Professional Documents

Culture Documents

Die Adjuster For Manual Oil Expelling: (A Technical Paper)

Uploaded by

plcuserOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Die Adjuster For Manual Oil Expelling: (A Technical Paper)

Uploaded by

plcuserCopyright:

Available Formats

DIE ADJUSTER FOR MANUAL OIL EXPELLING

( A Technical Paper)

ABSTRACT

Francisco C. Dime

6/27/2012

The present utility model generally relates to the manual method and process of extracting oil from vegetables and seeds specifically to the mechanism employed to improve oil extraction by screw pressing.

DIE ADJUSTER FOR MANUAL OIL EXPELLING

Makers: Francisco C. Dime and Remartin S. Maglantay The difficulty of controlling the cake which is a byproduct in expelling oil from fed is a major concern among oil expeller machines. Such control manifested in the cake thickness dictates the amount of oil recovery. This paper outlines the description, operation and claims on the Collar Assisted Choke Mechanism for Manual Oil Expelling. INTRODUCTION

The existing method and machine to manually extract oil from vegetable and seed are done primarily by screw pressing. A process by which the source of oil is fed and conveyed into a screw shaft while it is being turned manually by a lever acting as a fulcrum for multiplying power input. The choke is simply a cylinder with hole in the center where the pressed cake exits. For oil expeller with prime mover, engine or motor, the choke is provided with adjuster using a spanner. This pushes the choke to the required distance. OBJECTIVES The primary intent of the collar assisted choke mechanism for manual oil expelling is to ease the control of choke for optimum oil recovery while at the same time eliminates the necessity of using a hand tool to do it. The improvement of productivity is also a particular concern of this utility model.

Finally, the proposed utility model will improve the cost effectiveness of the manual oil expelling machine to which it forms a part.

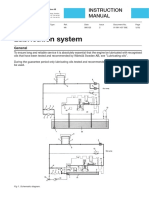

DESCRIPTION AND OPERATION Figure 1, marked as 10, shows the assembly drawing of the utility model which is numbered from 1 to 4. Item 1, labeled as choke (1) is a cylinder is held by the shaft (4) and connected to collar (3) which is threaded, by the U-joint (2). These three items (1, 2 and 3) comprises the choke mechanism which is under consideration of this patent application while item 4 is common for all manual oil expeller.

Figure 1. The Collar Assisted Choke Mechanism for Manual Oil Expelling

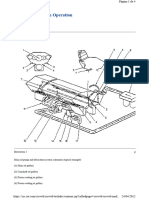

The operation is better understood with the entire manual oil expeller to which the proposed utility model forms part. Figure 2. shows the manual oil expeller in its entirety. The process starts with the fed (9) which passed the hopper (1) and moved forward by the screw (2) towards the end of the cylinder (3).

Figure 2. The manual screw oil expeller with the collar assisted choke mechanism components marked as 5,6 and 7. Once the cylinder (3) is filled up, the fed (9) will build up and the density will increase by further turning of the screw (2) through the handle (4) whose length multiply the power input by the lever principle until the oil (10) starts to trickle through the holes near the end of the cylinder (3) while at the same time thin layer of cake(8) or the solid part comes out at the choke (5) which is adjusted if the cake is loose by the collar (6) and effected by the u-joint (7) since the last three items are connected. As the cake (8) gets thinner by the continuous adjustment of the collar (7), more oil (10) is extracted and

the trickle turns into flow. The process above is repeated into cycle until all the fed is processed. CONCLUSION The Collar Assisted Choke Mechanism for Manual Oil Expelling is a very simple and practical addition for the oil expeller machine not only in the manually operated but also the mechanical or motorized model. It allows finer adjustment even if the machine is operating by merely turning the collar which is light and easy to grip. The collar assisted choke mechanism for manual oil expelling comprises of choke (1), u-joint (2) and collar (3) for optimum oil recovery from fed. The mechanism controls the distance and thickness of cake coming out of the manual oil expeller that increases oil extracted from vegetables and seeds like peanut.

