Professional Documents

Culture Documents

Audit Checklist

Uploaded by

gkiyer7Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Audit Checklist

Uploaded by

gkiyer7Copyright:

Available Formats

WORLD FOOD SAFETY GUIDELINES

For the Airline and Airline Catering

WORLD FOOD SAFETY GUIDELINES AUDIT CHECKLIST

STATION:

Compliant

CATERING: FINAL SCORE: CARRIED OUT BY: DATE:

All non-compliant CCPs require immediate action. All non-compliant SOPs require attention.

P

THIS AUDIT CHECKLIST IS BASED ON THE IFCA/IFSA WORLD FOOD SAFETY GUIDELINES.

(Tick appropriate box/es)

ITS PURPOSE IS TO VERIFY THAT A FOOD SAFETY CONTROL PROGRAM BASED ON HACCP PRINCIPLES IS IN PLACE WHICH ELIMINATES, REDUCES OR CONTROLS RELEVANT FOOD SAFETY HAZARDS THROUGHOUT THE FOOD CHAIN. IT ALSO AIMS TO DETERMINE THAT APPROPRIATE CORRECTIVE ACTION IS TAKEN AND RECORDED WHEN CRITICAL LIMITS ARE NOT MET OR IN CASE OF DEVIATIONS FROM SOP REQUIREMENTS.

CHECK POINTS

CCPs 4 1

SOPs 2

COMMENTS

FOOD SAFETY MANAGEMENT SYSTEM

FOOD SAFETY MANAGEMENT SYSTEM 1 Is there a documented food safety management system based on HACCP principles? HACCP VERIFICATION 2 Is there a verification programme for the HACCP system? 3 Is corrective action taken when necessary and recorded?

UNIT STRUCTURE, SIZE, LAYOUT AND DESIGN

4 Does unit size and layout permit effective segregation between clean and unclean materials and processes? 5 Does the building design permit effective cleaning and tidiness? - Floors, walls and ceilings have smooth and washable surfaces. - They are clean and well-maintained. - Floors incline to drains. Drains are open, clean and with grates. - All areas are well lit. - Ventilation is adequate to prevent excessive rises in air temperature in food preparation rooms. 6 Are all areas of unit clean and tidy, no visible dirt and debris? 7 Hand wash facilities - Are there hand wash facilities in each area with hot water, filled soap dispenser and single-use towels & signs for handwashing suitably placed? - Are hand wash facilities correctly used?

PEST CONTROL

8 Is there an effective and documented pest management program? - Building is properly proofed to prevent access of flying and crawling pests. - Unit plan, bait locations, list and type of eradication devices, list of approved insecticides/pesticides, material safety data, are available. - Records are kept for inspection, findings, treatments and corrective actions taken. - No signs of pest infestation.

EQUIPMENT

9 Food Preparation Equipment and Food Contact Surfaces - Are food preparation equipment and food contact surfaces made from food grade and non-porous material? - Are the equipment and food contact surfaces clean and in good condition? Subscore (minus points)

3rd Version, June 2010

CHECK POINTS

CCPs 4 1

SOPs 2

COMMENTS

CONTROL OF HAZARDOUS MEAL INGREDIENTS

10 Is there a procedure for control of potentially hazardous meal ingredients in place? - A list of hazardous meal ingredients is available and considered during menu design process, procurement and production.

