Professional Documents

Culture Documents

Cartridge Filter O&M Manual - Hitachi

Uploaded by

papum2013Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cartridge Filter O&M Manual - Hitachi

Uploaded by

papum2013Copyright:

Available Formats

HARMSCO

Poly Coat Filter Housings

Multi-Round Cartridge Housings

HBC

Universal Design

Harmsco HBC filter housings are designed with a universal bottom plate to accept 2-1/2 or 2-3/4 diameter cartridges with DOE (double open end), 222/Flat and 222/Fin end cap configurations.

22R

Features

304 stainless steel construction, standard 304 stainless steel cap/spring assemblies, standard 150 PSI (10.3 bar) pressure rating Universal bottom seal cups to accept DOE, 222/Flat or 222/Fin style cartridges Exterior poly coat finish, standard Heavy duty legs included on all models Bottom drain provided Vented lid Two gauge ports - inlet and outlet side Options: 316 stainless steel construction Alternative O-ring material

7R 12R 4R/5R

Applications

Commercial Drinking Water Cooling Tower Filtration Industrial Waste Water Treatment Reverse Osmosis Pre-filtration Ground Water Remediation Process Water Utility Water Well Water

HARMSCO Filtration Products

Harmsco Poly Coat Filter Housings

End Caps

HBC

Harmsco HBC Cartridge Housings come standard with alternative compression/hold down plates that allow for the use of DOE, 222/Flat or 222/Fin end caps.

22R

12R 7R Drawings available upon request.

4R/5R

DOE

222

Fin

Ordering Information

Uses 2-1/2 or 2-3/4 O.D. Cartridges

Filter Model Recd Flow Rate* (GPM) Max Flow Rate* (GPM) Max Flow Rate* (LPM) Max Flow Rate* (M3/Hr) Inlet/Outlet Connection No. of Cartridges Cartridge Service Height Housing Service Ht. (in.) Housing Wt. (lbs.)

HBC 4-1 4R HBC 4-2 HBC 4-3 HBC 4-4 HBC 5-1 5R HBC 5-2 HBC 5-3 HBC 5-4 HBC 7-1 7R HBC 7-2 HBC 7-3 HBC 7-4 12R 22R HBC 12-3 HBC 12-4 HBC 22-3 HBC 22-4

20 40 58-60 80 25 50 75 100 35 70 105 138 178-180 235 325 435

28 56 84 112 35 70 105 140 49 98 147 196 252 336 462 616

106 212 318 424 132 265 397 530 185 371 556 742 954 1,272 1,749 2,332

6 13 19 25 8 16 24 32 11 22 33 45 57 76 105 140

2 MNPT 2 MNPT 2 MNPT 2 MNPT 2 MNPT 2 MNPT 2 MNPT 2 MNPT 2 MNPT 2 MNPT 2 MNPT 2 MNPT 3 Flange 3 Flange 4 Flange 4 Flange

4 4 4 4 5 5 5 5 7 7 7 7 12 12 22 22

9-3/4 or 10 19-1/2 or 20 29-1/4 or 30 40 9-3/4 or 10 19-1/2 or 20 29-1/4 or 30 40 9-3/4 or 10 19-1/2 or 20 29-1/4 or 30 40 29-1/4 or 30 40 29-1/4 or 30 40

34 54 74 94 34 54 74 94 35 55 75 95 81 101 75 95

37 41 49 60 37 41 49 60 49 54 68 73 128 139 206 223

*Flow rates shown above are for guidelines only. Actual flow rates are based on cartridge type, micron rating, viscosity, solids content and various other factors. For complete flow and pressure drop information please refer to your cartridge manufacturer guidelines. Note: add suffix -6 for 316 option. Example: HBC 4-1-6 (4 round, 9-3/4 or 10 cartridge, 316 stainless steel).

