Professional Documents

Culture Documents

FEM in Twist

Uploaded by

Varthini RajaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FEM in Twist

Uploaded by

Varthini RajaCopyright:

Available Formats

CIRP Annals - Manufacturing Technology 59 (2010) 307310

Contents lists available at ScienceDirect

CIRP Annals - Manufacturing Technology

jou rnal homep age : ht t p: // ees .e lse vi er. com/ci rp/ def a ult . asp

Twist revisited: Twist phenomena in single point incremental forming

J.R. Duou (2)a,*, H. Vanhove a, J. Verbert a, J. Gu b, I. Vasilakos b, P. Eyckens c

a b c

Department of Mechanical Engineering, K.U.Leuven, 3001 Heverlee-Leuven, Belgium Department of Mechanics of Materials and Constructions, VUB, 1050 Brussels, Belgium Department of Metallurgy and Materials Engineering, K.U.Leuven, 3001 Heverlee-Leuven, Belgium

A R T I C L E I N F O

A B S T R A C T

Keywords: Incremental sheet forming Deformation Twist

Twist phenomena in incrementally formed parts have been observed both in the domain of single and two point incremental forming. In the reported experiments the resulting twist direction typically corresponds to the toolpath direction and can be explained by the monotonous tangential force component exerted on the workpiece when using unidirectional toolpaths. When processing parts with high drawing angles, however, twist deformations corresponding to in-plane shear in opposite toolpath direction have been observed by the authors. In this paper this phenomenon is documented and explained by means of strain measurements and FEA results. The role of asymmetric, cumulative, extended strain effects, resulting in severe thinning, and reinforced when stiff, semi-vertical rib features are present in the part geometry, is demonstrated by means of a detailed deformation analysis. 2010 CIRP.

1. Introduction 1.1. Conventional twist Twist as an unwanted deformation phenomenon occurring in Incremental Sheet Forming (ISF) has been observed by a number of authors [13]. The substantial twist (up to 308) observed by Matsubara in Two Point Incremental Forming (TPIF) was found to be caused by uncontrolled pivoting of the workpiece around the hemispherical support structure as a result of tangential forces exerted on the workpiece by the tool [1], and is visible in the obtained geometry when producing non-rotational parts. The twist phenomenon observed in Single Point Incremental Forming (SPIF) by Jadhav [2] can also be explained by tangential forces, which induce in-plane shear into the workpiece (Fig. 1). Tests performed by the authors allowed to conclude that this type of twist deformation can not only be observed in rotational part geometries, but is also present in, for example, pyramidal structures (Table 1). As illustrated by Aerens et al. in [4], ceteris paribus the tangential force component in the toolworkpiece interaction in SPIF is approximately constant in function of the drawing angle (a). In combination with a reduced residual wall thickness in function of the drawing angle for a constant blank thickness, the increase of the in-plane shear in function of a, and the corresponding twist angle (u) increase in the lower drawing angle range, can be explained (Table 1). The location of the contact zone between the tool and workpiece, as documented based on a detailed, multi-scale FEA in [4], extends over the tool tip zone, explaining why friction

cannot be totally avoided by rotating the tool. Neither a setup with a freewheeling nor a programmed rotating tool can in consequence substantially contribute to elimination of tangential forces and avoidance of the resulting twist phenomenon. While in TPIF the already formed zone of the workpiece can be displaced in the case of rotational support structures, resulting in residual twist effects measurable in the part geometry [1], in the case of SPIF the self-correcting nature of the incremental forming process continuously eliminates the effects of the twist displacement in the not yet processed zone of the sheet. The described twist phenomenon in SPIF in consequence does not signicantly affect the shape of the part. Both in the case of SPIF and TPIF accumulating twist can be prevented by alternating the toolpath direction [1,3]. However, an alternating toolpath is typically composed of consecutive 2D contours, separated by a discrete, incremental step in the tool axis direction, and results in clear surface quality deterioration at the location of the contour transition. Therefore a spiralling toolpath is often preferred, which however obstructs the alternating direction strategy. The remainder of this article is dedicated to the study of part quality affecting, twist related phenomena, as induced by unidirectional toolpaths in SPIF. 1.2. Observed twist at high drawing angles A phenomenon that clearly deviates from the twist occurring under the above described conditions can be observed when processing materials at drawing angles close to the formability limit (as identied with a cone forming test for a given sheet thickness [2,5]). Parts formed under these conditions, using backing plates with a clearance of 1 mm between the outer part surface and the supporting edge, show clear twist in the direction opposite to the toolpath (Fig. 2). This counter intuitive twist phenomenon is present both in conical and pyramidal shapes.

