Professional Documents

Culture Documents

EP2369289A1

Uploaded by

awe234Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

EP2369289A1

Uploaded by

awe234Copyright:

Available Formats

Printed by Jouve, 75001 PARIS (FR)

(19)

E

P

2

3

6

9

2

8

9

A

1

1111L|1111111

(11) EP 2 369 289 A1

(12) EUROPEAN PATENT APPLICATION

(43) Date of publication:

28.09.2011 Bulletin 2011/39

(21) Application number: 11153798.1

(22) Date of filing: 09.02.2011

(51) Int Cl.:

F41A 3/78

(2006.01)

F41A 5/34

(2006.01)

F41A 3/80

(2006.01)

F41A 3/86

(2006.01)

(84) Designated Contracting States:

AL AT BE BG CH CY CZ DE DK EE ES FI FR GB

GR HR HU IE IS IT LI LT LU LV MC MK MT NL NO

PL PT RO RS SE SI SK SM TR

Designated Extension States:

BA ME

(30) Priority: 23.03.2010 IT MI20100474

(71) Applicant: Gugliada, Giovanni

27058 Voghera (Pavia) (IT)

(72) Inventor: Gugliada, Giovanni

27058 Voghera (Pavia) (IT)

(74) Representative: Brasca, Marco

Bugnion S.p.A.

Viale Lancetti, 17

20158 Milano (IT)

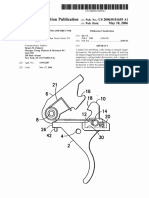

(54) Short recoil fire-arm

(57) The present invention relates to a short recoil

firearm (1) comprising a main body (2); a barrel (7) slid-

ingly mounted on the main body (2) and a movable be-

tween a forward percussion position and a backward re-

coil position; a slider (17) slidingly mounted on the main

body (2) and a movable between a forward position of

closure of the barrel (7) and a backward stop position.

The firearm (1) further comprises a plurality of cylindrical

rollers (22) operatively connected to a spirally wound

tape spring (26). The cylindrical rollers are movable be-

tween a first configuration, in which they lie mutually side

by side between the slider (17) and the barrel (7), to pre-

vent the relative movement thereof and to allow the in-

tegral displacement of same, and a second configuration,

in which they lie in a recovery chamber (27).

EP 2 369 289 A1

2

5

10

15

20

25

30

35

40

45

50

55

Description

[0001] The present invention relates to a short recoil

firearm. In particular, the present invention falls within

the field of semiautomatic light firearms such as pistols

or rifles employed in the military or sports field (e.g. hunt-

ing, target-shooting), with projectiles, large shots, shot

cartridges, etc.

[0002] It is known that there are semiautomatic fire-

arms (i.e. capable of recalling the movable masses after

the shot, ejecting the cartridge case and loading new

ammunitions) in which the breechblock and the barrel

carry out different recoil strokes following expansion of

the gases generated by the explosion. The barrel slides

backwards together with the breechblock over a first por-

tion, of smaller extent, and then stops and the breech-

block continues its stroke over a second portion, of great-

er extent, being disengaged from the barrel. Barrel and

breechblock are brought back to the percussion position

by suitable return springs. During the return travel, the

breechblock causes ejection of the cartridge case and

loading of a new ammunition in the barrel.

[0003] In this regard, the public document EP 1 950

520 discloses a semiautomatic smooth-bore rifle com-

prising a frame provided with breech, a barrel slidably

mounted on the frame relative to the breech, a breech-

block-slider assembly that is slidable relative to the

breech, and elastic means comprising a friction spring,

which means is able to oppose the translational motion

of said barrel.

[0004] The Applicant has felt the need to improve the

movement mechanism of the barrel and the breechblock

in semiautomatic short recoil firearms first of all for en-

suring a greater liability and a smaller wear of the parts

carrying out a relative motion.

[0005] In fact, the Applicant has noticed that during

separation between barrel and breechblock in the recoil

movement and/or recoupling of these elements during

return to the percussion position, the contact between

the parties in motion can lead to a quick wear of the parts,

giving rise, as a result, to possible seizing.

[0006] In addition, the usually helical springs that are

employed for return of the barrel and/or breechblock or

for damping the impulse movements of said barrel and/or

breechblock can be subjected to yield, over a long period

of use. As a result, the accuracy and functional qualities

of the arm are compromised.

[0007] In this context, the technical task underlying the

present invention is to propose a short recoil firearm over-

coming the aforesaid drawbacks of the known art.

