Professional Documents

Culture Documents

Pdoc 53 2013 Ra 04

Uploaded by

Akram FerchichiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pdoc 53 2013 Ra 04

Uploaded by

Akram FerchichiCopyright:

Available Formats

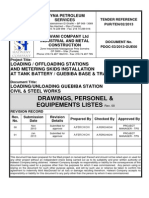

Client

THYNA PETROLEUM SERVICES

7 Avenue Abdelrahmen El Ghafiki BP 069 / 3069 Sfax-Hached Sfax (Tunisia) Phone: 216 74 229 999 - Fax: 216 74 299 916

TENDER REFERENCE PUR/TEN/02/2013

Constructor

HALWANI COMPANY Ltd INDUSTRIAL AND METAL CONSTRUCTION

Zone Industrielle Madagascar Prs Somatra CP 3000 Sfax (Tunisia) Phone: 216 74 497 166/010 - Fax: 216 74 497 795

DOCUMENT No. PDOC-53/2013-RA-04

Project Title:

LOADING / OFFLOADING STATIONS AND METERING SKIDS INSTALLATION AT TANK BATTERY / GUEBIBA BASE & TRAPSA

RISK ASSEMEMENT Rev. 00

REVISION RECORD

Rev. No.

00

Submission Date

Oct 28 2013

Revision Details

Submitted for approval

Prepared By Checked By

A.FERCHICHI A.FERCHICHI

Approved by

This document has been prepared for the titled project or named part thereof and should not be relied upon or used for any other project without an independent check being carried out as to its suitability and prior written authority of Halwani Company being obtained. Halwani Company accepts no responsibility or liability for the consequences of this document being used for a purpose other than the purposes for which it was commissioned. Any person using or relying on the document for such other purpose agrees, and will by such use or reliance be taken to confirm his agreement to indemnify Mott MacDonald for all loss or damage resulting therefrom. Halwani Company accepts no responsibility or liability for this document to any party other than the person by whom it was commissioned.

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: RISK ASSESSMENT PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-RA-04 Rev. : 00 Sheet : 2 of 11

Job Number Task or Work activities

: :

OF 053/2013 Supply and Erection of Trucks loading and offloading steel stations at Tank Battery / Guebiba base & Trapsa, including procurement and pre-construction will all Civil & Steel Works needs. TANK BATTERY Station GUEBIBA Base TRAPSA Terminal Civil Works: Concrete Mixer Truck, Concrete Pump, Hoses / Concrete shoots, Concrete buckets, Air Compressor, Survey Equipment, Level, Total Station ( Surveying instrument for checking the levels & distances ), Masonry Accessories, Wheel Barrows, Concrete Vibrators Erection Steel Works: Ladders, Mobile Scaffold, Hand tools, Forklifts, Crane

Site(s)

Equipment to be used

Working Environment Hazards Safety equipment to be used

: : :

Oil & Gas production and/or Storage area(s) Working at height, weather, moving vehicles, Safety harness & lanyard, hard hats, gloves, overall clothing (with hi-viz clothing in need), goggles, safety footwear All staff are experienced in the erection of steel frames structure and fully aware of risks involved. Only qualified personnel to operate plant. Young persons, persons with condition, anyone with a disability. a medical

Employees involved

Employees especially at risk

Non Employees who may be at risk :

Clients staff, other contractors near to work area, visitors.

Rev. : 00

Sheet : 2 of 11

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: RISK ASSESSMENT PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-RA-04 Rev. : 00 Sheet : 3 of 11

ACTIVITY Sequence of working activities Vehicle/ Equipment movement inside the restricted area

HAZARDS The potential to cause harm (heath, Injury, Property damage, environment etc.) Vehicle movement

CONSEQUANCES (The harm which could possibly occur) Driver Labors Forman

RISK RATING F 2 S 3 R HIGH

CONTROL MEASURES Describe controls that are required to be taken

RESIDUAL RISK F S 2 R LOW

Close supervision Identify vehicle routes Vehicle to leave the area once job is complete Journey Management system to be implemented

Manual Excavation

Employees working near the pits Environmental hazard H2S

Labors Forman

HIGH

All heavy machinery / vehicles should not be allowed working without assessing banks man Carry out a physical survey to whole surrounding area Limited workers allow to work at one location Close supervision

LOW

Mechanical excavation

Employees working near the moving equipment/trench Environmental hazard Equipment moving

