Professional Documents

Culture Documents

Cswa2007 PDF

Cswa2007 PDF

Uploaded by

yanpainOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cswa2007 PDF

Cswa2007 PDF

Uploaded by

yanpainCopyright:

Available Formats

CSWASampleExamQuestions

CertifiedSolidWorksAssociate(CSWA)

SampleExamQuestions

ThequestionsbelowrepresentsampleCSWAExamquestions.Partmodelingand assemblymodelingquestionsthatrequireyoutobuildmodelshouldbecorrectly answeredin45minutesorless.Question2andQuestion3shouldbecorrectly answeredin5minutesorless.

Question1.

BuildthispartinSolidWorks. Unitsystem:MMGS(millimeter,gram,second) Decimalplaces:2.Partorigin:Arbitrary A=63mm,B=50mm,C=100mm.Allholesthroughall. Partmaterial:CopperDensity=0.0089g/mm^3

PAGE1

CSWASampleExamQuestions

Whatisthe overallmassof thepartingrams? a)1205 b)1280 c)144 d)1108

PAGE2

CSWASampleExamQuestions

Question2.

COSMOSXPressallowschangestomeshsettings.Whichofthefollowing statementsisnotTrue? a)Afinemeshsettingproducesmoreaccurateresultsthanacoursemesh. b)Acoarsemeshsettingproduceslessaccurateresultsthanafinemesh. c)Afinemeshsettingcanbeappliedtoaspecificfaceinsteadoftheentire model. d)Alloftheabove

Question3.

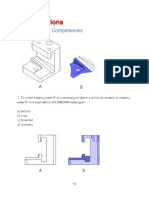

Tocreatedrawing view,Bitisnecessary tosketchaspline(as shown)ondrawing viewAandinsert whichSolidWorksview type?

a) Brokenout Section b) Aligned Section c) Section d) Detail

PAGE3

CSWASampleExamQuestions

Question4.

Buildthisassembly inSolidWorks. Itcontains3 machinedbrackets and2pins. Brackets:2mm thickness,andequalsize(holesthroughall).Material:6061Alloy,Density =0.0027g/mm^3.Thetopedgeofthenotchislocated20mmfromthetop edgeoftheMachinedBracket. Pins:5mmlengthandequalindiameter,Material:Titanium,Density= 0.0046g/mm^3.Pinsarematedconcentrictobracketholes(noclearance). Pinendfacesarecoincidenttobracketouterfaces.Thereisa1mmgap betweenthebrackets.Bracketsarepositionedwithequalanglemates(45 degrees). Unitsystem:MMGS(millimeter,gram,second) Decimalplaces:2 Assemblyorigin:Asshown. Whatisthecenterofmassoftheassembly? a) b) c) d) X=11.05 Y=24.08 X=40.24 Y=24.33 X=20.75 Y=24.33 Z=40.19 Z=20.75 Z=40.24 X=11.05 Y=24.08 Z=40.19

PAGE4

CSWASampleExamQuestions

Question5.

Buildthisassemblyin SolidWorks.Itcontains3 components:Base,Yoke, AdjustingPin.ApplytheMMGS unitsystem. Material:1060Alloyforall components.Density= 0.0027g/mm^3 Base:Thedistancebetweenthe frontfaceoftheBaseandthe frontfaceoftheYoke=60mm. Yoke:TheYokefitsinsidethe leftandrightsquarechannelsof theBasecomponent,(no clearance).Thetopfaceofthe Yokecontainsa12mm throughallhole. AdjustingPin:Thebottomface oftheAdjustingPinheadis located40mmfromthetopfaceoftheYokecomponent.TheAdjustingPin componentcontainsa5mmthoughallhole. Whatisthecenterofmassoftheassemblywithrespecttotheillustrated coordinatesystem? a) b) c) d) X=30.00 X=30.00 X=30.00 X=30.00 Y=40.16 Z=40.16 Y=40.16 Y=40.16 Y=40.16 Z=43.82 Z=50.20 Z=53.82

PAGE5

CSWASampleExamQuestions

Question6.