[0008] In particular, it is an object of the present inven-

tion to propose a short recoil firearm capable of ensuring

movement accuracy of the parts over time, the efficiency

of same being maintained substantially unchanged.

[0009] In greater detail, the present invention aims at

making available a short-recoil firearm ensuring a joined

and integral movement of the barrel and breechblock dur-

ing a first portion of the recoil stroke and a guided decou-

pling of the breechblock from the barrel during a second

portion of the recoil stroke.

[0010] The technical task mentioned and the aims

specified are substantially achieved by a short recoil fire

arm in which coupling between barrel and breechblock

is obtained through a train of movable cylindrical rollers

and a spirally-wound tape spring.

[0011] More specifically, in a first aspect, the present

invention relates to a short recoil firearm, comprising:

- a main body;

- a barrel comprising a tubular body having a proximal

opening and a distal opening; said barrel being sli-

dably mounted on the main body and movable be-

tween a forward percussion position and a backward

recoil position;

- a slider slidably mounted on the main body and mov-

able between a forward position of closure of the

barrel and a backward stop position;

- elastic means working on the slider to push said slid-

er towards the forward closure position; character-

ised in that it comprises a plurality of pushing ele-

ments operatively connected to the elastic means

and movable between a first configuration, in which

they lie mutually side by side along an operative di-

rection between the slider and the barrel, to prevent

the relative movement between said barrel and slider

and to allow the integral displacement of said barrel

with said slider, and a second configuration, in which

they lie in a recovery chamber placed on the side of

said operative direction; wherein, during passage

from the first configuration towards the second con-

figuration, the barrel displacement opens an access

for entrance of the pushing elements into said recov-

ery chamber, and wherein, during passage from the

second configuration towards the first configuration,

the elastic means forces said pushing elements to-

wards said first configuration through said access.

[0012] The above described solution enables the rel-

ative movement between barrel and slider, while at all

events maintaining, during this relative movement, a con-

tinuous mechanical coupling between said two elements

through the pushing elements.

[0013] Preferably, said pushing elements comprise a

plurality of cylindrical rollers disposed mutually side by

side at their cylindrical surfaces. The rollers are of simple

and sturdy construction and, through their sliding/rolling,

ensure a smooth movement of the mechanism without

any risk of seizing.

[0014] Preferably, the elastic means comprises a spi-

rally wound tape spring connected to an end pushing

element operatively connected to said plurality of pushing

elements; wherein in the first configuration said end

pushing element is positioned in said access. The tape

spring keeps its elastic features over time without yield-

ing, thus ensuring a constant and accurate operation of

the firearm.

1 2

EP 2 369 289 A1

3

5

10

15

20

25

30

35

40

45

50

55

[0015] Preferably, the recovery chamber is shaped as

an arc of a circle and, preferably, partly extends around

the tape spring. The resulting structure is simple and

compact.

[0016] Preferably, an operating portion of the slider

slides alongside the tubular body of the barrel and is

aligned with, and faces a radial portion of the barrel along

the operating direction; wherein the pushing elements,

at least in the first configuration, are placed between said

radial portion of the barrel and said operating portion of

the slider. The mechanism is positioned on the side of

the barrel and is not bulky for the user.

[0017] Preferably, said radial portion of the barrel has

a stop plane and the end pushing element has a stop

surface; wherein, in the first configuration, the stop plane

rests against said stop surface. Coupling between the

barrel and the end element on said plane ensures safe

locking of the elements in the return movement to the

percussion position and fully closes access to the recov-

ery chamber.

[0018] Preferably, the stop plane is inclined to an in/out

direction of the access, to facilitate entry of the pushing

elements in said recovery chamber or exit of the pushing

elements from said recovery chamber; wherein the push-

ing elements during passage between the first and sec-

ond configuration push against said stop plane, keeping

the barrel in the backward recoil position.

[0019] Preferably, the firearm comprises an adjusting

device operatively working on the tape spring to adjust

the preload of said tape spring. The force exerted by the

spring can be adjusted based on the features of the pro-

jectiles used.

[0020] Preferably, the firearm comprises a lock device

placed nearby the access and movable between a dis-

engaged position from said access, to allow entry or exit

of the pushing elements, and an engaged position in said

access, to lock the pushing elements when they are in

said recovery chamber and to help disassembling of the

arm.

[0021] Separation of the barrel from the support body

can therefore be carried out without the risk that the roll-

ers may fall out of the recovery chamber.

