Professional Documents

Culture Documents

Flowcoat HS

Uploaded by

fhsn84Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Flowcoat HS

Uploaded by

fhsn84Copyright:

Available Formats

Flowcoat HS

Description

Flowcoat HS is a durable, high performance epoxy resin coating system with a good level of chemical resistance.

Typical Uses

Flowcoat HS may be used as a hard wearing coloured floor coating in areas such as factories, warehouses, plant and storerooms where chemical resistance is required.

Benefits

- Good chemical resistant - Hard wearing - Abrasion resistant - Aesthetically attractive brightens up dull factories and warehouses - Seamless and hygienic finish - Low maintenance

Project References

Standard Colour Chart

HK Trade Development Council, KLIA, Snow Jelly Factory, New Strait Time Newspaper Factory, Erisson Mobile Comm S/B, Glaxo Pharmaceutical, China.

Typical System Design (Smooth Finish)

Magnolia Buff

Flowcoat HS (2 Coats)

Ocean Blue

Clipper Blue

Prepared Substrate

Forest Green

Pastel Green

Dark Grey

Tile Red

Goosewing Grey

Mid Grey

The applied colours may differ slightly from the examples shown above. Contact our customer services for a true colour sample or a sample or a special colour match.

www.flowcrete.com

Model Specification

Product: Flowcoat HS Finish: Gloss Thickness: 0.2 0.25 mm Colour: _______ Preparatory work and application in accordance with manufacturers instructions. Manufacturer: Flowcrete Asia Sdn Bhd Telephone: Customer Service - +603 6277 9575 The installation should be carried out by a Flowcrete approved applicator.

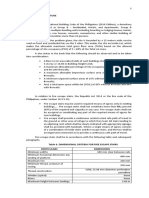

Technical Information

The figures that follow are typical properties achieved in laboratory tests at 20 oC and at 50% Relative Humidity.

Fire Resistance Slip Resistance Thermal Resistance Water Permeability Surface Hardness Chemical Resistance Abrasion Resistance BS476:Part 7: Surface spread of flame: Class 1 TRRL Pendulum Slip Test Dry 80 Wet - depends on specification Tolerant up to 60 oC Nil Karsten test (impermeable) 180 secs. Koenig Hardness Test Go to www.flowcrete.com Taber Abrader: 5 mg loss per 1000 cycles (1 kg load using CS17 wheels) BS8204:Part 2 Grade AR2 > 80 N/mm2 (BS6319) > 60 N/mm2 (BS6319) > 15 N/mm2 (BS6319) Greater than cohesive strength of 25 N/mm2 concrete. >1.5 MPa.

Substrate Requirements

Concrete or screed substrate should be a minimum of 25N/ mm2, free from laitance, dust and other contamination. The substrate should be dry to 75% RH as per BS8204 and free from rising damp and ground water pressure.

Compressive Strength Flexural Strength Tensile Strength Bond Strength

Products Included in this System

Flowcoat HS For actual coverage rates, refer to the appropriate project specification.

Detailed application instructions are available upon request.

Speed of Cure

10 oC Light traffic Full traffic Full chemical cure 48 hrs 72 hrs 12 days 20 oC 16 hrs 48 hrs 7 days 30 oC 12 hrs 40 hrs 7 days

Installation Service

The installation should be carried out by a Flowcrete approved applicator. Obtain details of our approved contractors by contacting our customer service team.

Focus on the Floorzone

Aftercare - Cleaning and Maintenance

Flowcrete Asia Sdn Bhd is a division of the Flowcrete Group, world leaders in specialist industrial and commercial flooring. Systems available include: underfloor heating systems, floor screeds, surface damp proof membranes, decorative floor finishes, seamless terrazzo, car park deck waterproofing, tank lining systems. Our objective is to satisfy your Floorzone needs.

Clean regularly using a single or double headed rotary scrubber drier in conjunction with a mildly alkaline detergent. Visit our website for more information www.flowcrete.com.

Further Information

To ensure you are specifying a fit for purpose flooring for your project please consult our Technical Advisors on the number below or visit our website to register your interest in specifying one of the most durable floors on the market.

Important Note

Flowcretes products are guaranteed against defective materials and manufacture and are sold subject to its standard Terms and Conditions of Sale, copies of which can be obtained on request.

