Professional Documents

Culture Documents

Ode - 21a2kv25

Uploaded by

meomimi9457Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ode - 21a2kv25

Uploaded by

meomimi9457Copyright:

Available Formats

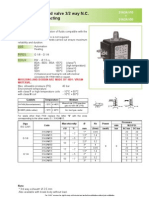

Solenoid valve 2/2 way N.C.

Direct acting

PRESENTA PRESENTATION: Direct acting S.V. for interception of fluids compatible with the construction materials. Minimum operational pressure is not required. The materials used and the tests carried out ensure maximum reliability and duration. Automation USE: Heating PIPES: COILS: G 1/8 - G 1/4 8W - 13 (1) BDA - BDS - BSA BDP BDF SDH 12W - 13 UDA 14W - 13 GDH 155C 160C 180C 180C (class F) (high temperature) (class H) (class H)

21A3KV15 21A2KV55

155C (class F) 180C (class H)

(1) Explosion-proof housing for coils with electrical

connections EN 175301-803 on request.

MOULDING AND BOBBIN ARE MADE BY 100% VIRGIN HIGHLIGHTED ITEMS ARE EX STOCK MATERIAL.

Gaskets

V=FKM (fluoroelastomer) B=NBR (nitrile rubber) E=EPDM (ethylene-propylene)

Temperature

- 10C +140C - 10C - 10C + 90C +140C

Medium

Mineral oils (2E),gasoline gas oil, fuel oils (7E) Air, inert gas, water Water, steam

Max. allowable pressure (PS) 40 bar Environment temperature: with coil class F and high temperature - 10C + 60C with coil class H - 10C + 80C

For seals other than FKM replace the letter V with the ones corresponding to the other seals. E.I. 21A2KE20. Pipe ISO 228/1 Code 21A3KV15 21A3KV20 21A3KV25 21A3KV30 21A3KV45 21A2KV15 21A2KV20 21A2K 21A2KV V 25 21a2k v25 30 G 1/4 21A2KV30 53 21A2KV45 21A2KV55 ~7 4,5 5,5 6,5 9 12 37 ~2 ~5 53 ~7 Max viscosity cSt 12 37 E ~2 ~5 mm 1,5 2 2,5 3 4,5 1,5 2 2,5 3 Kv l/min 1,4 2 3,2 4 6,5 1,4 2 3,2 4 Power (watt) 8 12 14 8 12 14 8 12 14 12 14 8 12 14 8 12 14 8 12 14 8 12 14 8 12 14 0 min bar Pressure M.O.P.D. AC bar DC bar 30 18 22 16 35 14 30 10 25 30 9 25 6 18 20 2 7 8 18 16 30 9 25 6 18 20 2 7 8 1 2,5 5

G 1/8

5

12 30 22 35 14 30 10 25 5 12 3 7 10

Note Also available with brass body without lead.

30-06-2002

The ODE reserves the right to carry out technical and aesthetic modifications without prior notification.

ODE

21A3KV15 21A2KV55

MATERIALS: MATERIALS: Body Armature tube Fixed core Plunger Phase displacement ring Spring Seal Orifice: < 3 mm Insert slot > 3 mm On request: Connector Connector conformity FEATURES: FEATURES: Electrical conformity Protection degree SPARE TS: SPARE PAR PARTS: 1. Coil: See coils list 2. Complete plunger: For orifice < 3 mm Code R450886/V For orifice > 3 mm Code R450898/V 3. Complete armature tube: Code R450606 KIT: KIT: < 3 mm KT130KV30-A=2+3 > 3 mm KT130KV55-A=2+3 Brass - UNI EN 12165 CW617N Stainless steel AISI series 300 Stainless steel AISI series 400 Stainless steel AISI series 400 Copper - Cu 99,9% Stainless steel AISI series 300 Standard: V=FKM On request: B=NBR E=EPDM Stainless steel AISI series 300 Brass - UNI EN 12165 CW617N Pg 9 or Pg 11 ISO 4400 IEC 335 IP 65 EN 60529 (DIN 40050) with coil fitted by connector.

