Professional Documents

Culture Documents

D Ulrich Moosheimer

Uploaded by

331623468Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

D Ulrich Moosheimer

Uploaded by

331623468Copyright:

Available Formats

Printing Technology

Printing Technologies Flexo Printing Gravure Printing

Munich

1.3 Million inhabitants Industrial and high-tech hub: BMW, MAN, Linde, Siemens et al. Top location for biotechnology & life sciences, media Germanys safest city

(ranked #1 / 50; source: Cologne Institute for Economic Research Consult survey 2009)

Most livable city

(ranked #7 / 221; source: Mercer Quality of Living Survey 2010)

Booming tourism destination Cultural center Capital of Bavaria

Prof. Dr. Ulrich Moosheimer

Seite 2

Professor Dr. Ulrich Moosheimer

Printing Technology

General Information about Munich University of Applied Sciences

Founded in 1971 about 15.000 Students 489 faculty members approx. 750 part time lecturers 500 staff Second largest University of Applied Sciences in Germany

Campus Pasing approx. 3.000 students

Campus Lothstrae approx. 9.000 students

Campus Karlstrae approx. 3.000 students

Prof. Dr. Ulrich Moosheimer

Seite 3

General Information about Munich University of Applied Sciences

14 Departments Engineering Business / Tourism Social Sciences Design More than 60 study programs: 29 Bachelors 33 Masters 2 Diploma

Applied Social Sciences; 10%

Business Tourism; 18%

Design ; 3% Engineering; 69%

Prof. Dr. Ulrich Moosheimer Seite 4

Professor Dr. Ulrich Moosheimer

Printing Technology

Bachelor of Engineering: Print and Media Technology

general modules individual modules

print 7 6 5 4 3 2 1 Bachelor thesis preferred in cooperation with industry laboratory work problem based learning business media

focus

focus

focus

industrial semester in-depth knowledge in pre-media technology, prepress technology, printing methods and machine technology, print finishing, technical and business process management, print media markets, financial accounting admission procedure

Prof. Dr. Ulrich Moosheimer

basics in mathematics, physics, chemistry, information technology, media programming and media design optional: preindustrial semester

Seite 5

Master of Engineering: Printmedia, Technology and Management

start summer term 2011 general modules

management 3 2 Master thesis preferred in cooperation with industry basic knowledge methods product development process development business methods communication basic research and development methods project work in management project work in technologies Access requirements bachelors degree from a German university diploma (FH) equivalent in print and media engineering equivalent from a foreign university markets business processes relevant future technologies products strategy leadership advanced research and development methods

individual modules

technology print and media processes and technologies

a n d

Prof. Dr. Ulrich Moosheimer

Seite 6

Professor Dr. Ulrich Moosheimer

Printing Technology

Print and Media Technologies

Prof. Dr. Ulrich Moosheimer

Seite 7

Where I studied: University Regensburg Applied Physics University of Colorado, Boulder Exchange student DAAD scholarship

Prof. Dr. Ulrich Moosheimer

Seite 8

Professor Dr. Ulrich Moosheimer

Printing Technology

Fraunhofer-Institute for Process Schreiner Group Engineering and Packaging Products and Processes Development and optimization Surface modification of polymer films

vacuum web coating lacquering lamination Management

Printing technologies

conventional and digital Dye cutting

Main research activities

Permeation and polymer films Adhesion mechanism

Patent management

defect in a SiOx layer coated on PET

Prof. Dr. Ulrich Moosheimer Seite 9

Printed Electronics - Added Value in a Book

Displays OLED Electroluminescent displays Electrochromic displays Conductive Elements Magnetic switch Switch plate Conductive lines Energy Supply RFID battery charger Solar cell Printed batteries Thin accumulator Production Printing Post-Printing www.the-interactive-book.com

Prof. Dr. Ulrich Moosheimer 10

Professor Dr. Ulrich Moosheimer

Printing Technology

What was the largest printing job worldwide?

