Professional Documents

Culture Documents

INTENSE ShiftPak Instructions

Uploaded by

Carmen N Angel DiazCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

INTENSE ShiftPak Instructions

Uploaded by

Carmen N Angel DiazCopyright:

Available Formats

INTENSE Street/Strip Shift Pak for 4T65E and 4T65E-HD Transaxles

SAC 9.6.05

Visit us at www.INTENSE-Racing.com!

Applications: 1998-current Grand Prix GT 1998-current Monte Carlo 1998-current other applications using the 4T65E (non -HD) transaxle 1997-current Grand Prix GTP 1997-current Regal GS 1997-current Bonneville SSEi 1997-current other applications using the 4T65E-HD transaxle Note: this kit will NOT fit 4T60E transaxles

Figure 1- The INTENSE Street/Strip Shift Pak comes complete with everything you need!

The INTENSE Street/Strip Shift Pak is designed to give you crisp shifts under light to medium throttle positions, and very firm shifts at wide-open throttle. It is not designed to rip your dashboard out, break your input shaft or destroy your transaxle drive chain (please see disclaimer at the end of these installation instructions). Installation should average one to two hours depending on your skill level. No special tools are required other than an inch-pound torque wrench.

The INTENSE Street/Strip Shift Pak is installed by removing the transaxle pan, then the accumulator cover. The accumulator housing contains the 1-2 and 2-3 pistons that control the rate at which fluid pressure gets applied to the clutch packs during upshifts and downshifts. Our kit contains custom springs and spacers to create the ideal shifts for a mix of street and strip use. Shorter shift cycle times mean less time when the PCM retards ignition timing during each shift to protect the transaxle. Shortening the shift times serves to increase clutch life, due to less slippage between gears. Less slippage equates to less heat, and less heat can extend overall transaxle life. There are two basic settings, depending on whether you have a 245 mm. (stock in 4T65E transaxles) or 258 mm. (stock in 4T65E-HD transaxles) torque converter. This kit is by far the most comprehensive shift modifier on the market for our transaxles. Every kit includes: 5 custom accumulator piston springs 3 custom flat spacers 8 custom cylindrical spacers sandpaper to smooth accumulator gasket surface for improved mating new accumulator gasket abrasive pad to scuff accumulator bores for increased oil on bore walls 2 new piston seals new transaxle filter new transaxle filter seal transmission assembly lubricant extremely detailed installation instructions with full color images explaining how to inspect your transaxle pan contents, and properly prepare the accumulator cover, accumulator pistons and piston pins

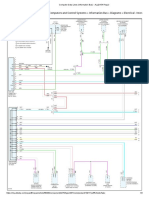

Installation Instructions: 1) On level ground, raise and support vehicle by the frame rails under the front floor pan. The frame rails are directly behind the rear cradle bolts. Use good quality jack stands to support the vehicle. 2) Allow vehicle to sit for approximately a half hour to drain fluid toward the transaxle pan and allow fluid to cool down a bit. 3) Place a large drain pan under vehicle and remove the transaxle pan by removing the bolts on the passenger side one at a time until fluid begins to drain. Remove remaining bolts slowly until pan is close to empty. Pan can now be removed. 4) Evaluate debris in pan to determine whether or not a shift kit is a wise thing to do. Metallic sludge on the magnet is normal. Slivers or fragments are not. The inside of the transaxle pan should not be discolored with sediment. Staining or hazing of the inside of the pan is indicative of clutch or band failure. Figures 2 and 3 are normal transaxle pan contents. Figures 4 and 5 are abnormal pan contents. If any of these abnormal conditions is present, please do not proceed with the shift kit installation. We recommend that you consult a transaxle expert, or send an email to Sales@INTENSE-Racing.com for advice.

