Professional Documents

Culture Documents

Us 20030130549

Uploaded by

Văn Đại - BKHNOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Us 20030130549

Uploaded by

Văn Đại - BKHNCopyright:

Available Formats

US 20030130549A1

(19) United States (12) Patent Application Publication (10) Pub. No.: US 2003/0130549 A1

Xie et al.

(54) PROCESS FOR SELECTIVE

DISPROPORTIONATION 0F TOLUENE AND

DISPROPORTIONATION AND Oct. 22, 2001 (CN) ..................................... .. 011319534

(43) Pub. Date:

(30)

Jul. 10, 2003

Foreign Application Priority Data

TRANSALKYLATION OF TOLUENE AND C9+ AROMATICS

Publication Classi?cation

(51) Int. Cl? ................................................... .. c07c 15/12

(75) Inventors: Zaiku Xie, Shanghai (CN); Weisheng

Yang, Shanghai (CN); Dejin Kong, Shanghai (CN); Dongmao Zhu, Shanghai (CN)

Correspondence Address: COHEN, PONTANI, LIEBERMAN & PAVANE

Suite 1210 551 Fifth Avenue

(52)

US. Cl. ............................................................ ..585/475

(57)

ABSTRACT

The present invention relates to a process for the selective

New York, NY 10176 (US)

disproportionation of toluene and the disproportionation and transalkylation of toluene and C9+ aromatics to mainly solve the problems in the prior arts of the great amount of recycle stream, high energy consumption or harsh requirement for

the reaction feedstocks. The present invention has better solved these problems by the technical solution using a process for selective disproportionation of toluene to pro

(73) Assignees: China Petroleum & Chemical Corpo ration; Shanghai Research Institute of Petrochemical Technology

duce mixed Xylenes containing a high concentration of

p-Xylene, and subsequent disproportionation and transalky

lation of C9+ aromatics and toluene to produce benzene and the mixed Xylenes Which are in the thermodynamic equilib rium. The process is applicable to the industrial production.

(21) Appl. No.:

(22) Filed:

10/277,694

Oct. 22, 2002

Patent Application Publication

Jul. 10, 2003 Sheet 1 0f 2

US 2003/0130549 A1

<3 F

1

i. 1

.4

P1.

6

B i

A

9

13

15 5

IV

16

+~~14

->12

PRIOR ART

Patent Application Publication

Jul. 10, 2003 Sheet 2 0f 2

US 2003/0130549 A1

17

L

_L___.,

M 2 "

if

4

I 7

* A,

l-+ 11

F" 9

6

5

H

13

___8~_,l

I

15

[V

16

l]V i

~---14 III L

US 2003/0130549 A1

Jul. 10, 2003

PROCESS FOR SELECTIVE DISPROPORTIONATION OF TOLUENE AND DISPROPORTIONATION AND TRANSALKYLATION OF TOLUENE AND C9+ AROMATICS

PRIORITY CLAIM

molecular sieve is used as the catalyst to treat a toluene

feedstock yielding C8A With a high concentration of p-xy lene (85-90% by Weight, the same beloW except otherWise noted) and nitration grade benZene. In the PX-Plus process, no industrialiZation of Which has been reported, to appli cants knowledge, the major reaction performance is a PX

selectivity of 90%, a mole ratio of benZene to PX of 1.37 in case of the toluene conversion of 30%.

[0001] This application claims priority from China Patent

Application Number 011319534 Which Was ?led on Oct.

[0008] Nevertheless, in these toluene selective dispropor

tionation processes, a high p-xylene selectivity is accompa nied by a harsh requirement to the feedstock selection, and

only toluene can be used as the feedstock. C9+A has no use for these processes, and at least it can not be directly used.

22, 2001.

BACKGROUND OF THE INVENTION

[0002]

[0003]

1. Field of the Invention

The present invention relates to a process for the

This is a vital shortcoming of the selective disproportion ation process.

selective disproportionation of toluene, and the dispropor tionation and transalkylation of toluene and C9+ aromatics

(C9+A), in particular it relates to a process for the selective

[0009]

The feed for the reactor of a typical Tatoray process

is toluene and C9 aromatics (C9+A). The xylenes produced

in the Tatoray process are a mixture of the isomers in

disproportionation of toluene, and the disproportionation

and transalkylation of toluene and C9+ aromatics followed by a process for producing p-xylene (PX) by a technique of the isomeriZation of C8 aromatics (C8A) and a technique of

thermodynamic equilibrium, and generally, the content of p-xylene having the most industrial application value is only about 24%. Compared to the selective disproportionation of

toluene Wherein mixed xylenes having a p-xylene concen tration of about 90% can be obtained, the Tatoray process is obviously inferior in this aspect, but a great advantage of the Tatoray process over the toluene selective disproportion ation process is that the Tatoray process can convert CQA to

p-xylene separation.

[0004] 2. Description of the Related Art

[0005] p-xylene is one of the major basic organic feed

stocks in petrochemical industry and has Widespread appli

cations in many ?elds such as chemical ?ber, synthetic resin, pesticide, medicine, plastic, etc. The traditional process for

benZene and xylenes.

[0010] The literature based on the Tatoray Process

producing p-xylene is shoWn in FIG. 1. C8 aromatics (C8A) in thermodynamic equilibrium produced from the catalytic

reforming process of naphtha passes through a multi-stage

subZero crystalliZation separation or molecular sieve simu

includes US. Pat. Nos. 4,341,914, 2,795,629, 3,551,510,

CN98110859.8, CN97106719.8, etc. The process disclosed

lation moving bed separation (abbreviated as adsorptive separation) to separate p-xylene from its isomer mixture With near boiling points. A C8A isomeriZation (abbreviated

as isomeriZation) process is generally used to isomeriZe

by the representative US. Pat. No. 4,343,914 comprises conducting the aromatics fractionation of the reformed prod uct, feeding the derived toluene and CQA to the Tatoray unit to conduct disproportionation and transalkylation reactions, recycling toluene, CQA, and a part of C10 aromatics (CloA)

after separating the products, WithdraWing benZene as a

o-xylene and m-xylene to p-xylene. The use of dispropor tionation of toluene, or the disproportionation and transalky lation of toluene and C9+ aromatics (C9+A) to produce

benZene and C8A, is an effective route for increasing the

product, feeding xylene together With the xylene from the

isomeriZation unit to the PX separation unit to separate the

high purity of p-xylene product. The other isomers of xylene

are fed to the isomeriZation unit to conduct the isomeriZation

output of p-xylene.

[0006] So far, the typical and mature processes relating to toluene disproportionation in the World are the Tatoray traditional toluene disproportionation process of UOP Inc.

industrialiZed in the end of 1960s, the MTDP process of

reaction of xylene, yielding the mixed xylenes in thermo

dynamic equilibrium again.