General Terms in the Field of Printing Technology The process of information reproduction by printing is divided in the sections

Seite 11

plate making cylinder preparation

printing finishing

Prof. Dr. Ulrich Moosheimer

Seite 12

Professor Dr. Ulrich Moosheimer

Printing Technology

Teamwork: Gravur and Flexo Printing

Vernissage

Prof. Dr. Ulrich Moosheimer

Seite 13

Gravure printing Printing Technology using the lower parts of the printing block for ink transfer. Types of gravure printing block plate cylinder substrate material

impression cylinder

doctor blade printing cylinder ink

Prof. Dr. Ulrich Moosheimer

Seite 14

Professor Dr. Ulrich Moosheimer

Printing Technology

Gravure Printings - Schematic filling of the cells

doctor blading

transfer to the substrate

Prof. Dr. Ulrich Moosheimer

Seite 15

Gravure Printing - manually, art techniques - copperplate engraving - copperplate etching - industrial technology - gravure printing - pad printing

Prof. Dr. Ulrich Moosheimer

Seite 16

Professor Dr. Ulrich Moosheimer

Printing Technology

Gravure printing: Components Printing block with engraved printing - screen ruling 40 to 200 lines/cm - cell wall between the cells 0,003 0,005 mm - cell depth 0,01 max. 0,05 mm - cell width 0,03 0,230 mm - cell volume and density determine the final ink thickness

doctor blade - removes ink from non-printing parts Soft impression cylinder - ink transferred from printing block to substrate material - electrostatic support - pressure 1,5 5 MPa - small diameter for small contact zone

Prof. Dr. Ulrich Moosheimer Seite 17

Prepress Gravure printing engraving and polishing testing and corrections REACH: Use of Cr(III): cancerogen, poissening, acid, No alternative process without drastically increasing the prodction costs

/1/ /1/

Seite 18

Professor Dr. Ulrich Moosheimer

Printing Technology

Types of Cells differences - depth variable cells - constant cell area - variable cell depth highlight middle dark

- area variable cells (autotypic) - variable cell area - constant cell depth

- depth and area variable cells (semi-autotypic) - variable cell area - variable cell depth

Prof. Dr. Ulrich Moosheimer

Seite 19

Engraving Technology Direct engraving

Prof. Dr. Ulrich Moosheimer

Seite 20

Professor Dr. Ulrich Moosheimer

10

Printing Technology

Gravure Printing Cylinder for Packaging Setup from steel cylinder to printing layer steel base cylinder width up copper base layer about 2 mm thick polishing for high true running accuracy copper engraving layer about 0.1 mm thick chromium layer for high abrasion resistance about 0.006 mm thick

Prof. Dr. Ulrich Moosheimer

Seite 21

Printing Block Production: Gravure Printing electro-mechanical gravure semi-autotypic

/1/

Prof. Dr. Ulrich Moosheimer

Seite 22

Professor Dr. Ulrich Moosheimer

11

Printing Technology

Printing Block Production: Gravure Printing electro-mechanical gravure variation of the penetration depth of the gravure head frequency about 11.000 dots / s

Prof. Dr. Ulrich Moosheimer

Seite 23

Engraving Technology Direct laser engraving Copper or zinc cylinder

Prof. Dr. Ulrich Moosheimer

Seite 24

Professor Dr. Ulrich Moosheimer

12

Printing Technology

Vibration Gravure

Seite 25

Extreme Gravure

Seite 26

Professor Dr. Ulrich Moosheimer

13

Printing Technology

Direct engraving Screen ruled cells half cells smooth lines variable cell depth

Screen lines: 1.000 l/cm / 2.540 dpi

Prof. Dr. Ulrich Moosheimer

Seite 27

Comparison: Direct Laser to Electromechanical Engraving Direct Laser to Electromechanical Engraving

Direct Laser Engraving

Electromechanical Laser Engraving

Prof. Dr. Ulrich Moosheimer Seite 28

Professor Dr. Ulrich Moosheimer

14

Printing Technology

Comparison: Direct Laser to Electromechanical Engraving

Prof. Dr. Ulrich Moosheimer

Seite 29

Comparison: Direct Laser to Electromechanical Engraving

Vibration Gravure screening lines gravure speed abrasion dot form 70 L/cm 11.000 dots / s gravure head given by gravure head and variable in size

Laser Gravure 80 - 140 L/cm 70.000 dot / s none variable in form and size

Prof. Dr. Ulrich Moosheimer

Seite 30

Professor Dr. Ulrich Moosheimer

15

Printing Technology

Engraving Technology: Non-direct Laser

Seite 31

Engraving Technology: Non-direct Laser Think-Laser Imaging into polymer layer by laser Variability of cell areas as well as cell depths High resolution of 1 2 m Small-sized fonts possible Saw tooth free outline of letters Very deep cells for high layer thicknesses

Seite 32

Professor Dr. Ulrich Moosheimer

16

Printing Technology

Engraving Technologies Direct engraving packaging decor illustration Direct laser engraving packaging decor illustration security elements Non-direct laser engraving packaging high resolution printing security elements

Seite 33

Cost development of gravure cylinders (Average Values)