SUPPLIER APPROVAL

11 Is there an effective approval process for high-risk ready-to-eat food suppliers?

CONTROLS OF FOOD HANDLING

FOOD RECEIVING 12 Is there a food temperature control system for safe receipt of potentially hazardous foods? - Temperature of potentially hazardous foods is monitored and recorded: Critical: 8C / 46F Chilled food: Surface temperature Frozen food: Solid frozen. - Corrective action is taken and recorded when critical limit is not met. FOOD STORAGE 13 Is there a food temperature control system for safe storage of potentially hazardous foods? Critical: 5C / 41F - Chilled food: Surface temperature - Records are kept and corrective action taken when critical limit is not met. 14 Is there a robust control system to ensure that food is consumed within its shelf-life? - Are foods date-marked or color-coded and correctly rotated (no out-of-date foods)? 15 Are foods covered to protect from contamination? 16 Is there a process which controls in-house freezing of products? THAWING 17 Is thawing performed in such a way that prevents the growth of pathogens and cross-contamination (e.g. under refrigeration)? - Product is in sealed packaging if thawed in water. - Product surface temperature is monitored and recorded when thawed outside of refrigeration. Target: 8C / 46F - Product surface temperature: FRUIT & VEGETABLE WASHING AND SANITIZING 18 Is there a documented washing process? - Each batch of raw vegetables and fruits are washed in clean and potable water or suitable alternative, with records kept. - Where permitted, sanitiser with correct concentration is used with records kept. - Appropriate segregation of washed and unwashed products. HOT MEAL PRODUCTION 19 Are foods cooked to safe core temperature with records kept? CCP - Refer to CCP 3 of WFSG for minimum cook core temperature requirements. 20 Are foods cooled safely? Food core temperature is reduced from: CCP - 60C / 140F to 10C / 50F in 4 hrs, OR - 60C / 140F to 5C / 41F in 6 hrs, provided it reaches 21C / 70F in 2 hrs.

CCP 1

CCP 2

- Records are kept and corrective action taken when critical limits are not met. Subscore (minus points)

3rd Version, June 2010

CHECK POINTS

CCPs 4 1

SOPs 2

COMMENTS

HANDLING OF READY-TO-EAT FOODS 21A Ambient temperature is less than or equal to 5C/41F. - Is ambient temperature monitored? - Are records kept and corrective action taken when necessary?

CCP 5

OR

21B Ambient temperature is higher than 5C/41F but less than or equal to 15C/59F. - Is ambient temperature monitored? - Food exposure time does not exceed Critical limit of 90 mins. - Are records kept and corrective action taken when necessary?

CCP 5

OR

21C Ambient temperature is higher than 15C/59F but less than or equal to 21C/70F. - Is ambient temperature monitored? - Food surface temperature does not Critical limit of 15oC/59oF exceed or Food exposure time does not exceed Critical limit of 45 mins. - Are records kept and corrective action taken when necessary?

CCP 5

OR

21D Ambient temperature is higher than 21C/70F. - Is ambient temperature monitored? - Food surface temperature does not Critical limit of 15oC/59oF exceed and Food exposure time does not exceed Critical limit of 45 mins. - Are records kept and corrective action taken when necessary? DESPATCH, TRANSPORT AND LOADING 22 Despatch - High-risk cold food: maximum surface temperature 5C/41F. - Hot food: minimum core temperature 63C/145F. - Records are kept and corrective action taken in case of deviation from above. 23 Are ice machines and scoops clean and well-maintained? 24 Transport and loading - High-risk cold food: maximum surface temperature 10C/50F. - Hot food: minimum surface temperature 60C/140F. - Is there sufficient regular monitoring and recording of food temperature at loading to show compliance with above requirement? 25 Is there a food safety based risk-assessment in the event of an aircraft delay?

CCP 5

CONTROL OF PHYSICAL CONTAMINATION

26 Is there a documented, risk-assessment based control measures to prevent physical contaminations, e.g. glass breakage?

PREVENTION OF CROSS CONTAMINATION

27 Is there clear segregation between raw and ready-to-eat food during storage? 28 Is there clear segregation between raw and ready-to eat food during preparation? 29 Are there effective controls to ensure safe production of special meals, e.g. avoidance of allergens?

PERSONAL HYGIENE

30 31 32 33 Are uniforms suitable, clean and correctly worn? Is there a company rule regarding jewellery based on risk assessment? Are toilets and changing rooms clean and well-maintained? Wherever possible, are tools (including gloves) used for portioning of food to minimise direct food contact? 34 When worn, are disposable gloves changed after being used for unclean handling processes?