Flowcrete Asia Sdn Bhd (366254-X) The Flooring Technology Centre Lot 37631 & 37632, Jalan 6/37A, Taman Bukit Maluri, Industrial Area Kepong, 52100 Kuala Lumpur, Malaysia. Tel: +(603) 6277 9575 Fax: +(603) 6277 4645 Email: malaysia@flowcrete.com Flowcrete Asia Sdn Bhd is an RPM company

Flowcrete Thailand 252/119, Unit B12, 24th Floor, Maung Thai-Phatra Complex, Tower II, Rachadaphisek Rd, Bangkok,10320 Tel: + 662 693 0775 Fax: + 662 694 3295 E-mail: thailand@flowcrete.com

Flowcrete Vietnam Representative Office Suite 68A, Level 6, 6 Phung Khac Khoan St., Dist.1,HCMC, Vietnam Tel: + 84 8 823 4602 Fax: + 84 8 827 4842 E-mail: ngoc@flowcrete.com

Flowcrete (Hong Kong) Ltd Unit 1004, 10/F., COL Tower, World Trade Square, 123 Hoi Bun Road, Kwun Tong, Kowloon, Hong Kong. Tel: + 852 2795 0478 Fax: + 852 2795 4842 E-mail: hongkong@flowcrete.com

www.flowcrete.com

2008-06-01 ASIA

You might also like

- 12V140 Seris Engine Shop ManualDocument471 pages12V140 Seris Engine Shop ManualRaed Mahyoub100% (4)

- DOPE Personality TestDocument8 pagesDOPE Personality TestMohammed Hisham100% (1)

- Prod NormsDocument48 pagesProd NormsJamsheer A Abdu100% (1)

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Escalation Clause Necessary Dealing With Price Fluctuations in Dredging Contracts Terra Et Aqua 125 1Document7 pagesEscalation Clause Necessary Dealing With Price Fluctuations in Dredging Contracts Terra Et Aqua 125 1fhsn84No ratings yet

- Rajiv Dua Bsc. (Eng), PMP: Managing Cost Overruns and Project ManagementDocument193 pagesRajiv Dua Bsc. (Eng), PMP: Managing Cost Overruns and Project Managementfhsn84No ratings yet

- Industrial Piping (Process Plant) Productivity StandardsDocument30 pagesIndustrial Piping (Process Plant) Productivity Standardsburerey100% (4)

- Carboguard 890 PDSDocument2 pagesCarboguard 890 PDSLinnie McleodNo ratings yet

- A Research Paper On DormitoriesDocument5 pagesA Research Paper On DormitoriesNicholas Ivy EscaloNo ratings yet

- Awb 4914934813Document1 pageAwb 4914934813Juandondr100% (1)

- Early Childhood EducationDocument76 pagesEarly Childhood Educationfhsn84No ratings yet

- Fidic UpdateDocument3 pagesFidic Updatefhsn84No ratings yet

- Method Statement For Coating of TanksDocument18 pagesMethod Statement For Coating of Tanksmkcsekar79% (14)

- Advanced Coating Solutions For The OilDocument4 pagesAdvanced Coating Solutions For The OilManivannanMudhaliarNo ratings yet

- Flowshield SL: Standard Colour ChartDocument2 pagesFlowshield SL: Standard Colour ChartManjunath HrmNo ratings yet

- TDS - Flowflake KristalinaDocument2 pagesTDS - Flowflake KristalinaCông NguyễnNo ratings yet

- Deckshield by FlowcreteDocument3 pagesDeckshield by FlowcreteJay GalvanNo ratings yet

- Deckshield IDDocument2 pagesDeckshield IDMinhHyNo ratings yet

- Flowfresh MFDocument2 pagesFlowfresh MFfhsn84No ratings yet

- M - TDS - Flowcoat PU 140314Document2 pagesM - TDS - Flowcoat PU 140314AjjuParmarNo ratings yet

- Aliphatic Acrylic Polyurethane Finish CoatDocument4 pagesAliphatic Acrylic Polyurethane Finish CoatDexter R. RoqueNo ratings yet

- RAK Poxy 200HB MIO TiecoatDocument3 pagesRAK Poxy 200HB MIO Tiecoatqc_531040655No ratings yet

- Isocrete 4000Document2 pagesIsocrete 4000Krish DoodnauthNo ratings yet

- Source Approval Kataline Part 2Document13 pagesSource Approval Kataline Part 2Arun KumarNo ratings yet