Quelle: Wessendorf, Ansgar. Im Fokus der DRUPA 2012: Der Flexodruck Flexo+Tief-Druck 3-2012

Prof. Dr. Ulrich Moosheimer

Seite 34

Professor Dr. Ulrich Moosheimer

17

Printing Technology

Virtual Walk through a Gravure Printing Station

Prof. Dr. Ulrich Moosheimer

Seite 35

Beispiel: Kinder Schoko Bons

60-fach

10-fach 200-fach

Seite 36

Professor Dr. Ulrich Moosheimer

18

Printing Technology

Identification - Saw tooth at letters and lines - High printing quality - Semi-autotypic - Halftone dots in different sizes and color densities - Spreading of the color - Light dots with open center

/1/

Seite 37

Identification Example

/1/

Seite 38

Professor Dr. Ulrich Moosheimer

19

Printing Technology

Illustration Printer 10 printing units (face and reverse printing) Folding unit Printing width up to 4320 mm

/1/

Seite 39

Packaging Printing - Flexible films - Multilayer films of metals, polymers and papers - Carrier bags

- Paper - Folded boxes (cigarettes, laundry detergent) - Soft drinks - Gift wrap paper - High variations in - Formats - Substrates - Printing width about ca. 1400 mm - Limits due to the stability of the substrates - PET-films (thickness 0,012 mm) - PE-films (thickness 0,040 mm) - OPP-films (thickness 0,016 mm)

Seite 40

Professor Dr. Ulrich Moosheimer

20

Printing Technology

Gravure printing machine for packaging - post press units often integrated as - flexo printing units - lacquering units - coating units - lamination units

Seite 41

Comparison of illustration and packaging printing

Illustration Printing Market segments Product variations Substrates Formats Solvent Printing width Printing speed Printing units Integrated post printing 90 % small Paper Standard cylinders Toluene max.4320 mm max. 900 m/min 2 times 4 or 5 Folding units

Packaging Printing 10 % very high Paper, metals and polymers Variable cylinders Alcohol, ester, water max.1500 mm max. 600 m/min 6 to 12 Flexo printing units Lacquering units Coating units Lamination units

Seite 42

Professor Dr. Ulrich Moosheimer

21

Printing Technology

Gravure printing: other application areas

Decor print Banknotes Security elements Stamps Art print

Seite 43

Pros and Cons of Gravure Printing Pros

Easy printing process simple setup of printing unit Constant high printing quality at high volumes Enlarged color space Reproducible printing quality Variability in report length High printing speed up to 900 m/min Colors containing high amount of solvent printable Colors containing metallic pigments for mirror like layers

Cons - Quality of letters compared to offset printing - Costs of printing cylinders - (Proof of printing cylinders) - Set-up costs - Economic printing starting at volumes higher then > 200.000 - 500.000 - Storage costs of printing cylinders

Seite 44

Professor Dr. Ulrich Moosheimer

22

Printing Technology

What was the largest printing job worldwide? IKEA catalogue 2008 200 Millionen (1 km tour on a Tennis court) 27 languages 52 Ausgaben 38 contries Reading by 200 Millionen people Advantage Low costs per cataloguet Use of cheap papers Stable printing process 55% paper 25 % color 7 % postpress 3 % repro K.A. print ?

Largest cost blocks

Seite 46

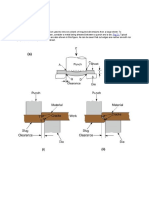

Letterpress Printing technology using the higher parts of the printing block for ink transfer.

Example: potato printing flexo printing

/1/

Prof. Dr. Ulrich Moosheimer

Seite 47

Professor Dr. Ulrich Moosheimer

23

Printing Technology

Components of a Flexo Printing Unit Gravure roll with doctor blade 100 to 600 lines/cm screen ruling ceramic or hard chrome coating printing thickness depends on cell volume

Printing cylinder (elastic) printing block plate cylinder sleeve Impression steel cylinder kiss printing Curing thermal curing UV curing

printing cylinder with plate

impression cylinder

anilox roller ink reservoir with doctor blade

Seite 48

Prof. Dr. Ulrich Moosheimer

Flexo Printing Plate Production - live potato printing Method Murmelgruppe Prepare a printing plate containing the elements quadrate as large as possible 3 dots as small as possible discussion of the printing quality Proposal for improving the printing quality