Driver Labors Forman

HIGH

Emergency procedure and contingency plan to be in place and cascaded to all crew members and really available at sit locations Primary and secondary assembly point to be assigned by considering the prevailing Close supervision

LOW

F = Frequency

S = Severity

R = Rating (FxS) = High (6 & 9), Medium (3 & 4), and Low (1 & 2)

Rev. : 00

Sheet : 3 of 11

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: RISK ASSESSMENT PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-RA-04 Rev. : 00 Sheet : 4 of 11

Lifting operation and installation of pre-cast foundations and slabs foundations and slabs into the trench

Lifting Wind speed

Labors Forman

HIGH

Close supervision Identify rigging location Lifting machine placement shall be at safe distance from live lines/equipment Lifting machine leave the plant once complete the job

LOW

Mixing & Pouring of concrete

Cement Moving parts of the rotating mixer

Labors Forman

HIGH

Close supervision

LOW

Back filling and Compacting of sand & Gatch

Moving Equipment operation Dust Vibration Impact/Hitting from compacting machine

Labors Forman Operator

HIGH

All rotating parts of the machine should be in place Avoid long time exposure to dust/vibration: frequent rests Employ a minimum hand grip to observe less vibration

LOW

F = Frequency

S = Severity

R = Rating (FxS) = High (6 & 9), Medium (3 & 4), and Low (1 & 2)

Rev. : 00

Sheet : 4 of 11

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: RISK ASSESSMENT PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-RA-04 Rev. : 00 Sheet : 5 of 11

Erection of precast elements with mobile/crane

fall of person from height Failure of slings or other lifting gears Electrocution from portable hand tools Cut and bruise injuries to erectors Unsafe lifting and fixing by erectors Untrained erectors Miss communication between rigger, tirfor lifters and crane operator. Structural failure Collapse of edge protection

Erector Forman

HIGH

All works to be carried out as per approved method statement document All crane lifts to be controlled by a competent and authorize signaler/Banks man. The crane will be tested and certified as per manufacturers regulations. All lifting gear (Slings, chain, etc.) to be tested. Daily before the start of work Forman should visually examine all lifting gears for any defects: Responsibility Site Forman Only competent erectors to be used for the structure erection Mutually understandable signals to be used between crane operator and rigger. If necessary use the walky talkie All erectors to use full body harness and latch them to the standard lifeline Forman should inspect the precast structure on arrive for any crack or defects than can lead to the collapse of it during erection All the workers and staff should have specifics site safety induction by safety officer and records to be kept. recommendations and statuary

LOW

F = Frequency

S = Severity

R = Rating (FxS) = High (6 & 9), Medium (3 & 4), and Low (1 & 2)

Rev. : 00

Sheet : 5 of 11

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: RISK ASSESSMENT PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-RA-04 Rev. : 00 Sheet : 6 of 11

Unloading of structure parts

Failure of Crane, Slings, clutch Fall of persons from height Crushing injuries to workers caused by coming between structure parts and truck Overloading the crane Structural failure Impact or collision

Labor Operator

HIGH

Respective supervisor/ operator should examine the slings Clutches, before starting the work. Cranes should have valid third party inspection certificate Clearly marking safe working load Labors should use ladders to go up release the clutch Labors always wear full body harness and latch them at Top Labors should be very careful during the work and not to put body parts under the structure part(s) Competent and trained operator to do the lift Every lift has to be pre-planned.

LOW

Scaffolding & Ladders

Collapse of scaffold Fall from height Falling from ladders Falling objects Crane associated hazards Splinters, protruding nails, sharp edges Unsafe positioning of

Rigger Operator Labor

HIGH

Scaffold must be erected by competent person/ under competent supervision. All crane lifts to be controlled by a competent and authorize signaler /Banks man. This risk assessment must be communicated to the workers on site. An effective access/egress design is to be followed All platforms are to be fully boarded and hand

MED

F = Frequency

S = Severity

R = Rating (FxS) = High (6 & 9), Medium (3 & 4), and Low (1 & 2)

Rev. : 00

Sheet : 6 of 11

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: RISK ASSESSMENT PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-RA-04 Rev. : 00 Sheet : 7 of 11

ladders

railed No board is to be unrestrained at its ends. Toe boards are to be installed on all used platform levels. Tool-retainers (boxes and buckets) to be used to reduce the risk of tools falling form scaffold. All workers in elevated positions are to wear a safety harness. Secure the ladders/ stairs properly. Minimize number of people in the area. A suitable qualified supervisor or deputy should be present during the erection of the scaffolds. Stairs should have regular landings where workers can rest effectively. Regular cleaning will be done to minimize trip hazards and the buildup of surplus materials on platforms

10

Hot Work Operation

Fire and explosion Metal spatter Prolonged exposure to heat Gases & fumes Improper welding equipments

Welder Helper

HIGH

A competent fire watch with suitable fire extinguishers must be Improper welding equipments present at hot work area Where possible all flammable material should be removed from the welding operations area. Only competent and authorized personnel to use equipment (i.e. welders, cutter/burners).