Figure 2 normal transaxle pan contents

Figure 3 normal transaxle pan contents

Figure 4 abnormal transaxle pan contents

Figure 5 abnormal transaxle pan contents

5) With the pan removed, you can now remove the filter. Be sure to have the drain pan positioned to catch fluid from filter removal. 6) Remove shift accumulator assembly from transaxle by removing the necessary bolts. Remove accumulator tubes and differential oil tube. Differential oil tube can be removed by popping the retainer clip out, then coaxing the tube out. 7) With the accumulator assembly placed on a clean workbench, remove the remaining bolts and disassemble. Remove and discard the accumulator piston seals and accumulator cover gasket. Using aerosol brake cleaner, thoroughly clean all components. Be sure to remove all metal residue from the accumulator bores. Clean the rest of the accumulator and the differential oil tubes as well. 8) Inspect the accumulator cover for signs of damage. Figure 6 is an example of normal accumulator cover condition. If an accumulator piston has deformed the area indicated, then your accumulator cover must be replaced before reassembly. These can be purchased at any G.M. dealership, by asking for part number 24205584.

Figure 6 normal accumulator cover

9) Inspect the accumulator piston pins for excessive wear and/or damage. Both pins should be smooth and free of lips or recesses that would indicate the piston has been binding on the pin. Evidence of this warrants replacement of the piston(s) and piston pin(s) before reassembly. These can be purchased at any G.M. dealership, by asking for part numbers 24206857 (accumulator piston) and 24203979 (accumulator piston pin).

10) Prepare the accumulator bores by using the provided abrasive pad to scuff each bore. This procedure ensures longer seal life due to increased oil on the bore walls. Using one piece of the provided sandpaper, polish the piston pins to remove any small scratches. Use the other piece of sandpaper to smooth the flat gasket mating surfaces of the accumulator cover and housing. With these preparation steps complete, again THOROUGHLY clean all components with aerosol brake cleaner.

Figure 7 side view of accumulator

Figure 8 top view of accumulator

11) Install the provided new seals on the accumulator pistons. Thoroughly lubricate the bores and seals with the lubricant provided. 12) Determine what size torque converter you have using the following chart: 1997-current Grand Prix GTP - stock torque converter is 258 mm 1997-current Regal GS - stock torque converter is 258 mm 1997-current Bonneville SSEi - stock torque converter is 258 mm 1997-current other applications using the 4T65E-HD transaxle - stock torque converter is 258 mm All known aftermarket torque converters for these vehicles are 245 mm.

1998-current Grand Prix GT - stock torque converter is 245 mm. 1998-current Monte Carlo - stock torque converter is 245 mm 1998-current other applications using the 4T65E (non -HD) transaxle - stock torque converter is 245 mm All known aftermarket torque converters for these vehicles are 245 mm.

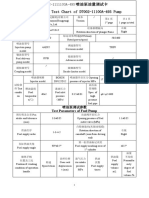

13) Figure 9 is the recommended assembly sequence for all applications with a 258 mm. torque converter. 2-3 is assembled as follows: pin, #3 spacer, #1 spacer, white spring, red spring, plain spring, accumulator piston/seal assembly, one flat spring spacer, #2 spacer, 2-3 shift spring (large coils). 1-2 is assembled as follows: pin, white spring, plain spring, #3 spacer, #1 spacer, accumulator piston/seal assembly, #2 spacer, 1-2 shift spring (small coils). Hint: assembly is easier if you use the provided assembly lubricant to glue the plain spring into the piston before installation. Note: the four different sizes of cylindrical spacers are numbered 1 through 4, with 1 being the shortest and 4 being the longest.

Figure 9 recommended assembly sequence for all 258 mm. torque converter applications

14) Figure 10 is the recommended assembly sequence for all applications with a 245 mm. torque converter. 2-3 is assembled as follows: pin, #3 spacer, #1 spacer, white spring, red spring, plain spring, accumulator piston/seal assembly, two flat spring spacers, #4 spacer, 2-3 shift spring (large coils). 1-2 is assembled as follows: pin, #3 spacer, #1 spacer, white spring, plain spring, accumulator piston/seal assembly, one flat spring spacer, #4 spacer, 1-2 shift spring (small coils). Hint: assembly is easier if you use the provided assembly lubricant to glue the plain spring into the piston before installation. Note: the four different sizes of cylindrical spacers are numbered 1 through 4, with 1 being the shortest and 4 being the longest.