- Epirez 733 Ultra High Build Epoxy CoatingDocument3 pagesEpirez 733 Ultra High Build Epoxy CoatingRai Hasnain Ahmad DahaNo ratings yet

- Epirez 733Document3 pagesEpirez 733Andy AcousticNo ratings yet

- X-Tech DeckCoat CP (Anti Skid Coat) PDFDocument2 pagesX-Tech DeckCoat CP (Anti Skid Coat) PDFAhmed TahaNo ratings yet

- Bitumastic 300MDocument2 pagesBitumastic 300Mtharman749781No ratings yet

- Sikafloor261sys1 PdsDocument4 pagesSikafloor261sys1 PdsTPNo ratings yet

- Intergard 251 Tech Data SheetDocument0 pagesIntergard 251 Tech Data SheetL Mahender ReddyNo ratings yet

- Epiz 3Document3 pagesEpiz 3Bobbie RuckNo ratings yet

- Devran 224HS Epoxy 4392 P Eng Usa LTRDocument4 pagesDevran 224HS Epoxy 4392 P Eng Usa LTRAlex Torres CamizanNo ratings yet

- Product Description: Epoxy Coating System, 100% SolidsDocument4 pagesProduct Description: Epoxy Coating System, 100% SolidsKatherine GonzalesNo ratings yet

- Pds Psx700 Jan 2008Document3 pagesPds Psx700 Jan 2008mjayhawk28No ratings yet

- Liquid ThermoDocument2 pagesLiquid Thermomanox007No ratings yet

- X-Tech CrystalClear 3Document2 pagesX-Tech CrystalClear 3EGO AnimationNo ratings yet

- PlastisealDocument4 pagesPlastisealVenkata RaoNo ratings yet

- Carbo Guard 893 SGDocument2 pagesCarbo Guard 893 SGsuzilamatsallehNo ratings yet

- Rex ThaneDocument4 pagesRex Thanesas999333No ratings yet

- Chockfast Red SG TDSDocument2 pagesChockfast Red SG TDSYhony CoriNo ratings yet

- Sikagrout 215 (New)Document3 pagesSikagrout 215 (New)ArbiNo ratings yet

- Devran 224HS PdsDocument2 pagesDevran 224HS Pdsjopedro96No ratings yet

- Carbomastic 15 PDSDocument2 pagesCarbomastic 15 PDSAnonymous 4fVUDODNo ratings yet

- Sikafloor - 91: Heavy Duty Epoxy Resin Floor ScreedDocument2 pagesSikafloor - 91: Heavy Duty Epoxy Resin Floor Screedthe pilotNo ratings yet

- Kata Logs P Nauti KaDocument73 pagesKata Logs P Nauti KaSlobodan MaricicNo ratings yet

- Acrolon 218 HSDocument4 pagesAcrolon 218 HSAndres MoralesNo ratings yet

- Renderoc LaxtraDocument2 pagesRenderoc LaxtraAlexi ALfred H. TagoNo ratings yet

- Complete Poly-Crete SLB ShopFlr AT Submittal Package PDFDocument45 pagesComplete Poly-Crete SLB ShopFlr AT Submittal Package PDFDilson CoêlhoNo ratings yet

- Nterior PaintingDocument23 pagesNterior PaintingJaysonT.BautistaNo ratings yet

- E - 9039 - Sika - Per - 3326 EG-HDocument4 pagesE - 9039 - Sika - Per - 3326 EG-HBogdan DavidescuNo ratings yet

- Magnaglide D68, D150, D220 & D320Document2 pagesMagnaglide D68, D150, D220 & D320Anibal RiosNo ratings yet

- Cmci Cmci: High Performance Epoxy Grout SystemDocument2 pagesCmci Cmci: High Performance Epoxy Grout Systempravi3434No ratings yet

- Anti Condensation CatalogueDocument8 pagesAnti Condensation CatalogueBoBo KyawNo ratings yet

- PrePrufe Grout EG 75Document2 pagesPrePrufe Grout EG 75tharazainNo ratings yet

- X-Tech UraFloor CSDocument2 pagesX-Tech UraFloor CSLONG LASTNo ratings yet

- SikaGrout 212 Product Data B25956Document2 pagesSikaGrout 212 Product Data B25956Guillermo Garcia50% (2)

