Professional Documents

Culture Documents

Performance metrics and operational data from a cement kiln over 72 hours

Uploaded by

Elwathig BakhietOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance metrics and operational data from a cement kiln over 72 hours

Uploaded by

Elwathig BakhietCopyright:

Available Formats

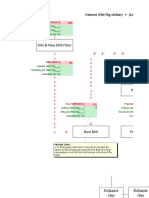

Performance Averageof Secondary air during normal operation Nm3/h Average of Tertiary air during normal operation Nm3/h

Tertiary air temp Secondary air temp Average of primary air during normal operation Nm3/h Cooler Efficency % total kiln feed during 72 hrs (ton) Clinker production (ton/hr) clinker factor during 72 hrs clinker factor during 72 hrs

PGT 82824.4 100223.4 974.9 1061.1 11132 78.5

25657 15411.02 1.665 ton raw material to produce 1 ton ( 0.6005) 0.6

Total amount of natural gas used Nm3/h during 72 hr 1404542 total amount of fuel for main burner ( natural gas) during 72 hr Nm3/h 643582 total amount of fuel for calciner ( natural gas) during 72 hr Nm3/h 760960 % of fuel between main burner to calciner 45.82 % : 54.18 % Heat Consumtion without By pass(Kcal/Kg) 702.4 Heat Consumtion with By pass(Kcal/Kg) 767.4 Smoke chamber air volume Nm3/h gas volume of mixing chamber ( included dilution fan air flow) Nm3/h gas volume of dilution fan air flow Nm3/h 105024.3 70272.8 44197.8 25559.2 24.36 23.59 81.78 0.23 0.02 0.58 81.78

Net Gas volume bypassed from kiln Nm3/h

By Pass Ratio % SpecificPower (Kw/tons) Average of Clinker temp + ambient temp Chloride in kiln feed during 72 hr Chloride in Clinker during 72 hr Free lime (%) Clinker temp(dgree)

You might also like

- HT-2.2 RMR Heat Belance 5 Stage T17 M7,9Document1 pageHT-2.2 RMR Heat Belance 5 Stage T17 M7,9GiequatNo ratings yet

- Bestway Cement Limited heat balance and WHR analysisDocument4 pagesBestway Cement Limited heat balance and WHR analysisKiran Veerubhotla100% (1)

- Coal Mill Ball Interlocks-V0.0Document11 pagesCoal Mill Ball Interlocks-V0.0Junaid MazharNo ratings yet

- Inleaking AirDocument6 pagesInleaking Airirfan100% (2)

- Coolheat1 AmericanDocument103 pagesCoolheat1 AmericanPrabhakar Reddy PeramNo ratings yet

- HOT AIR VOLUME ESTIMATION BASED ON OXYGEN LEVELSDocument4 pagesHOT AIR VOLUME ESTIMATION BASED ON OXYGEN LEVELSMohd AliNo ratings yet

- Kiln Eval Line IDocument1 pageKiln Eval Line IRaji SuriNo ratings yet

- Hot AirDocument6 pagesHot AirElancheran RengaNo ratings yet

- Instruction For Filling Up The Form-Sb & Keeping Records and Information For Verification ProcessDocument57 pagesInstruction For Filling Up The Form-Sb & Keeping Records and Information For Verification ProcessBùi Hắc HảiNo ratings yet

- Plant InvesticationDocument3 pagesPlant InvesticationirfanNo ratings yet

- User Guide PDFDocument27 pagesUser Guide PDFbulentbulut100% (1)

- Cooler Air Distribution CalculationDocument18 pagesCooler Air Distribution CalculationSatish KumarNo ratings yet

- Improvement of Productivity Using Tromp Curve MeasDocument11 pagesImprovement of Productivity Using Tromp Curve MeasRachit Bansal BJ20099No ratings yet

- Cooler Air Flow Vs Kiln FeedDocument2 pagesCooler Air Flow Vs Kiln FeedBùi Hắc HảiNo ratings yet

- Rectangular Jet Air Nozzles and Swirler Improving Ignition and Flame FormationDocument24 pagesRectangular Jet Air Nozzles and Swirler Improving Ignition and Flame Formationhmaza shakeelNo ratings yet

- Heat Balance For Kiln: Jasveer SinghDocument4 pagesHeat Balance For Kiln: Jasveer SinghAlok RanjanNo ratings yet

- Cpi CoolersDocument47 pagesCpi CoolersRobert BrownNo ratings yet

- LINE-2 PYRO PROCESS SITE DATA FOR BHARATHI CEMENTS KADAPADocument44 pagesLINE-2 PYRO PROCESS SITE DATA FOR BHARATHI CEMENTS KADAPAirfanNo ratings yet

- Ball Charge Design Methods GuideDocument12 pagesBall Charge Design Methods GuidePaulo VidasNo ratings yet

