Professional Documents

Culture Documents

CNC SYSTEMS Electrical Component

Uploaded by

Rajendra Kumar YadavOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CNC SYSTEMS Electrical Component

Uploaded by

Rajendra Kumar YadavCopyright:

Available Formats

CNC SYSTEMS - ELECTRICAL COMPONENTS

(1) Power units In machine tools, power is generally required for

For driving the main spindle For driving the saddles and carriages. For providing power for some ancillary units.

The motors used for CNC system are of two kinds

Electrical - AC , DC or Stepper motors Fluid - Hydraulic or Pneumatic

Electric motors are by far the most common component to supply mechanical input to a linear motion system. Stepper motors and servo motors are the popular choices in linear motion machinery due to their accuracy and controllability. They exhibit favourable torque-speed characteristics and are relatively inexpensive.

(1.1) Stepper motors Stepper motors convert digital pulse and direction signals into rotary motion and are easily controlled. Although stepper motors can be used in combination with analog or digital feedback signals, they are usually used without feedback (open loop). Stepper motors require motor driving voltage and control electronics. The rotor of a typical hybrid stepper motor has two soft iron cups that surround a permanent magnet which is axially magnetized. The rotor cups have 50 teeth on their surfaces and guide the flux through the rotor- stator air gap. In most cases, the teeth of one set are offset from the teeth of the other by one-half tooth pitch for a two phase stepper motor.

Figure 24.1 Unipolar and Bipolar Stepper Motor

The stator generally has the same number of teeth as the rotor, but can have two fewer depending upon the motor's design. When the teeth on the stator pole are energized with North polarity, the corresponding teeth on the rotor with South polarity align with them. Similarly, teeth on the stator pole energized with South polarity attract corresponding teeth on the rotor that are energized with North polarity. By changing the polarity of neighbouring stator teeth one after the other in a rotating sequence, the rotor begins to turn correspondingly as its teeth try to align themselves with the stator teeth. The strength of the magnetic fields can be precisely controlled by the amount of current through the windings, thus the position of the rotor can be precisely controlled by these attractive and repulsive forces. There are many advantages to using stepper motors. Since maximum dynamic torque occurs at low pulse rates (low speeds), stepper motors can easily accelerate a load. Stepper motors have large holding torque and stiffness, so there is usually no need for clutches and brakes (unless a large external load is acting, such as gravity). Stepper motors are inherently digital. The number of pulses determines position while the pulse frequency determines velocity. Additional advantages are that they are inexpensive, easily and accurately controlled, and there are no brushes to maintain. Also, they offer excellent heat dissipation, and they are very stiff motors with high holding torques for their size. The digital nature of stepper motors also eliminates tuning parameters. There are disadvantages associated with stepper motors. One of the largest disadvantages is that the torque decreases as velocity is increased. Because most stepper motors operate open loop with no position sensing devices, the motor can stall or lose position if the load torque exceeds the motor's available torque. Open loop stepper motor systems should not be used for high-performance or high-load applications, unless they are significantly derated. Another drawback is that damping may be required when load inertia is very high to prevent motor shaft oscillation at resonance points. Finally, stepper motors may perform poorly in high-speed applications. The maximum steps/sec rate of the motor and drive system should be considered, carefully. ( 1.2) Servo Motors Servo motors are more robust than stepper motors, but pose a more difficult control problem. They are primarily used in applications where speed, power, noise level as well as velocity and positional accuracy are important. Servo motors are not functional without sensor feedback. They are designed and intended to be applied in combination with resolvers, tachometers, or encoders (closed loop). There are several types of servo motors, and three of the more common types are described as follows. The DC brush type servo motors are most commonly found in low-end to mid-range CNC machinery. The "brush" refers to brushes that pass electric current to the rotor of the rotating core of the motor. The construction consists of a magnet stator outside and a coil rotor inside. A brush DC motor has more than one coil. Each coil is angularly displaced from one another so when the torque from one coil has dropped off, current is automatically switched to another coil which is properly