[0022] Further features and advantages of the present

invention will become more apparent from the description

given by way of non-limiting example of a preferred but

not exclusive embodiment of a short recoil firearm, as

shown in the accompanying drawings, in which:

- Fig. 1 is a diagrammatic sectional view of a semiau-

tomatic short recoil pistol according to the present

invention, in an operating configuration;

- Fig. 2 shows the pistol seen in Fig. 1 in a different

operating configuration;

- Fig. 3 is a partial front view of the pistol in Fig. 1;

- Fig. 4 shows two views of a first detail of the pistol

referred to in the previous figures;

- Fig. 5 shows two views of a second detail of the pistol

referred to in the previous figures.

[0023] In the accompanying drawings, a firearm that

in the non-limiting example is a pistol or hand gun, has

been identified with reference numeral 1.

[0024] Pistol 1 comprises, in known manner and there-

fore not described in detail, a main body or frame 2 pro-

vided with a grip 3 that also performs the function of pro-

jectile 4 housing, and a trigger 5 operatively connected

to a hammer 6.

[0025] Mounted on the main body 2 is a barrel 7 com-

prising a tubular body 8 extending along an axis "X-X".

The tubular body 8 is provided with a proximal opening

9 placed in the vicinity of grip 3 and an opposite or distal

opening 10. The tubular body 8 confines a chamber 11

close to the proximal opening 9, which chamber is adapt-

ed to contain a projectile 4 at a time. Barrel 7 can slide

on the main body 2 carrying out a stroke S

1

of few milli-

metres (5 mm - 10 mm, for example) between a forward

percussion position (Fig. 1) and a backward recoil posi-

tion (Fig. 2). In addition, barrel 7 comprises a radial por-

tion 12 extending away from the tubular body 8 in the

same direction as grip 3. This radial portion 12 has a stop

surface 13 facing the grip 3 and a stop element 14 be-

longing to the main body 2. In the configuration shown

in Fig. 1, the distance between the stop surface 13 of the

radial portion 12 and the stop element 14 corresponds

to the stroke S

1

. This radial portion 12, on the opposite

side relative to the stop surface 13, has a stop plane 15

inclined to a direction orthogonal to the axis "X-X" of bar-

rel 8. The radial portion 12 further has a holding surface

16 alongside the stop plane 15, which too is placed on

the opposite side relative to the stop surface 13, close to

the tubular body, and is preferably of concave shape.

[0026] Pistol 1 comprises a slider 17 mounted on the

main body 2. Slider 17 in turn comprises a breechblock

18 aligned with barrel 7 along axis "X-X" and such dis-

posed as to face the proximal opening 9 and an operating

portion 19 integral with the breechblock 18 and placed

on the side of the tubular body 8. The operating portion

19 is guided in a guide defined in the main body 2, is

aligned with the radial portion 12 of barrel 7 along an

operating direction "Y-Y" parallel to axis "X-X" of barrel

7 and faces said radial portion 12. Slider 17 can translate

on the main body 2 between a forward position, shown

in Fig. 1, in which the breechblock 18 closes the proximal

opening 9 of barrel 7 and a backward stop position,

shown in Fig. 2, in which the breechblock 18 is spaced

apart from the proximal opening 9. In the forward position,

the operating portion 19 of slider 17 lies spaced apart

from the radial portion 12 of barrel 7 and confines a chan-

nel 20, together with said radial portion 12 and the main

body 2. In the second backward position, the operating

portion 19 of slider 17 lies close to the radial portion 12.

The operating portion 19 has a preferably concave hold-

ing surface thereof turned towards the radial portion 12.

[0027] Pistol 1 further comprises a plurality of pushing

elements 22 that, as in the embodiment shown, prefer-

ably consist of cylindrical rollers disposed mutually side

by side at their cylindrical side surfaces. The cylindrical

3 4

EP 2 369 289 A1

4

5

10

15

20

25

30

35

40

45

50

55

roller train 22, when slider 17 is in the first forward position

shown in Fig. 1, is placed in channel 20 and said rollers

22 are mutually aligned along the operating direction "Y-

Y" and packed between the holding surface 16 of barrel

7 and the holding surface 21 of slider 17.

[0028] In the embodiment shown, the two first cylindri-

cal rollers 22 disposed close to the operating portion 19

of slider 17 are mutually secured by means of a first plate

23 on which they are both hinged around their main axes.