DIMENSIONS:

COIL Type 21A3KV 21A2KV Pipe ISO 228/1 G 1/8 G 1/4 W 8W 12 W 14 W

ODE

POWER ABSORPTION Inrush VA ~ 25 35 43 Hold VA ~ 14,5 25 27

DIMENSIONS TYPE D E F mm mm mm B S U G 30 32 36 52 42 48 55 54 60 67

30-06-2002

21A3KV15 21A2KV55

You might also like

- Solenoid Valves Datasheet Series 21WA W WN PDFDocument38 pagesSolenoid Valves Datasheet Series 21WA W WN PDFdaliasssNo ratings yet

- 3100 GemsDocument6 pages3100 GemsJoão PauloNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Marine Electrical Practice: Marine Engineering SeriesFrom EverandMarine Electrical Practice: Marine Engineering SeriesRating: 4 out of 5 stars4/5 (8)

- Audio Duplication SystemDocument10 pagesAudio Duplication SystemPatrick Smith100% (2)

- Level SensorDocument8 pagesLevel SensortuyentruongNo ratings yet

- Microbiology-ELISA Testing Lab ReportDocument2 pagesMicrobiology-ELISA Testing Lab Reportsaraebo33% (3)

- Phase Diagrams & MicrostructuresDocument3 pagesPhase Diagrams & MicrostructuresAli El-Gazzar0% (1)

- 051 - PR 03 - Charge Distributions As Dirac Delta FunctionsDocument1 page051 - PR 03 - Charge Distributions As Dirac Delta FunctionsBradley NartowtNo ratings yet

- Sesame or Tahini Halva RecipeDocument2 pagesSesame or Tahini Halva RecipeOved KedemNo ratings yet

- Solenoid valve 3/2 way N.C. direct acting featuresDocument2 pagesSolenoid valve 3/2 way N.C. direct acting featuresJoseph A. LoeNo ratings yet

- 21A Solenoid Valves Series DatasheetDocument40 pages21A Solenoid Valves Series Datasheetportusan2000No ratings yet

- 032u1252 DanfossDocument8 pages032u1252 DanfossJorge Eduardo Aguirre ONo ratings yet

- Ode Solenoid Valve 21wa3z0b130 - 21wa4z0b130Document2 pagesOde Solenoid Valve 21wa3z0b130 - 21wa4z0b130Uno MariconNo ratings yet

- Asco Direct Acting Solenoid Valve - 320Document6 pagesAsco Direct Acting Solenoid Valve - 320SatyamEng100% (1)

- Amisco Pilot ValveDocument8 pagesAmisco Pilot ValveRaul CostiniucNo ratings yet

- Nor GrenDocument5 pagesNor GrenSarlo11No ratings yet

- Manual Reset Construction 1/4 To 1/2: No Voltage Release (Lever Type)Document6 pagesManual Reset Construction 1/4 To 1/2: No Voltage Release (Lever Type)dharmendrabholeNo ratings yet

- Modern Steam Valve Technical BrochureDocument7 pagesModern Steam Valve Technical BrochureDaniel GalarzaNo ratings yet

- DS6213 Standard EU enDocument5 pagesDS6213 Standard EU enwinwin2302No ratings yet

- Schrack Miniature Relay PT: General Purpose RelaysDocument4 pagesSchrack Miniature Relay PT: General Purpose RelaysMelih GuneriNo ratings yet

- p128 22 PDFDocument3 pagesp128 22 PDFFernando CeballosNo ratings yet

- Valvulas Sole No Ides IsDocument12 pagesValvulas Sole No Ides Isaaa3131No ratings yet

- 100P Series: High Pressure FiltersDocument6 pages100P Series: High Pressure FiltersPartsGopher.comNo ratings yet

- Solenoid ValveDocument2 pagesSolenoid ValveHeru PurwantoNo ratings yet

- Catalogue Pages TC15Document21 pagesCatalogue Pages TC15Truong ThuatNo ratings yet

- ASCONDocument6 pagesASCONNithyANo ratings yet

- Direct acting solenoid valve 2/2 way N.CDocument2 pagesDirect acting solenoid valve 2/2 way N.CPepe Garcia DiazNo ratings yet

- Guide to Inductive Sensors Specifications and Wiring DiagramsDocument2 pagesGuide to Inductive Sensors Specifications and Wiring DiagramsHernan SanchezNo ratings yet