Buildthispartin SolidWorks. Material:6061 Alloy.Density= 0.0027g/mm^3 Unitsystem: MMGS (millimeter,gram, second) Decimalplaces:2. Partorigin: Arbitrary A=100. Allholesthrough all,unlessotherwisespecified Whatistheoverallmassofthepartingrams? a)2040.57 b)2004.57 c)102.63 d)1561.23

PAGE6

CSWASampleExamQuestions

For further preparation, please complete the SolidWorks tutorials, located in SolidWorks under the Help Menu, before taking the CSWA Exam. Review the About the CSWA Exam document located at www.solidworks.com/cswa.

Good Luck, Certification Program Manager, SolidWorks Corporation

Correctanswers: 1. b 2. c 3. a 4. c 5. d 6. a

PAGE7

You might also like

- An Introduction To The Mechanics of Solids 2nd (S.H.crandall) SolutionsDocument276 pagesAn Introduction To The Mechanics of Solids 2nd (S.H.crandall) Solutionsassaf64% (14)

- Mastering Multi-Band Compression - 17 Step by Step Multiband Compression Techniques For Getting Fla - Ion, Sound Design & Mixing Audio Series - Book 4) - NodrmDocument109 pagesMastering Multi-Band Compression - 17 Step by Step Multiband Compression Techniques For Getting Fla - Ion, Sound Design & Mixing Audio Series - Book 4) - NodrmGandhi Wasuvitchayagit100% (2)

- CSWP Examen de EjemploDocument3 pagesCSWP Examen de EjemploJoa Molina100% (8)

- 250+ TOP MCQs On Tolerances and AnswersDocument6 pages250+ TOP MCQs On Tolerances and AnswersManjunath a nNo ratings yet

- Kinetics Technical CommunicationDocument12 pagesKinetics Technical Communicationapi-575715390No ratings yet

- UIDAHO Exam 1.1Document6 pagesUIDAHO Exam 1.1dgm929No ratings yet

- Test Questions: Part 1: Drafting CompetenciesDocument11 pagesTest Questions: Part 1: Drafting Competencies4112 - Subhash NNo ratings yet

- Solidworks Exercise 1Document3 pagesSolidworks Exercise 1Waqar DarNo ratings yet

- Cert Cswpcdessample2008Document7 pagesCert Cswpcdessample2008Gustavo Reaño PulacheNo ratings yet

- Certifiedsolidworksassociate (Cswa) : SampleexamquestionsDocument2 pagesCertifiedsolidworksassociate (Cswa) : SampleexamquestionsRahmadiNo ratings yet

- CsWa Sample Exam QuestionsDocument6 pagesCsWa Sample Exam QuestionsgurisNo ratings yet

- Edu Cswa Sample Exam 2013 EngDocument10 pagesEdu Cswa Sample Exam 2013 Engtigerman_nr10% (1)

- CSWP-WLDM Sample ExamDocument12 pagesCSWP-WLDM Sample Examtito36bcnNo ratings yet

- Part Modeling: The Following Images Are To Be Used To Answer Questions #3 - 4Document8 pagesPart Modeling: The Following Images Are To Be Used To Answer Questions #3 - 4AliNo ratings yet

- CSWASample Exam 2010Document14 pagesCSWASample Exam 2010Rich Mack100% (1)

- CSWP Sample Exam 2009Document9 pagesCSWP Sample Exam 2009Yassine BziouiNo ratings yet

- CSWP-WLDM Sample ExamDocument12 pagesCSWP-WLDM Sample ExamJose CuevasNo ratings yet

- To Create Drawing View B' It Is Necessary To Sketch A Spline (As Shown) On Drawing View A' and Insert Which SOLIDWORKS View Type?Document7 pagesTo Create Drawing View B' It Is Necessary To Sketch A Spline (As Shown) On Drawing View A' and Insert Which SOLIDWORKS View Type?Javier McleonNo ratings yet