INFECTION CONTROL

35 Is there a monitoring procedure in place to prevent contamination of food through contact with infected employees and visitors? 36 Are wounds properly covered? - Conspicuous, waterproof dressings. Subscore (minus points)

3rd Version, June 2010

CHECK POINTS

CCPs 4 1

SOPs 2

COMMENTS

TRAINING

37 Is there a job-related food safety training program for employees and management? - Induction and refresher training. - Tests are included. - Training records are available for each member of staff.

CLEANING AND SANITIZING

38 Is there a documented cleaning and sanitizing program for food contact and non-food contact surfaces? 39 Cleaning chemicals - Food grade detergents and sanitisers are available in all working areas. - Separate chemical store with chemicals correctly labelled. 40 Pot wash/Dish wash Thermal sanitizing - Do equipment washing machines achieve equipment surface temperature of 71C/160F or final rinse temperatare of 82C/180F? - Is final rinse temperature monitored and recorded at beginning of each shift by reading temperature display or by using thermolabel? OR Chemical sanitizing - Does manual washing procedure include a disinfection step? - Is chemical concentration monitored and recorded? Are washed equipment visually clean? 41 Equipment Storage - Is there clear segregation between clean and dirty equipment? - Are cleaned equipment stored in a way which ensures quick drying and prevents contamination?

WASTE DISPOSAL

42 Waste bins - Are waste bins well-maintained, emptied and cleaned when necessary? - Are lidded bins foot operated? 43 Waste collection station - Is the area clean and well maintained? - Is the area covered and/or enclosed to deter pest activity?

INSTRUMENT CALIBRATION

44 Are measuring equipment used to monitor CCPs and SOPs identified and calibrated minimum annually with records kept?

PRODUCT RECALL PROCEDURE

45 Is there a documented product recall procedure in place? - Procedure is tested to ensure preparedness and effectiveness.

FOOD SAFETY COMPLAINT PROCEDURE

46 Is there a documented procedure for effective receipt, recording and management of food safety related complaints? - Investigations are carried out and recorded. - Action to prevent recurrence is taken and recorded. Subscore (minus points) Total number of minus points Final Score (100 less total number of minus points) 0 0 0 100 0

3rd Version, June 2010

You might also like

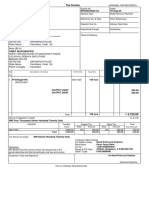

- Hi Tracy: Total Due Here's Your Bill For JanuaryDocument6 pagesHi Tracy: Total Due Here's Your Bill For JanuaryalexNo ratings yet

- 5000 GRE Word ListDocument140 pages5000 GRE Word Listsravan_kacha86% (28)

- GMP and HACCP Checklist for Food Safety AuditsDocument16 pagesGMP and HACCP Checklist for Food Safety Auditsdiansyahputra100% (5)

- Guidelines For Validation Cooking InstructionsDocument39 pagesGuidelines For Validation Cooking InstructionsktigranNo ratings yet

- H.7 Supplier Approval QuestionnaireDocument4 pagesH.7 Supplier Approval QuestionnairePrabhu Prabhu100% (1)

- Final PISA Report on Main Survey in IndiaDocument11 pagesFinal PISA Report on Main Survey in Indiagkiyer7100% (1)

- Reliance BillDocument3 pagesReliance Billgkiyer750% (2)

- Platinium Marine Products SDN BHD Hazard Analysis and Critical Control Point (Haccp) Manual Title Section: Process Flow ChartDocument7 pagesPlatinium Marine Products SDN BHD Hazard Analysis and Critical Control Point (Haccp) Manual Title Section: Process Flow ChartHas platiniumNo ratings yet

- Food Safety Sanitation and Personal Hygiene 1481758586Document75 pagesFood Safety Sanitation and Personal Hygiene 1481758586Mutiara SyafitriNo ratings yet