These rollers 22 are further secured to said operating

portion 19 of slider 17 through a second plate 24 having

one end hinged on the first plate 23 and the opposite end

hinged on the operating portion 19. The remaining cylin-

drical rollers 22 (five in number in the pistol shown) are

not mutually linked but merely lie side by side.

[0029] The main body 2 of pistol 1, on the side of chan-

nel 20, comprises a box-shaped body 25 in which a spi-

rally wound tape spring 26 is installed. The main body 2

extends under barrel 7 like grip 3 and in front of trigger

5. A recovery chamber 27 is confined between the tape

spring 26 and an outer wall of the box-shaped body 25,

which recovery chamber partly extends around said tape

spring 26 and is shaped like an arc of a circle (subtending

an angle of about 270). The recovery chamber 27 and

tape spring 26 extend around an axis "Z-Z" orthogonal

to the operating direction "Y-Y" and preferably orthogonal

to a symmetry plane of pistol 1. The recovery chamber

27 has a closed end and an opposite end that is open

through an access 27a opening into the main body 2

towards barrel 7, as described in more detail in the fol-

lowing.

[0030] An inner end of the tape spring 26 is fastened

to a pin 28 mounted on the box-shaped body 25. Rotation

of pin 28 around axis "Z-Z" allows adjustment of the tape

spring 26, i.e. preload thereof to be regulated. An outer

end of the tape spring 26 is fastened to an end pushing

element 29 that can slide inside the recovery chamber

27 along a path shaped like an arc of a circle guided, on

one side, by the radially outermost turn of said tape spring

27 and, on the other side, by the outer wall of the box-

shaped body 25.

[0031] The end pushing element 29 comprises (Fig. 4)

a hooking portion 29a to the tape spring 27 and a thrust

portion 29b designed to come into contact with one of

the cylindrical rollers 22 and the radial portion 12 of barrel

7. The thrust portion 29b has a cavity inside which a stop

surface 30 is present.

[0032] At the radial portion 12 of barrel 7 there is a

conveyor 31 that is fixed relative to the main body 2.

Conveyor 31 (Fig. 5) is in the form of a fork disposed

around said radial portion 12 and its ends 32 are turned

towards channel 20. When barrel 7 is in its forward per-

cussion position, these ends 32 are disposed on the sides

of the radial portion 12 and do not project inside channel

20. Shown in Fig. 1 is only a portion in section of said

conveyor 31. When barrel 7 is in its backward position

and the access 27a is clear, these ends 32 project inside

channel 20 and their shape guides rollers 22 to said ac-

cess 27a (Fig. 2).

[0033] Pistol 1 further comprises a lock device 33

placed nearby the access 27a and movable between a

disengaged position from said access 27a, to allow entry

or exit of the pushing elements 22, and an engaged po-

sition in said access 27a, to retain rollers 22 when they

are in the recovery chamber 27 and enable disassem-

bling of barrel 7 without rollers 22 falling out. The illus-

trated lock device 33 is a rotatable element that is oper-

ated manually.

[0034] In use, when pistol 1 is ready to shoot with a

projectile 4 in chamber 11 (Fig. 1), barrel 7 is in its forward

percussion position with the stop surface 13 of the radial

portion 12 spaced apart from the stop element 14 by the

distance S

1

. The end pushing element 29 closes access

27a and the stop plane 15 of the radial portion 12 of barrel

7 bears against the stop surface 30. Said radial portion

12 cooperates with the end pushing element 29a for clos-

ing said access 27a. Slider 17 is in its forward closure

position in which the breechblock 18 bears against the

proximal opening 9 of barrel 7 (and closes it) and the

operating portion 19 is spaced apart from the radial por-

tion 12. All rollers 22 are contained in channel 20 and the

roller 22 close to access 27a bears partly against the

holding surface 16 of the radial portion 12 of barrel 7 and

partly against the hooking portion 29b of the end element

29a.