located to produce maximum torque. The switching is accomplished mechanically by the brushes and a commutator as shown below. There are distinct advantages to using DC brush servo motors. They are very inexpensive to apply. The motor commutates itself with the brushes and it appears as a simple, two-terminal device that is easily controlled. Among the disadvantages it is the fact that they are thermally inefficient, because the heat must dissipate through the external magnets. This condition reduces the torque to volume ratio, and the motor performance may suffer inefficiencies. Also, the brushed motor will require maintenance, as the brushes will wear and need replacement. Brushed servo motors are usually operated under 5000 rpm. The DC brushless type offers a higher level of performance. They are often referred to as "inside out" DC motors because of their design. The windings of a brushless motor are located in the outer portion of the motor (stator), and the rotor is constructed from permanent magnets as shown below. DC brushless motors are typically applied to high-end CNC machinery, but the future may see midrange machinery use brushless technology due to the narrowing cost gap. AC servo motors are another variety that offers high-end performance. Their physical construction is similar to that of the brushless DC motor; however, there are no magnets in the AC motor. Instead, both the rotor and stator are constructed from coils. Again, there are no brushes or contacts anywhere in the motor which means they are maintenance-free. They are capable of delivering very high torque at very high speeds; they are very light and there is no possibility of demagnetization. .However, due to the electronic commutation, they are extremely complex and expensive to control. Perhaps the largest advantage of using servo motors is that they are used in closed loop form, which allows for very accurate position information and also allows for high output torque to be realized at high speeds. The motor will draw the required current to maintain the desired path, velocity, or torque, and is controlled according to the requirements of the application rather than by the limitations of the motor. Servo motors put out enormous peak torque at or near stall conditions. They provide smooth, quiet operation, and depending upon the resolution of the feedback mechanism, can have very small resolutions. Among the disadvantages of servo motors are the increased cost, the added feedback component, and the increased control complexity. The closed loop feature can be a disadvantage for the case when there is a physical obstacle blocking the path of motion. Rather than stalling, the servo motor will continue to draw current to overcome the obstacle. As a result, the system hardware, control electronics, signal amplifier and motor may become damaged unless safety precautions are taken.

( 2 ) Encoders An encoder is a device used to change a signal or data into a code. These encoders are used in metrology instruments and high precision machining tools ranging from digital calipers to CNC machine tools.

( 2.1) Incremental encoders With incremental linear encoders, the current position is determined by stating a datum and counting measuring steps. The output signals of incremental rotary encoders are evaluated by an electronic counter in which the measured value is determined by counting "increments". These encoders form the majority of all rotary encoders. Incremental rotary encoders with integral couplings used for length measurement are also in the market. The resolution of these encoders can be increased by means of electronic interpolation. There are, of course, the precision rotary encoders specifically designed for angle measurement. If finer resolution is required, standard rotary encoders often utilize electronic signal interpolation. Rotary encoders for applications in dividing heads and rotary tables, with very small measuring steps (down to 0.36 arc second) have in principle the same basic design features as standard rotary encoders, but incorporate some overall varying construction.

Figure 24.2 Rotary encoders

( 2.2 ) Absolute encoders Absolute linear encoders require no previous transfer to provide the current position value. Absolute rotary encoders provide an angular position value which is derived from the pattern of the coded disc. The code signal is processed within a computer or in a numerical control. After system switch-on, such as following a power interruption, the position value is immediately available. Since these encoder types require more sophisticated optics and electronics than incremental versions, a higher price is normally to be expected. Apart from these two codes, a range of other codes have been employed, though they are losing their significance since modern computer programs usually are based on the binary system for reasons of high speed. There are many versions of absolute encoders available today, such as single-turn or multi-stage versions to name only two, and each must be evaluated based on its intended application. ( 2.3 ) Rotary and Linear encoders A linear encoder is a sensor, transducer paired with a scale that encodes position. The sensor reads the scale in order to convert the encoded position by a digital