Specifications

Finish - Poly Coat standard (exterior only) Inlet/Outlet - 2 MNPT, 3 flange, 4 flange Construction - 304 stainless steel standard, 316 optional Closure - Band clamp closure, O-ring, Buna-N Pressure - up to 150 PSI (10.3 bar) max Temperature - up to 250F (121C); filter housing only

Note: This publication is to be used as a guide. The data within has been obtained from many sources and is considered to be accurate. Harmsco does not assume liability for the accuracy and/or completeness of this data. Changes to the data can be made without notification. Temperature, Pressure, Flow Rates, Differential Pressures, Chemical Combinations and other unknown factors can affect performance in unknown ways. Limited Warranty: Harmsco warrants their products to be free of material and workmanship defects. Determination of suitability of Harmsco products for uses and applications contemplated by Buyer shall be the sole responsibility of Buyer. The end user/installer/buyer shall be liable for the products performance and suitability regarding their specific intended applications. End users should perform their own tests to determine suitability for each application.

HARMSCO Filtration Products

www.harmsco.com

Harmsco, Inc. 12E 08 7/11

P.O. Box 14066, North Palm Beach, FL 33408 (561) 848-9628 Toll-free: (800) 327-3248 Fax: (561) 845-2474 E-mail: sales@harmsco.com

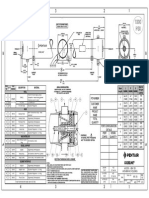

THE INFORMATION CONTAINED IN THIS DRAWING IS THE SOLE PROPERTY OF HARMSCO INC. ANY REPRODUCTION IN PART OR WHOLE WITHOUT EXPRESSED WRITTEN CONSENT IS PROHIBITED.

PROPRIETARY / CONFIDENTIAL

E FILE:

HBC 12

DRAWING SIZE: B

REV.

REVISIONS DESCRIPTION

DATE

APPROVED

16.70.25 8.35.13 .55, QTY 3 AS SHOWN LOCATED ON 16.8 B.C. 16.8 REF 1/4" FNPT 14.34 REF 5.94 REF 45 12" 5.94 REF 1/2" FNPT QTY 2 "X" INLET 3" FLANGE OUTLET 3" FLANGE 11.88 REF INLET 3" FLANGE OUTLET 3" FLANGE

90

MAX. CART. SERVICE STOCK "X" MATERIAL SHP. BOX SIZE CODE LENGTH HEIGHT * 51" 30" 20" x 19" x 56" HBC12-3 81" 304SS HBC12-4 61" 40" 101" 20" x 19" x 64" 51" 30" 20" x 19" x 56" HBC12-3-6 81" 316SS HBC12-4-6 61" 40" 101" 20" x 19" x 64" * - SERVICE HEIGHT BASED ON MAXIMUM CARTRIDGE LENGTH. PORTS ARE NPT ANSI B1.20.1 UNLESS NOTED OTHERWISE. FINISH - POLY COAT, EXTERIOR ONLY O-RING MATERIAL: BUNA-N ALL STOCK CODES RATED FOR 150 PSI @ 250F MAX WORKING PRESSURE. WEIGHT 128 lb 139 lb 128 lb 139 lb CUSTOMER INITIALS

1 15 8 " 3 94"

3 38" 3 94" 3 34"

CUSTOMER APPROVAL

1/2" FNPT

COMPANY: NAME (printed): SIGNATURE: DATE: APPROVALS DRAWN APPROVED

DATE

RS 7-14-11

HARMSCO INC.

P.O. BOX 14066

SCALE

UNLESS OTHERWISE SPECIFIED DIMENSIONS ARE IN INCHES TOLERANCES ARE: FRACTIONS DECIMALS ANGLES +/- 1/8 +/- 30' +/- .060

N. PALM BEACH, FL

"1:8"

DRAWN ON CAD DO NOT SCALE

12 ROUND MULTI-CARTRIDGE POLY COAT HOUSING

PART NO.

HBC12 _

HBC Cartridge Filter Vessel Installation & Service Instructions

1. 2. 3. 4. 5. 6. 7. Place vessel on a flat surface and secure using mounting legs. Prior to install, note port labels to confirm proper flow direction (inlet/outlet). Connect piping to inlet/outlet ports. Loosen T-nut and remove band-clamp. Open lid. Inspect lid o-ring to confirm that it is free of defects and/or debris. Loosen & remove hand-nut(s) from threaded rods and remove holddown/compression plate(s). 8. Install filter cartridges. If using DOE cartridges, place cap/spring assembly on top of each cartridge. 9. Install hold-down/compression plate. 10. Tighten hand-nut(s) to compress springs/secure cartridges. 11. Close lid & reinstall band-clamp. 12. Tighten T-nut and confirm that band-clamp is evenly engaged around the vessel lid (a gap of ~1/2 should remain between each of the clamp segments). 13. Close outlet valve. 14. Slowly open inlet valve to allow liquid to fill vessel. 15. Open vent valve at top of vessel- leave open until steady stream of liquid is present. 16. Close vent valve. 17. Slowly open outlet valve. 18. Open inlet valve completely. 19. Inspect lid and all port connections for leaks.