[0035] Just after percussion, by effect of the pressure

generated by the bursting gases, barrel 7 and slider 17

jointly move backwards being steadily locked to each oth-

er by the train of cylindrical rollers 22 over the first stroke

portion S

1

. The packed rollers 22 constitute a metal clo-

sure block enabling maximum exploitation of the bursting

gases under expansion. When the first stroke portion S

1

has been covered, the stop surface 13 of the radial por-

tion 12 of barrel 7 stops in its backward recoil position

against the stop element 14. The stop plane 16 of the

radial portion 12 moves away from the stop surface 30

of the end pushing element 29 and clears access 27a

opening into channel 20. This stop plane 16 is oriented

like the access walls 27a. The projectile 4 comes out of

barrel 7 through the distal opening 10. Rollers 22 are

pushed by the operating portion 19 of slider 17 and push

the end pushing element 29 into the recovery chamber

27, in turn entering said recovery chamber 27 one after

the other being guided by the stop plane 16 and conveyor

31. The end pushing element 29 almost reaches the

closed end of the recovery chamber 27. Opening of ac-

cess 27a and entry of rollers 22 therefore disengage slid-

er 17 from barrel 7. Barrel 7 has reached its end of stroke

but slider 17 continues its recoil stroke over a portion S

2

(50mm-70mm) that is much greater than S

1

. The breech-

block 18 moves backwards until the end of its stroke,

recocks the hammer and ejects the fired cartridge case.

This action is counteracted by the tape spring 26 that

during the backward movement of slider 17, is loaded,

being pushed by rollers 22.

[0036] At this point, the tape spring 26 tends to run

5 6

EP 2 369 289 A1

5

5

10

15

20

25

30

35

40

45

50

55

down and go back to the starting configuration. The tape

spring 26 pushes the end pushing element 29 towards

access 27a that in turn pushes rollers 22 out of the re-

covery chamber 27. Rollers 22 push the operating portion

19 of slider 17 towards the forward position and the

breechblock 18 towards barrel 7. The breechblock 18, in

its forward movement, introduces a new projectile 4 into

chamber 11 and goes on until all rollers 22 are again

aligned in channel 20 and locked between barrel 7 and

slider 17. Then barrel 7 that is no longer retained in the

backward position by the alternation of rollers 22 sliding

against the stop plane 15, can move forward together

with slider 17. The stop plane 15 is inserted into the cavity

of the end pushing element 29 and stops against the stop

surface 30, thus completing the closure block.

Claims

1. Short recoil firearm, comprising:

- a main body (2);

- a barrel (7) comprising a tubular body (8) pre-

senting a proximal opening (9) and a distal open-

ing (10); said barrel (7) being slidingly mounted

on the main body (2) and movable between a

forward percussion position and a backward re-

coil position;

- a slider (17) slidingly mounted on the main body

(2) and movable between a forward position of

closure of the barrel (7) and a backward stop

position;

- elastic means (26) working on the slider (17)

to push said slider (17) towards the forward clo-

sure position; characterised in that it compris-

es a plurality of pushing elements (22) opera-

tively connected to the elastic means (26) and

movable between a first configuration, in which

they lie mutually side by side along an operative

direction (Y-Y) between the slider (17) and the

barrel (7), to prevent the relative movement be-

tween said barrel (7) and said slider (17) and to

allow the integral displacement of said barrel (7)

with said slider (17), and a second configuration,

in which they lie in a recovery chamber (27)

placed on the side of said operative direction (Y-

Y); wherein, during the passage from the first

configuration towards the second configuration,

the displacement of the barrel (7) opens an ac-

cess (27a) for entrance of the pushing elements

(22) into said recovery chamber (27), and

wherein, during the passage from the second

configuration towards the first configuration, the

elastic means (26) force said pushing elements

(22) towards said first configuration through said

access (27a).

2. Arm according to claim 1, wherein said pushing el-

ements (22) comprise a plurality of cylindrical rollers

mutually placed side by side on cylindrical surfaces

of said rollers.

3. Arm according to claim 1 or 2, wherein the elastic

means (26) comprise a spirally wound tape spring

connected to an end pushing element (29) opera-

tively connected to said plurality of pushing elements

(22); wherein in the first configuration said end push-

ing element (29) is placed in said access (27a).

4. Arm according to claim 1, 2 or 3, wherein the recov-

ery chamber (27) is shaped as an arc of a circle.

5. Arm according to the preceding claim when depends

on claim 3, wherein the recovery chamber (27) par-

tially extends around the tape spring (26).

6. Arm according to one of the preceding claims,

wherein an operative portion (19) of the slider (17)

slides alongside the tubular body (8) of the barrel (7)

and is aligned with and faced to a radial portion (12)

of the barrel (7) along the operative direction (Y-Y);

wherein the pushing elements (22), at least in the

first configuration, are placed between said radial

portion (12) of the barrel (7) and said operative por-

tion (19) of the slider (17).