- Quality Assurance Requirements For Licensees-07162010Document4 pagesQuality Assurance Requirements For Licensees-07162010Norma GarciaNo ratings yet

- Induction Training - 2021Document95 pagesInduction Training - 2021Fajar PrasetyoNo ratings yet

- Basic GMP Inspection Checklist - Written Sanitation Program 2015ADocument1 pageBasic GMP Inspection Checklist - Written Sanitation Program 2015AMarkNo ratings yet

- Good Manufacturing Practices (GMP) Checklist Name of Winner's Outlet: Month: DateDocument4 pagesGood Manufacturing Practices (GMP) Checklist Name of Winner's Outlet: Month: DateYashini BhuguthNo ratings yet

- Audit Your Supplier's Facility with This ChecklistDocument1 pageAudit Your Supplier's Facility with This ChecklistJoshua Laksamana100% (1)

- Sample Food Safety Audit ChecklistDocument11 pagesSample Food Safety Audit Checklistgkiyer7No ratings yet

- Management of Renal DiseasesDocument57 pagesManagement of Renal DiseasesAyana KeikoNo ratings yet

- Op QD 015Document5 pagesOp QD 015ujangketul62100% (1)

- HACCP-Based Personal Hygiene SOPDocument2 pagesHACCP-Based Personal Hygiene SOPMung'atia AquiniusNo ratings yet

- Checklist For OHSAS Audits For A Manufacturing PlantDocument1 pageChecklist For OHSAS Audits For A Manufacturing PlantC P ChandrasekaranNo ratings yet

- 1A. Vendor Pre Qualification & Registration Form (HKG)Document3 pages1A. Vendor Pre Qualification & Registration Form (HKG)Arun Raj Arun RajNo ratings yet

- Preventive MaintenanceDocument15 pagesPreventive MaintenancePrincess LumadayNo ratings yet

- CAP PLANT VIETNAM GLASSDocument6 pagesCAP PLANT VIETNAM GLASSCuong PhanNo ratings yet

- Lab QA Plan OutlineDocument2 pagesLab QA Plan Outlineimran24No ratings yet

- SOP Overview and StandardsDocument49 pagesSOP Overview and StandardsMohamed YehiaNo ratings yet

- Quality Assurance Manager Job DescriptionDocument2 pagesQuality Assurance Manager Job DescriptionDaniel Ratna RajuNo ratings yet

- Food Safety Culture in Nigeria - Pathway To Behavioural FSMS Development in Nigerian Food IndustryDocument6 pagesFood Safety Culture in Nigeria - Pathway To Behavioural FSMS Development in Nigerian Food IndustryAdeniji Adeola StephenNo ratings yet

- Nt-Fm-Sop02 Sop For CanteenDocument4 pagesNt-Fm-Sop02 Sop For CanteenSuraj RawatNo ratings yet

- Sanitation Standard Operating Procedure PDF FreeDocument5 pagesSanitation Standard Operating Procedure PDF FreeMahmoud KhatabNo ratings yet

- Team Leader (Food and Safety) Job Description 201210117Document3 pagesTeam Leader (Food and Safety) Job Description 201210117stevierayoNo ratings yet

- sSOP Pre-ProductionDocument4 pagessSOP Pre-ProductionAlfred RangelNo ratings yet

- Personal Hygiene, Food Safety and SanitationDocument14 pagesPersonal Hygiene, Food Safety and SanitationCess Dae Lim100% (1)

- SOP - Vendor Induction & Approval Procedure 062Document1 pageSOP - Vendor Induction & Approval Procedure 062ASIMNo ratings yet

- PersonalHygieneDocument3 pagesPersonalHygieneAliova MonaNo ratings yet

- Project: NO. Module (S) Aps Task Description CURRENT (As of Nov-18) 1 System MaintenanceDocument18 pagesProject: NO. Module (S) Aps Task Description CURRENT (As of Nov-18) 1 System MaintenanceElvera GeorgeNo ratings yet