* Corresponding author. E-mail address: Joost.Duou@mech.kuleuven.be (J.R. Duou). 0007-8506/$ see front matter 2010 CIRP. doi:10.1016/j.cirp.2010.03.018

308

J.R. Duou et al. / CIRP Annals - Manufacturing Technology 59 (2010) 307310

Fig. 1. Twist (u) in the toolpath direction observed at lower drawing angles in the SPIF process.

Fig. 3. Observed strain patterns in the outer surface for a 708 truncated cone (left) and pyramid (right), with close up illustrating the initial twist in toolpath direction (A) and counter toolpath twist (B). In blue a vertical reference line, in red a line of the twisted grid pattern.

The presented results were obtained on a rigid 3-axis milling machine. The part clamping conditions were veried not to affect the stiffness of the experimental setup. For the tested materials the twist phenomenon was found to be independent of the rotation speed of the tool, the tool diameter, and the forming speed. While with an increased stepsize between contours a higher rate of twist was observed. In order to clarify the underlying forming mechanism, a number of detailed strain measurements were conducted, as illustrated in the next sections. 2. Experimental observations By means of grid patterns printed on the outer surface of the workpiece, the degree of twist could be determined and the corresponding in-plane strains could be qualitatively observed in different zones of the test parts. The following process parameter settings were used for this purpose: step size 0.612 mm, tool diameter 10 mm, no tool rotation, continuous lubrication, backing plate adjusted to the outer workpiece dimensions with a clearance of 1 mm. The material used for the reported tests was Al3103 with a thickness of 1.5 mm. In all produced parts an initial twist in the toolpath direction could be observed over a depth of approximately 15 mm (Fig. 3A),

Fig. 4. Twist angle (u) in function of the horizontal angle (b, see also Fig. 2) of the rib features.

Table 1 Twist angles in SPIF formed parts (Al3103, thickness 1.5 mm, step size 0.612 mm, tool diameter 10 mm, no tool rotation). Part shape Cone Drawing angle (a) 308 508 308 408 508 Height (h) 40 mm 80 mm 40 mm 55 mm 80 mm Twist angle (u) 0.328 0.468 0.128 0.398 0.228

Pyramid

followed by a twist reversal in the counter toolpath direction (Fig. 3B) and an approximately constant twist angle over the remaining height of the part. As documented in Fig. 3, compared to a cone and for equal drawing angles, the average twist angle corresponding to the counter toolpath direction twist phenomenon is clearly larger for pyramidal workpieces. For truncated pyramids characterised by a polygonal basis with a varying number of sides, the twist angle u shows a decreasing trend in function of the horizontal angle of the rib features (Fig. 4). Within the anges of the produced truncated pyramids a clear asymmetry can be observed. More extreme eyy strains occur in the area of the anges processed rst by the tool during every contour. These severe strains correspond to similarly asymmetric thickness measurements (Fig. 5). In order to better understand the cause of the asymmetric strain patterns, detailed in-process strain measurements were performed by means of Digital Image Correlation (DIC) techniques. Details of the measurement setup used for this purpose can be found in [6]. The obtained results are analysed in the next section and have been enhanced with nite element analysis results presented in Section 4.

Fig. 2. Twist observed in different parts at near failure drawing angles.

Fig. 5. Thickness distribution for a 708 pyramid wall with a nominal blank thickness of 1.5 mm.

J.R. Duou et al. / CIRP Annals - Manufacturing Technology 59 (2010) 307310

309

Fig. 6. Cumulative tangential Lagrange strain exx (starting from contour 82) for a 708 truncated pyramid wall.

Fig. 9. Incremental equivalent plastic strain for contours 7, 15, 23, 31 and 39 in a AA3003-O 738 truncated cone with 1.2 mm initial sheet thickness.

higher eyy strains. With similar effects occurring in every processed pyramid wall, the residual reverse twist effect can be understood. 4. Finite element analysis

Fig. 7. Cumulative Lagrange strain eyy (starting from contour 82) for a 708 truncated pyramid wall.