7. Arm according to the preceding claim when depends

on claim 3, wherein said radial portion (12) of the

barrel (7) presents a stop plane (15) and the end

pushing element (29) presents a stop surface (30);

wherein, in the first configuration, the stop plane (15)

rests against said stop surface (30).

8. Arm according to the preceding claim, wherein the

stop plane (15) is inclined with an in/out direction of

the access (27a), to help entry of the pushing ele-

ments (22) in said recovery chamber (27) or exit of

the pushing elements (22) from said recovery cham-

ber (27); wherein the pushing elements (22) during

passage between the first configuration and the sec-

ond configuration push against said stop plane (15)

keeping the barrel (7) in the backward recoil position.

9. Arm according to the claim 3, comprising an adjust-

ing device (28) operatively working on the tape

spring (26) to adjust the preload of said tape spring

(26).

10. Arm according to one of the preceding claims, com-

prising a lock device (33) placed nearby the access

(27a) and movable between a disengaged position

from said access (27a), to allow entry or exit of the

pushing elements (22), and an engaged position in

said access (27a), to stop the pushing elements (22)

when they are in said recovery chamber (27) and to

help disassembling of the arm (1).

7 8

EP 2 369 289 A1

6

EP 2 369 289 A1

7

EP 2 369 289 A1

8

EP 2 369 289 A1

9

EP 2 369 289 A1

10

REFERENCES CITED IN THE DESCRIPTION

This list of references cited by the applicant is for the readers convenience only. It does not form part of the European

patent document. Even though great care has been taken in compiling the references, errors or omissions cannot be

excluded and the EPO disclaims all liability in this regard.

Patent documents cited in the description

EP 1950520 A [0003]

You might also like

- Practical Guide to the Operational Use of the PPS-43 Submachine GunFrom EverandPractical Guide to the Operational Use of the PPS-43 Submachine GunNo ratings yet

- Us4522105 PDFDocument10 pagesUs4522105 PDFJin SongNo ratings yet

- United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Document15 pagesUnited States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Jin Song100% (1)

- 锤执行器的枪支 PDFDocument7 pages锤执行器的枪支 PDFJin SongNo ratings yet

- Revolver PatentDocument5 pagesRevolver PatentdududadamikeNo ratings yet

- Post 4 23085 M6 Scout InfoDocument32 pagesPost 4 23085 M6 Scout InfoMike Nichlos100% (2)

- 180 Misc .DXFDocument392 pages180 Misc .DXFNester Tovar0% (1)

- Us1517483 PDFDocument10 pagesUs1517483 PDFJin SongNo ratings yet

- FN FAL Gas Block Conversion InfoDocument2 pagesFN FAL Gas Block Conversion InfoAdam HemsleyNo ratings yet

- Home N Ew Arrivals C Loseouts Schem Atics Sell Your PartsDocument2 pagesHome N Ew Arrivals C Loseouts Schem Atics Sell Your Partstwinscrewcanoe100% (1)

- Ruger MkII Ejector Dimension Ed FlatDocument1 pageRuger MkII Ejector Dimension Ed FlatMike NichlosNo ratings yet

- Us 20060101695Document11 pagesUs 20060101695galak12001100% (1)

- Mauser Model 45 ENGLISH PDFDocument19 pagesMauser Model 45 ENGLISH PDFIM_JohnnyV100% (1)

- MAX1045 ManualDocument13 pagesMAX1045 Manualbrowar444100% (1)

- Us 3722358Document9 pagesUs 3722358awe234No ratings yet

- Patented June 1, 1901. No. 675,999.: L. HellfritzschDocument4 pagesPatented June 1, 1901. No. 675,999.: L. HellfritzschСлэйтер Строительная компанияNo ratings yet

- Ruger MKII Extractor RemovalDocument3 pagesRuger MKII Extractor Removalapi-3840428100% (1)

- V3 ECM Tutorial v1.0Document40 pagesV3 ECM Tutorial v1.0lmkkilo3No ratings yet

- Puma M1887 Lever Shotgun ManualDocument24 pagesPuma M1887 Lever Shotgun Manualesporadico123100% (1)

- Tm9 1005 229 35 Submachine Gun Caliber 45 m3 We 1005 672 1767 Submachine Gun Caliber 45 M3a1 We 1005 672 1771 September 1969Document54 pagesTm9 1005 229 35 Submachine Gun Caliber 45 m3 We 1005 672 1767 Submachine Gun Caliber 45 M3a1 We 1005 672 1771 September 1969Gary SchmitNo ratings yet