LOW

F = Frequency

S = Severity

R = Rating (FxS) = High (6 & 9), Medium (3 & 4), and Low (1 & 2)

Rev. : 00

Sheet : 7 of 11

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: RISK ASSESSMENT PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-RA-04 Rev. : 00 Sheet : 8 of 11

Free standing/without protection cap for Gas Bottles Incorrect PPE

Appropriate PPE to be used when carrying out hot works operations Equipment to be well maintained and inspected as per Manufacturers recommendations. All oxy/Acetylene cutting sets must be provided with flash back arresters. Cylinders must be stored, handled and transported in a safe manner. Effective fume control equipment should be provided when working in confined area. (in need) Extra ventilation should be introduced to reduce the likelihood of heat stress occurrence. (in need) The placing of a second person on stand-by in case of emergency should be considered. Prolonged welding operations to be shielded from the sightline of adjacent operatives to reduce the risk of 'arc-eve'.

11

Work at height

Fall person Absence edge protection Trips Falling object from up Improper Accesses

Labor Staff

HIGH

Provide guardrail all the un-protected edges Close the open wholes property Arrange barricading and warning signs wherever needed. Must wear full body harness and latch the lanyard. Work area very clear

MED

F = Frequency

S = Severity

R = Rating (FxS) = High (6 & 9), Medium (3 & 4), and Low (1 & 2)

Rev. : 00

Sheet : 8 of 11

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: RISK ASSESSMENT PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-RA-04 Rev. : 00 Sheet : 9 of 11

Make sure nobody can have work in the up Before using any access make inspection it is safe Secured your tools by wire rope

12

Office Activities (Temp Cabins)

Fire Poor House keeping Slip, trip and falls Poor posture Improper use of work station Over loading of electric sockets Trailing cables on walk ways

Office Staffs

HIGH

Good housekeeping habit must be enforced Control smoking in temporary cabins Ensure firefighting procedure Provide emergency access and keep them clear always. Train employees on manual handling and ergonomics where applicable. Use conduits for electrical cords. Use right kitchen wares and equipments Prepare emergency evacuation plan and taught to office staffs Assign trained fire warden for all areas.

LOW

F = Frequency

S = Severity

R = Rating (FxS) = High (6 & 9), Medium (3 & 4), and Low (1 & 2)

Rev. : 00

Sheet : 9 of 11

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: RISK ASSESSMENT PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-RA-04 Rev. : 00 Sheet : 10 of 11

1. Risk assessment to be made available and approved by the Owner of the project 2. Method Statement to be made available and approved by the Owner of the project 3. Ensure that all manpower safety inducted and know the Emergency numbers (Fire = 198 | Medical 190)

F = Frequency

S = Severity

R = Rating (FxS) = High (6 & 9), Medium (3 & 4), and Low (1 & 2)

Rev. : 00

Sheet : 10 of 11

HALWANI COMPANY Ltd AUTHOR: AKRAM FERCHICHI DOC.: RISK ASSESSMENT PROJECT: LOADING / OFFLOADING STATIONS

Job No : 53-2013 PDOC-53/2013-RA-04 Rev. : 00 Sheet : 11 of 11

F = Frequency

S = Severity

R = Rating (FxS) = High (6 & 9), Medium (3 & 4), and Low (1 & 2)

Rev. : 00

Sheet : 11 of 11

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Flange Asme ViiiDocument21 pagesFlange Asme Viiizahidwahla1No ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 4 SOC ConsultingDocument54 pages4 SOC Consultingriadelidrissi100% (3)

- Risk Assessment, Mitigation, & Contingency PlanDocument16 pagesRisk Assessment, Mitigation, & Contingency PlanAliNo ratings yet