Prof. Dr. Ulrich Moosheimer

Seite 49

Professor Dr. Ulrich Moosheimer

24

Printing Technology

Flexo Printing Plate Production: CtP (Computer-to-Plate) Schematic

back side curing UVA

digital engraving

front side curing UVA

development

solvent based plus drying thermal (Cyrel Fast)

post curing UVA and UVC

Prof. Dr. Ulrich Moosheimer Seite 50

Flexo Printing Plate Production: CtP (Computer-to-Plate) Best practice results: - minimum dot size 0,030 0,05 mm - separation of printing plates according to - areas and - small dots or fonts

/1/

/1/

Prof. Dr. Ulrich Moosheimer

Seite 51

Professor Dr. Ulrich Moosheimer

25

Printing Technology

HD-Flexo 2.0 (Esko-Graphics) 4.000 dpi (8000 dpi opt.) with spec. screen pattern > 70 l/cm at 256 gray levels (otherwise: Standard 2540 dpi 62,5 L/cm at 256 gray levels) New printing screening technology highlights supporting dots higher stability of highlights expanded tonal range (about 30 %) down to almost 1 % midtones defined dot contact homogenous printing gradient solids MicroCells homogenous high solid coverage higher solids larger gamut Enhanced printing quality and reduced quality gap towards gravure and offset

Prof. Dr. Ulrich Moosheimer

Seite 52

HD-Flexo 2.0 (Esko-Graphics)

defined dot contact Brilliant Highlights

homogenous high solid coverage higher solids larger gamut

Prof. Dr. Ulrich Moosheimer

Seite 53

Professor Dr. Ulrich Moosheimer

26

Printing Technology

HD-Flexo 2.0 (Esko-Graphics)

Prof. Dr. Ulrich Moosheimer

Seite 54

Comparsion of Solid Tone coverage CTP and Mikro Screening

Quelle: Klein, Thomas: Dokumentation zur 61. DFTA Fachtagung, S. 23

Prof. Dr. Ulrich Moosheimer

Seite 55

Professor Dr. Ulrich Moosheimer

27

Printing Technology

Flexel-NX Flexographic System (Kodak) Printing quality (Flexo-Tief-Druck 1-2011, S. 4-5) flexible packaging qualitative alternative to gravure printing Corrugated board quality equal to Offset Tonal range: 0,4 99,6 % at 90 L/cm Production process

SquareSpot Imaging

IR-Laser (830 nm) 10.000 dpi

Lamination

(self adhesive) on flexo platte; oxygen inhibation

UVA reverse side and

Main Curing

Development

Prof. Dr. Ulrich Moosheimer

Seite 56

Flexel-NX Flexographic System (Kodak) Halftone dots with flat plateau sharp bordered plateau stabile connected to plate higher stability (high volumes)

(Flexo-Tief-Druck 1-2011, S. 5)

Prof. Dr. Ulrich Moosheimer

Seite 57

Professor Dr. Ulrich Moosheimer

28

Printing Technology

Flexel-NX Flexographic System (Kodak) Digi Cap NX-Screening Improved ink transfer homogenous high solid coverage higher solids larger gamut 0,4 for magenta, cyan, key 0,2 for yellow more opaque layers LAMS plate

(Flexo-Tief-Druck 1-2011, S. 4)

Digi Cap NX Screening

Prof. Dr. Ulrich Moosheimer

Seite 58

Laser Engraving of Flexo Cylinders

Base Material

rubber on fiber-reinforced plastic sleeve stone polishing of the sleeves true running accuracy of 0,02 mm circumference tolerance of +/-0,05 mm CO2 high speed laser 1000 Watt dot frequency of 7000 Hertz Direct engraving into the rubber Screen ruling 54 lines / cm 80 lines / cm

Prof. Dr. Ulrich Moosheimer

Seite 59

Professor Dr. Ulrich Moosheimer

29

Printing Technology

Printing Blocks for Flexo Printing plate

Platte Klebeband Sleeve

sleeve

cylinder

Prof. Dr. Ulrich Moosheimer

Seite 60

Flexo Printing Blocks Plates (thickness 0,76 6,35 mm) - mounting on printing cylinder by pressure sensitive tapes Sleeves - rubber coated sleeves plus direct engraving - photopolymer-sleeve with base roll Cylinder - gravure into the cylinder

Plates Storage volume Costs Print quality Mounting Accuracy of print length Sleeves Cylinders --++ ++ ++

+

++

+ + ++

+

--

Prof. Dr. Ulrich Moosheimer

Seite 61

Professor Dr. Ulrich Moosheimer

30

Printing Technology

Flexo Printing Identification - dot fringe - dot structure of the anilox roll - missing dots at highlight areas

Prof. Dr. Ulrich Moosheimer

Seite 62

Substrates for Flexo Printing Printing materials

- absorbend (paper) - non-absorbend (polymer films, metall plates) - rough surface (cardboard, corrugated board)