[0011] One representative aromatics complex based on the selective disproportionation process is the PX-Plus Process. The greatest difference betWeen the PX-Plus Process and the

Mobil Chemical Company developed in the end of 1980s,

the S-TDT process of Shanghai Institute of Petrochemical

traditional aromatics complex Tatoray process is that C9+A

is WithdraWn as a byproduct instead of as a feed in the

Industry developed recently, and the TransPlus transalkyla

tion process of heavy aromatics of Mobil Chemical Com

pany. The selective disproportionation of toluene is a neW

PX-Plus process.

route for producing p-xylene. Since the selective dispropor

tionation of toluene on modi?ed ZSM-5 catalysts can pro

[0012] It is readily seen from summariZing the above processes that the traditional aromatics production process uses the disproportionation and transalkylation process to

duce benZene and C8A With a high concentration of p-xy

lene, the dif?culty in the separation of p-xylene is greatly

alleviated. In recent years, along With the improvement of the catalyst performance, this process has made a great

progress. The typical processes are the Mobil toluene selec

attain the object of increasing the output of xylenes, but the amount of the recycled xylenes is large since the produced mixed xylenes are the isomers of xylene in the thermody

namic equilibrium and therefore the concentration of p-xy lene is loW. The other isomers of xylene have to pass through the isomeriZation unit to be converted to p-xylene, thus

tive disproportionation process MSTDP industrialiZed in late 1980s and the UOP toluene selective disproportionation process PX-Plus developed in late 1990s.

[0007] In the industrialiZed toluene selective dispropor

tionation process MSTDP, a converted ZSM-5 mesoporous

resulting in heavy xylene recycles and high energy con sumption in the isomeriZation unit, PX separation unit and aromatics fractionation unit. Although mixed xylenes With high concentration of p-xylene can be obtained by the aromatics production process using the selective dispropor

US 2003/0130549 A1

Jul. 10, 2003

tionation process, and thereby the feeds of the isomeriZation unit and the like are greatly reduced, the selective dispro

portionation process can not treat C9+A, Which results in a Waste of the C9+A resource, and a reduced output of the

tion considered in conjunction With the accompanying draW ings. It is to be understood, hoWever, that the draWings are

designed solely for purposes of illustration and not as a de?nition of the limits of the invention, for Which reference should be made to the appended claims. It should be further understood that the draWings are not necessarily draWn to

target product, p-xylene.

[0013] Therefore, it is very desirable to develop a process

for producing high yield of the desire product p-xylene,

Which does not have harsh strict requirement to the feed stock. It is also desirable to greatly reduce the energy

scale and that, unless otherWise indicated, they are merely intended to conceptually illustrate procedures described

herein.

BRIEF DESCRIPTION OF THE DRAWINGS

consumption or increase the capacity of processing the

feedstock.

SUMMARY OF THE INVENTION

[0024] In the draWings:

[0025]

[0026]

[0014] Thus, one object of the present invention is to overcome the shortcomings present in the prior art of loW concentration in the mixed xylenes, high energy consump tion, or harsh requirement to the reaction feedstock in the

FIG. 1 is the How diagram of the traditional

FIG. 2 is the How diagram of the process for

complex for aromatics production.

selective disproportionation and disproportionation and

production of p-xylene.

[0015] Another object of the present invention is to pro

vide a novel process for the selective disproportionation of

transalkylation of xylene+C9+A for producing p-xylene in

accordance With one embodiment of the present invention.

DETAILED DESCRIPTION OF THE PRESENTLY PREFERRED EMBODIMENTS

toluene and the disproportionation and transalkylation of toluene and C9+ aromatics. The improved economical viabil ity and pro?tability of producing p-xylene are obtained by increasing the capacity of the Whole process and the output

[0027] Typically, the feed stream comprising benZene,

toluene, C8 aromatics, and C9+ aromatics may be from a catalytic reforming unit Where the feedstock naphtha is

converted to an oil rich in aromatics Which further undergoes the treatment of depentaniZing and aromatics extraction etc. The benZene separated from this feed stream may be sent out

of the target products p-xylene and benZene, greatly reduc ing the scale of the p-xylene separation unit, isomeriZation unit, and the aromatics fractionation unit, and thereby

decreasing the energy consumption of the Whole process.

[0016] These and other objects are attained by a novel process of the selective disproportionation of toluene and the

the separation unit as a product. C10+ aromatics, if present in

the feed stream, may also be separated from this feed stream and sent out the separation unit as a product, and the purity

disproportionation and transalkylation of toluene and C9+ aromatics comprising:

[0017] a) separating a feed stream comprising ben Zene, toluene, C8 aromatics, and C9+ aromatics into

a ?rst benZene stream, a toluene stream, a ?rst C8

of C9 aromatics in the separated C9+ aromatics stream may

be further increased in this case.

[0028]

In accordance With the present invention, the sec

aromatics stream, and a C9+ aromatics stream;

ond C8 aromatics has a high purity of the target product p-xylene, thus the second C8 aromatics rich in p-xylene may

or may not be further separated to extract the p-xylene

[0018] b) introducing a part of the toluene stream into

a toluene selective disproportionation unit to conduct

the toluene selective disproportionation reaction for producing a ?rst effluent comprising C8 aromatics

product. It is preferable to send the second C8 aromatics to a p-xylene separation unit. The separation of the p-xylene target product from the second aromatics stream may be

conducted independently or With either or both of the ?rst

rich in p-xylene, and benZene;

[0019] c) separating a second C8 aromatics stream

and a second benZene stream from the ?rst ef?uent

and the third aromatics stream together. Similarly, the sepa ration of the p-xylene target product from the third aromatics

stream may be conducted independently or With either or

produced in the step of b);

both of the ?rst and second aromatics stream together. It is

preferable that the separation of the p-xylene from the ?rst,

the second, and third C8 aromatics stream is conducted in the same separation unit. The methods of separating the p-xy

[0020] d) introducing another part of the toluene

stream and the C9+ aromatics stream into a toluene

disproportination and transalkylation unit to conduct the toluene disproportionation and transalkylation

reaction in the presence of hydrogen for producing a

lene product from the C8 aromatics stream includes adsorp tive separation and subZero crystalliZation separation etc.

second ef?uent comprising C8 aromatics and ben

Zene;

[0029] After the target p-xylene is separated, the remain

ing mixed xylene is preferably sent to an isomeriZation unit to conduct the reaction of isomeriZation for converting the

[0021] e) separating a third C8 aromatics stream and

a third benZene stream from the second ef?uent

remaining mixed xylenes to the p-xylene. The effluent of the

isomeriZation unit may be sent to a deheptaniZer Where a C8+A stream is WithdraWn from the bottom, a stream con

produced in the step of d); and

[0022] f) separating the ?rst, and third C8 aromatics

stream into a p-xylene product and a remaining mixed xylenes stream.

taining benZene and toluene are WithdraWn from the top. The

C8+A stream may be sent to an aromatics fractionation unit

?rst, and the C8 aromatics separated may undergo a similar separation With the ?rst, second, or the third C8 aromatics

stream as discussed above, so that the p-xylene product can be obtained.