- PCI Pulley Selection Guide 2014Document32 pagesPCI Pulley Selection Guide 2014Akram FerchichiNo ratings yet

- Lighting Control SystemDocument5 pagesLighting Control SystemarifzakirNo ratings yet

- Method Statement: Loading / Offloading Stations and Metering Skids Installation at Tank Battery / Guebiba Base & TrapsaDocument13 pagesMethod Statement: Loading / Offloading Stations and Metering Skids Installation at Tank Battery / Guebiba Base & TrapsaAkram FerchichiNo ratings yet

- Water and Wastewater Calculation Spreadsheet InstructionsDocument10 pagesWater and Wastewater Calculation Spreadsheet InstructionsshahqazwsxNo ratings yet

- Observation Training Report GCTDocument32 pagesObservation Training Report GCTAkram FerchichiNo ratings yet

- IT Project ManagementDocument139 pagesIT Project ManagementThirukkovlaur Raghuveer100% (1)

- FIDIC (Silver Book)Document15 pagesFIDIC (Silver Book)a74engNo ratings yet

- Great Accounting Topics For Your Research PaperDocument11 pagesGreat Accounting Topics For Your Research PaperJennybabe Peta100% (2)

- DNV Lifeboats and Rescue Boats 2007Document16 pagesDNV Lifeboats and Rescue Boats 2007Akram FerchichiNo ratings yet

- Positive Theory of Accounting Policy and DisclosureDocument6 pagesPositive Theory of Accounting Policy and DisclosureMirnah AmirNo ratings yet

- Pulse TechnipDocument24 pagesPulse TechnipHendrico PanggabeanNo ratings yet

- Belt Conveyor PulleysDocument24 pagesBelt Conveyor PulleysPok Jak Salleh100% (2)

- Design, Construction and Evaluation of An Experimental Ceramic Membrane Facility With Investigation Into Fouling ControlDocument157 pagesDesign, Construction and Evaluation of An Experimental Ceramic Membrane Facility With Investigation Into Fouling ControlAkram FerchichiNo ratings yet

- Risk Management Module 1Document56 pagesRisk Management Module 1Genrev Garcia100% (1)

- Steel Structure Design Report for Loading Station ShelterDocument35 pagesSteel Structure Design Report for Loading Station ShelterAkram FerchichiNo ratings yet

- Teaching Students With Emojis, Emoticons, & Text SpeakDocument49 pagesTeaching Students With Emojis, Emoticons, & Text SpeakNastase Daniela EcaterinaNo ratings yet

- Cheat Sheets: Change Management Best PracticeDocument31 pagesCheat Sheets: Change Management Best PracticeJodeeNo ratings yet

- Note de Calcul Mécanique Convoyeur OCPDocument11 pagesNote de Calcul Mécanique Convoyeur OCPAkram FerchichiNo ratings yet

- Asia AIDocument17 pagesAsia AIhungbkpro90No ratings yet

- Structural Toolkit V3Document13 pagesStructural Toolkit V3Akram FerchichiNo ratings yet

- UX Ethnography and PossibilitiesDocument80 pagesUX Ethnography and PossibilitiesAkram FerchichiNo ratings yet

- 10 Ways Bad Bosses Destroy Employee MotivationDocument16 pages10 Ways Bad Bosses Destroy Employee MotivationAkram FerchichiNo ratings yet

- Allaboutailuminarylabsjanuary122017 170112151616Document28 pagesAllaboutailuminarylabsjanuary122017 170112151616pruebaprueba00No ratings yet

- Rapport Heli WinchDocument29 pagesRapport Heli WinchAkram FerchichiNo ratings yet

- Note de Calcul Convoyeur MarocDocument10 pagesNote de Calcul Convoyeur MarocAkram FerchichiNo ratings yet

- Note de Calcul Convoyeur MarocDocument10 pagesNote de Calcul Convoyeur MarocAkram FerchichiNo ratings yet

- Design Calculations Reboiler & Surge VesselDocument161 pagesDesign Calculations Reboiler & Surge VesselAkram Ferchichi100% (1)

- Fire Safety Provision For LPG Storage Tank - Tawar MallDocument3 pagesFire Safety Provision For LPG Storage Tank - Tawar MallAkram FerchichiNo ratings yet

- E40000 Aquatherm Red Pipe 02Document74 pagesE40000 Aquatherm Red Pipe 02Akram FerchichiNo ratings yet