Printing inks

- solvent based - solvent free (water based) - UV curable inks - no thermal heat load on the materials - improved printing quality - reduced dot growth - off ordoe reduced by inert gas curing (nitrogen atmosphere) - higher costs

Prof. Dr. Ulrich Moosheimer

Seite 63

Professor Dr. Ulrich Moosheimer

31

Printing Technology

Comparison: Gravure to Flexo Printing and UV-Flexo Printing Gravure printing - fine dots - saw-tooth effect

Prof. Dr. Ulrich Moosheimer

Seite 64

Comparison: Gravure to Flexo Printing and UV-Flexo Printing Flexo printing - dot fringes

Prof. Dr. Ulrich Moosheimer

Seite 65

Professor Dr. Ulrich Moosheimer

32

Printing Technology

Comparison: Gravure to Flexo Printing and UV-Flexo Printing Gravure printing - fine dots - saw-tooth effect

Flexo printing - dot fringes UV-Flexo printing - homogenous printing gradient - smooth edges

Prof. Dr. Ulrich Moosheimer

Seite 66

Comparison: Gravure to Flexo Printing and UV-Flexo Printing Gravure printing - fine dots - saw-tooth effect

Flexo printing - dot fringes UV-Flexo printing - homogenous printing gradient - smooth edges

Prof. Dr. Ulrich Moosheimer

Seite 67

Professor Dr. Ulrich Moosheimer

33

Printing Technology

Decor Printing Pilot Printing Unit for Sampling

Prof. Dr. Ulrich Moosheimer

Seite 68

Flexo Printing Machine NOVOFLEX CM (Windmller & Hlscher)

Printing Units 8 /10

Quelle: Windmller & Hlscher KG

Printing Width 1300 1650 mm Printing Length Web Seep. max. 1250 mm 400 / 600 m/min

Seite 69

Professor Dr. Ulrich Moosheimer

Quelle: Windmller & Hlscher KG

tension sensitive films PE-films shrink films

34

Printing Technology

Flexo Printing Machines - central cylinder a) - unit construction b) - compact construction c)

/1/

/1/

/1/

Prof. Dr. Ulrich Moosheimer

Seite 70

Pros and Cons of Flexo Printing Pros

Easy printing process simple setup of printing plates Enlarged color space Variability in report length High printing speed up to 600 m/min High number of printable substrates, including rough surfaces

Cons - Lower quality compared to gravure and offset printing - Min. dot size reduced tonal range - Dot fringes - Set-up of plates on cylinders - Set-up of colors also at reruns

Seite 71

Professor Dr. Ulrich Moosheimer

35

Printing Technology

Comparison: Gravure to Flexo Printing (Methode geteilte Murmelgruppe) Strength of Gravure Printing Strength of Flexo printings

Prof. Dr. Ulrich Moosheimer

Seite 72

Summery Printing process plate making and cylinder preparation printing finishing high printing quality

Gravure printing

Flexo printing

cost advantage

Summabstimmung

Prof. Dr. Ulrich Moosheimer Seite 73

Professor Dr. Ulrich Moosheimer

36

You might also like

- Friction, Wear and Wear ProtectionFrom EverandFriction, Wear and Wear ProtectionAlfons FischerNo ratings yet

- 3D Printing: A Revolutionary Process for Industry ApplicationsFrom Everand3D Printing: A Revolutionary Process for Industry ApplicationsNo ratings yet

- INTRO TO PRINTING PROCESSESDocument20 pagesINTRO TO PRINTING PROCESSESKe WalNo ratings yet

- Micro Nano Systems Eng MasterDocument4 pagesMicro Nano Systems Eng MasterAhmed Fathy MoustafaNo ratings yet

- Unit 3 Fabric PrintingDocument57 pagesUnit 3 Fabric PrintingCarlo Gojo Cruz HalasanNo ratings yet

- History About Screen PrintingDocument14 pagesHistory About Screen Printingbluffy1No ratings yet

- Sefar ArchitectureDocument67 pagesSefar ArchitecturecarlosdayanaNo ratings yet

- Shreya Injection Molding MachinesDocument40 pagesShreya Injection Molding Machinests.anirudhaNo ratings yet

- Module 1 - Introduction, 3D Printing Hardware, 3D Printing SoftwareDocument140 pagesModule 1 - Introduction, 3D Printing Hardware, 3D Printing SoftwareNgọc Anh Trần100% (1)