- SOP For Raw Material Release PG PDFDocument2 pagesSOP For Raw Material Release PG PDFMosub Al.DirdiryNo ratings yet

- Standard Operating Procedure Index - Food Hygiene & SafetyDocument1 pageStandard Operating Procedure Index - Food Hygiene & SafetyBAlaNo ratings yet

- Food Quality Control & Study of Critical Control Points Ensuring Food SafetyDocument135 pagesFood Quality Control & Study of Critical Control Points Ensuring Food Safetymnegm2890No ratings yet

- Weekly Food Safety AuditDocument4 pagesWeekly Food Safety AuditNina YoungNo ratings yet

- Quality Assurance Supplier Survey Audit FormDocument4 pagesQuality Assurance Supplier Survey Audit FormstevierayoNo ratings yet

- SOP Facility and Equipment HygieneDocument6 pagesSOP Facility and Equipment HygieneHenry Taguma100% (1)

- Q R ManualDocument118 pagesQ R Manualangela1590No ratings yet

- Standard Operation Procedure Production ProcessDocument2 pagesStandard Operation Procedure Production ProcessHarits As SiddiqNo ratings yet

- New Haccp Manual DD 02 Feb 17 (1) BijaliDocument89 pagesNew Haccp Manual DD 02 Feb 17 (1) BijaliRavinder Singh RajanNo ratings yet

- Food SafetyDocument18 pagesFood SafetyPraveen Sehgal100% (1)

- 08 HFSC Personal Hygiene Checklist 2019 PDFDocument1 page08 HFSC Personal Hygiene Checklist 2019 PDFRobin100% (1)

- Master List of Forms FormatsDocument1 pageMaster List of Forms Formatschahi100% (1)

- Procedure For Emergency PreparenessDocument4 pagesProcedure For Emergency PreparenessNaizil KareemNo ratings yet

- GMP Checklist For PremisesDocument2 pagesGMP Checklist For PremisesEtta JeneeNo ratings yet

- Food Product Flow: Objective: in This Chapter The Student Will Able ToDocument15 pagesFood Product Flow: Objective: in This Chapter The Student Will Able ToRosiee Salazar TejadaNo ratings yet

- Internal QA & QC Audit ManualDocument15 pagesInternal QA & QC Audit ManualALIY100% (1)

- Intertek Cristal Security-Check Datasheet CMYK PDFDocument1 pageIntertek Cristal Security-Check Datasheet CMYK PDFNasir LuqmanNo ratings yet

- HACCP Plan PDFDocument13 pagesHACCP Plan PDFAnonymous qfCJwxib7No ratings yet

- SOP Regular MaintenanceDocument2 pagesSOP Regular MaintenancePeter Tran MinhNo ratings yet

- Garyville AWS Case Study - PDFDocument3 pagesGaryville AWS Case Study - PDFDias M.NNo ratings yet

- CCP 3B Tempering Room Log ChartDocument2 pagesCCP 3B Tempering Room Log CharttarunNo ratings yet

- PREREQUISITE PROGRAMDocument29 pagesPREREQUISITE PROGRAMsridharanNo ratings yet

- PAS 220 2008 ChecklistDocument18 pagesPAS 220 2008 ChecklistMau TauNo ratings yet

- Best Practices For Foodservice Operations: (Revised 4/19/2005)Document9 pagesBest Practices For Foodservice Operations: (Revised 4/19/2005)Nadzirah MaripatNo ratings yet

- Purpose: Top ManagementDocument4 pagesPurpose: Top Managementdaizhussain004No ratings yet

- SPC Microtech Lab Waste Disposal GuideDocument3 pagesSPC Microtech Lab Waste Disposal GuideBernardoNo ratings yet

- JP (K1022) Document Status - Latest Only: in Reference Reply RefereceDocument7 pagesJP (K1022) Document Status - Latest Only: in Reference Reply Referecemarzouk64No ratings yet