Figure 10 recommended assembly sequence for all 245 mm. torque converter applications

15) With your shift kit assembled in the bores, install the gasket and cover and HAND TIGHTEN the bolts shown in Figure 11. Then torque them slowly and carefully torque these same bolts to 106 inch-pounds (NOT foot-pounds!).

Figure 11 reassembled accumulator assembly

16) With the assembly complete, lubricate both ends of all three tubes with the lubricant provided, and reinstall the accumulator assembly into the transaxle using the remaining bolts. It may be necessary to wiggle the accumulator a little bit in order to properly align the bolt holes and tubes simultaneously. HAND TIGHTEN the bolts shown in Figure 12. Then torque them slowly and carefully torque these same bolts to 106 inch-pounds (NOT foot-pounds!).

Figure 12 bolts that fasten accumulator assembly to transaxle

17) Install new filter and filter seal, and reinstall cleaned transaxle pan. Pan gasket can be reused. Torque all bolts to 120 inch-pounds (NOT foot-pounds!). 18) Lower the vehicle and ad six quarts of transaxle fluid initially. Allow the car to run until completely warmed up. With the emergency brake engaged, and your foot firmly on the brake pedal, run the transaxle through all the gears several times. Then check the transaxle fluid level with the engine running and add additional fluid as necessary.

19) Once fluid has reached the proper level, go ahead and drive the car. The shifts should feel crisp under light to medium throttle positions, and very firm at full throttle. Remember, the object of this shift kit is to decrease shift times, and not damage the transaxle by slamming into gears. 20) Enjoy!

Disclaimer: Transaxle components fail especially in cars modified for increased power outputs. Transaxle failures occur in completely stock transaxles and ones with shift kits too. Your purchase and/or installation of this product constitutes your acceptance of any and all liability with regard to this product. INTENSE Enterprises, Inc. will not be held liable for any transaxle or other damage that occurs due to the installation, misinstallation or use of this product.

You might also like

- DIY Shift Kit Filter Fluid ChangeDocument6 pagesDIY Shift Kit Filter Fluid ChangeCarmen N Angel DiazNo ratings yet

- Samsung Galaxy s2 - User GuideDocument164 pagesSamsung Galaxy s2 - User GuideMindfk GsNo ratings yet

- Samsung Galaxy s2 - User GuideDocument164 pagesSamsung Galaxy s2 - User GuideMindfk GsNo ratings yet

- Samsung Galaxy s2 - User GuideDocument164 pagesSamsung Galaxy s2 - User GuideMindfk GsNo ratings yet

- Trumpet Lesson 8 PedalsDocument6 pagesTrumpet Lesson 8 PedalsCarmen N Angel Diaz100% (1)

- TagDocument14 pagesTagCarmen N Angel DiazNo ratings yet

- Hatha Yoga BreathingDocument6 pagesHatha Yoga BreathingCarmen N Angel DiazNo ratings yet

- Gas Weedwacker TrimmerDocument32 pagesGas Weedwacker TrimmerCarmen N Angel DiazNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Manage The Operation of Propulsion Plant From UKP AllDocument73 pagesManage The Operation of Propulsion Plant From UKP AllAndhikaNo ratings yet

- Using The Schematic of The Hydro-Pneumatic Fuel Control of From Your Text Book, in Your Own Words, Summarize How TheDocument6 pagesUsing The Schematic of The Hydro-Pneumatic Fuel Control of From Your Text Book, in Your Own Words, Summarize How TheNurul Lyana Muhamad100% (1)