- 978-3-030-11280-6 (1)Document370 pages978-3-030-11280-6 (1)MỸ VÕ HOÀNGNo ratings yet

- Master of Science in Embedded Systems EngDocument4 pagesMaster of Science in Embedded Systems EngAtiqMahmoodNo ratings yet

- Download ebook Injection Moulds For Beginners Pdf full chapter pdfDocument67 pagesDownload ebook Injection Moulds For Beginners Pdf full chapter pdfharold.thompson458100% (26)

- WPCDocument8 pagesWPCcipteNo ratings yet

- 10.1007@978 3 319 92267 6Document958 pages10.1007@978 3 319 92267 6riadhNo ratings yet

- ITA Techtextil 2011 booth hall 3.1 A33 Press ReleaseDocument4 pagesITA Techtextil 2011 booth hall 3.1 A33 Press ReleaseHéctor LópezNo ratings yet

- Alexander Biedermann, H. Gregor Molter - Design Methodologies For Secure Embedded SystemsDocument215 pagesAlexander Biedermann, H. Gregor Molter - Design Methodologies For Secure Embedded Systemsskipmars2No ratings yet

- 3d Printing AdvantagesDocument10 pages3d Printing AdvantagesRipudaman Kochhar100% (1)

- Joshua Mishael Sakyi - 10022300102Document7 pagesJoshua Mishael Sakyi - 10022300102Joshua MishaelNo ratings yet

- Download Injection Moulds For Beginners Rainer Dangel Eds full chapterDocument67 pagesDownload Injection Moulds For Beginners Rainer Dangel Eds full chapterdana.williams472100% (4)

- Advanced Building Skins 2012 PapersDocument287 pagesAdvanced Building Skins 2012 Papersbatteekh100% (1)

- Springer Mittlelmann2003 Sensing With Terahertz Radiation PDFDocument350 pagesSpringer Mittlelmann2003 Sensing With Terahertz Radiation PDFskinhugoNo ratings yet

- 3d Printing of Concrete StructuresDocument110 pages3d Printing of Concrete StructuresGabriel ComerlatoNo ratings yet

- SensorsDocument79 pagesSensorsveselieNo ratings yet

- Packing LearningDocument166 pagesPacking LearningPhuc Thien NguyenNo ratings yet

- Factory Planning ManualDocument30 pagesFactory Planning Manualmostafa piNo ratings yet

- MECH 502: Advanced/Additive Manufacturing Engineering: Course DescriptionDocument4 pagesMECH 502: Advanced/Additive Manufacturing Engineering: Course Descriptionparveenrathee123No ratings yet

- Toaz - Info Seminar Report On 3d Printing PRDocument27 pagesToaz - Info Seminar Report On 3d Printing PRhellgate.vishesh25No ratings yet

- 3D Printing TechnologyDocument14 pages3D Printing TechnologyM IsmailNo ratings yet

- 3D Printing Guide: History, Technologies, Materials and ApplicationsDocument21 pages3D Printing Guide: History, Technologies, Materials and ApplicationsGouthamNo ratings yet

- Michaël Prieur - Functional Elements and Engineering Template-Based Product Development Process (2009, KIT Scientific Publishing)Document220 pagesMichaël Prieur - Functional Elements and Engineering Template-Based Product Development Process (2009, KIT Scientific Publishing)DanilloSanchezNo ratings yet

- Program - Inkjet Printing of Functional Polymers and Materials - Dutch Polymer Institute, June 28, 2004Document11 pagesProgram - Inkjet Printing of Functional Polymers and Materials - Dutch Polymer Institute, June 28, 2004inzanerNo ratings yet

- 3D Printed Bionic Prosthetic Hands: Conference PaperDocument7 pages3D Printed Bionic Prosthetic Hands: Conference PaperDaniel BarajasNo ratings yet

- Dyeing Dyes: PrintingDocument16 pagesDyeing Dyes: Printingjack omeNo ratings yet

- Alexander Biedermann, H. Gregor Molter - Design Methodologies For Secure Embedded SystemsDocument215 pagesAlexander Biedermann, H. Gregor Molter - Design Methodologies For Secure Embedded SystemsBranko NikolicNo ratings yet

- Manual of Multistorey Timber ConstructionDocument5 pagesManual of Multistorey Timber ConstructionCarol ArtioliNo ratings yet

- 3D PRINTING ReportDocument15 pages3D PRINTING ReportArjun Oberai100% (1)

- Seminar Report On 3D Printing TechnologyDocument27 pagesSeminar Report On 3D Printing TechnologyjohnNo ratings yet