Close inlet valve. Open vent valve. Open drain valves. Loosen T-nut and remove band-clamp. Open lid. Loosen & remove hand-nut(s) from threaded rods and remove holddown/compression plate(s). 7. Remove spent filter cartridges. 8. Inspect lid o-ring to confirm that it is free of defects and/or debris. Replace if necessary. 9. Repeat steps #8-19.

1. 2. 3. 4. 5. 6.

Removal of Spent Cartridges

Warning/Safety

If improperly used, pressure vessels may cause serious injury or death. Always wear proper protective clothing for the liquid being filtered. Check your MSDS sheets for instructions or suggestions. Do not operate the vessel in excess of the rated pressure and/or temperature found on the vessel label. Confirm chemical compatibility of selected o-ring and vessel material prior to vessel installation. 1

HARMSCO

Band Clamp Bag Housings

Designed with Snap Fit V Ring Bag

BCB Series Bag Housings are designed for a variety of industrial filtration applications where clean effluent is critical. Offered in Extended Area bag sizes to increase contaminant removal and provide longer bag life.

BCB

Commercial Grade

Features

304 stainless steel construction, standard Electropolished finish, standard 150 psi (10.3 bar) pressure rating Flow rates up to 200 gpm All filter housings hydrostatically tested Band clamp closure to simplify maintenance Internal parts are 304 stainless steel Drill in-place legs Patented Extended Area replacement bags available (approx. 30% more surface area vs. Std. bags) 1.5 FNPT or 2 FNPT connections available 316 stainless steel perforated basket, standard Options: 316 stainless steel Chemical resistant coating

BCB-1

BCB-2

Applications

Paint Process Water Plating Solutions Coatings Industrial Waste Water Treatment Lubricants Solvents Hydraulic Fluids Cutting Fluids Ground Water Remediation

HARMSCO Filtration Products

Made in USA

Harmsco Band Clamp Bag Housings

#1

Standard #1 Bag Housing

Standard Extended #1 #1 Basket Basket Option Option

BCB

Bag Options

#2

Standard #2 Bag Housing

Standard #2 Basket Option Extended #2 Basket Option

A B C C B D A

Standard #1 Standard #2 (shown) Extended #1 Extended #2

BCB-1

Chemical Resistant Coating

BCB-2 Harmsco Band Clamp Bag Housings are available with a 3M fusion bonded epoxy coating for chemical resistance. The coating is NSF Standard 61 Certified. It is applied to all stainless steel surfaces (inside and out), and is far more resistant than 316L stainless steel. Fusion bonded epoxy coating is ideal for sea water applications and when resistance to agressive chemicals is required.

Ordering Information

Standard #1 and #2 Bag Housings

Filter Model Max Flow Rate*(GPM) Max Flow Rate*(LPM) Max Flow Rate*(M3/Hr) Height

Chemical Resistant Coating Available

Diameter

Height

Height

I/O FNPT

Standard Bag Size

BCB-1-1.5-STD BCB-1-2-STD BCB-2-1.5-STD BCB-2-2-STD

90 90 200 200

341 341 757 757

20.4 20.4 45.4 45.4

28-1/4 28-1/4 42-3/4 42-3/4

8 8 8 8

22-3/4 22-3/4 37-1/4 37-1/4

4-1/2 4-1/2 4-1/2 4-1/2

1.5 2 1.5 2

1 Std 1 Std 2 Std 2 Std

Extended #1 and #2 Bag Housings

Filter Model Max Flow Rate*(GPM) Max Flow Rate*(LPM) Max Flow Rate*(M3/Hr) Height