You might also like

- Manual Sport Jet 90-120hp Oil Injection SystemDocument5 pagesManual Sport Jet 90-120hp Oil Injection SystemGerardo Espinola CardozoNo ratings yet

- Lubrication System: Systems OperationDocument4 pagesLubrication System: Systems OperationHasby Potter100% (1)

- Transmision D6D PDFDocument72 pagesTransmision D6D PDFJose Luis Garcia Blanco100% (3)

- C13 Oil SystemDocument6 pagesC13 Oil Systemjeddo2005100% (1)

- Brakesaver: Systems OperationDocument17 pagesBrakesaver: Systems OperationRichard ChuaNo ratings yet

- Thornycroft Marine Engine PDFDocument42 pagesThornycroft Marine Engine PDFAnonymous 3xJyAmcNo ratings yet

- Neuman Interschalt PDFDocument51 pagesNeuman Interschalt PDFCostelNo ratings yet

- Integrating With HCM PDFDocument520 pagesIntegrating With HCM PDFVicky D. PutraNo ratings yet

- STA 2200 Probability and Statistics IIDocument4 pagesSTA 2200 Probability and Statistics IImichaelNo ratings yet

- Collar Assisted Choke Mechanism For Manual Oil Expelling: (A Technical Paper)Document5 pagesCollar Assisted Choke Mechanism For Manual Oil Expelling: (A Technical Paper)plcuserNo ratings yet

- Lubrication Systems For Industrial Gas Turbines: Yusuf AfegbuaDocument7 pagesLubrication Systems For Industrial Gas Turbines: Yusuf AfegbuaafegbuaNo ratings yet

- AMTE-126 - Midterm Assignment#1Document5 pagesAMTE-126 - Midterm Assignment#1Maybelyn ConsignadoNo ratings yet

- LUB SYSTEM F20 9199143700eDocument10 pagesLUB SYSTEM F20 9199143700eLIVIANo ratings yet

- 56 Valvula de Secuencia 3500Document4 pages56 Valvula de Secuencia 3500Franklin LezamaNo ratings yet

- Hid Fan 966fDocument5 pagesHid Fan 966fSyahdiNo ratings yet

- Hydraulic Fan SystemDocument4 pagesHydraulic Fan SystemEVER DAVID SAAVEDRA HUAYHUA100% (1)

- Oil Mist LubricationDocument15 pagesOil Mist Lubricationchetan_thakur4278No ratings yet

- 1980 Dual Jet E2 MDocument40 pages1980 Dual Jet E2 MNestor CastilloNo ratings yet

- Lubrication System: Systems OperationDocument5 pagesLubrication System: Systems OperationbejoythomasNo ratings yet

- Screw CompressorDocument4 pagesScrew Compressordarksun2011100% (2)

- 4 Lubrication SystemDocument3 pages4 Lubrication SystemKopyuk Kopyuk Kopyuk KopyukNo ratings yet

- 14H Lubrication SystemDocument6 pages14H Lubrication SystemDaniel Rhasty-ghee AhmanorNo ratings yet

- 930R e 930T Power TrainDocument34 pages930R e 930T Power TrainGilson RodriguesNo ratings yet

- SM 03 BDocument34 pagesSM 03 BMark OreschnickNo ratings yet

- Sezione 2 PDFDocument8 pagesSezione 2 PDFMAZZI1978100% (1)

- 912 Oil ChangeDocument4 pages912 Oil ChangeGaberNo ratings yet

- Yamaha DS7 (72) RD250 (73) R5C (72) RD350Document113 pagesYamaha DS7 (72) RD250 (73) R5C (72) RD350Igor Majksner100% (5)

- Manual Reparación Turbo GARRETDocument24 pagesManual Reparación Turbo GARRETFelipe Lepe MattaNo ratings yet

- Instruction ManualDocument36 pagesInstruction ManualJoséNo ratings yet

- Lubrication System OperationDocument6 pagesLubrication System OperationMartin Carhuaz AcunaNo ratings yet

- Mathematical Modeling of Marine by CitoDocument12 pagesMathematical Modeling of Marine by CitoCito JulioNo ratings yet