3. Strain analysis Figs. 6 and 7 contain plots of the cumulative exx and eyy Lagrange strains, respectively, as measured in the wall of a four sided truncated pyramid. The cumulative strains were monitored from the 82nd contour onwards, over a range of 100 contours, till the nal shape was obtained. The tangential strain exx is negligible, except for local bending effects occurring at the locations of the tool passage through the corner rib features. This strain pattern corresponds to a limited, approximately constant material displacement per contour in the counter toolpath direction over the entire wall. The eyy strain plot in Fig. 8 shows the clearly asymmetric pattern observed earlier, with maximum strain values approximately a factor 1.7 higher than the lowest values measured at the same level in the wall. The strain history for different points at the same initial contour level in a ange (Fig. 8) illustrates that most of the eyy strain is built up over a substantial number of tool contours after the tool passage. This extended straining outside the direct contact zone affects the material drawn into the wall in the tool workpiece contact zone underneath the affected area, with in comparison less material pulled into the wall below the wall area characterised by

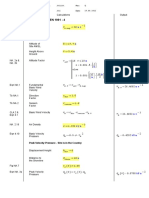

Observation of the extended straining patterns outside the tool contact zone, and comparison with the thickness distribution in the corresponding workpiece area, claries the self-supporting nature of the phenomenon. Extended straining leads to further reduction of the wall thickness, which, once initiated, contributes to a high local equivalent stress level in a growing workpiece area above the tool contact zone. This extended straining mechanism corresponds well with FE simulation results showing a distributed necking phenomenon when forming at a near failure angle. Abaqus/Standard was used as FEM platform for this purpose, representing the workpiece by means of three layers of brick elements. An isotropic elasticplastic material behaviour was assumed for the AA3003-O alloy, with the von Mises yield criterion and a Swift-type hardening law s = 184(e + 0.00196)0.224 (MPa). Further details of the modelling approach can be found in [7]. Fig. 9 contains results of a simulation of a 408 FE pie model of a 738 truncated cone formed by a tool of 10 mm diameter at a 0.5 mm incremental step size. The gure shows the incremental equivalent plastic strain in the mid plane of the pie segment as caused by a single toolpath contour (additional strain between contours n 1 and n) in different stages. The FE model was also used to study the stress distribution in the workpiece area outside the tool contact zone in order to better understand the asymmetry in the observed strain patterns in the case of the pyramidal structures. Fig. 10 shows the von Mises equivalent stress distribution on the inner surface of the pie segment model described above. The results demonstrate a clear asymmetry in the stress eld. In a conical part every point located in the already formed wall undergoes a complete stress cycle, with both the A and B-like stress situation (Fig. 10) occurring as part of a single tool contour. Instantaneous asymmetrical straining is therefore continuously

Fig. 8. Strain history in function of the number of contours (for the initial location of the measurements points A, B and C see Fig. 7).

Fig. 10. von Mises equivalent stress for contour 22 in a 738 truncated cone (0.5 mm stepsize, initial sheet thickness 1.2 mm).

310

J.R. Duou et al. / CIRP Annals - Manufacturing Technology 59 (2010) 307310

Fig. 11. Thickness strain ezz (A) and through thickness shear angle gxz (degrees) (B) after contour 40 in a 508 truncated cone (shown in original blank location).

compensated, which results in a reduced inverse twist effect and a homogeneous nal eyy strain over every horizontal contour. In non-rotational structures, such as the pyramidal parts studied, this continuous correction is not occurring in the vicinity of the semi-vertical rib features. This asymmetry is likely to be further reinforced by specic strain conditions in the vicinity of the rib features bounding the pyramid walls. Through Thickness Shear (TTS) in the xz-plane is believed to vary over the pyramid wall, with little or no TTS occurring immediately after the tool direction change in the semi-vertical edge features and a slow build up towards the central zone of the wall. This is illustrated in Fig. 11 by means of the FE simulation results for a 408 pie model of a 508 truncated cone (details of the model can be found in [7]). Due to imposed symmetry boundary conditions at the 08- and 408-sections, the TTS angle gxz necessarily equals 0 at the pie model edges (Fig. 11B). However the build up of TTS over the 408 pie model shows a clear asymmetry, with low initial levels and a high gradient towards the end of the toolpath trajectory. The symmetry imposing boundary conditions used for the FE model only approximate the vicinity of the stiff corner features of the pyramidal structures. The observed asymmetric thinning effects (marked zone in Fig. 11A) however seem to qualitatively conrm the suitability of the model approximation. 5. Conclusions The observed continued eyy strain accumulation, in combination with the simulated asymmetric stress levels, allows to understand the counter intuitive twist phenomenon occurring in SPIF at high drawing angles in different part geometries.