Diameter

Height

Height

I/O FNPT

Extended Bag Size

BCB-1-1.5-EXT BCB-1-2-EXT BCB-2-1.5-EXT BCB-2-2-EXT

90 90 200 200

341 341 757 757

20.4 20.4 45.4 45.4

28-1/4 28-1/4 42-3/4 42-3/4

8 8 8 8

22-3/4 22-3/4 37-1/4 37-1/4

4-1/2 4-1/2 4-1/2 4-1/2

1.5 2 1.5 2

1 Ext 1 Ext 2 Ext 2 Ext

*Flow rates shown above are for guidelines only. Actual flow rates are based on bag type, micron rating, viscosity, solids content and various other factors. For complete flow and pressure drop information please refer to your bag manufacturer guidelines.

Specifications

Finish - Electropolished Inlet/Outlet - 1.5 FNPT or 2 FNPT Construction - 304 stainless steel, standard; 316 stainless steel and/or chemical resistant coating, optional Pressure - Up to 150 psi (10.3 bar) Temperature - up to 250F(121C), housing only Closure - O-ring Housing Seal - Buna-N

Note: This publication is to be used as a guide. The data within has been obtained from many sources and is considered to be accurate. Harmsco does not assume liability for the accuracy and/or completeness of this data. Changes to the data can be made without notification. Temperature, Pressure, Flow Rates, Differential Pressures, Chemical Combinations and other unknown factors can affect performance in unknown ways. Limited Warranty: Harmsco warrants their products to be free of material and workmanship defects. Determination of suitability of Harmsco products for uses and applications contemplated by Buyer shall be the sole responsibility of Buyer. The end user/installer/buyer shall be liable for the products performance and suitability regarding their specific intended applications. End users should perform their own tests to determine suitability for each application.

HARMSCO Filtration Products

www.harmsco.com

Made in USA

P.O. Box 14066, North Palm Beach, FL 33408 (561) 848-9628 Toll-free: (800) 327-3248 Fax: (561) 845-2474 E-mail: sales@harmsco.com

Harmsco, Inc. 16B 10 7/11

BCB Bag Filter Vessel Installation & Service Instructions

1. Place vessel on a flat surface and secure using mounting legs. 2. Prior to install, note port labels to confirm proper flow direction (inlet/outlet). 3. Connect piping to inlet/outlet ports. Recommended that isolation valves be installed in inlet, and outlet ports or piping. A drain port can be created by fitting a pipe tee with a drain valve in the outlet piping between the vessel and outlet isolation valve (valves & fittings provided by others). 4. Loosen T-nut and remove band-clamp and open lid. 5. Remove NPT plug from lid vent port and install venting valve or petcock (valve provided by others). 6. Inspect lid o-ring to confirm that it is free of defects and/or debris. 7. Remove bag basket. Inspect inside of vessel for any shipping or construction debris and remove as needed. 8. Reinstall bag basket and install filter bag (sold separately). Flange of filter bag must be set into the filter bag receiver ring for proper seal. 9. Close lid & reinstall band-clamp. 10. Tighten T-nut of band-clamp and confirm that band-clamp is evenly engaged around the vessel lid (a gap of ~1/2 should remain between each of the clamp segments). 11. Close outlet valve, if open and drain valve, if installed. 12. Slowly open inlet valve to allow liquid to fill vessel. 13. Open vent valve at top of vessel, leave open until steady stream of liquid is present. 14. Close vent valve. 15. Slowly open outlet valve. 16. Open inlet valve completely. 17. Inspect lid and all port connections for leaks. 1. Close inlet and outlet valve. 2. Slowly open drain valve, if installed, if not use vent valve to release any pressure inside vessel. Use caution while slowly opening valves. 3. Open vent valve and allow vessel to drain. 4. Loosen band-clamp T-nut, remove band-clamp and open lid. 5. Remove spent filter bag. 6. If drain valve is installed flush any debris inside of vessel to drain as needed. 7. Install new filter bag. Flange of filter bag must be set into the filter bag receiver ring for proper seal. 8. Inspect lid o-ring to confirm that it is free of defects and/or debris. Replace if necessary. 9. Repeat steps #9-17.