- Brake Control Valve (Parking) 966Document6 pagesBrake Control Valve (Parking) 966Ahmed RezkNo ratings yet

- Compressor With Seal OilDocument7 pagesCompressor With Seal OilKamel NaimiNo ratings yet

- Sistema de Operacion Transmision 980f 3Document47 pagesSistema de Operacion Transmision 980f 3DiegoMenaNo ratings yet

- Transmission 2Document23 pagesTransmission 2ait mimouneNo ratings yet

- D399 Operation SystemDocument64 pagesD399 Operation SystemNOUR ZAINNo ratings yet

- Lubrication System: Systems OperationDocument11 pagesLubrication System: Systems OperationRichard ChuaNo ratings yet

- Leroi Om Rotary Screw Manual1Document49 pagesLeroi Om Rotary Screw Manual1cesosqui0% (1)

- Oil Filter ReplacedDocument10 pagesOil Filter ReplacedEbied YoussefNo ratings yet

- Sistema de Lubricacion Emd 645Document21 pagesSistema de Lubricacion Emd 645Adriana Rojas VerasteguiNo ratings yet

- The Turbine Lubricating Oil System: ObjectivesDocument23 pagesThe Turbine Lubricating Oil System: Objectivesefmaggio100% (2)

- Systems Operation: Previous ScreenDocument18 pagesSystems Operation: Previous ScreenTóth KrisztiánNo ratings yet

- Systems Operation (Senr7046-00) d9h TransmisionDocument56 pagesSystems Operation (Senr7046-00) d9h TransmisionAlbertoNo ratings yet

- Lubrication System: Shutdown SIS Previous ScreenDocument7 pagesLubrication System: Shutdown SIS Previous ScreenHector VallesNo ratings yet

- Engine Principles: Topics Covered in ThisDocument11 pagesEngine Principles: Topics Covered in ThisBogdan PuiaNo ratings yet

- Cooling System 3306 67dDocument97 pagesCooling System 3306 67draezaputra gNo ratings yet

- 5sistema de Lubricacion G3500Document5 pages5sistema de Lubricacion G3500gabrielNo ratings yet

- 777F MG SistemasDocument118 pages777F MG SistemasDenerMendozaLayza100% (6)

- Lubrication System: Systems OperationDocument5 pagesLubrication System: Systems OperationGerardo VelazquezNo ratings yet

- Lubrication SystemDocument5 pagesLubrication SystemMinn Thet NaingNo ratings yet

- Eccentric Weight Housing Oil - Change: Operation and Maintenance ManualDocument3 pagesEccentric Weight Housing Oil - Change: Operation and Maintenance ManualLuis AugustoNo ratings yet

- Operacion Impeller ClutchDocument6 pagesOperacion Impeller ClutchticoplazaNo ratings yet

- Lubrication SystemDocument5 pagesLubrication SystemzhiNo ratings yet

- TFE 731 Chap 79Document24 pagesTFE 731 Chap 79Egor8550% (2)

- Lube Oil System.Document10 pagesLube Oil System.Muhammad luqmanNo ratings yet

- Actual Sysem Setup: 2.2 System ExplanationDocument11 pagesActual Sysem Setup: 2.2 System Explanationtomsonthomas7No ratings yet

- Vane Pump (Pilot and Braking) : Página 1 de 3 966G II Wheel Loader ANZ00001-UP (MACHINE) POWERED BY 3176C Engine..Document3 pagesVane Pump (Pilot and Braking) : Página 1 de 3 966G II Wheel Loader ANZ00001-UP (MACHINE) POWERED BY 3176C Engine..martinaguilarespinoNo ratings yet

- Tren de Fuerza HidraulicoDocument8 pagesTren de Fuerza HidraulicoRafaelNo ratings yet

- 930T de Prefixo 57Z Power TrainDocument37 pages930T de Prefixo 57Z Power TrainGilson Rodrigues100% (1)

- Self Lubricated BearingsDocument16 pagesSelf Lubricated Bearingsfedericoceriati100% (1)