- Solenoid Valves 3 - 2 General Service 327 CAT 80402GBDocument6 pagesSolenoid Valves 3 - 2 General Service 327 CAT 80402GBsaifulNo ratings yet

- Solenoide Ode - GenebreDocument10 pagesSolenoide Ode - GenebreRenzo Huarcaya HuaraccNo ratings yet

- Schneider GV2 Motor Circuit BreakerDocument19 pagesSchneider GV2 Motor Circuit BreakeruuraydinNo ratings yet

- CS310ADocument4 pagesCS310Arabacet2923No ratings yet

- 3100 Series and 3200 Heavy Duty Series: Compact OEM Pressure TransmittersDocument5 pages3100 Series and 3200 Heavy Duty Series: Compact OEM Pressure TransmittersAlejandro CagideNo ratings yet

- Aks 3000Document8 pagesAks 3000gatoluisNo ratings yet

- 21XN4K1V120Document2 pages21XN4K1V120Ramius HamdaniNo ratings yet

- TGE 5, TGE 5-Ex, TGM 5, TGM 5-Ex, TGU 5, TGU 5-Ex: Transmitter For Angular PositionDocument10 pagesTGE 5, TGE 5-Ex, TGM 5, TGM 5-Ex, TGU 5, TGU 5-Ex: Transmitter For Angular Positionvinodk335No ratings yet

- Ventile Electromagnetice Normal DeschiseDocument4 pagesVentile Electromagnetice Normal DeschiseSani PoulouNo ratings yet

- BW Series Brass Body Solenoid Pilot Diaphragm ValvesDocument10 pagesBW Series Brass Body Solenoid Pilot Diaphragm ValvesjadetorresNo ratings yet

- Data Sheet Liquidring Pump: Series L-Bv5 - Range 2BV5 110 CompressorDocument4 pagesData Sheet Liquidring Pump: Series L-Bv5 - Range 2BV5 110 Compressortutuli1990No ratings yet

- Containing 2 To 12 Valves 2/2 Normally Closed, Direct Operated 1/8Document8 pagesContaining 2 To 12 Valves 2/2 Normally Closed, Direct Operated 1/8Urip S. SetyadjiNo ratings yet

- Emp2 Box Pressure TransmitterDocument8 pagesEmp2 Box Pressure TransmitterAsif HameedNo ratings yet

- HVAC Valves and Actuators Catalogue: Issue: July 2009Document60 pagesHVAC Valves and Actuators Catalogue: Issue: July 2009isombardNo ratings yet

- N en en 5 8 120 82090Document2 pagesN en en 5 8 120 82090refaeNo ratings yet

- Potter & Brumfield Power PCB Relay RT2: General Purpose Relays PCB RelaysDocument3 pagesPotter & Brumfield Power PCB Relay RT2: General Purpose Relays PCB RelaysrrebollarNo ratings yet

- Electronic Timer CT-VBS.17+18: OFF-delayed Without Auxiliary Voltage, For DC Contactors Data SheetDocument7 pagesElectronic Timer CT-VBS.17+18: OFF-delayed Without Auxiliary Voltage, For DC Contactors Data SheetRoga29No ratings yet

- 3 SF 21Document15 pages3 SF 21vohoncoiNo ratings yet

- Schrack RM732024 DatasheetDocument4 pagesSchrack RM732024 Datasheetpaula09No ratings yet

- Astm A106 Ts EnglDocument4 pagesAstm A106 Ts EnglxaviereduardoNo ratings yet

- Solenoid Valve 2/2 Way N.O. Direct Acting - Dampness-Proof IP 67Document2 pagesSolenoid Valve 2/2 Way N.O. Direct Acting - Dampness-Proof IP 67Ramius HamdaniNo ratings yet

- A Kamlock CouplingsDocument11 pagesA Kamlock Couplingsgroup_electricNo ratings yet

- 3/2-Way Solenoid Valve, Direct-Acting, NcornoDocument7 pages3/2-Way Solenoid Valve, Direct-Acting, NcornoAmarnath YadavNo ratings yet

- General Purpose Relays Power PCB Relay RT2Document3 pagesGeneral Purpose Relays Power PCB Relay RT2Jose G. Cantillo L.No ratings yet