While in pyramidal structures the asymmetry in the deformation patterns is not compensated during consecutive contours, thus reinforcing the reverse twist phenomenon, in rotational part geometries, the rotating stress eld assures equal alternating exposure to increased straining to all areas in the workpiece, resulting in a homogeneous, axisymmetrical strain eld. The presence of semi-vertical rib features in parts to be manufactured by SPIF has an important inuence on the observed strain patterns and can trigger excessive continued straining in combination with severe thinning. The lower the corner angle of the rib feature, the more pronounced this effect. For industrial applications when confronted with high drawing angles in the direct vicinity of semi-vertical rib features, the benecial effect of unidirectional spiralling toolpaths on surface quality on the one hand, and the excessive thinning effects on the other should be carefully considered. Independent of the twist phenomenon discussed in this article, the observed, non-local, continued plastic straining at a signicant distance from the tool contact zone contributes to a better understanding of deformation phenomena occurring in already processed workpiece zones when applying SPIF. As such the controllability of the process is affected. Signicant extended straining outside the tool contact zone also forms a major obstacle for any single step adaptive forming strategy. Acknowledgements The authors would like to recognize the support of the Research Foundation - Flanders (FWO), the Belgian Science Policy Ofce and the Innovation by Science and Technology Agency (IWT). References

[1] Matsubara S (2001) A Computer Numerically Controlled Dieless Incremental Forming of a Sheet Metal. Journal of Engineering Manufacture 215(7):959966. [2] Jadhav S (2004) Basic Investigations of the Incremental Sheet Metal Forming Process on a CNC Milling Machine, Dr.-Ing. Dissertation, University of Dortmund. [3] Jeswiet J, Micari F, Hirt G, Bramley A, Duou J, Allwood J (2005) Asymmetric Single Point Incremental Forming of Sheet Metal. CIRP Annals-Manufacturing Technology 54(2):623650. [4] Aerens R, Eyckens P, Van Bael A, Duou JR (2010) Force Prediction for Single Point Incremental Forming Deduced from Experimental and FEM Observations. International Journal of Advanced Manufacturing Technology 46(912):969982. [5] Ham M, Jeswiet J (2007) Forming Limit Curves in Single Point Incremental Forming. CIRP Annals-Manufacturing Technology 56(1):277280. [6] Vasilakos I, Gu J, Belkassem B, Sol H, Verbert J, Duou JR (2009) Investigation of Deformation Phenomena in SPIF Using an In-Process DIC Technique. Proceedings of the 13th International Conference on Sheet Metal, Birmingham, 401409. [7] Van Bael A, Eyckens P, He S, Boufoux C, Henrard C, Habraken AM, Duou J, Van Houtte P (2007) Forming Limit Predictions for Single-Point Incremental Sheet Metal Forming. Proceedings of the 10th ESAFORM Conference on Material Forming, 309314.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Renewable Energy: Salih N. Akour, Mohammed Al-Heymari, Talha Ahmed, Kamel Ali KhalilDocument9 pagesRenewable Energy: Salih N. Akour, Mohammed Al-Heymari, Talha Ahmed, Kamel Ali KhalilJuan ApzNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureDocument16 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Design of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesDocument20 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesVarthini RajaNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureDocument20 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Design of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesDocument18 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesVarthini RajaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureDocument12 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Design of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesDocument40 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesVarthini RajaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureDocument14 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Design of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesDocument21 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesVarthini RajaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Design of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesDocument40 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesVarthini RajaNo ratings yet

- Design of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesDocument37 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesVarthini RajaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureDocument11 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Design of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesDocument18 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Locating and Clamping PrinciplesVarthini RajaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Design of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureDocument27 pagesDesign of Jigs, Fixtures and Press Tools UNIT 1: Jigs and FixtureVarthini RajaNo ratings yet