- CSWA Practice 2013Document24 pagesCSWA Practice 2013pacomermela69No ratings yet

- Segment 1 - CSWP-CORE ExamDocument9 pagesSegment 1 - CSWP-CORE ExammengodNo ratings yet

- Q1 11Document5 pagesQ1 11SeymurH-vNo ratings yet

- CSWP Core Sample Exam 2009Document9 pagesCSWP Core Sample Exam 2009Jose Luis AtaullucoNo ratings yet

- 60 AutoCAD 2D & 3D PracticeDocument65 pages60 AutoCAD 2D & 3D PracticeAkash MahmudNo ratings yet

- EDU Motion Student 2013 ENGDocument20 pagesEDU Motion Student 2013 ENGcbr6000No ratings yet

- CAD Contest QuestionDocument37 pagesCAD Contest QuestionFahad AbdullahtNo ratings yet

- CSWP TipsDocument24 pagesCSWP Tipskwokshern50% (2)

- Instructions Answer 5 Questions in AllDocument6 pagesInstructions Answer 5 Questions in AllOyewumi Oladapo Rasheed100% (1)

- CSWP MBD SampleexamDocument24 pagesCSWP MBD SampleexamUfficio TecnicoNo ratings yet

- Official Guide To Certified Solidworks Associate Exams: Cswa, Csda, Cswsa-FeaDocument22 pagesOfficial Guide To Certified Solidworks Associate Exams: Cswa, Csda, Cswsa-FeaShafier KhanNo ratings yet

- A Certified SOLIDWORKS Professional Is An Individual Who Has Successfully Passed Our Advanced Skills ExaminationDocument3 pagesA Certified SOLIDWORKS Professional Is An Individual Who Has Successfully Passed Our Advanced Skills ExaminationsravanNo ratings yet

- CSWPDocument1 pageCSWPNeo NMNNo ratings yet

- Simulation Instructor WB 2011 ENGDocument57 pagesSimulation Instructor WB 2011 ENGjorgemariovega4910No ratings yet

- SW Tips - CSWP - Weldments ReviewDocument66 pagesSW Tips - CSWP - Weldments ReviewWill FongNo ratings yet

- Official Guide To Certified SOLIDWORKS Associate Exams PlanchardDocument354 pagesOfficial Guide To Certified SOLIDWORKS Associate Exams PlanchardvictorynwobiaNo ratings yet

- Basic: Cad-Based For Greater PowerDocument2 pagesBasic: Cad-Based For Greater PowerraduvascautiNo ratings yet

- Certified Solidworks Sustainability (Cswa-Sustainability)Document1 pageCertified Solidworks Sustainability (Cswa-Sustainability)Harshi BavishiNo ratings yet

- Solidwize: Online Solidworks TrainingDocument9 pagesSolidwize: Online Solidworks Trainingjuanito pipas0% (1)

- CSWP Book - Segment3 - SamplesDocument30 pagesCSWP Book - Segment3 - SamplesMohamed ShafeekNo ratings yet

- Quiz Basic Gear Concepts and CalculationsDocument4 pagesQuiz Basic Gear Concepts and CalculationsLister NambatacNo ratings yet

- Solid Works Drawing and DetailingDocument69 pagesSolid Works Drawing and Detailingapi-3848892100% (1)

- CSWP1803 Segment 1Document10 pagesCSWP1803 Segment 1PaoloDeMatteisNo ratings yet

- SOLIDWORKS Certification Exam Guide & Practice Test: CSWPA-MM: Certified SOLIDWORKS Professional Advanced Mold MakingDocument31 pagesSOLIDWORKS Certification Exam Guide & Practice Test: CSWPA-MM: Certified SOLIDWORKS Professional Advanced Mold MakingjesusNo ratings yet