[0023] Other objects and features of the present invention Will become apparent from the folloWing detailed descrip

US 2003/0130549 A1

Jul. 10, 2003

[0030] The separation in the steps of a), c), and e) may be

conducted independently or With either or both of the other

selective disproportionation unit, toluene selective dispro

portionation reaction takes place, as a result, toluene con

tWo steps together. For example, the ?rst effluent and the

second effluent may enter the same aromatics fractionation

verts to p-xylene With high selectivity. This kind of process route not only can convert C9+A to xylenes, eliminating the

harsh requirement to the feedstock, but also can convert toluene to mixed xylenes With a high content of p-xylene

unit as employed in the step of a). Similarly, the separation

to C8+A stream derived from the isomeriZation unit may also be conducted independently or With at least one of the steps

through the selective disproportionation, further raising the

concentration of the p-xylene in the mixed xylene feed entering into the PX separation unit, facilitating the PX separation, and loWering the scale of the isomeriZation unit and the like, and thereby loWering the energy consumption

of the Whole aromatics complex and attaining a better

of a), c), and e) together.

[0031] In accordance With one preferred embodiment of

the present invention the separation of the step of c) is

speci?cally equipped With an aromatics fractionation unit so that it can be conducted independently. Preferably, the second C8 aromatics stream is further separated into a part of the p-xylene product and a residual liquid by the subZero

crystalliZation separation method. More preferably, the

residual liquid may be admixed With the ?rst and the third C8 aromatics stream to form a mixture, and then the mixture

technical effect. Besides, the present invention is especially applicable to the reconstruction of the existing aromatic complex for extension. The reconstruction is very simple:

reserving the disproportionation and transalkylation, isomer iZation, p-xylene separation, and aromatics fractionation

units as they are, setting up a neW selective disproportion ation unit. In this Way, it is possible to increase the output of

may be separated into the p-xylene product and the remain

ing mixed xylene by the adsorptive separation method.

[0032] The normal operation conditions of the reaction

Zone of the toluene selective disproportionation unit may be a pressure of 1-4 MPa, a reaction temperature of 300-480 C., a hydrogen to hydrocarbon mole ratio of 05-10, and a

p-xylene and benZene by raising the capacity of the reform

ing unit or purchasing an adequate amount of toluene, and

meanWhile, the energy consumption is obviously loWered

and better effects are obtained.

liquid Weight space velocity of 0.8-8 h_1; the catalyst used

in the toluene selective disproportionation unit may be a

[0034] NoW referring to FIG. 1 and FIG. 2, I represents

the aromatics fractionation unit, comprising a benZene sepa ration toWer, a toluene separation toWer and a xylene sepa

ZSM-type molecular sieve catalyst, and preferably a ZSM

S-type molecular sieve catalyst; the SiO2/Al2O3 mole ratio

of the ZSM-S-type molecular sieve is 15-100; the ZSM-S

ration toWer, and optionally a heavy aromatics separation

toWer to be dependent on the concrete situation; II represents

type molecular sieve preferably contains ODDS-5%, prefer

ably 0.01-1%, by Weight of at least one metal or oxide of the element selected from the group consisting of platinum,

the disproportionation and transalkylation unit; III repre

sents the PX separation unit; IV represents the isomeriZation unit; and V represents the toluene selective disproportion

ation unit. Whether units II and V are equipped With the independent aromatics separation device of their oWn

depends on the concrete situation. Line 1 is the mixed stream

molybdenum and magnesium. The normal operation condi

tions of the reaction Zone of the disproportionation and transalkylation unit may be are a reaction pressure of 1-5

MPa, a reaction temperature of 250-480 C., a hydrogen to

hydrocarbon mole ratio of 05-10, and a liquid Weight space velocity of 0.8-8 h_1, the content of C9 aromatics in the feed is 5-60% by Weight; the catalyst used in the disproportion

ation and transalkylation unit is at least one molecular sieve

selected from the group consisting of [3-Zeolite, mordenite, and MCM-22, With [3-Zeolite or/and mordenite being pre ferred; the SiO2/Al2O3 mole ratio of the molecular sieve is 10-100, preferably 10-50; the preferred catalyst is a catalyst

containing metal bismuth or its oxide, the amount of Which

is ODDS-5% by Weight, preferably ODS-2% by Weight. The

toluene from the aromatics fractionation unit is preferably the toluene separated in the aromatics fractionation unit or the toluene separated in the aromatics fractionation unit and

a foreign toluene from other available source as a supple

of benZene and toluene, line 2 is the C8+A stream WithdraWn from the bottom of the deheptaniZer, line 3 is the high purity benZene product WithdraWn from the top of the benZene toWer, line 4 is the toluene WithdraWn from the top of the toluene toWer, line 5 is the C8A WithdraWn from the top of the xylene toWer, line 6 is the CQA and a part of C1OA WithdraWn from the top of the heavy aromatics toWer of the aromatics fractionation unit I, line 7 is C10+A WithdraWn from the bottom of the heavy aromatics toWer, line 8 is the effluent WithdraWn from the bottom of the stabiliZation toWer of the disproportionation and transalkylation unit, line 9 is the benZene product, line 10 is the effluent WithdraWn

from the bottom of the stabiliZation toWer of the selective

ment. The amount of the toluene entering into the toluene

selective disproportionation unit is preferably 5-95%, more preferably 20-80% of the total amount of toluene. The Weight ratio of the toluene feed to the C9+ aromatics in the

disproportionation unit, line 11 is the benZene product, line 12 is the high purity p-xylene product, line 13 is the small amount of toluene separated from the PX separation unit, line 14 is the mixed xylenes after separating PX, line 15 is the C8+A stream WithdraWn from the bottom of the dehep

taniZer of the isomeriZation unit, and line 16 is the benZene and toluene-containing stream WithdraWn from the top of the deheptaniZer of isomeriZation unit IV and line 17 is a foreign toluene.

disproportionation and transalkylation unit is 80/20-40/60.

[0033] In the toluene disproportionation and transalkyla

tion unit of the present invention, the adopted bismuth containing Zeolite catalyst has the function to convert tolu

ene and C9+A to xylenes and benZene in the presence of

hydrogen through the disproportionation and transalkylation

reactions. Because the decrease in the proportion of toluene and increase in the proportion of CQA in the feedstock bene?t the occurrence of the transalkylation reaction of toluene and C9A+, more C8A is produced. In the toluene

[0035] The How scheme of the traditional complex for producing aromatics is shoWn in FIG. 1. BenZene and toluene stream 1 from the aromatics extraction unit and the bottom ef?uent C8+A stream 2 of the deheptaniZer of the catalytic reforming unit enter into the aromatics fraction ation unit I separately and the separated benZene stream 3

and C10+A stream 7 are WithdraWn as the products. Toluene stream 4 and C9+A stream 6 serve as the feed of toluene

US 2003/0130549 A1

Jul. 10, 2003

disproportionation and transalkylation unit II and mixed xylene stream 5 is fed to xylene separation unit III. Whether toluene disproportionation and transalkylation unit II is equipped With the aromatics separation device depends on

the concrete situation. When the aromatics separation device

[0037] The folloWing examples illustrate the invention Without limiting it.