- Pulse Valves - Turbocontrols - It PDFDocument40 pagesPulse Valves - Turbocontrols - It PDFRicardo Ferrari TrevisanNo ratings yet

- AN17831ADocument9 pagesAN17831AJose LeonNo ratings yet

- Pressure Control BrochureDocument12 pagesPressure Control Brochurebkpaul3107No ratings yet

- Brooks Rotameter Variable AreaDocument22 pagesBrooks Rotameter Variable Areamhidayat108No ratings yet

- 6 Solenoid Valve ODEDocument2 pages6 Solenoid Valve ODEHA TRADINGSNo ratings yet

- Mbs 1900Document6 pagesMbs 1900selmeco5241No ratings yet

- L282Document2 pagesL282Dedu IonutNo ratings yet

- MDM PROPORTIONAL PRESSURE-REDUCING VALVE TECHNICAL SPECSDocument4 pagesMDM PROPORTIONAL PRESSURE-REDUCING VALVE TECHNICAL SPECSSilvio Roman100% (1)

- 8735GBDocument4 pages8735GBHebert Dacorrégio HeidenreichNo ratings yet

- 6 21a2k0e45 or 1 4Document2 pages6 21a2k0e45 or 1 4Juan PiñerosNo ratings yet

- FCE Writing Connectors Argumentative EssayDocument2 pagesFCE Writing Connectors Argumentative EssayGNo ratings yet

- McDonalds CaseDocument1 pageMcDonalds Casechaterji_aNo ratings yet

- ActinobacillosisDocument17 pagesActinobacillosisKhalid Gul100% (1)

- Gynisol SyrupDocument2 pagesGynisol Syruphk_scribdNo ratings yet

- Useful EquationsDocument3 pagesUseful EquationsAal KhalidNo ratings yet

- Business Logistics IE317 Course OverviewDocument1 pageBusiness Logistics IE317 Course OverviewJacky SuccarNo ratings yet

- Teaching about various concepts and idiomsDocument4 pagesTeaching about various concepts and idiomsMunchKing1986No ratings yet

- Changodar SIRDocument1 pageChangodar SIRniravhirparaNo ratings yet

- Fishing On The White RiverDocument1 pageFishing On The White RiverSunlight FoundationNo ratings yet

- Humastar 80Document4 pagesHumastar 80rizal_aspanNo ratings yet

- Capital Budgeting Decision Tree ApproachDocument5 pagesCapital Budgeting Decision Tree ApproachShipra JainNo ratings yet

- Basic Salary Requirments of Nepalese Workers in UAEDocument3 pagesBasic Salary Requirments of Nepalese Workers in UAEdinkarjoshi100% (4)

- Match verbs and nouns of cooking stepsDocument4 pagesMatch verbs and nouns of cooking stepsFredy Jesus Choque HinojoNo ratings yet

- Sim Quick Results KeyDocument2 pagesSim Quick Results KeyBalavignesh VenugopalNo ratings yet

- Thread Rolling Machine GuideDocument2 pagesThread Rolling Machine GuideBaldev SinghNo ratings yet

- HMDocument2 pagesHMgangrukaNo ratings yet

- Fral FD750 and FD980 Spec SheetDocument1 pageFral FD750 and FD980 Spec SheetmoisturecarevidsNo ratings yet

- Ficha Ingles 6º AnoDocument3 pagesFicha Ingles 6º AnoMário FernandesNo ratings yet

- 02 F30 Powertrain1Document50 pages02 F30 Powertrain1Sameera GodakandaNo ratings yet

- MM1080 Ie 3Document3 pagesMM1080 Ie 3Paul RuckNo ratings yet

- Irregular Plural Nouns PDFDocument2 pagesIrregular Plural Nouns PDFelenaflorinNo ratings yet

- Kw06-286 Clamp Meter Mini Ac AutoranginDocument1 pageKw06-286 Clamp Meter Mini Ac AutoranginRusnadi TokNo ratings yet

- Soalan Science Tingkatan 1Document8 pagesSoalan Science Tingkatan 1Sabri AwangNo ratings yet

- Shopbearing Full Details 304223 BearingsDocument2 pagesShopbearing Full Details 304223 BearingsshopbearingNo ratings yet