- CEILCOTE 163 CorocreteDocument2 pagesCEILCOTE 163 CorocreteGabor VictorNo ratings yet

- ResiGard SL2Document4 pagesResiGard SL2fhsn84No ratings yet

- Sikafloor - 262 AS: 2-Part Epoxy Electrostatically Conductive Self-Smoothing SystemDocument6 pagesSikafloor - 262 AS: 2-Part Epoxy Electrostatically Conductive Self-Smoothing Systemthe pilotNo ratings yet

- MasterEmaco ADH 326 (Concresive Liq)Document4 pagesMasterEmaco ADH 326 (Concresive Liq)RodCorniNo ratings yet

- Fairtop Fast Floor - Cementitious Self Levelling Flooring SystemsDocument8 pagesFairtop Fast Floor - Cementitious Self Levelling Flooring SystemsfairmatechemicalNo ratings yet

- Chemco Marine BrochureDocument10 pagesChemco Marine BrochureLawrence de RijkNo ratings yet

- Sikadur - 42 HS: High Strength Pourable Epoxy GroutDocument4 pagesSikadur - 42 HS: High Strength Pourable Epoxy GroutMuhammad Azlan AhmadNo ratings yet

- Fast Clad Urethane Spec SheetDocument4 pagesFast Clad Urethane Spec SheetScott Van PeltNo ratings yet

- Graphit 33Document2 pagesGraphit 33Manuel Armindo RibeiroNo ratings yet

- Oasis QD Special PrimerDocument2 pagesOasis QD Special PrimerMaurice DavisNo ratings yet

- Carboguard 89dfsfs0 PDSDocument2 pagesCarboguard 89dfsfs0 PDSMayur PatelNo ratings yet

- X-Roc Epoxybond: Technical Data SheetDocument2 pagesX-Roc Epoxybond: Technical Data SheetJanaka Dinesh100% (1)

- Cloverdale EcosheetDocument2 pagesCloverdale EcosheetJennyNo ratings yet

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Hand Book - QSDocument11 pagesHand Book - QSfhsn84No ratings yet

- Early Childhood EducationDocument75 pagesEarly Childhood Educationfhsn84No ratings yet

- Hand Book - CTRMDocument11 pagesHand Book - CTRMfhsn84No ratings yet

- How To Use If Function in Excel - Examples For Text, Numbers, Dates, Blank CellsDocument87 pagesHow To Use If Function in Excel - Examples For Text, Numbers, Dates, Blank Cellsfhsn84No ratings yet

- Thesis Assignment TopicsDocument11 pagesThesis Assignment Topicsfhsn84No ratings yet

- List of Dissertation Topics and Possible Supervisors in Education SciencesDocument3 pagesList of Dissertation Topics and Possible Supervisors in Education Sciencesfhsn84No ratings yet

- Slqs Journal Slqs Journal Slqs JournalDocument7 pagesSlqs Journal Slqs Journal Slqs Journalfhsn84No ratings yet

- Preliminary Study On Causative Factors Leading To Construction Cost OverrunDocument15 pagesPreliminary Study On Causative Factors Leading To Construction Cost Overrunfhsn84No ratings yet

- Diss 2Document192 pagesDiss 2fhsn84No ratings yet

- Building Information Modeling and Quantity Surveying PracticeDocument11 pagesBuilding Information Modeling and Quantity Surveying PracticeSamir PatilNo ratings yet

- Surveying The Field: Changes in Quantity Surveying: Smashwords Edition, License NotesDocument27 pagesSurveying The Field: Changes in Quantity Surveying: Smashwords Edition, License Notesfhsn84No ratings yet

- 33.2 Alternative Dispute Resolution 0Document7 pages33.2 Alternative Dispute Resolution 0fhsn84No ratings yet

- Adr Public Eval ReportDocument8 pagesAdr Public Eval Reportfhsn84No ratings yet

- A Revisit On The Current Practice of Dispute Resolution and ADR in The Malaysian Construction IndustryDocument13 pagesA Revisit On The Current Practice of Dispute Resolution and ADR in The Malaysian Construction Industryfhsn84No ratings yet

- PO & HRM Model Question Paper - 2Document2 pagesPO & HRM Model Question Paper - 2fhsn84No ratings yet