EXAMPLE 1

[0038]

The capacity for producing PX and energy con

is equipped, nitration grade benZene product 9 is WithdraWn

from the selective disproportionation unit and C8A stream 8 enters into the PX separation unit to separate PX; When the toluene disproportionation unit is not equipped With the aromatics fractionationunit, bottom effluent 8 WithdraWn from the stripping toWer directly enters into the aromatics

sumption of the present invention Was examined based on

the composition of various substances of C6A-C1O+ aromat ics in the aromatics stream WithdraWn from the reforming unit of a typical aromatics complex as the fundamental data. [0039] Table 1 is the composition of the aromatics With draWn from a typical reforming unit and the How rates of

fractionation unit for separation. Target product p-xylene 12 is separated from p-xylene separation unit III, the small

amount of toluene 13 returns to the toluene disproportion

various components used in the present example.

TABLE 1

composition and floW rates of the reformed aromatics

ation unit, and other mixed xylenes 14 enter into xylene

isomeriZation unit IV to conduct the isomeriZation reaction.

C8+A stream 15 WithdraWn from the bottom of deheptaniZer

of the isomeriZation unit is fed to the aromatics fractionation unit and benZene- and toluene-containing stream 16 With draWn from the top of the deheptaniZer is fed to the aromatics extraction unit.

Component

Ben Tol

Content, %

11.65 43.09

FloW rate, kg/h

10000 37000

[0036]

The process How scheme of the complex for pro

C8A C9A C1D+A

E

31.45 11.51 2.30

100

27000 9882 1976

85858

ducing aromatics in accordance With one embodiment of the present invention is shoWn in FIG. 2. Compared to the

traditional process, the improvement of the present inven

tion is the addition of a toluene selective disproportionation unit based on the traditional process and the corresponding modi?cation of the process route. The similarity betWeen FIG. 1 and FIG. 2 Will not be described and the difference Will be described belloW in detail. The present process divides the toluene 4 Which entirely serves as the feed of the

[0040]

The feedstock shoWn in Table 1 and the aforesaid

technique of the present invention (aromatics fractionation device is included in the selective disproportionation unit)

are used to produce p-xylene. 75% of toluene stream 4 enters

into the selective disproportionation unit, and the remaining 25% enters into the disproportionation and transalkylation

unit. The Weight ratio of toluene to CQA Was 60/40. The

toluene disproportionation and transalkylation unit origi

nally into tWo streams. One still serves as the feed of the

catalyst used in the toluene selective disproportionation unit

Was a ZSM-5 molecular sieve With a SiO2/Al2O3 mole ratio

toluene disproportionation transalkylation unit and the

remaining toluene serves as the feed of toluene selective

of 50, on Which 0.1% by Weight of platinum Was supported;

the reaction conditions Were a reaction pressure of 1.5 MPa,

disproportionation unit V. Whether the selective dispropor tionation unit is equipped With the aromatics separation

device depends on the concrete situation. When the aromat

a reaction temperature of 420 C., a hydrogen to hydrocar bon mole ratio of 3, and a liquid Weight space velocity of 4 h_1. The catalyst used in the toluene disproportionation unit

Was a mordenite molecular sieve With a SiO2/Al2O3 mole

ics separation device is equipped, nitration grade benZene product 11 is WithdraWn from the selective disproportion ation unit. The unreacted toluene is recycled, and p-xylene rich C8A stream 10 enters into the subZero crystalliZation separation unit to separate PX; When the selective dispro portionation unit is not equipped With the aromatics frac tionation unit, bottom ef?uent 8 WithdraWn from the strip ping toWer directly enters into the aromatics fractionation

for separation, and no benZene stream 11 is WithdraWn. Foreign toluene 17 enters the aromatics fractionation unit I

as another stream of the feedstock.

ratio of 30, on Which 0.8% by Weight of bismuth Was

supported; the reaction conditions are a reaction pressure of 3.0 MPa, a reaction temperature of 360 C., a hydrogen to

hydrocarbon mole ratio of 6, and a liquid Weight space velocity of 1.5 h_1. Under the above situations, the feed and

effluent of the selective disproportionation unit, dispropor

tionation and transalkylation unit, and isomeriZation unit are shoWn in Table 2, the treating scales of various units of the aromatics complex are shoWn in Table 3, the outputs of the products p-xylene and benZene are shoWn in Table 4.

TABLE 2

Process materials in Example 1

Selective Disproportionation disproportionation and transalkylation

Component

Feed into Ben Tol

Isomerization

unit

0 125

Adsorptive separation

unit Xylene toWer

0 125

unit

11 86823

unit

3 27698

125

unit, Kg/h

CSA C9A

84

C1D+A

E

/ /

86918

238 18908 657

47505

161555 41

161722

21447 41

214613

214661 18979

3632

237398

US 2003/0130549 A1

Jul. 10, 2003

TABLE 2-continued

Process materials in Example 1

Selective Disproportionation disproportionation and transalkylation

Component

FloW- Ben out of Tol

Isomerization

unit

2061 1043

Adsorptive separation

unit

0 125

unit

12006 59799

unit

3866 16818

Xylene toWer

0 125

unit, kg/h

C8A C9A CHfA

E

12195 703 20

84723

15704 7540 1458

45386

155915 825

159844

214447 41

214613

214661 18979 3632

237398

Where Ben is benzene, T01 is toluene, CSA is C8 aromatics, C9A is C9 aromatics, and C1U*A is C10 and higher aromatics.

[0041]

TABLE 3

Treating scales of various units in Example 1

Disproportionation

and transalkylation

Unit unit

Adsorptive

Isomerization

unit

Xylene

Benzene/toluene

fractionation unit

separation

unit

fractionation

unit

Scale, kg/h

47505

161722

210658

96240

233214

[0042]

TABLE 4

based on the composition of the feedstock and 22% more How rate of the feed shoWn in Table 1. The composition and How rate of the feed are shoWn in Table 5. The speci?c

out ms and urities of the roducts in Exam 1e 1

Product p_Xy1ene Benzene Output, kg/h 48936 27933 Purim % 998 99-94

portionation unit, disproportionation and transalkylation

unit, and isomeriZation unit are shoWn in Table 6, the treating scales of various units of the aromatics complex are shoWn in Table 7, and the outputs of the products p-xylene and benzene are shoWn in Table 8.

TABLE 5

Contents and floW rates of the reformed aromatics

Component Content, % FloW rate, kg/h

situations of the feed and effluent'of the selective dispro

[0043] The results shoW that the energy consumption Was 575 Mkcal/t (p-xylene+benzene), Which Was reduced by 18% in the technique of the present invention relative to the

702 Mkcal/t (p-xylene+benzene) ~ in the ~ following Compara ' '

tive Example 1. In the present invention, the Weight con centration of the p-xylene in the mixed xylenes entering into

t'e a sorp rve separa 1on uni Was

Ben

Tol

(38A

11-65

3145

12200

32940

t.

t.

.t

0, W 1c

Was

43.09

45140

higher than that in the Comparative Example 1 (19.2%).