- Bomba de Combustible UniversalDocument2 pagesBomba de Combustible UniversalCAR6No ratings yet

- Service Manual XT 125 2005Document32 pagesService Manual XT 125 2005Bálint GézaNo ratings yet

- Engine Removal/InstallationDocument10 pagesEngine Removal/Installationorly pocoateNo ratings yet

- Onan 7500 Parts ManualDocument72 pagesOnan 7500 Parts Manualjustin tuckerNo ratings yet

- Yamaha Xjr1300 1999 2003 Service ManualDocument20 pagesYamaha Xjr1300 1999 2003 Service Manualkirk100% (32)

- TEREXDocument72 pagesTEREXklausNo ratings yet

- PCM 2.0l 5 de 5Document2 pagesPCM 2.0l 5 de 5Felix VelasquezNo ratings yet

- MAN B&W S40 MC c9 Marine Engine Product ManualDocument318 pagesMAN B&W S40 MC c9 Marine Engine Product ManualCalifornia KnightNo ratings yet

- Crankshaft Main Bearing TESTINGDocument2 pagesCrankshaft Main Bearing TESTINGRECTIMANSANo ratings yet

- V2 8TCDocument2 pagesV2 8TCMiguel RojasNo ratings yet

- 65615ee47688a3e47631fd01 90019837958Document2 pages65615ee47688a3e47631fd01 90019837958kuangyongserviceNo ratings yet

- Repair Guides - Gasoline Fuel Injection Systems - Sequential Multi-Port Fuel Injection System (Sfi) - AutoZoneDocument26 pagesRepair Guides - Gasoline Fuel Injection Systems - Sequential Multi-Port Fuel Injection System (Sfi) - AutoZonecjtovarNo ratings yet

- ACP 116 UNIT 13 Airframes: Chapter 7: UndercarriageDocument36 pagesACP 116 UNIT 13 Airframes: Chapter 7: UndercarriageAnonymous 84PIIHNo ratings yet

- Corolla 2018Document3 pagesCorolla 2018Jeison Jose Anthonio castro SagastumeNo ratings yet

- Commande 12.21Document2 pagesCommande 12.21M B F SOLUTIONNo ratings yet

- Service Manual KorandoDocument1,460 pagesService Manual Korandodangim100% (2)

- Parts Manual - SoNALIKA WorldTrac 60 75 90 PDFDocument578 pagesParts Manual - SoNALIKA WorldTrac 60 75 90 PDFkvsj2001No ratings yet

- Jinan Qingong International Trade Co.,Ltd.: Item Part Number Part Name Specifications Price PhotoDocument16 pagesJinan Qingong International Trade Co.,Ltd.: Item Part Number Part Name Specifications Price PhotoMoges AberaNo ratings yet

- OTR - Catalog TITAN PDFDocument107 pagesOTR - Catalog TITAN PDFjorgegachaNo ratings yet

- Hyundai I10Document29 pagesHyundai I10tmonga100% (2)

- Rear Axle 1994 Volvo 960 SamosvorDocument19 pagesRear Axle 1994 Volvo 960 Samosvoraaa222No ratings yet

- LeafletDocument2 pagesLeafletYunendarNo ratings yet

- YC4108 Fuel Injection PumpDocument3 pagesYC4108 Fuel Injection PumpCarlos GuajardoNo ratings yet

- TSK50Document6 pagesTSK50Manuel BerriosNo ratings yet

- Ecu-Pin PDFDocument39 pagesEcu-Pin PDFJimmy Brian KaifitiNo ratings yet

- Examen de Conocmientos Técnicos KomatsuDocument29 pagesExamen de Conocmientos Técnicos KomatsuWilbort Encomenderos RuizNo ratings yet

- Synchrophaser Vs SynchronisingDocument5 pagesSynchrophaser Vs SynchronisingAnish Kumar SinghNo ratings yet

- Ethyl AdditivesDocument204 pagesEthyl Additivessergeiivan100% (2)