- Final 3d PrintingDocument29 pagesFinal 3d PrintingRonak PereiraNo ratings yet

- Nonwovens enDocument36 pagesNonwovens enEn10139No ratings yet

- Project ManagementDocument43 pagesProject ManagementMish HaqueNo ratings yet

- Letter of MotivationDocument2 pagesLetter of MotivationAbdul Ahad SaeedNo ratings yet

- Screw Machines Call For PapersDocument4 pagesScrew Machines Call For Papersalaine1114No ratings yet

- Uttara University: AssignmentDocument11 pagesUttara University: AssignmentMOJAHID HASAN Fall 19No ratings yet

- Ecaade2010 LowresDocument904 pagesEcaade2010 Lowreslmn_grssNo ratings yet

- 2015 06 R.J.M. Wolfs Graduation ThesisDocument110 pages2015 06 R.J.M. Wolfs Graduation Thesiss_barriosNo ratings yet

- Simufact - Professional Forming SimulationDocument12 pagesSimufact - Professional Forming SimulationMrLanternNo ratings yet

- Additive Manufacturing Technologies 3D printing in OrganicDocument15 pagesAdditive Manufacturing Technologies 3D printing in OrganicakshayNo ratings yet

- Plastics PotentialDocument11 pagesPlastics Potentialjuanjoselh22No ratings yet

- 3D Printed Chalk Holder with Laser PointerDocument12 pages3D Printed Chalk Holder with Laser PointerNAGARJUN RNo ratings yet

- Lopez Vega PA1 PMDocument6 pagesLopez Vega PA1 PMMAURICIO DAVID SALAZAR TORONo ratings yet

- Embedded Systems EngDocument4 pagesEmbedded Systems EngSaurabh MelveettilNo ratings yet

- Digital Printing Applications in the Textile and Printing Industries of TurkeyDocument6 pagesDigital Printing Applications in the Textile and Printing Industries of TurkeyarunaNo ratings yet

- Multimedia Systems: Prof. Dr. Paul MüllerDocument28 pagesMultimedia Systems: Prof. Dr. Paul Müllerajaygoswami92No ratings yet

- dormans (Lecture Notes in Computer Science 7522 Information Systems and Applications, incl. Internet_Web, and HCI) Edirlei Soares de Lima, Bruno Feijó, Cesar T. Pozzer, Angelo E. M. Ciarlini (auth.), Marc Her.pdfDocument629 pagesdormans (Lecture Notes in Computer Science 7522 Information Systems and Applications, incl. Internet_Web, and HCI) Edirlei Soares de Lima, Bruno Feijó, Cesar T. Pozzer, Angelo E. M. Ciarlini (auth.), Marc Her.pdfmuhammad ansharNo ratings yet

- Fused Filament Deposition (3D Printing)Document13 pagesFused Filament Deposition (3D Printing)azad khan khanNo ratings yet

- Springer - Factory Planning Manual - Situation-Driven Production Facility Planning - 2010Document421 pagesSpringer - Factory Planning Manual - Situation-Driven Production Facility Planning - 2010GuidoMascia100% (1)

- Characteristics in PrintingDocument16 pagesCharacteristics in PrintingKeerthanaNo ratings yet

- Printed Electronics Assignment (Unit 4)Document7 pagesPrinted Electronics Assignment (Unit 4)Rutuja MahindrakarNo ratings yet

- Factory Planning ManualDocument421 pagesFactory Planning ManualAtakan Korkmazlar80% (5)

- Experimental and Theoretical Study of Low-Dimensional Iron Oxide NanostructuresDocument29 pagesExperimental and Theoretical Study of Low-Dimensional Iron Oxide Nanostructures331623468No ratings yet

- G2 - Afga Graphic - Technologies and ProductsDocument103 pagesG2 - Afga Graphic - Technologies and Products331623468No ratings yet

- Ch2 OverviewDocument43 pagesCh2 Overview331623468No ratings yet

- Ch2 OverviewDocument43 pagesCh2 Overview331623468No ratings yet

- Rate Analsis Chapter No. 15 (Sheet Pilling)Document16 pagesRate Analsis Chapter No. 15 (Sheet Pilling)M HAFEEZ RAJANo ratings yet

- MSRR 6523Document5 pagesMSRR 6523pradelles100% (1)

- CSWIP 3.1 New Book PDFDocument590 pagesCSWIP 3.1 New Book PDFAsim90% (10)

- Aspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetDocument1 pageAspen Exchanger Design and Rating Shell & Tube V12: File: E-103 - 1.edr Printed: 24/01/2023 at 7:11:33 P. M. TEMA SheetNATALIA SALAZAR OROZCONo ratings yet