EXAMPLE 2

(39A

C1U+HCs 2

1151

2.30 100

12056

2410 104746

[0044] By still using the process ?oW, process conditions, and catalyst in Example 1, the capacity of the technique of

the present invention for producing PX Was re-examined [0045]

TABLE 6

Process materials in Example 2

Selective Disproportionation disproportionation and transalkylation

Component

Feed into Ben Tol

Isomerization

unit

0 153

Adsorptive separation

unit Xylene toWer

0 125

unit

13 105875

unit

4 33847

125

US 2003/0130549 A1

Jul. 10, 2003

TABLE 6-continued

Process materials in Example 2

Selective Disproportionation disproportionation and transalkylation

Component

unit, C8A Kg/h C9A Cuf'A

E FloW- Ben out of Tol

Isomerization

unit

201195 50

201397 2566 1296

Adsorptive separation

unit

214447 41

214613 0 125

unit

102 / /

105991 14641 72921

unit

295 23106 3819

61071 5323 20535

Xylene toWer

214661 18979 3632

237398 0 125

unit, kg/h

C8A C9A C1D*A

E

14871 857 24

103314

20126 9217 2017

57218

194172 1026

199060

214447 41

214613

214661 18979 3632

237398

[0046]

TABLE 7

Treating scales of various units in E amnle 2

Disproportionation

and transalkylation

Unit unit

Adsorptive

Isomerization

unit

Xylene

Benzene/toluene

fractionation unit

separation

unit

fractionation

unit

Scale, kg/h

61071

201397

261926

118380

289732

[0047]

TABLE 8

Outputs and purities of the products in Example 2

99.8% of that in Comparative Example 1. Therefore, by using the technique of the present invention, the treating

capacity of the device and the output of the products

p-xylene and benzene can be increased.

EXAMPLE 3

Product

p-xylene

Benzene

Output, kg/h

60528

34731

Purity, %

99.8

99.94

[0049] By still using the process ?oW, process conditions, and catalyst in Example 1, the capacity of the technique of

the present invention for producing PX Was re-examined based on the How rate of the feedstock shoWn in Table 1, but

[0048] Compared to Comparative Example 1, the treating

capacity of the device in Example 2 increased by 22%, the output of p-xylene increased by 18.4%, and the output of benzene increased by 30.8%, While the treating scales of the

other units did not increase except the selective dispropor tionation unit, Which Was not equipped in Comparative Example 1. The nearest treating capacities Were in the

purchased 53000 kg/h pure toluene entered into the selective disproportionation unit. The speci?c situations of the feed and effluent of the selective disproportionation unit, dispro

portionation and transalkylation unit, and isomerization unit

are shoWn in Table 9, the treating scales of various units of the aromatics complex are shoWn in Table 10, and the outputs of the products p-xylene and benzene are shoWn in Table 11.

TABLE 9

Process materials in Example 3

adsorptive separation unit, but the treating capacity Was only

Selective Disproportionation disproportionation and transalkylation

Component

Feed into Ben Tol CSA

Isomerization

unit

0 245 183099

Adsorptive separation

unit

125 214447

unit

22 256328 201

unit

3 31722 288

Xylene toWer

0 125 214661

unit, Kg/h

C9A C1D*A

/

256551 34969 177790

21647 688

54349 4392 19261

41

183386 2277 1270

41

214613 0 125

18979 3632

237398 0 125

E FloW- Ben out of Tol

US 2003/0130549 A1

Jul. 10, 2003

TABLE 9-continued

Process materials in Example 3

Selective Disproportionation disproportionation and transalkylation

Component

unit, kg/h C8A C9A Cuf'A

E

Isomerization

unit

176776 922

181245

Adsorptive separation

unit

214447 41

214613

unit

35437 2046 57

250299

unit

17858 8839 1578

51928

Xylene toWer

214661 18979 3632

237398

[0050]

TABLE 10

Treating scales of various units in Example 3

Disproportionation

and transalkylation

Unit unit

Adsorptive

Isomerization

unit

Xylene

Benzene/toluene

fractionation unit

separation

unit

fractionation

unit

Scale, kg/h

54349

183386

256880

103347

82395

[0051]

EXAMPLE 4

TABLE 11

Outputs and purities of the products in Example 3

[0053] By still using the process ?oW, process conditions,

and catalyst in Example 1, and the same feedstock as

Example 3, the capacity of the technique of the present

invention for producing PX Was re-examined, but the dif ference Was that the process for separating the mixed

Product

p-xylene

Benzene

Output, kg/h

73494

51638

Purity, %

99.8

99.94

xylenes produced by the toluene selective disproportion

ation changed from the adsorptive separation to the subzero crystallization separation. The treating scales of various

units of the aromatics complex are shoWn in Table 12, and the outputs of the products p-xylene and benzene are shoWn in Table 13.

TABLE 12

Treating scales of various units in Example 4

[0052] The results shoW that in the present example, the output of p-xylene increases by 45%, and the output of

Disproportionation

and transalkylation

Unit unit

Adsorptive

Isomerization

unit

Xylene

Benzene/toluene

fractionation unit

Subzero

crystallization

unit

separation

unit

fractionation

unit

Scale, kg/h

54323

182414

232553

103315

258054

37573

benzene increases by 197%, While the treating scales of the other units did not increase except the selective dispropor tionation unit, Which Was not equipped in Comparative

[0054]

Thus, While there have shoWn and described and

pointed out fundamental novel features of the invention as

Example 1. Therefore, by using the technique of the present invention, the treating capacity of the system and the outputs

of the products p-xylene and benzene can be greatly increased by only setting up a neW selective disproportion

ation unit containing an aromatics fractionation unit and

purchasing an adequate amount of toluene, but keeping the scale of the original units unvaried. In addition, the Weight concentration of the p-xylene in the mixed xylenes entering into the adsorptive separation unit increases by 29.6%.

applied to a preferred embodiment thereof, it Will be under stood that various omissions and substitutions and changes in the form and details of the processes illustrated, and in their operation, may be made by those skilled in the art Without departing from the spirit of the invention. For example, it is expressly intended that all combinations of those elements and/or method steps Which perform substan

tially the same function in substantially the same Way to achieve the same results are Within the scope of the inven

tion. Moreover, it should be recognized that elements and/or

US 2003/0130549 A1

Jul. 10, 2003

method steps shown and/or described in connection With any

disclosed form or embodiment of the invention may be incorporated in any other disclosed or described or sug gested form or embodiment as a general matter of design

8. The process of claim 1 Wherein a C10+ aromatics stream

is also separated from the feed stream in the step of a) When the C10+ aromatics is present in the feed stream. 9. The process of claim 1 Wherein the p-xylene is sepa

choice. It is the intention, therefore, to be limited only as indicated by the scope of the claims appended hereto.

We claim: 1. A process for the selective disproportionation of tolu

rated by utiliZing an adsorptive separation method.

10. The process of claim 1 Wherein the p-xylene is

separated by utiliZing a subZero crystalliZation separation

method. 11. The process of claim 1 Wherein the step of c) is conducted independently in an aromatics fractionation unit

ene and the disproportionation and transalkylation of toluene

and C9+ aromatics comprising: a) separating a feed stream comprising benZene, toluene,

C8 aromatics, and C9+ aromatics into a ?rst benZene

stream, a toluene stream, a ?rst C8 aromatics stream, and a C9+ aromatics stream;

speci?cally equipped for the step of c), and the second C8

aromatics stream is further separated into a part of the

p-xylene product and a residual liquid by the subZero

crystalliZation separation method.