- NX CAD Training ReportDocument22 pagesNX CAD Training ReportSatyam SharmaNo ratings yet

- SolidWorks 2015 Learn by doing-Part 3 (DimXpert and Rendering)From EverandSolidWorks 2015 Learn by doing-Part 3 (DimXpert and Rendering)Rating: 4.5 out of 5 stars4.5/5 (5)

- Certified Solidworks Associate (Cswa) : Sample Exam QuestionsDocument7 pagesCertified Solidworks Associate (Cswa) : Sample Exam Questionsagus fikri rosjadi100% (10)

- Certified Solidworks Associate (Cswa) : Sample Exam QuestionsDocument3 pagesCertified Solidworks Associate (Cswa) : Sample Exam QuestionsMeme BohNo ratings yet

- Cs Was Ample Exam 2010Document14 pagesCs Was Ample Exam 2010El FilyNo ratings yet

- Solidworks Corporation: Cswa Sample ExamDocument14 pagesSolidworks Corporation: Cswa Sample ExamReena MoisesNo ratings yet

- CSWASample Exam2010Document11 pagesCSWASample Exam2010Elmika TrầnNo ratings yet

- Solidworks Corporation: Cswa Sample ExamDocument12 pagesSolidworks Corporation: Cswa Sample Examboussaid nejlaNo ratings yet

- Solidworks Corporation: CSWP Sample ExamDocument3 pagesSolidworks Corporation: CSWP Sample ExamlevannuNo ratings yet

- Solidworks Corporation: CSWP Sample Exam: Certified Solidworks Professional: Solid Modeling Specialist (Cswp-Core)Document62 pagesSolidworks Corporation: CSWP Sample Exam: Certified Solidworks Professional: Solid Modeling Specialist (Cswp-Core)bontrager1306100% (1)

- MM 361: Advanced Manufacturing: InstructionsDocument3 pagesMM 361: Advanced Manufacturing: InstructionsSimLo Lulumani Ko'osiko Taloanimae'aNo ratings yet

- CSWP Advanced Sheet Metal Sample ExamDocument7 pagesCSWP Advanced Sheet Metal Sample Examroberto1793No ratings yet

- EXO3Document19 pagesEXO3Douaa GhazouaniNo ratings yet

- Solidworks Corporation: CSWP Advanced Sheet Metal Sample ExamDocument7 pagesSolidworks Corporation: CSWP Advanced Sheet Metal Sample ExamKamal GifariNo ratings yet

- Pieza AvanzadaDocument9 pagesPieza AvanzadaLuis PNo ratings yet

- Solidworks Corporation: CSWP Sample Exam: Certified Solidworks Professional: Solid Modeling Specialist (Cswp-Core)Document8 pagesSolidworks Corporation: CSWP Sample Exam: Certified Solidworks Professional: Solid Modeling Specialist (Cswp-Core)Klever MoralesNo ratings yet

- Assignment ADCIM 2007Document17 pagesAssignment ADCIM 2007kumareshNo ratings yet

- Solidworks Corporation: CSWP Sample Exam: Certified Solidworks Professional: Solid Modeling Specialist (Cswp-Core)Document9 pagesSolidworks Corporation: CSWP Sample Exam: Certified Solidworks Professional: Solid Modeling Specialist (Cswp-Core)lachhelNo ratings yet

- Mech3002y 3 2007 2 PDFDocument6 pagesMech3002y 3 2007 2 PDFKeshav GopaulNo ratings yet

- Qualitative Theory of Volterra Difference Equations - RaffoulDocument333 pagesQualitative Theory of Volterra Difference Equations - RaffoulJuan Rodriguez100% (1)

- ABS Terluran GP22Document2 pagesABS Terluran GP22Alan MoraisNo ratings yet

- PrEN1998-4 - (Silos, Tanks and Pipelines)Document83 pagesPrEN1998-4 - (Silos, Tanks and Pipelines)Mohamed Ali LamraouiNo ratings yet