- 2013 BM Future QsDocument12 pages2013 BM Future Qsfhsn84100% (1)

- A DR Methods and TechniquesDocument4 pagesA DR Methods and Techniquesfhsn84No ratings yet

- Assignment FormatDocument3 pagesAssignment Formatfhsn84No ratings yet

- Discussion 2: OOA: Case Study Robot in MazeDocument17 pagesDiscussion 2: OOA: Case Study Robot in MazeArmmetNo ratings yet

- Week 14 Report2Document27 pagesWeek 14 Report2Melaku DesalegneNo ratings yet

- Analysis and Design of Cantilever Slab Analysis and Design of Cantilever SlabDocument3 pagesAnalysis and Design of Cantilever Slab Analysis and Design of Cantilever SlabMesfinNo ratings yet

- Adsa Ka SyllabusDocument3 pagesAdsa Ka SyllabusHacker RanjanNo ratings yet

- How To Get Jobs in Neom Saudi Arabia 1703510678Document6 pagesHow To Get Jobs in Neom Saudi Arabia 1703510678Ajith PayyanurNo ratings yet

- Makenna Resort: by Drucker ArchitectsDocument12 pagesMakenna Resort: by Drucker ArchitectsArvinth muthuNo ratings yet

- Business Design Thinking - Nguyễn Quang MinhDocument39 pagesBusiness Design Thinking - Nguyễn Quang MinhbuikimhoangoanhtqkNo ratings yet

- 2022 05 141RBSF351652506386Document6 pages2022 05 141RBSF351652506386tathagat jhaNo ratings yet

- The Roosh ProgramDocument2 pagesThe Roosh ProgramVal KerryNo ratings yet

- Interplater 85/125P HDX: Setting New Processing Standards For High-End UsersDocument2 pagesInterplater 85/125P HDX: Setting New Processing Standards For High-End Usershackko24No ratings yet

- Chuck Eesley - Recommended ReadingDocument7 pagesChuck Eesley - Recommended ReadinghaanimasoodNo ratings yet

- Unit 3 Approaches To The Study of Medieval Urbanisation : StructureDocument20 pagesUnit 3 Approaches To The Study of Medieval Urbanisation : StructureSunil SunilNo ratings yet

- Experiential MarketingDocument23 pagesExperiential Marketingambesh Srivastava100% (5)

- Understanding ISO 9001 Calibration RequirementsDocument6 pagesUnderstanding ISO 9001 Calibration RequirementsAldrin HernandezNo ratings yet

- April 7-9 2022-WPS OfficeDocument3 pagesApril 7-9 2022-WPS OfficeAllen AntolinNo ratings yet

- Rail Inspection Vehicle Using Ir Sensor and Spot Marking SystemDocument63 pagesRail Inspection Vehicle Using Ir Sensor and Spot Marking SystemNarayananNanuNo ratings yet

- Project TitleDocument2 pagesProject TitleVISHAL S. VNo ratings yet

- Conventional and Box-Shaped Piled RaftsDocument6 pagesConventional and Box-Shaped Piled RaftsAdrian VechiuNo ratings yet

- AutoCAD 2006 Installing Network License Manager0Document12 pagesAutoCAD 2006 Installing Network License Manager0gurugovindanNo ratings yet

- Example of Presentation Planning Document 1uf6cq0Document2 pagesExample of Presentation Planning Document 1uf6cq0Wilson MorenoNo ratings yet

- PDF - Gate Valve OS and YDocument10 pagesPDF - Gate Valve OS and YLENINROMEROH4168No ratings yet

- Detail Project Report: (Heidelberg Cement Group)Document42 pagesDetail Project Report: (Heidelberg Cement Group)saravananNo ratings yet

- Mahmoud Darwish TMADocument15 pagesMahmoud Darwish TMABassant Ayman Ahmed Abdil Alim100% (1)

- FMDS0102Document69 pagesFMDS0102hhNo ratings yet

- Science 8: Learning Activity SheetDocument9 pagesScience 8: Learning Activity SheetVan Amiel CovitaNo ratings yet

- Pricing and Marketing Strategy: Rahul Mishra, Narendra Singh, Dinesh KumarDocument12 pagesPricing and Marketing Strategy: Rahul Mishra, Narendra Singh, Dinesh KumarGaurav ChauhanNo ratings yet