- C 96 BroomhandledisassemblyDocument56 pagesC 96 BroomhandledisassemblyKristjan ReinoNo ratings yet

- HK Flat Bending JigDocument7 pagesHK Flat Bending JigRon Walsh100% (1)

- Operator'S Manual: B&T Tp9-Us Bt-30105-2Document36 pagesOperator'S Manual: B&T Tp9-Us Bt-30105-2KnesekGuns100% (1)

- Ruger Mark IDocument7 pagesRuger Mark IAdam OrionNo ratings yet

- AK47 Variation ChartDocument50 pagesAK47 Variation ChartNester Tovar100% (3)

- 9mm BSP Machine Gun: Legal NoteDocument29 pages9mm BSP Machine Gun: Legal NoteLeonBackups100% (1)

- Winchester Model 37 ShotgunDocument3 pagesWinchester Model 37 Shotgunblowmeasshole1911No ratings yet

- Escort Instruction Manual GBDocument20 pagesEscort Instruction Manual GBJorge Andres Hartl100% (2)

- Klashnikovak 47 130330015107 Phpapp01Document15 pagesKlashnikovak 47 130330015107 Phpapp01elvergonzalez1100% (2)

- Blueprints PPSH41 Yugo49-57 American180 Browning1919Document7 pagesBlueprints PPSH41 Yugo49-57 American180 Browning1919Mika100% (2)

- UZI PRO Pistol Operator Manual 08 011 05 09 30 - 1Document60 pagesUZI PRO Pistol Operator Manual 08 011 05 09 30 - 1Ricardo C TorresNo ratings yet

- Unlted States Patent (10) Patent N0.2 US 7,421,937 B1Document24 pagesUnlted States Patent (10) Patent N0.2 US 7,421,937 B1Jin SongNo ratings yet

- BarrelDocument1 pageBarrelNO2NWO100% (2)

- United States "Patents PDFDocument17 pagesUnited States "Patents PDFTien Nguyen VanNo ratings yet

- 44 Magnum PDFDocument19 pages44 Magnum PDFAnderson Perosa100% (1)

- Sten mk2 Complete Machine Instructions PDFDocument24 pagesSten mk2 Complete Machine Instructions PDFTristan Jones100% (2)

- M1911 A1 ReduxDocument59 pagesM1911 A1 Reduxaudrea100% (1)

- Product Instructions - Flat Bending Jig InstructionsDocument34 pagesProduct Instructions - Flat Bending Jig InstructionsDale WadeNo ratings yet

- Mod Firearm Beretta - US Patent 5596162Document9 pagesMod Firearm Beretta - US Patent 5596162luanfunari100% (1)

- Sub Machine Gun MGV 176 ManualDocument19 pagesSub Machine Gun MGV 176 ManualknockelfliesNo ratings yet

- System For Shooting Using Compressed Gas - US Patent 5909000Document21 pagesSystem For Shooting Using Compressed Gas - US Patent 5909000Aride4everNo ratings yet

- Sterling Build V2Document16 pagesSterling Build V2Nester Tovar100% (2)

- Carl Gustav m45Document18 pagesCarl Gustav m45lobosolitariobe100% (2)

- Ruger Mark IV Target Pistol Model# 40159 SpecsDocument2 pagesRuger Mark IV Target Pistol Model# 40159 SpecsAmmoLand Shooting Sports NewsNo ratings yet

- ###Escopeta de Asalto Diy AutoDocument5 pages###Escopeta de Asalto Diy AutoMiguel Omar Pieszko100% (1)

- GSG MP40 - 9x19 - America PDFDocument20 pagesGSG MP40 - 9x19 - America PDFeric100% (1)

- A 518298Document19 pagesA 518298browar444No ratings yet

- AMT LightningDocument9 pagesAMT LightningJustinNo ratings yet

- Ruger MkIIEjectorDimmedDocument1 pageRuger MkIIEjectorDimmedMike NichlosNo ratings yet

- Australian F1 SUBMACHINE GUNDocument4 pagesAustralian F1 SUBMACHINE GUNCaprikorn100% (4)

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationFrom EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationNo ratings yet

- Practical Guide to the Operational Use of the PPSh-41 Submachine GunFrom EverandPractical Guide to the Operational Use of the PPSh-41 Submachine GunRating: 5 out of 5 stars5/5 (2)

- Hunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.From EverandHunting with Muzzleloading Revolvers: New powders and bullets have made these guns capable game killers.Rating: 5 out of 5 stars5/5 (1)

