digital multi meter,3 the cathode is Broken digit 4- The lamp does not start although one of the cathode circuit is intact 5- the lamp operated but one of the cathodes is deactivated or broken(Rectifying effect) 6- opening or bridging other points in the circuit where the diagram indicates that such a Fault condition may impair safety

Unable to check

12

Dimension

Steel scale, Vernier caliper Digital Small Steel scale, Vernier caliper Digital Big 11B IDRC AC power source CF-500T with voltage variac & Digital indicator

The lamp dimensions shall comply with the requirements as indicated by the manufacturer 1-Case dia 2-Tube Lenth 3-Total lamp Lenth

Not specified

OK

Starting

13

UI 2000 power meter The lamps shall fully light up and remain alight within 4.0sec when measured as (Electronic Ballast per A-2 of IS 15111 P-2 Tester), Connected with integrated software to measure a starting time 12B

Unable to check

�Run-up test

PM-200 lumen meter with integrated software with timer to The time to reach 80% of the lumen measure a Run-up time characteristics shall not exceed 120sec when measured as per A-2 of IS 15111 P-2 12C Integrating sphere Power meter UI-2008A Chuangui make Spectrocolorimeter CMS-2000 with integrated software Chuangui make Digital power meter The initial luminous flux measured (WT-100) after the ageing time shall not be less than 90% of the rated luminous flux. The value shall be Integrating sphere expressed in lumen. Constant Current DC power supply Standard Lamp (OSRAM) calibrated by NPL The color co-ordinates must b within the chromaticity as specified, but shall be 5 SDCM fm the targeted value The power factor of the combination of the ballast and lamp must be greater than 0.5. The Harmonics of the input current when measured in accordance with IS 6873 (part 5) shall not exceed the limits specified in IS 15111(part 2):2002. >0.5 0.93 OK The power dissipated by the lamp shall not differ from the rated wattage by more than 15 percent when measured as per A3 of IS 15111 P-2

Unable to check

14

Lamp Wattage

15 W

OK

15

Luminous Flux

> 90% of rated luminous

902.7 lm

OK

16

Color

Unable to check

17

Power Factor

18

Harmonics Test

Unable to check

�19

Lumen maintenance

After 2000 Hrs. of operation including ageing period the lumen maintenance shall not be less than 90% of the initial luminous characteristics.

Unable to check

20

Life test

OFF TIMER TM-01 (Rack capacity:240holder) 19A, HOUR METER 19C, Power Meter Ui 2008A 19D

1- 'n' no of lamps are taken and are allowed to glow till 50% of them are failed, to fined the Average Life. 2- The average life of CFL shall not be less than the rated life of 50% failures

average life must not be less than 6000h

Unable to check