- Catia SurfaceDocument14 pagesCatia Surfaceapi-3799982100% (2)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Formability of Stamping Magnesium-Alloy AZ31 SheetsDocument5 pagesFormability of Stamping Magnesium-Alloy AZ31 SheetsVarthini RajaNo ratings yet

- FEM Lecture NotesDocument188 pagesFEM Lecture NotesHenry Martinez CarmonaNo ratings yet

- Seating Arrangement2Document9 pagesSeating Arrangement2Varthini RajaNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Strength of Materials Lab PDFDocument33 pagesStrength of Materials Lab PDFDeanna ChapmanNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Genetic AlgorithmDocument11 pagesGenetic AlgorithmVarthini RajaNo ratings yet

- A Machine Vision System For Real-Time Automated Gear Fatigue Pitting DetectionDocument4 pagesA Machine Vision System For Real-Time Automated Gear Fatigue Pitting DetectionVarthini RajaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Artificial Neural Networks For BeginnersDocument8 pagesArtificial Neural Networks For BeginnersVarthini RajaNo ratings yet

- Aluminium in AerospaceDocument2 pagesAluminium in AerospaceVarthini RajaNo ratings yet

- VK Jain - PDFV K JAIN Advanced Maching ProcessV K JAIN Advanced Maching ProcessDocument328 pagesVK Jain - PDFV K JAIN Advanced Maching ProcessV K JAIN Advanced Maching ProcessVarthini Raja60% (5)

- Niyama Criteria Niyama Criteria Niyama CriteriaDocument18 pagesNiyama Criteria Niyama Criteria Niyama CriteriaVarthini RajaNo ratings yet

- 2012 VisionSolutions Bro WebDocument24 pages2012 VisionSolutions Bro WebVarthini RajaNo ratings yet

- Role of Bottom-Up and Top-Down Role of Bottom-Up and Top-Down A.pdf Role of Bottom-Up and Top-Down A.pdf Role of Bottom-Up and Top-Down A.pdf ADocument2 pagesRole of Bottom-Up and Top-Down Role of Bottom-Up and Top-Down A.pdf Role of Bottom-Up and Top-Down A.pdf Role of Bottom-Up and Top-Down A.pdf AVarthini RajaNo ratings yet

- Yale Romance Reading ListDocument9 pagesYale Romance Reading ListVarthini Raja100% (4)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- ZincDocument2 pagesZincVarthini RajaNo ratings yet

- ME201 Material Science & Engineering: Imperfections in SolidsDocument23 pagesME201 Material Science & Engineering: Imperfections in SolidsAmar BeheraNo ratings yet

- Simple & Powered Machines SetDocument2 pagesSimple & Powered Machines Setsuhasacharya117No ratings yet

- Hooke's Law - Lesson 3 PDFDocument5 pagesHooke's Law - Lesson 3 PDFNurfatynzulaikha ZukilaNo ratings yet

- Minimum Number of Transfer Units and Reb PDFDocument50 pagesMinimum Number of Transfer Units and Reb PDFsalvatore raffaNo ratings yet

- Fastener Modeling For Joining Parts Modeled by Shell and SolidDocument26 pagesFastener Modeling For Joining Parts Modeled by Shell and SolideguldirimNo ratings yet

- HydraulicsDocument234 pagesHydraulicsChristine CastroNo ratings yet

- 09 m2 Gold 1Document18 pages09 m2 Gold 1Abdel Rahman Mohamed NegimNo ratings yet

- Plasma AntennaDocument9 pagesPlasma Antennaleena999No ratings yet

- How Do I Compute Li and Drag?: Comsol Blog Comsol BlogDocument10 pagesHow Do I Compute Li and Drag?: Comsol Blog Comsol Blogadrian_63No ratings yet

- Grade 9 Science UP 4Document30 pagesGrade 9 Science UP 4MR. BEST100% (1)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- DVPPS01-02 Instruction TseDocument2 pagesDVPPS01-02 Instruction TseAndrés AracenaNo ratings yet

- Polymorphic Phase TransitionsDocument24 pagesPolymorphic Phase Transitionsnimmy kumariNo ratings yet

- ALFAsim Technical Manual EN USDocument70 pagesALFAsim Technical Manual EN UScleuberNo ratings yet