Removal of Spent Filter Bag

Warning/Safety

If improperly used, pressure vessels may cause serious injury or death. Always wear proper protective clothing for the liquid being filtered. Check your MSDS sheets for instructions or suggestions. Do not operate the vessel in excess of the rated pressure and/or temperature found on the vessel label. Confirm chemical compatibility of selected o-ring, filter bag, and vessel material prior to vessel installation. 1

APPENDIX H: PRESSURE VESSEL S SP ECIFICATIONS AND OPERATI ON INSTRUCTIONS

41

Wave Cyber (Shanghai) Co., Ltd.

8 End Port Membrane Housing Users Guide

If you want to get more information of Wave Cyber Products, please visit our website http://www.wave-cyber.com

Page 1

You might also like

- Filtration Liquid Solutions: Product CatalogDocument28 pagesFiltration Liquid Solutions: Product Catalogwpt_meNo ratings yet

- Xiga Uf Membrane Module ConfigurationsDocument7 pagesXiga Uf Membrane Module ConfigurationsprakashNo ratings yet

- Pumpapi675presentation 150805065440 Lva1 App6891 PDFDocument42 pagesPumpapi675presentation 150805065440 Lva1 App6891 PDFsanthoshkumarplNo ratings yet

- Microbiocide Cooling Systems ProductDocument2 pagesMicrobiocide Cooling Systems ProductJunaid Jamil100% (1)

- OPTIMIZING LOW-TEMPERATURE ORCSDocument14 pagesOPTIMIZING LOW-TEMPERATURE ORCSmonsterh5No ratings yet

- Catálogo de Flujometros Industriales Spirax SarcoDocument152 pagesCatálogo de Flujometros Industriales Spirax SarcosaconaconacaNo ratings yet

- Grundfosliterature 1563Document60 pagesGrundfosliterature 1563Montoya SantiagoNo ratings yet

- TrueUnion - True Union Ball ValveDocument4 pagesTrueUnion - True Union Ball ValveKarthick VenkateshNo ratings yet

- 10418AE0026-30 - Rev - 0 Rev CCDocument43 pages10418AE0026-30 - Rev - 0 Rev CCcecilNo ratings yet

- ONIK ENTERPRISES Offers 1000LPH RO PlantDocument11 pagesONIK ENTERPRISES Offers 1000LPH RO PlantALPHA AND OMEGA SYSTEMSNo ratings yet

- Detail A: Shuqaiq 3 Independent Water ProjectDocument1 pageDetail A: Shuqaiq 3 Independent Water ProjectABAID ULLAHNo ratings yet

- Damper TorqueDocument3 pagesDamper TorqueNguyễn LinhNo ratings yet

- DeepFlex BrochureDocument4 pagesDeepFlex Brochureribeiro30No ratings yet

- Impact Sprinkler Troubleshooting GuideDocument11 pagesImpact Sprinkler Troubleshooting GuidemuthuvelaaNo ratings yet

- HPX Oh2 Api610 New enDocument8 pagesHPX Oh2 Api610 New enAlexander RivillasNo ratings yet

- Spec - Chiller Lắp Đặt ChillerDocument42 pagesSpec - Chiller Lắp Đặt ChillerBay MưaNo ratings yet

- Booster PumpDocument28 pagesBooster PumpCollin PhelpsNo ratings yet

- Air Valve Basic TrainingDocument49 pagesAir Valve Basic TrainingGyogi MitsutaNo ratings yet

- Engineering Tips-Cooling TowerDocument6 pagesEngineering Tips-Cooling TowerSharon LambertNo ratings yet

- Types of Fire PumpsDocument3 pagesTypes of Fire PumpsEhab KamalNo ratings yet

- Best Potable Water Pressure Tank SeriesDocument6 pagesBest Potable Water Pressure Tank SeriesGhislaine SousaNo ratings yet

- Air Calculations and Conversions Guide for Particulate, SO2, and NO2 EmissionsDocument4 pagesAir Calculations and Conversions Guide for Particulate, SO2, and NO2 EmissionsveschaferNo ratings yet

- Reynolds ExperimentDocument4 pagesReynolds Experimentmukesh3021100% (1)