- Rotary Kiln Brick CountDocument5 pagesRotary Kiln Brick CountThaigroup CementNo ratings yet

- BurnerDocument3 pagesBurnerRavi sharmaNo ratings yet

- L-2 Fans 21.11.11Document5 pagesL-2 Fans 21.11.11Aaron HortonNo ratings yet

- Cement Cooler EffDocument1 pageCement Cooler Effsafwat hassanNo ratings yet

- Solid Fuels: 朱信 Hsin Chu Professor Dept. of Environmental Engineering National Cheng Kung UniversityDocument36 pagesSolid Fuels: 朱信 Hsin Chu Professor Dept. of Environmental Engineering National Cheng Kung UniversitysreeNo ratings yet

- Proposal For Reducing Emissions of SOx in Cement Plants PDFDocument4 pagesProposal For Reducing Emissions of SOx in Cement Plants PDFharrazyNo ratings yet

- Plant Location: Preheater Feed Preheater String - Calciner TypeDocument33 pagesPlant Location: Preheater Feed Preheater String - Calciner TypeDilnesa EjiguNo ratings yet

- WBCSD Cement Sustainability Initiative CO2 Emissions Inventory ProtocolDocument33 pagesWBCSD Cement Sustainability Initiative CO2 Emissions Inventory ProtocolRodrigo DíazNo ratings yet

- Reduce CO2 emissions with calcined clay cementDocument3 pagesReduce CO2 emissions with calcined clay cementtimothyNo ratings yet

- Najran Cement Company:: Najran: NCC Line-2 Kiln By-Pass ReportDocument2 pagesNajran Cement Company:: Najran: NCC Line-2 Kiln By-Pass ReportIrfan AhmedNo ratings yet

- Brick CaclulatorDocument7 pagesBrick CaclulatorAbul QasimNo ratings yet

- Detailed Study of Burining Problems Caused by Sulphur: Prepared by Suraj Bhaskaran Process EngineerDocument14 pagesDetailed Study of Burining Problems Caused by Sulphur: Prepared by Suraj Bhaskaran Process Engineerbsuraj100% (2)

- HOCM MAR Fez CoolerHeatBalanceDocument1 pageHOCM MAR Fez CoolerHeatBalanceOUSSAMA LAKHILI100% (2)

- QUESTIONNAIRE FOR PYROPROCESSING MODIFICATION COMPANYDocument8 pagesQUESTIONNAIRE FOR PYROPROCESSING MODIFICATION COMPANYVijay BhanNo ratings yet

- Upgrade Possibilities in Cement Plants - MR Anil Kumar CM, F L SmidthDocument7 pagesUpgrade Possibilities in Cement Plants - MR Anil Kumar CM, F L Smidthmail2quraishi3084No ratings yet

- The Purpose of A Cooler Is, Obviously To Cool The Clinker - This Is Important For A Several ReasonsDocument31 pagesThe Purpose of A Cooler Is, Obviously To Cool The Clinker - This Is Important For A Several ReasonsZegera MgendiNo ratings yet

- Rotary Kiln HEAT UP CHARTDocument5 pagesRotary Kiln HEAT UP CHARTsyeedismailNo ratings yet

- Nozzle Ring Area of Raw MillDocument5 pagesNozzle Ring Area of Raw MillThaigroup CementNo ratings yet

- Ball Mill SimulatorDocument4 pagesBall Mill SimulatorIrshad HussainNo ratings yet

- Mass BalanceDocument2 pagesMass BalanceElwathig Bakhiet100% (1)

- 3-5 stage cement kiln comparison chartDocument1 page3-5 stage cement kiln comparison chartzementheadNo ratings yet

- Grinding Media ConsumptionDocument9 pagesGrinding Media ConsumptionMuhammadNo ratings yet

- Heat Balance DataDocument6 pagesHeat Balance DataOuaddani amineNo ratings yet

- Cement Kiln Installed Capacity Calculation MethodsDocument2 pagesCement Kiln Installed Capacity Calculation Methodsemad sabriNo ratings yet

- Study of The Grinding Balls Distribution Inside The MillDocument2 pagesStudy of The Grinding Balls Distribution Inside The Millsempatik721No ratings yet

- NOx Reduction PDFDocument7 pagesNOx Reduction PDFfahimulehsanNo ratings yet

- NOx Control Technologies for Thermal and Fuel NOx ReductionDocument14 pagesNOx Control Technologies for Thermal and Fuel NOx ReductionsdgalaponNo ratings yet

- By Pass System in The Dry ProcessDocument34 pagesBy Pass System in The Dry Processfaheemqc100% (1)

- Solid Fuel PreperationDocument1 pageSolid Fuel PreperationvvijaybhanNo ratings yet

- Cost of Klinker Against C3SDocument2 pagesCost of Klinker Against C3SIrfan AhmedNo ratings yet