- Practical Guide to the Use of the SEMI-AUTO PPS-43C Pistol/SBRFrom EverandPractical Guide to the Use of the SEMI-AUTO PPS-43C Pistol/SBRNo ratings yet

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsFrom EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsNo ratings yet

- Punching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesFrom EverandPunching Holes: Buying Ammunition, Gun Accessories, Knives and Tactical Gear at Wholesale PricesNo ratings yet

- M 40 A 3Document172 pagesM 40 A 3Sean Clark100% (1)

- Makarov Air PistolDocument6 pagesMakarov Air PistolСвинаренко МихаилNo ratings yet

- Certified Parts Order Form 62722Document12 pagesCertified Parts Order Form 62722Diogo Ala YagiNo ratings yet

- HK Mp5 Armorers ManualDocument90 pagesHK Mp5 Armorers Manualktoggunner100% (4)

- User Manual Hecate2Document14 pagesUser Manual Hecate2tingkeenguong840113No ratings yet

- HK Catalog Feb 2012s Mp5Document1 pageHK Catalog Feb 2012s Mp5Iqbal Baryar100% (1)

- Ruger PC Carbine Spec SheetDocument2 pagesRuger PC Carbine Spec SheetAmmoLand Shooting Sports NewsNo ratings yet

- M-4 Preliminary Marksmanship Instruction & Evaluation (TC 3-20.40 Training and Qualification Individual Weapons TC3-22.9 Rifle & CarvineDocument147 pagesM-4 Preliminary Marksmanship Instruction & Evaluation (TC 3-20.40 Training and Qualification Individual Weapons TC3-22.9 Rifle & CarvineJose Vega CosmeNo ratings yet

- Troubleshooting ChecklistDocument4 pagesTroubleshooting ChecklistIrma KnuttNo ratings yet

- Us 5117735Document14 pagesUs 5117735sdfsdf333No ratings yet

- S W Centerfire PistolDocument15 pagesS W Centerfire PistoltakashiroNo ratings yet

- Forensic BallisticsDocument3 pagesForensic BallisticsDenver TevesNo ratings yet

- Armalite Arms 2012 CatalogDocument40 pagesArmalite Arms 2012 Catalogsergey62No ratings yet

- PKM Squad Automatic WeaponDocument4 pagesPKM Squad Automatic Weaponsaledin1100% (6)

- Desert EagleDocument12 pagesDesert EagleKarlos AlkatNo ratings yet

- Pathfinder 2e Firearms by DaddyXenDocument3 pagesPathfinder 2e Firearms by DaddyXeneihwaz369No ratings yet

- Selective Fire Kit For Lightning Link Using ARDocument3 pagesSelective Fire Kit For Lightning Link Using ARSpector_27567% (12)

- Harrington and Richardson Arms Company - Firearms MFGDocument3 pagesHarrington and Richardson Arms Company - Firearms MFGblowmeasshole1911No ratings yet

- BALLISTICSDocument18 pagesBALLISTICSvan vanNo ratings yet

- Marlin 49 22LRDocument16 pagesMarlin 49 22LRp317No ratings yet

- 2021 Product CatalogueDocument151 pages2021 Product CatalogueMirsad Struja HalilovićNo ratings yet

- PredatAR 7.62 ManualDocument12 pagesPredatAR 7.62 ManualvashcjnNo ratings yet

- 2563 EVP and PLDocument5 pages2563 EVP and PLaNo ratings yet

- Own Man J-DoublesDocument16 pagesOwn Man J-DoublesSelwinNo ratings yet

- HK - 416 PROJECT .22 Parts BreakdownDocument28 pagesHK - 416 PROJECT .22 Parts BreakdownhodhodhodsribdNo ratings yet

- The Army: Close-Up Picturetof Uermarir Jap and Italian GunsDocument24 pagesThe Army: Close-Up Picturetof Uermarir Jap and Italian Gunsjohn obrienNo ratings yet

- Les-Baer 2011 CatalogDocument37 pagesLes-Baer 2011 CatalogMario LopezNo ratings yet

- 2016 Bushmaster CatalogDocument70 pages2016 Bushmaster CatalogMario Lopez100% (1)

- Para TestDocument3 pagesPara TestToti CruzNo ratings yet

- List of Most-Produced Firearms - WikipediaDocument8 pagesList of Most-Produced Firearms - WikipediasorinartistuNo ratings yet