- Choosing the Right Vane Pump for Your ProcessDocument25 pagesChoosing the Right Vane Pump for Your ProcessGirlish JackieNo ratings yet

- 05 - Sulzer - Separator InternalsDocument53 pages05 - Sulzer - Separator InternalsVicente RegulezNo ratings yet

- Compressor Inlet Piping - Compressed Air Best PracticesDocument10 pagesCompressor Inlet Piping - Compressed Air Best PracticesBehroozRaadNo ratings yet

- 3620 10th Lores 2Document8 pages3620 10th Lores 2Dinh Quang NhamNo ratings yet

- SWCC PDFDocument43 pagesSWCC PDFSturovo TurboNo ratings yet

- Grundfos Design HVACDocument68 pagesGrundfos Design HVACmishraenggNo ratings yet

- AODD Pumps in Chemical ProcessesDocument7 pagesAODD Pumps in Chemical ProcessesAlexNo ratings yet

- Standard Parts of Pipe SupportsDocument5 pagesStandard Parts of Pipe SupportsMohit BauskarNo ratings yet

- X GX BlackmerDocument2 pagesX GX BlackmerrasottoNo ratings yet

- Steam TurbineDocument16 pagesSteam TurbineMedo GemyNo ratings yet

- DeepFlex Overview March-2014Document32 pagesDeepFlex Overview March-2014bzkxt100% (1)

- Technical OfferDocument59 pagesTechnical OfferAli YassineNo ratings yet

- TSSA Safety Info Bulletin SB12-01 - Venting-DischargeDocument3 pagesTSSA Safety Info Bulletin SB12-01 - Venting-DischargemurigurNo ratings yet

- HDPE Pipe Catalogue PDFDocument12 pagesHDPE Pipe Catalogue PDFRadicalNo ratings yet

- Booster Pump-TechPart - 2of2 BDocument71 pagesBooster Pump-TechPart - 2of2 BKatie RamirezNo ratings yet

- Office Equipment List (SAMPLE)Document2 pagesOffice Equipment List (SAMPLE)Trisha TimpogNo ratings yet

- Section 10 Specs For Cooling TowerDocument13 pagesSection 10 Specs For Cooling Towermjmehta81No ratings yet

- Forbes Marshall Consultancy specifications for compressed air accessoriesDocument2 pagesForbes Marshall Consultancy specifications for compressed air accessoriessppatilNo ratings yet

- Osmosis InversaDocument40 pagesOsmosis Inversashapira22No ratings yet

- NGL PumpsDocument4 pagesNGL Pumpsamol patkiNo ratings yet

- Electrode BoilerDocument7 pagesElectrode BoilerBrijendra MathurNo ratings yet

- Vacuum PumpDocument50 pagesVacuum PumpsuryakanthareddyNo ratings yet

- Centrifugal Pump Troubleshooting ChecklistDocument8 pagesCentrifugal Pump Troubleshooting Checklistab_s5036No ratings yet

- Cleaning Balls PDFDocument8 pagesCleaning Balls PDFAlexandruNicolaNo ratings yet

- Outside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesDocument42 pagesOutside Screw and Yoke (OS&Y) Gate Valve - Flanged: Technical FeaturesayaNo ratings yet

- Indupump Process Pump Brochure SmallDocument16 pagesIndupump Process Pump Brochure SmalljasonventNo ratings yet

- Premium Pumping Technology For Desalination: PumpsDocument16 pagesPremium Pumping Technology For Desalination: PumpsShark1971No ratings yet

- Filtration SystemDocument11 pagesFiltration Systemwaleed.murad@gmail.comNo ratings yet

- Proposal-Surge AnalysisDocument3 pagesProposal-Surge AnalysisSaad Raza KhanNo ratings yet

- Chlorsys: Electro-Chlorination PackageDocument8 pagesChlorsys: Electro-Chlorination Packagegkdora574No ratings yet

- Woods Silencer Catalogue and Technical DataDocument12 pagesWoods Silencer Catalogue and Technical DataJagatjeet MaanNo ratings yet

- Materials of Construction ConstructionDocument6 pagesMaterials of Construction ConstructionIlkuNo ratings yet

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Document3 pagesDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)RamanNegiNo ratings yet