- Oil SepratorsDocument4 pagesOil SepratorsMohammad Amer0% (1)

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingFrom EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingRating: 5 out of 5 stars5/5 (1)

- Silicone Mold ProcedureDocument8 pagesSilicone Mold ProcedureMaria_Basta1No ratings yet

- Lecture 5 - Climper and Clamper CircuitDocument22 pagesLecture 5 - Climper and Clamper CircuitArifah HamidunNo ratings yet

- System Ims Services MarketDocument5 pagesSystem Ims Services MarketAngelica PérezNo ratings yet

- Work Measurement 3Document16 pagesWork Measurement 3Miguel HernandezNo ratings yet

- Active Teaching and Learning Approaches Methodologies in FETResource ListDocument21 pagesActive Teaching and Learning Approaches Methodologies in FETResource ListWahyu HidayatNo ratings yet

- Chapter 7 (FIT10) PDFDocument5 pagesChapter 7 (FIT10) PDFGABBAR GAMINGNo ratings yet

- Vehicle Network Toolbox™ Release NotesDocument33 pagesVehicle Network Toolbox™ Release NotesLorenzo CarrieriNo ratings yet

- Debt J-LDocument621 pagesDebt J-LkenindiNo ratings yet

- Farwell - Shroud - Full ScoreDocument11 pagesFarwell - Shroud - Full ScoremarcmaesbpNo ratings yet

- Swagelok Tubular FittingsDocument8 pagesSwagelok Tubular FittingstotcsabNo ratings yet

- Expression Web 4 Quick Start Tutorial Beaches Part IDocument17 pagesExpression Web 4 Quick Start Tutorial Beaches Part IClaricee FajutaganaNo ratings yet

- Bomba Desplazamiento PositivoDocument14 pagesBomba Desplazamiento PositivoAlvaro Jose DíazNo ratings yet

- Updated 7 Point Container Inspection SheetDocument2 pagesUpdated 7 Point Container Inspection SheetMohd Shahrul Irwan Mohd Zin0% (1)

- Warmachine VengeanceDocument142 pagesWarmachine VengeancehniqvcaurxnwiakuowNo ratings yet

- XMLReports DownloadattachmentprocessorDocument44 pagesXMLReports DownloadattachmentprocessorjayapavanNo ratings yet

- Abbey SealDocument20 pagesAbbey SealDamonNo ratings yet

- Piaggio Fly150 Service Manual 150ccmDocument239 pagesPiaggio Fly150 Service Manual 150ccmgtperformasNo ratings yet

- Engineering Hydrology & HydraulicsDocument153 pagesEngineering Hydrology & HydraulicsMihirNo ratings yet

- f2620 - Standar Practce For Heat Fusion Joining of Polyethylene PipeDocument21 pagesf2620 - Standar Practce For Heat Fusion Joining of Polyethylene PipeDeyvi Vasquez PittmanNo ratings yet

- J1000 PQ33 Mixing-Equalizer Portico-5033 Style ManualDocument1 pageJ1000 PQ33 Mixing-Equalizer Portico-5033 Style ManualErpel GruntzNo ratings yet

- Anchor Bolts in Light-Frame Construction at Small Edge Distances PDFDocument8 pagesAnchor Bolts in Light-Frame Construction at Small Edge Distances PDFmlamourNo ratings yet

- Electric Galley Range HDocument7 pagesElectric Galley Range HCocoman Seba CuentasNo ratings yet

- Falling HazardsDocument8 pagesFalling HazardsZainorin AliNo ratings yet

- Iceservice 1 2014Document206 pagesIceservice 1 2014Ben BelleckNo ratings yet

- Specialization in TourismDocument12 pagesSpecialization in TourismItalo Arbulú Villanueva0% (1)

- Using Atrenta Spyglass in GUI ModeDocument33 pagesUsing Atrenta Spyglass in GUI Modevenu.lancer8205100% (1)

- Sidebyside Audio CD DownloadDocument4 pagesSidebyside Audio CD DownloadAngel Leuris0% (3)