12. The process of claim 11 further comprising steps of:

b) introducing a part of the toluene stream into a toluene selective disproportionation unit to conduct the toluene selective disproportionation reaction for producing a

admixing the residual liquid With the ?rst and the third

aromatics stream to form a mixture; and

?rst ef?uent comprising C8 aromatics rich in p-xylene, and benZene;

c) separating a second C8 aromatics stream and a second benZene stream from the ?rst ef?uent produced in the

separating the mixture into the p-xylene product and the

remaining mixed xylene by the adsorptive separation

method. 13. The process of claim 1 Wherein the reaction Zone of

step of b);

d) introducing another part of the toluene stream and the C9+ aromatics stream into a toluene disproportination and transalkylation unit to conduct the toluene dispro portionation and transalkylation reaction in the pres

ence of hydrogen for producing a second ef?uent

the toluene selective disproportionation unit is normally

operated at a reaction pressure of 1-4 MPalIla reaction

temperature of 300-480 C., a hydrogen to hydrocarbon mole ratio of 05-10, and a liquid Weight space velocity of 0.8-8 h_1.

14. The process of claim 1 Wherein the reaction Zone of

comprising C8 aromatics and benZene;

e) separating a third C8 aromatics stream and a third benZene stream from the second effluent produced in

the disproportionation and transalkylation unit is normally

operated at a reaction pressure of 1-5 MPa, a reaction

the step of d); and f) separating the ?rst, and third C8 aromatics stream into a p-xylene product and a remaining mixed xylenes

stream.

temperature of 250-480 C., a hydrogen to hydrocarbon mole ratio of 05-10, a liquid Weight space velocity of 0.8-8 h_1, and a content of the C9+ aromatics of 5-60% by Weight

in the toluene stream and the C9+ aromatics stream intro

duced in the step of d).

15. The process of claim 1 Wherein the toluene selective

2. The process of claim 1 further comprising a step of

disproportionation unit is normally operated in the presence

of a ZSM-type molecular sieve catalyst. 16. The process of claim 15 Wherein the ZSM-type molecular sieve catalyst is a ZSM-S-type molecular sieve With a SiO2/Al2O3 mole ratio of 15-100. 17. The process of claim 16 Wherein the ZSM-type catalyst contains a 0.01-1% by Weight of metal or oxide thereof, the metal is selected from the group consisting of

separating the second C8 aromatics into the p-xylene product

and the remaining mixed xylenes stream.

3. The process of claim 1 Wherein the amount of the

toluene introduced in the step of b) accounts for 5-95% of the total amount of the toluene introduced in the step of b)

and e).

4. The process of claim 1 Wherein the amount of the

toluene introduced in the step of b) accounts for 20-80% of the total amount of the toluene introduced in the step of b)

platinum, molybdenum, magnesium, and combinations

thereof. 18. The process of claim 1 Wherein the disproportionation

and e).

5. The process of claim 1 Wherein the Weight ratio of the

toluene and the C9+ aromatics introduced in the step of d) is 80/20-40/60.

6. The process of claim 3 Wherein the total amount of the

and transalkylation unit is normally operated in the presence

of a molecular sieve type catalyst selected from the group

consisting of [3-Zeolite, mordenite, MCM-22 and combina

tions thereof. 19. The process of claim 18 Wherein the molecular sieve

toluene includes the toluene separated in the step of a) and

a foreign toluene. 7. The process of claim 1 further comprising steps of

type catalyst is selected from the group consisting of [3-Zeo lite, mordenite, and combinations thereof, the molecular

sieve has a SiO2/Al2O3 mole ratio of 15-50. 20. The process of claim 18 Wherein the molecular sieve

sending the remaining mixed xylenes stream to an isomer iZation unit to conduct the reaction of isomeriZation for

converting the remaining mixed xylenes to the p-xy

type catalyst contains ODS-2% by Weight of metal bismuth

or its oxide.

lene;

separating the p-xylene product from the effluent of the

reaction of isomeriZation.

You might also like

- Recent Advances in the Science and Technology of Zeolites and Related Materials: Proceedings of the 14th International Zeolite Conference, Cape Town, South Africa, 25-30th April 2004From EverandRecent Advances in the Science and Technology of Zeolites and Related Materials: Proceedings of the 14th International Zeolite Conference, Cape Town, South Africa, 25-30th April 2004No ratings yet

- Tatoray ReacrorsDocument2 pagesTatoray ReacrorsgshdavidNo ratings yet

- 0910 8 AbsDocument9 pages0910 8 Absjlcheefei9258No ratings yet

- United States Patent (10) Patent N0.: US 8,013,202 B2Document13 pagesUnited States Patent (10) Patent N0.: US 8,013,202 B2Duy Thanh NguyễnNo ratings yet

- United States Patent: Kong Et A)Document9 pagesUnited States Patent: Kong Et A)Văn Đại - BKHNNo ratings yet

- Advances in The OCC Process For Propylene ProductionDocument6 pagesAdvances in The OCC Process For Propylene ProductionAngel Richard MamaniNo ratings yet

- Petrochemical FeedstockDocument16 pagesPetrochemical FeedstockAstri HandayaniNo ratings yet

- Benzene Recovery 1Document12 pagesBenzene Recovery 1Student 80No ratings yet

- Industrial Catalytic Processes-Phenol Production: Robert J. SchmidtDocument15 pagesIndustrial Catalytic Processes-Phenol Production: Robert J. SchmidtUzair WahidNo ratings yet

- Pce-II Unit-I & II 1Document84 pagesPce-II Unit-I & II 1Pavan SatishNo ratings yet

- Uop Tatoray Process: Antoine Negiz and Thomas J. StoodtDocument10 pagesUop Tatoray Process: Antoine Negiz and Thomas J. StoodtBharavi K SNo ratings yet

- Poster Expoquimia08dDocument1 pagePoster Expoquimia08dajrojas1359No ratings yet

- PERP Program - Optimizing Aromatics Production New Report AlertDocument4 pagesPERP Program - Optimizing Aromatics Production New Report AlertTissa Novida Aulia ZahraNo ratings yet

- CBI Ethylene Enhancement ArticleDocument4 pagesCBI Ethylene Enhancement ArticleChi-Hao LoNo ratings yet

- ISOMARDocument5 pagesISOMARscribd405No ratings yet

- Exxonmobil Pxmaxsm P Xylene From TolueneDocument13 pagesExxonmobil Pxmaxsm P Xylene From Tolueneooimooi1111No ratings yet

- European Patent Application C08F 136/06, C08F 4/70: Synthesis of Elastomeric High Trans-1,4-PolybutadieneDocument10 pagesEuropean Patent Application C08F 136/06, C08F 4/70: Synthesis of Elastomeric High Trans-1,4-Polybutadieneماجد عليNo ratings yet

- Xylene From MethylationDocument8 pagesXylene From Methylationalicia1990No ratings yet

- Us 7601311Document10 pagesUs 7601311Văn Đại - BKHNNo ratings yet

- Bisphenol A Synthesis - Modeling of Industrial Reactorand Catalyst DeactivationDocument7 pagesBisphenol A Synthesis - Modeling of Industrial Reactorand Catalyst DeactivationDaniela JuradoNo ratings yet