- Audit Checklist TemplateDocument16 pagesAudit Checklist TemplateManasa Ravi100% (3)

- GDD&WD Ceha FindingsDocument3 pagesGDD&WD Ceha Findingscrni rokoNo ratings yet

- HACCP ManualDocument24 pagesHACCP ManualSanchit kanwar100% (1)

- Food Hygiene CodeDocument28 pagesFood Hygiene Codesherio9No ratings yet

- A-Based SOPsDocument36 pagesA-Based SOPsAhmed DuraibiNo ratings yet

- PRIDI Urgency and PossibilityDocument84 pagesPRIDI Urgency and Possibilitygkiyer7No ratings yet

- Measuring What MattersDocument42 pagesMeasuring What Mattersgkiyer7No ratings yet

- Measuring and Forecasting Progress Towards The Education-Related SDG TargetsDocument13 pagesMeasuring and Forecasting Progress Towards The Education-Related SDG Targetsgkiyer7No ratings yet

- Sustainability 03 00097 PDFDocument58 pagesSustainability 03 00097 PDFgkiyer7No ratings yet

- Invest in ECD - James HeckmanDocument2 pagesInvest in ECD - James Heckmangkiyer7No ratings yet

- Emergence of Path-Breaking and Smart Health Technologies in Paediatric FieldDocument9 pagesEmergence of Path-Breaking and Smart Health Technologies in Paediatric Fieldgkiyer7No ratings yet

- How Do Educational Systems ImproveDocument8 pagesHow Do Educational Systems Improvegkiyer7No ratings yet

- Learning Assesment System in Latin AmericaDocument32 pagesLearning Assesment System in Latin Americagkiyer7No ratings yet

- BDP Training Manual Final 2011Document117 pagesBDP Training Manual Final 2011Anonymous BtmbEkwtENo ratings yet

- Rte - Edu8211Document27 pagesRte - Edu8211gkiyer7No ratings yet

- Educational Research: Some Basic Concepts and TerminologyDocument57 pagesEducational Research: Some Basic Concepts and TerminologySetyo Nugroho100% (11)

- Dvsa1202 OdsDocument225 pagesDvsa1202 Odsgkiyer7No ratings yet

- Public Private Partnership PaperDocument5 pagesPublic Private Partnership Papergkiyer7No ratings yet

- Right of Children To Free and Compulsory Education Act 2009 (English) (Copiable - Searchable)Document13 pagesRight of Children To Free and Compulsory Education Act 2009 (English) (Copiable - Searchable)gkiyer7No ratings yet

- Ducational Echnology: Osition AperDocument47 pagesDucational Echnology: Osition AperSandeep ChaudharyNo ratings yet

- AEP - Teachers WorkbookDocument211 pagesAEP - Teachers Workbooksudharamalingam100% (1)

- Ducational Echnology: Osition AperDocument47 pagesDucational Echnology: Osition AperSandeep ChaudharyNo ratings yet

- Evaluating Whole School Reform EffortsDocument132 pagesEvaluating Whole School Reform Effortsgkiyer7No ratings yet

- Blindfold Rope Square Team Building Exercise at Timber TrailDocument3 pagesBlindfold Rope Square Team Building Exercise at Timber Trailgkiyer7No ratings yet

- 14independence Day SpeechDocument12 pages14independence Day Speechgkiyer7No ratings yet

- Corporate Social Responsibility and Financial PerformanceDocument6 pagesCorporate Social Responsibility and Financial Performancegkiyer7No ratings yet

- (WWW - Entrance-Exam - Net) - UGC-NET (General Paper, Teaching and Research Aptitude) Sample Paper 1Document24 pages(WWW - Entrance-Exam - Net) - UGC-NET (General Paper, Teaching and Research Aptitude) Sample Paper 1gkiyer7No ratings yet

- Education Vouchers For IndiaDocument22 pagesEducation Vouchers For Indiagkiyer7No ratings yet