- Unit-II Two Mark QuestionsDocument7 pagesUnit-II Two Mark QuestionshariharanbookNo ratings yet

- Ansys Fluent Simulation ReportDocument9 pagesAnsys Fluent Simulation ReportME 26 PRADEEP KUMARNo ratings yet

- Cambridge O Level: Mathematics (Syllabus D) 4024/11Document20 pagesCambridge O Level: Mathematics (Syllabus D) 4024/11Good DeedsNo ratings yet

- Steam Surface CondensersDocument15 pagesSteam Surface CondensersUmangtarang100% (1)

- PQ070XF02SZH: Features Outline DimensionsDocument4 pagesPQ070XF02SZH: Features Outline DimensionsJulio Cesar CastilloNo ratings yet

- Introduction To Philosophy of The Human Person: Quarter 2 (Week 2)Document7 pagesIntroduction To Philosophy of The Human Person: Quarter 2 (Week 2)Nathalie SerafinNo ratings yet

- Edison Opto - PLCC - 3433 0.2W RGB 6PIN - 2T15X2M100037SA1 - Eng - V1 (3-RD-01-G0507)Document15 pagesEdison Opto - PLCC - 3433 0.2W RGB 6PIN - 2T15X2M100037SA1 - Eng - V1 (3-RD-01-G0507)Ufuk AricanNo ratings yet

- A Comparative Evaluation of Two Different Heat-Recovery Schemes As Applied To A Two-Bed Adsorption ChillerDocument11 pagesA Comparative Evaluation of Two Different Heat-Recovery Schemes As Applied To A Two-Bed Adsorption ChillersaruthanNo ratings yet

- Physics Test 02-02-12 Final 12Document13 pagesPhysics Test 02-02-12 Final 12Dewan Olin ChotepadaeNo ratings yet

- Composite Materials: Design, Analysis & ApplicationsDocument10 pagesComposite Materials: Design, Analysis & ApplicationsTayyab AttariNo ratings yet

- Loops ProteinsDocument37 pagesLoops ProteinsSanjeev KumarNo ratings yet

- Danaher Motion - Kollmorgen AKM Series DatasheetDocument46 pagesDanaher Motion - Kollmorgen AKM Series Datasheetcristian2340No ratings yet

- l3 Probability DistributionsDocument3 pagesl3 Probability Distributionsapi-287224366No ratings yet

- American Welding Society Welding SymbolsDocument11 pagesAmerican Welding Society Welding SymbolsGVNo ratings yet

- Inprocess Inspection ReportDocument8 pagesInprocess Inspection Reportpardeep kumarNo ratings yet

- Academic Lyceum "Physical-Technical High School" Named After Zh. I. AlfyorovDocument13 pagesAcademic Lyceum "Physical-Technical High School" Named After Zh. I. AlfyorovАмир АхундзяновNo ratings yet

- 20 FAQ Phy 2024Document23 pages20 FAQ Phy 2024dav02032006No ratings yet

- MRI The Basics Book ReviewDocument1 pageMRI The Basics Book ReviewSamantha ToNo ratings yet

- Carbonyl Compounds I: 6 Edition Paula Yurkanis BruiceDocument91 pagesCarbonyl Compounds I: 6 Edition Paula Yurkanis BruiceAssyakurNo ratings yet

- 6061 Aluminum Material Property Data SheetDocument6 pages6061 Aluminum Material Property Data Sheetneurolepsia3790No ratings yet

- SLHT Sci 8 Q3 Wk3Document7 pagesSLHT Sci 8 Q3 Wk3Jim Alesther LapinaNo ratings yet

- 30 - Kerstel Grenoble - NanobobDocument13 pages30 - Kerstel Grenoble - NanobobPatrick GelardNo ratings yet

- Design of Retaining Wall..Document9 pagesDesign of Retaining Wall..Sovan PramanickNo ratings yet

- 2, FibresDocument70 pages2, FibresDiwakar KumarNo ratings yet