- Synthesis of P-Xylene by Selective Methylation of TolueneDocument2 pagesSynthesis of P-Xylene by Selective Methylation of TolueneIngrid ContrerasNo ratings yet

- NCL 2006 Pet. Chem.Document58 pagesNCL 2006 Pet. Chem.madurchinnaNo ratings yet

- Cumene Methods 2520of ProductionDocument4 pagesCumene Methods 2520of ProductionYunardi YusufNo ratings yet

- Separation and Puri Fication Technology: SciencedirectDocument5 pagesSeparation and Puri Fication Technology: SciencedirectTrang Phạm ThịNo ratings yet

- New Olefin Production Technologies in SINOPECDocument10 pagesNew Olefin Production Technologies in SINOPECTrevor J. HutleyNo ratings yet

- Naphtha Cracking For Light Olefins ProductionDocument5 pagesNaphtha Cracking For Light Olefins Productionbasura12345No ratings yet

- Chapter 1 3Document25 pagesChapter 1 3Stephannie SyNo ratings yet

- Reactive AdsorptionDocument9 pagesReactive AdsorptionLinhXuânPhạmNo ratings yet

- Preparation of High-Purity Normal Hexane From Reformate Raffinate by Adsorption and Distillation ProcessesDocument9 pagesPreparation of High-Purity Normal Hexane From Reformate Raffinate by Adsorption and Distillation ProcessesJayesh PanjabiNo ratings yet

- Cumene Mass & Energy Balance PDFDocument33 pagesCumene Mass & Energy Balance PDFMeet Khunt100% (1)

- Toluene IntroductionDocument4 pagesToluene IntroductionVinay BabuNo ratings yet

- AmmoniaDocument46 pagesAmmoniabac_nobita7657No ratings yet

- US20100249366A1Document5 pagesUS20100249366A1DenisNo ratings yet

- 5962 8417eDocument4 pages5962 8417eThanh Thanh Hai LeNo ratings yet

- Topical and Prospective Processes of Acetoxylation: Grzegorz Lewandowski, Marcin Bartkowiak, Eugeniusz MilchertDocument6 pagesTopical and Prospective Processes of Acetoxylation: Grzegorz Lewandowski, Marcin Bartkowiak, Eugeniusz MilchertAnonymous b9fcR5No ratings yet

- Cumene Production Robert SchmidtDocument14 pagesCumene Production Robert SchmidtVatsalNo ratings yet

- 01pa JB 2 6 PDFDocument9 pages01pa JB 2 6 PDFMarcelo Varejão CasarinNo ratings yet

- Data Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateDocument5 pagesData Originating From Sources Other Than The EPO May Not Be Accurate, Complete, or Up To DateVatsalNo ratings yet

- US3816523Document5 pagesUS3816523Argo Rizky Kusuma 2007110716No ratings yet

- Coking Kinetics On The Catalyst During Alkylation of FCC Off-Gas With Benzene To EthylbenzeneDocument7 pagesCoking Kinetics On The Catalyst During Alkylation of FCC Off-Gas With Benzene To EthylbenzeneAndres PeñaNo ratings yet

- Integrate Ethyl Benzene Production With An Olefins Plant, HC Processing, 1999, Pg77-88Document8 pagesIntegrate Ethyl Benzene Production With An Olefins Plant, HC Processing, 1999, Pg77-88ypzoNo ratings yet

- Phenol UOPDocument2 pagesPhenol UOPruk1921No ratings yet

- EthyleneDocument8 pagesEthyleneEman El Dsouky100% (1)

- Green Chemistry: Accepted ManuscriptDocument10 pagesGreen Chemistry: Accepted ManuscriptSyarif HidayatNo ratings yet

- Process Design For The Production of Ethylene From EthanolDocument144 pagesProcess Design For The Production of Ethylene From EthanolJorge RicoNo ratings yet

- Process Design For The Production of Ethylene From EthanolDocument144 pagesProcess Design For The Production of Ethylene From EthanolWilmer Rios DiazNo ratings yet

- Fractional Batch Distillation PDFDocument10 pagesFractional Batch Distillation PDFmacleod230286No ratings yet

- Advanced Recycle Paraffin Isomersation TechnologyDocument8 pagesAdvanced Recycle Paraffin Isomersation TechnologytungksnbNo ratings yet

- Methanol SynthesisDocument14 pagesMethanol SynthesisArias AlbertoNo ratings yet

- Process Selection Catalytic CrackingDocument5 pagesProcess Selection Catalytic CrackingKimal WasalathilakeNo ratings yet

- Review Proses CumeneDocument15 pagesReview Proses Cumenerachma tiaNo ratings yet

- EthyleneDocument6 pagesEthylene2065001779207No ratings yet

- Tech Papers PxMax and XyMaxDocument18 pagesTech Papers PxMax and XyMaxSaurav De100% (1)

- Multiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsFrom EverandMultiphase Reactor Engineering for Clean and Low-Carbon Energy ApplicationsYi ChengNo ratings yet

- Sustainable synthesis of ciclopentene derivatives through multicomponent reactions in continuous flow regimeFrom EverandSustainable synthesis of ciclopentene derivatives through multicomponent reactions in continuous flow regimeNo ratings yet

- GC/LC, Instruments, Derivatives in Identifying Pollutants and UnknownsFrom EverandGC/LC, Instruments, Derivatives in Identifying Pollutants and UnknownsNo ratings yet

- (21910324 - High Temperature Materials and Processes) Current Practices in Tungsten Extraction and RecoveryDocument16 pages(21910324 - High Temperature Materials and Processes) Current Practices in Tungsten Extraction and RecoveryVăn Đại - BKHNNo ratings yet

- Vocabulary Unit 1-4Document7 pagesVocabulary Unit 1-4Văn Đại - BKHNNo ratings yet

- Metals 07 00230Document9 pagesMetals 07 00230Văn Đại - BKHNNo ratings yet

- Metals 07 00230Document9 pagesMetals 07 00230Văn Đại - BKHNNo ratings yet

- Materials 10 00142 v2Document11 pagesMaterials 10 00142 v2Văn Đại - BKHNNo ratings yet

- Unit 1 TenseDocument12 pagesUnit 1 TenseVăn Đại - BKHNNo ratings yet

- Lesson Summary: Lesson: Unit 4 Part B Date: July 9 Class: HND994-017 Teacher: Duy NamDocument2 pagesLesson Summary: Lesson: Unit 4 Part B Date: July 9 Class: HND994-017 Teacher: Duy NamVăn Đại - BKHNNo ratings yet

- Minerals 05 00298 PDFDocument16 pagesMinerals 05 00298 PDFKỹ Thuật Hóa HọcNo ratings yet

- Aroma SotayDocument36 pagesAroma SotayVăn Đại - BKHNNo ratings yet

- Unit 2 PassiveDocument7 pagesUnit 2 PassiveVăn Đại - BKHNNo ratings yet

- Solvent Extraction Equilibria - ch4Document93 pagesSolvent Extraction Equilibria - ch4Văn Đại - BKHNNo ratings yet