- PersonalDevelopment Q1 Module 2Document7 pagesPersonalDevelopment Q1 Module 2Stephanie DilloNo ratings yet

- History of LotteryDocument29 pagesHistory of LotteryBala G100% (2)

- Questions DR JekyllDocument4 pagesQuestions DR JekyllMaRieNo ratings yet

- Relation of Sociology with other social sciencesDocument4 pagesRelation of Sociology with other social sciencesBheeya BhatiNo ratings yet

- Orbit BioscientificDocument2 pagesOrbit BioscientificSales Nandi PrintsNo ratings yet

- Food Processing & ClassificationDocument3 pagesFood Processing & ClassificationAzrielle JaydeNo ratings yet

- Managment Information Question BankDocument302 pagesManagment Information Question BankLuca Papasizza100% (2)

- 14 XS DLX 15 - 11039691Document22 pages14 XS DLX 15 - 11039691Ramdek Ramdek100% (1)

- W220 Engine Block, Oil Sump and Cylinder Liner DetailsDocument21 pagesW220 Engine Block, Oil Sump and Cylinder Liner DetailssezarNo ratings yet

- Lecture1 SEODocument24 pagesLecture1 SEOUsman AnwarNo ratings yet

- KG Technologies Inc Metric: K119X-DX024P-1AT-90A-C399Document2 pagesKG Technologies Inc Metric: K119X-DX024P-1AT-90A-C399Bhushan PAwarNo ratings yet

- TIA Portal v11 - HMI ConnectionDocument4 pagesTIA Portal v11 - HMI ConnectionasdasdasdasdasdasdasadaNo ratings yet

- GVP College of Engineering (A) 2015Document3 pagesGVP College of Engineering (A) 2015Abhishek SunilNo ratings yet

- Times Leader 04-10-2013Document37 pagesTimes Leader 04-10-2013The Times LeaderNo ratings yet

- Unit-2 Fourier Series & Integral: 2130002 - Advanced Engineering MathematicsDocument143 pagesUnit-2 Fourier Series & Integral: 2130002 - Advanced Engineering MathematicsDarji DhrutiNo ratings yet

- Hbet1103 Introduction To General LinguisticsDocument11 pagesHbet1103 Introduction To General LinguisticsNasidah NasahaNo ratings yet

- Jamaica's Unemployment Aims, Causes and SolutionsDocument23 pagesJamaica's Unemployment Aims, Causes and Solutionsnetzii300067% (3)

- It - Unit 14 - Assignment 2 1Document8 pagesIt - Unit 14 - Assignment 2 1api-669143014No ratings yet

- HDFC Bank's Organizational Profile and BackgroundDocument72 pagesHDFC Bank's Organizational Profile and Backgroundrohitkh28No ratings yet

- Mar 2021Document2 pagesMar 2021TanNo ratings yet

- Module 1: Overview of Implementation of The NSTP (Activities)Document3 pagesModule 1: Overview of Implementation of The NSTP (Activities)RonnelNo ratings yet

- Resume John BunkerDocument8 pagesResume John BunkerJohn BunkerNo ratings yet

- 8086 ProgramsDocument61 pages8086 ProgramsBmanNo ratings yet

- Fundamentals of Accounting - I FinallDocument124 pagesFundamentals of Accounting - I Finallyitbarek MNo ratings yet

- GUCR Elections Information 2017-2018Document10 pagesGUCR Elections Information 2017-2018Alexandra WilliamsNo ratings yet

- GRADE 8 English Lesson on Indian LiteratureDocument3 pagesGRADE 8 English Lesson on Indian LiteratureErold TarvinaNo ratings yet

- Day 3Document18 pagesDay 3SamNo ratings yet

- The Power of Compounding: Why It's the 8th Wonder of the WorldDocument5 pagesThe Power of Compounding: Why It's the 8th Wonder of the WorldWaleed TariqNo ratings yet