- Double FerruleDocument51 pagesDouble FerrulecristianmihaiNo ratings yet

- (2012) Complete IELTS Bands 5-6.5 Student's BookDocument3 pages(2012) Complete IELTS Bands 5-6.5 Student's BookAhmed Hamdy0% (1)

- Drawing 80H30Document3 pagesDrawing 80H30kpranjal15No ratings yet

- 01 Rubber HoseDocument26 pages01 Rubber Hosewenny_tpdNo ratings yet

- 45INDPRDocument104 pages45INDPRpapum2013No ratings yet

- 2.5 Screen MAIN O&MDocument27 pages2.5 Screen MAIN O&Mpapum20130% (1)

- 1615nDocument44 pages1615npapum2013No ratings yet

- User Guide 80S H EnglishDocument48 pagesUser Guide 80S H Englishpapum2013No ratings yet

- SD 160-350 Service ManualDocument54 pagesSD 160-350 Service Manualpapum2013No ratings yet

- Action PlanDocument5 pagesAction Planpapum2013No ratings yet

- User Guide 80S H EnglishDocument48 pagesUser Guide 80S H Englishpapum2013No ratings yet

- Standard Safety Training MatrixDocument1 pageStandard Safety Training Matrixpapum2013No ratings yet

- Api 510Document2 pagesApi 510papum2013No ratings yet

- Welding Procedure PreparationDocument122 pagesWelding Procedure Preparationthe_badass1234100% (21)

- IGC3 - HEALTH AND SAFETY OBSERVATIONSDocument3 pagesIGC3 - HEALTH AND SAFETY OBSERVATIONSpapum201371% (7)

- PHSD ElectricalAppEngDocument12 pagesPHSD ElectricalAppEngpapum2013No ratings yet

- Complementary Commutation by AshakoorDocument16 pagesComplementary Commutation by AshakoorSobi100% (2)

- MHS-15 Prod NoteDocument2 pagesMHS-15 Prod Noteyenlitu50% (2)

- ME 188 - Combined Brayton & Rankine CyclesDocument44 pagesME 188 - Combined Brayton & Rankine CyclesAzherRoiFerrer100% (1)

- Industrial Visit Report LatestDocument11 pagesIndustrial Visit Report Latesthanif100% (2)

- Coconut Cocos Nucifera As An Alternative To Paraffin FloorwaxDocument7 pagesCoconut Cocos Nucifera As An Alternative To Paraffin FloorwaxMiguel Piquero67% (9)

- Material Properties of EPDM, NBR, and FPM Rubber Seals - Technical - Resources - BLUCHERDocument3 pagesMaterial Properties of EPDM, NBR, and FPM Rubber Seals - Technical - Resources - BLUCHERManish Pareek100% (1)

- Phase Inversion of W/O Emulsions by Adding Hydrophilic Surfactant - A Technique For Making Cosmetics ProductsDocument8 pagesPhase Inversion of W/O Emulsions by Adding Hydrophilic Surfactant - A Technique For Making Cosmetics ProductsAsshole FuckerNo ratings yet

- Electricity PowerPoint-0Document34 pagesElectricity PowerPoint-0Ryan P. YapNo ratings yet

- Heinrich2001 EconomicGeologyOfTheSandAndSandstoneResourcesOfMichigan PDFDocument31 pagesHeinrich2001 EconomicGeologyOfTheSandAndSandstoneResourcesOfMichigan PDFkarma2011No ratings yet

- A-3 LM Sol (Pulley)Document28 pagesA-3 LM Sol (Pulley)rockingjoeNo ratings yet

- O Level Physics 2023-2025 ATP TipsDocument7 pagesO Level Physics 2023-2025 ATP TipsAmy WolmesNo ratings yet

- How Microprocessors Are Manufactured PDFDocument2 pagesHow Microprocessors Are Manufactured PDFdanielconstantin4No ratings yet

- Aerospace Standard: (R) Fittings, Straight Threaded Boss or Flanged, Fluid ConnectionDocument16 pagesAerospace Standard: (R) Fittings, Straight Threaded Boss or Flanged, Fluid ConnectionAlberto De La CruzNo ratings yet