- Cement Process Engineering Vade Mecum: 2. StatisticsDocument15 pagesCement Process Engineering Vade Mecum: 2. StatisticsTamer FathyNo ratings yet

- Coal Drying (Dry Basis)Document9 pagesCoal Drying (Dry Basis)billyNo ratings yet

- CEMENT MILL NO 2 DATASHEETDocument2 pagesCEMENT MILL NO 2 DATASHEETThaigroup CementNo ratings yet

- Process Control of LURM MillDocument6 pagesProcess Control of LURM Millimam janiNo ratings yet

- Training on Waste Heat Recovery & CogenerationDocument26 pagesTraining on Waste Heat Recovery & CogenerationPhani KumarNo ratings yet

- Tips On Kiln OperationDocument10 pagesTips On Kiln OperationElwathig Bakhiet100% (2)

- KPI v0Document4 pagesKPI v0sersehNo ratings yet

- Furnaces in Power BoilerDocument34 pagesFurnaces in Power BoilerMohammed AzharuddinNo ratings yet

- Dryer Output CalculationDocument1 pageDryer Output CalculationSatish DaveNo ratings yet

- Impact of SC On Specific EnergyDocument33 pagesImpact of SC On Specific EnergyManish GautamNo ratings yet

- Cyclonic Furnace Sizing ExampleDocument4 pagesCyclonic Furnace Sizing ExampleRufus D SNo ratings yet

- Refractory workshop – Castable selection and installation guideDocument37 pagesRefractory workshop – Castable selection and installation guideElwathig Bakhiet100% (4)

- TACH20: Combo TachometerDocument5 pagesTACH20: Combo TachometerElwathig BakhietNo ratings yet

- Low Cement CastablesDocument38 pagesLow Cement CastablesElwathig Bakhiet100% (1)

- First PrinciplesDocument2 pagesFirst PrinciplesElwathig BakhietNo ratings yet

- Cement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 2.6 ExerciseDocument1 pageCement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 2.6 ExerciseElwathig BakhietNo ratings yet

- Ss PolymorphsDocument9 pagesSs PolymorphsElwathig BakhietNo ratings yet

- Mineralisation PDFDocument11 pagesMineralisation PDFElwathig BakhietNo ratings yet

- Ijfeat: Application of Electrostatic Precipitator in Cement PlantDocument7 pagesIjfeat: Application of Electrostatic Precipitator in Cement PlantElwathig BakhietNo ratings yet

- Bogue DeviationDocument8 pagesBogue DeviationElwathig BakhietNo ratings yet

- Survival Fuels: Technical ForumDocument2 pagesSurvival Fuels: Technical ForumElwathig Bakhiet100% (1)

- Burnability ExercisesDocument1 pageBurnability ExercisesElwathig BakhietNo ratings yet

- Survival Fuels: Technical ForumDocument2 pagesSurvival Fuels: Technical ForumElwathig Bakhiet100% (1)

- Burnability ExercisesDocument1 pageBurnability ExercisesElwathig BakhietNo ratings yet

- First PrinciplesDocument2 pagesFirst PrinciplesElwathig BakhietNo ratings yet

- Cement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 3.3 - ExerciseDocument1 pageCement Kiln Process Chemistry: Cemnet Training - Course Ckpc01 Module 3.3 - ExerciseElwathig BakhietNo ratings yet

- Alkali CyclesDocument14 pagesAlkali CyclesElwathig BakhietNo ratings yet

- RedoxDocument7 pagesRedoxElwathig BakhietNo ratings yet

- CSAF ExerciseDocument1 pageCSAF ExerciseElwathig BakhietNo ratings yet

- Viscosity PDFDocument1 pageViscosity PDFElwathig BakhietNo ratings yet

- Cost & Quality of HomogeneityDocument2 pagesCost & Quality of HomogeneityElwathig BakhietNo ratings yet

- MicroscopicDocument5 pagesMicroscopicElwathig BakhietNo ratings yet

- Under The MicroscopeDocument3 pagesUnder The MicroscopeElwathig BakhietNo ratings yet

- Final FrontierDocument1 pageFinal FrontierElwathig BakhietNo ratings yet

- Viscosity PDFDocument1 pageViscosity PDFElwathig BakhietNo ratings yet

- Final FrontierDocument1 pageFinal FrontierElwathig BakhietNo ratings yet

- Calci NationDocument11 pagesCalci NationElwathig BakhietNo ratings yet

- International Cement Review, September 2002: Burning The MixDocument5 pagesInternational Cement Review, September 2002: Burning The MixarylananylaNo ratings yet

- First PrinciplesDocument2 pagesFirst PrinciplesElwathig BakhietNo ratings yet

- Chloride BypassesDocument8 pagesChloride BypassesElwathig BakhietNo ratings yet