- Pilot Plant DesignDocument98 pagesPilot Plant DesignChima Ugwuegbu100% (2)

- HND994-017 - Course ScheduleDocument2 pagesHND994-017 - Course ScheduleVăn Đại - BKHNNo ratings yet

- Itireport008 R203241 PDFDocument8 pagesItireport008 R203241 PDFKỹ Thuật Hóa HọcNo ratings yet

- KSB Know-How, Volume 0 - Selecting-Centrifugal-Pumps-data PDFDocument92 pagesKSB Know-How, Volume 0 - Selecting-Centrifugal-Pumps-data PDFRodrigo Astudillo AedoNo ratings yet

- 88485004en PDFDocument8 pages88485004en PDFVăn Đại - BKHNNo ratings yet

- Technical Review - Copper Solvent Extraction in Hydrometallurgy PDFDocument39 pagesTechnical Review - Copper Solvent Extraction in Hydrometallurgy PDFKỹ Thuật Hóa HọcNo ratings yet

- Hydro Metallurgy of Copper PDFDocument256 pagesHydro Metallurgy of Copper PDFVăn Đại - BKHNNo ratings yet

- Quick Guide For Pump Selection - EngDocument43 pagesQuick Guide For Pump Selection - EngAnonymous hJFuHnTsBNo ratings yet

- Determine ThiosulfateDocument2 pagesDetermine ThiosulfateVăn Đại - BKHNNo ratings yet

- Diluent Effects in Solvent Extraction: BstractDocument9 pagesDiluent Effects in Solvent Extraction: BstractKỹ Thuật Hóa HọcNo ratings yet

- Dư A N Lo C Da U Nghi Sơn PDFDocument418 pagesDư A N Lo C Da U Nghi Sơn PDFVăn Đại - BKHN100% (1)

- Cours FP GBDocument30 pagesCours FP GBSana KhanNo ratings yet

- 88488008EN Manual 848 Titrino Plus PDFDocument148 pages88488008EN Manual 848 Titrino Plus PDFVăn Đại - BKHNNo ratings yet

- 88488004EN Tutorial 848 877 Titrino Plus PDFDocument41 pages88488004EN Tutorial 848 877 Titrino Plus PDFVăn Đại - BKHNNo ratings yet

- Pilot Plant Testwork Services PDFDocument4 pagesPilot Plant Testwork Services PDFVăn Đại - BKHNNo ratings yet

- Minerals 05 00298 PDFDocument16 pagesMinerals 05 00298 PDFKỹ Thuật Hóa HọcNo ratings yet

- Minerals 05 00298 PDFDocument16 pagesMinerals 05 00298 PDFKỹ Thuật Hóa HọcNo ratings yet

- Ritcey1980 PDFDocument11 pagesRitcey1980 PDFVăn Đại - BKHNNo ratings yet

- Explicit Dynamics Chapter 6 Explicit MeshingDocument50 pagesExplicit Dynamics Chapter 6 Explicit MeshingAnonymous 0tqzNTWyy100% (4)

- Calculating The Volume of A Stainless Steel WeldDocument6 pagesCalculating The Volume of A Stainless Steel WeldOkayNo ratings yet

- Craftsman 82141 User ManualDocument36 pagesCraftsman 82141 User ManualJoe100% (1)

- Boeing Fire AERO - 2011 - Q2 - Article3Document10 pagesBoeing Fire AERO - 2011 - Q2 - Article3Braulio GomesNo ratings yet

- IR2200 - IR2800 - IR3300 Error CodeDocument7 pagesIR2200 - IR2800 - IR3300 Error CodeTiger DineshNo ratings yet

- Interactive CatalogDocument76 pagesInteractive CatalogahmedelhajNo ratings yet

- Banana ChipsDocument5 pagesBanana Chipsbikram limbuNo ratings yet

- Kata LogDocument48 pagesKata LogsofiakeramikNo ratings yet

- Oxygen Booster ManualDocument27 pagesOxygen Booster ManualAldo Tolaba Quiroga100% (3)

- Electrostatic Powder PaintingDocument9 pagesElectrostatic Powder PaintingfirdausNo ratings yet

- 7-Strengthening Mechanisms - SlidesDocument74 pages7-Strengthening Mechanisms - SlidesRyan TorresNo ratings yet

- Ferroelectric RAM FRAM Seminar Report1Document20 pagesFerroelectric RAM FRAM Seminar Report1Gaurav ReddyNo ratings yet

- Lab 4Document14 pagesLab 4rhinsaokiNo ratings yet

- Wabco GuideDocument16 pagesWabco GuideMohd FairusNo ratings yet

- Epoxylite TSA 220 - TDS - 2008Document3 pagesEpoxylite TSA 220 - TDS - 2008Anonymous sAmJfcVNo ratings yet

- How To Install Openbravo ERP On Debian LennyDocument4 pagesHow To Install Openbravo ERP On Debian LennyfromemNo ratings yet

- HART Tech Short FormDocument9 pagesHART Tech Short FormJediael JuniorNo ratings yet

- York Ducted Split Ac Yefe 18-48Document6 pagesYork Ducted Split Ac Yefe 18-48DANISH0% (1)

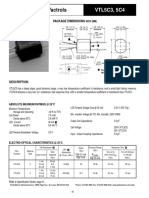

- Low Cost Axial Vactrols: VTL5C3, 5C4Document2 pagesLow Cost Axial Vactrols: VTL5C3, 5C4sillyNo ratings yet

- Civil & Environmental Engineering: Dept. Report October 2002Document40 pagesCivil & Environmental Engineering: Dept. Report October 2002Leonardo HernandezNo ratings yet

- Standard Rain GaugeDocument43 pagesStandard Rain GaugeAku PalsuNo ratings yet

- AXE400P User Manual With Centos6.0 Dahdi V2.0 D130603 enDocument12 pagesAXE400P User Manual With Centos6.0 Dahdi V2.0 D130603 enCartimex S.A.No ratings yet

- Difference Between Forging and CastingDocument2 pagesDifference Between Forging and CastingMOHAMMAD ALINo ratings yet

- SEPG and Consulting ProcessDocument20 pagesSEPG and Consulting ProcesszafzNo ratings yet

- Standard Operating Procedure-Standard Maintenace ProcedureDocument11 pagesStandard Operating Procedure-Standard Maintenace ProcedureVikram JitNo ratings yet

- Sin EncoderDocument6 pagesSin Encoderboynew87No ratings yet

- 5 Gaikindo Production Data Jandec2018 Rev HondaDocument3 pages5 Gaikindo Production Data Jandec2018 Rev HondaWira WijayaNo ratings yet

- Users Manual For Oslo, Bremen and Turboaire.: Installation, Operation and Maintenance InstructionsDocument40 pagesUsers Manual For Oslo, Bremen and Turboaire.: Installation, Operation and Maintenance Instructionsbuttler25No ratings yet

- Compare Models - RitchieSpecsDocument4 pagesCompare Models - RitchieSpecsMochammad JihadNo ratings yet

- Water Cooled Chiller (SHUBAILY GRAND MALL)Document40 pagesWater Cooled Chiller (SHUBAILY GRAND MALL)kdpmansiNo ratings yet