- Luminell Datasheet English Version2.0Document4 pagesLuminell Datasheet English Version2.0marius_brkt6284No ratings yet

- API 2H Grade 50 Steel Plate SpecificationDocument3 pagesAPI 2H Grade 50 Steel Plate SpecificationJym GensonNo ratings yet

- Especificacion Tecnica Tanques FRP CANATUREDocument3 pagesEspecificacion Tecnica Tanques FRP CANATURETomasae1980No ratings yet

- AMIE Project Synopsis ReportDocument10 pagesAMIE Project Synopsis ReportpavanNo ratings yet

- Biological Indicators TOC PDFDocument20 pagesBiological Indicators TOC PDFnsk79in0% (1)

- Device Fabrication Technology: Modern Semiconductor Devices For Integrated Circuits (C. Hu) Slide 3-1Document40 pagesDevice Fabrication Technology: Modern Semiconductor Devices For Integrated Circuits (C. Hu) Slide 3-1EASACOLLEGENo ratings yet

- Chemistry 9 Chap 1 Long QADocument17 pagesChemistry 9 Chap 1 Long QAAkbar Ali AhmedNo ratings yet

- Prehensive Viva Test (Responses)Document80 pagesPrehensive Viva Test (Responses)Srikanth TanguduNo ratings yet

- Ammonia: Latent Heat of OFDocument34 pagesAmmonia: Latent Heat of OFCastoriadisNo ratings yet

- Water Flooding: Buckely-Leverett TheoryDocument23 pagesWater Flooding: Buckely-Leverett Theoryبشير الزامليNo ratings yet

- D Block ElementDocument48 pagesD Block ElementPrabhakar BandaruNo ratings yet

- Production Technology Course OutDocument5 pagesProduction Technology Course Outmurjass85No ratings yet

- 13NO03 GN 60 001 Deliverable ListDocument4 pages13NO03 GN 60 001 Deliverable Listbagus handokoNo ratings yet

- HVAC Validation TestsDocument4 pagesHVAC Validation TestsemonwreNo ratings yet

- K3 Skema Cemerlang Set 1Document4 pagesK3 Skema Cemerlang Set 1annurshah05No ratings yet

- Transformed: Moving to the Product Operating ModelFrom EverandTransformed: Moving to the Product Operating ModelRating: 4 out of 5 stars4/5 (1)

- Design for How People Think: Using Brain Science to Build Better ProductsFrom EverandDesign for How People Think: Using Brain Science to Build Better ProductsRating: 4 out of 5 stars4/5 (8)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsFrom EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsNo ratings yet

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableFrom EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableNo ratings yet

- 507 Mechanical Movements: Mechanisms and DevicesFrom Everand507 Mechanical Movements: Mechanisms and DevicesRating: 4 out of 5 stars4/5 (28)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureFrom EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureRating: 4.5 out of 5 stars4.5/5 (2)

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryFrom EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryRating: 4 out of 5 stars4/5 (5)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsFrom EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsNo ratings yet

- The User's Journey: Storymapping Products That People LoveFrom EverandThe User's Journey: Storymapping Products That People LoveRating: 3.5 out of 5 stars3.5/5 (8)

- Electrical Principles and Technology for EngineeringFrom EverandElectrical Principles and Technology for EngineeringRating: 4 out of 5 stars4/5 (4)

- Operational Amplifier Circuits: Analysis and DesignFrom EverandOperational Amplifier Circuits: Analysis and DesignRating: 4.5 out of 5 stars4.5/5 (2)

- Design Is The Problem: The Future of Design Must Be SustainableFrom EverandDesign Is The Problem: The Future of Design Must Be SustainableRating: 1.5 out of 5 stars1.5/5 (2)

- The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorFrom EverandThe Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorRating: 4 out of 5 stars4/5 (7)

- Iconic Advantage: Don’t Chase the New, Innovate the OldFrom EverandIconic Advantage: Don’t Chase the New, Innovate the OldRating: 4 out of 5 stars4/5 (1)

- Top-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsFrom EverandTop-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsNo ratings yet

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceFrom EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceRating: 4 out of 5 stars4/5 (19)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationFrom EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationRating: 4.5 out of 5 stars4.5/5 (2)