- Meteodyn Complex Terrain Modeling CFD Software Bolund Hill Round Robin TestDocument18 pagesMeteodyn Complex Terrain Modeling CFD Software Bolund Hill Round Robin TestMeteodyn_UrbawindNo ratings yet

- Self-Focusing and Guiding of Short Laser Pulses in Ionizing Gases and Plasmas PDFDocument36 pagesSelf-Focusing and Guiding of Short Laser Pulses in Ionizing Gases and Plasmas PDFAjit UpadhyayNo ratings yet

- Homework Chapter 02Document8 pagesHomework Chapter 02Muzamil ShahNo ratings yet

- GTM - Torque Primary Standard MachineDocument12 pagesGTM - Torque Primary Standard MachinergénezNo ratings yet

- More Accurate Localized Wire Rope Testing Based On Hall Sensor ArrayDocument2 pagesMore Accurate Localized Wire Rope Testing Based On Hall Sensor ArrayNesanNo ratings yet

- Phuong Phap Tinh Tai Theo Phan Mem MistralDocument8 pagesPhuong Phap Tinh Tai Theo Phan Mem Mistralntt_121987No ratings yet

- Fundamentals of Heat and Mass Transfer 7th Edition Incropera Solutions Manual20190709 74173 2j05lf PDFDocument20 pagesFundamentals of Heat and Mass Transfer 7th Edition Incropera Solutions Manual20190709 74173 2j05lf PDFAndiNo ratings yet

- 1 Year Study Plan For IIT JEE MainDocument9 pages1 Year Study Plan For IIT JEE MainShubham kumar100% (1)

- Wind Loads Is en 1991-1-4Document1 pageWind Loads Is en 1991-1-4David O'MearaNo ratings yet

- Koutandos 23Document4 pagesKoutandos 23Κουταντου ΕφηNo ratings yet

- 1969 - Fessler - NotchesDocument10 pages1969 - Fessler - NotchesChiara GastaldiNo ratings yet

- Tutorial Sheet 10Document2 pagesTutorial Sheet 10dineshazm83No ratings yet

- Nuclear Physics - Mind Map - Lakshya NEET 2024Document1 pageNuclear Physics - Mind Map - Lakshya NEET 2024aanyakaurchonaNo ratings yet

- Induction MotorDocument14 pagesInduction Motorhamba0007No ratings yet

- 107D Iv Feg 05a 00012Document68 pages107D Iv Feg 05a 00012vinayak jadhavNo ratings yet

- T.E. (Electrical) (Semester - II) Power System - IIDocument4 pagesT.E. (Electrical) (Semester - II) Power System - IIShubham KaklijNo ratings yet

- What Is Buoyancy?: Archimedes' PrincipleDocument1 pageWhat Is Buoyancy?: Archimedes' PrincipleYelchuri Kumar PhanindraNo ratings yet

- Defensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityFrom EverandDefensive Cyber Mastery: Expert Strategies for Unbeatable Personal and Business SecurityRating: 5 out of 5 stars5/5 (1)

- Generative AI: The Insights You Need from Harvard Business ReviewFrom EverandGenerative AI: The Insights You Need from Harvard Business ReviewRating: 4.5 out of 5 stars4.5/5 (2)

- Algorithms to Live By: The Computer Science of Human DecisionsFrom EverandAlgorithms to Live By: The Computer Science of Human DecisionsRating: 4.5 out of 5 stars4.5/5 (722)

- ChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindFrom EverandChatGPT Money Machine 2024 - The Ultimate Chatbot Cheat Sheet to Go From Clueless Noob to Prompt Prodigy Fast! Complete AI Beginner’s Course to Catch the GPT Gold Rush Before It Leaves You BehindNo ratings yet

- ChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveFrom EverandChatGPT Side Hustles 2024 - Unlock the Digital Goldmine and Get AI Working for You Fast with More Than 85 Side Hustle Ideas to Boost Passive Income, Create New Cash Flow, and Get Ahead of the CurveNo ratings yet

- Chaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyFrom EverandChaos Monkeys: Obscene Fortune and Random Failure in Silicon ValleyRating: 3.5 out of 5 stars3.5/5 (111)

- Cyber War: The Next Threat to National Security and What to Do About ItFrom EverandCyber War: The Next Threat to National Security and What to Do About ItRating: 3.5 out of 5 stars3.5/5 (66)