- Pdoc 53 2013 Gue General DrawingsDocument10 pagesPdoc 53 2013 Gue General DrawingsAkram FerchichiNo ratings yet

- Pdoc 53 2013 Gue General DrawingsDocument7 pagesPdoc 53 2013 Gue General DrawingsAkram FerchichiNo ratings yet

- Pdoc 53 2013 Gue General DrawingsDocument10 pagesPdoc 53 2013 Gue General DrawingsAkram FerchichiNo ratings yet

- Pdoc 53 2013 Fi 06Document5 pagesPdoc 53 2013 Fi 06Akram FerchichiNo ratings yet

- GRATINGS Gitterrost EngDocument72 pagesGRATINGS Gitterrost EngNajib KiwanNo ratings yet

- GUEBIBA Loading-Offloading StationDocument9 pagesGUEBIBA Loading-Offloading StationAkram FerchichiNo ratings yet

- PQR & WQ - Storage Tank TUNISAIR TECHNICS PDFDocument23 pagesPQR & WQ - Storage Tank TUNISAIR TECHNICS PDFAkram FerchichiNo ratings yet

- Moral N Ethical Issues in Human Genome Editing 2019 1120 GE - CECDocument87 pagesMoral N Ethical Issues in Human Genome Editing 2019 1120 GE - CECJoseph ChanNo ratings yet

- PWC How Malaysian Banks Can Keep The Lights On and Recalibrate For The FutureDocument9 pagesPWC How Malaysian Banks Can Keep The Lights On and Recalibrate For The FutureNurhayatiNo ratings yet

- Risk Based Verification: DNV-OSS-300Document28 pagesRisk Based Verification: DNV-OSS-300IzaMtzNo ratings yet

- Construction ErgonomicsDocument33 pagesConstruction ErgonomicsShailesh AtkariNo ratings yet

- Citibank EuroclearDocument8 pagesCitibank EuroclearGlaucia F SiqueiraNo ratings yet

- Bunny Health Teaching PlanDocument5 pagesBunny Health Teaching Planbigdipper102090No ratings yet

- Week 1: Third Quarter-Health 9Document3 pagesWeek 1: Third Quarter-Health 9Catherine Sagario OliquinoNo ratings yet

- 10 Axioms of FinManDocument1 page10 Axioms of FinManNylan NylanNo ratings yet

- BSBSTR801 Project PortfolioDocument12 pagesBSBSTR801 Project PortfolioraviNo ratings yet

- OCCUPATIONAL - SAFETY - AND - HEALTH - ISSUES - IN20200303 80220 Ic4o3h With Cover Page v2Document21 pagesOCCUPATIONAL - SAFETY - AND - HEALTH - ISSUES - IN20200303 80220 Ic4o3h With Cover Page v2GAANJANA SUDHARANo ratings yet

- OS Power System Opt MGT L5Document38 pagesOS Power System Opt MGT L5ProNo ratings yet

- Evaluasi Tindak Lanjut Temuan Audit Internal Sebagai Unsur Mengoptimalkan Pengelolaan KeuanganDocument12 pagesEvaluasi Tindak Lanjut Temuan Audit Internal Sebagai Unsur Mengoptimalkan Pengelolaan KeuanganjeffryNo ratings yet

- Competency Standards With Performance Indicators and Code of Ethics PDFDocument17 pagesCompetency Standards With Performance Indicators and Code of Ethics PDFrenandNo ratings yet

- Risk Management: by DR Safdar A ButtDocument18 pagesRisk Management: by DR Safdar A ButtMunnah BhaiNo ratings yet

- Informed Consent Informed Consent: Annex ADocument3 pagesInformed Consent Informed Consent: Annex AJason PaquibulanNo ratings yet

- Practical Aspects in Health, Safety, Welfare in The Work EnvironmentDocument14 pagesPractical Aspects in Health, Safety, Welfare in The Work EnvironmentkailasamsomuNo ratings yet

- Basic Security Safety Awareness Session PlanDocument8 pagesBasic Security Safety Awareness Session Planraregala.safetyNo ratings yet

- Property & Casualty Insurance Price OptimizationDocument5 pagesProperty & Casualty Insurance Price OptimizationTamara AlvaradoNo ratings yet

- HIRARC PRCTDocument16 pagesHIRARC PRCTLeo OelNo ratings yet

- Assessment of Smart Home: Security and PrivacyDocument18 pagesAssessment of Smart Home: Security and Privacybez plagijataNo ratings yet