- Minimum Bend Radii for Sheet Metal BendsDocument5 pagesMinimum Bend Radii for Sheet Metal Bendsmimi_chan_17No ratings yet

- The Science and Engineering of Materials, 4 Ed: Chapter 22 - Corrosion and WearDocument56 pagesThe Science and Engineering of Materials, 4 Ed: Chapter 22 - Corrosion and WearSanidhyaKumarNo ratings yet

- Pyro Processing and Cement Grinding. Mechanical TrainingDocument6 pagesPyro Processing and Cement Grinding. Mechanical TrainingSamehibrahemNo ratings yet

- Types of Press Tools - Wikipedia, The Free EncyclopediaDocument5 pagesTypes of Press Tools - Wikipedia, The Free Encyclopediaललिल पाण्डेयNo ratings yet

- 6 - Iron Types - ApplicationsDocument18 pages6 - Iron Types - ApplicationsZhiwar oramariNo ratings yet

- Simulation of Methanol Production From Biomass Gasification in Interconnected Fluidized BedsDocument9 pagesSimulation of Methanol Production From Biomass Gasification in Interconnected Fluidized BedsKelly TorresNo ratings yet

- Mapei Sports Flooring SystemsDocument38 pagesMapei Sports Flooring SystemsWolves CreataNo ratings yet

- WC67K CNC Hydraulic Sheet Metal Press Brake Bender Machine With DA41s SystemDocument7 pagesWC67K CNC Hydraulic Sheet Metal Press Brake Bender Machine With DA41s SystemryneleeNo ratings yet

- FCB Horomill® Grinding Plant: FCB Horomill® Provides Solutions For Multipurpose or Specific NeedsDocument2 pagesFCB Horomill® Grinding Plant: FCB Horomill® Provides Solutions For Multipurpose or Specific NeedsBehrangNo ratings yet

- Aircraft Corrosion Protection MethodsDocument5 pagesAircraft Corrosion Protection MethodsMekhmanNo ratings yet

- Carlisle 307865 Specification SheetDocument1 pageCarlisle 307865 Specification SheetMike BongolanNo ratings yet

- Unit 203 Principles of Manufacturing Technology: Level: 2 Credit Value: 7 Uan: K/503/0175 Unit AimDocument4 pagesUnit 203 Principles of Manufacturing Technology: Level: 2 Credit Value: 7 Uan: K/503/0175 Unit AimEóin O CeranaighNo ratings yet

- Table 6.3 Welder Qualification-Number, Types of Test, Production Welds, and Positions Qualified (See 6.3)Document8 pagesTable 6.3 Welder Qualification-Number, Types of Test, Production Welds, and Positions Qualified (See 6.3)Lassaad ZarraaNo ratings yet

- Spareparts F 600 P27 011010Document6 pagesSpareparts F 600 P27 011010beoNo ratings yet

- QAQC Monthly Maintenance Report (Form)Document3 pagesQAQC Monthly Maintenance Report (Form)sarahNo ratings yet

- Chapter 2 Milling FixturesDocument15 pagesChapter 2 Milling FixturesTamirat NemomsaNo ratings yet

- SHEARINGDocument6 pagesSHEARINGanmol6237No ratings yet

- Topic2 Casting Spring08-09Document85 pagesTopic2 Casting Spring08-09Ayush KishoreNo ratings yet

- MA8110 TDS Rev11Document2 pagesMA8110 TDS Rev11Rushikesh DeshpandeNo ratings yet

- Synopsis (Shubham Shekhawat)Document6 pagesSynopsis (Shubham Shekhawat)moderate machines pvt. ltd.No ratings yet

- CORDEL Advanced Manufacturing ReportDocument32 pagesCORDEL Advanced Manufacturing ReportAníbal DI LUCHNo ratings yet

- BrsuhcoatDocument1 pageBrsuhcoatpravi3434No ratings yet

- Lesson 1 Tools and Materials Commercial Refrigeration and AirconditioningDocument26 pagesLesson 1 Tools and Materials Commercial Refrigeration and AirconditioningEddie AbugNo ratings yet

- Perforated Type Cable Tray: Raceway DuctsDocument3 pagesPerforated Type Cable Tray: Raceway DuctsAkash VakkayilNo ratings yet

- b6 Drill Bit Flyer enDocument1 pageb6 Drill Bit Flyer enNelson de la RosaNo ratings yet

- 4 Growth & DevelopmentDocument7 pages4 Growth & Developmentphoenix eastwoodNo ratings yet