readout (DRO). Linear encoder technologies include capacitive, inductive, eddy current, magnetic and optical. A rotary encoder, also called a shaft encoder, is an electro-mechanical device used to convert the angular position of a shaft to a digital code, making it a sort of a transducer. Rotary encoders serve as measuring sensors for rotary motion, and for linear motion when used in conjunction with mechanical measuring standards such as lead screws. There are two main types: absolute and relative rotary encoders. Incremental rotary encoder uses a disc attached to a shaft. The disc has several radial lines. An optical switch, such as a photodiode, generates an electric pulse whenever one of the lines passes through its field of view. An electronic control circuit counts the pulses to determine the angle through which the shaft has turned. As the present trend of machine tools evolves toward increasingly higher accuracy and resolution, increased reliability and speeds, and more efficient working ranges, so too must feedback systems. Currently, linear feedback systems are available that will achieve resolutions in the submicron range.

Figure 24.3: Exposed and sealed linear encoders

Submicron resolutions, for example, are required in the semiconductor industry and in ultra-precision machining. Achieving these resolutions is possible with the use of linear scales which transmit displacement information directly to a digital readout. As in rotary, linear scales operate on the same photoelectric scanning principle, but the linear scales are comprised in an overall straight construction, and their output signals are interpolated or digitized differently in a direct manner. One of these signals is always used by the accompanying digital readout or numerical control to determine and establish home position on the linear machine axis in case of a power interruption or for workpiece referencing. Overall, there are two physical versions of a linear scale: exposed or enclosed as shown in the figure 24.3. With an enclosed or "sealed" scale, the scanning unit is mounted on a small carriage guided by ball bearings along the glass scale; the carriage is connected to the machine slide by a backlash-free coupling that compensates for alignment errors between the scale and the machine tool guide ways. A set of sealing lips protects the scale from contamination. The typical applications for the enclosed linear encoders are primarily machine tools. Exposed linear encoders also consist of a glass scale and scanning unit, but the two components are physically separated. The typical advantages of the non-contact system are

easier mounting and higher traversing speeds since no contact or friction between the scanning unit and scale exists. Exposed linear scales can be found in coordinate measuring machines, translation stages, and material handling equipment. Another version of the scale and scanning unit arrangement is one that uses a metal base rather than glass for the scale. With a metal scale, the line grating is a deposit of highly reflective material such as gold that reflects light back to the scanning unit onto the photovoltaic cells. The advantage of this type of scale is that it can be manufactured in extremely great lengths, up to 30 meters, for larger machines. Glass scales are limited in length, typically three meters. There are several mechanical considerations that need to be understood when discussing linear encoders. It is not a simple matter to select an encoder based just on length or dimensional profile and install the encoder onto a machine. These characteristic considerations include permissible traversing speeds, accuracy and resolution requirements, thermal behaviour and mounting guidelines.

Figure 24.4: Principle of rotary and linear encoders

( 3 ) CNC Controller There are two types of CNC controllers, namely closed loop and open loop controllers. These have been discussed in details in section 22.2. ( 3.1 ) Controller Architecture: Most of the CNC machine tools were built around proprietary architecture and could not be changed or updated without an expensive company upgrade. This method of protecting their market share worked well for many years when the control technology enjoyed a four-to-five year life cycle. Now a day the controller life cycle is only eight-to-twelve months. So CNC manufacturers are forced to find better and less expensive ways of upgrading their controllers. Open architecture is the less costly than the alternatives. GE Fanuc and other manufacturers introduced control architecture with PC connectivity to allow users to take advantage of the new information technologies that were slowly gaining acceptance on the shop floor. They created an open platform that could easily communicate with other devices over commercially available MS Windows operating system, while maintaining the performance and reliability of the CNC machine tool.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Role of Accounting Information in Management Decision MakingDocument25 pagesThe Role of Accounting Information in Management Decision MakingarunprasadvrNo ratings yet

- 5400 Replace BBU BlockDocument15 pages5400 Replace BBU BlockAhmed HaggarNo ratings yet

- Amie Material Science NotesDocument276 pagesAmie Material Science NotesRajendra Kumar Yadav100% (2)

- Tool Changing ArrangementsDocument5 pagesTool Changing ArrangementsRajendra Kumar YadavNo ratings yet

- CNC WorkingDocument6 pagesCNC WorkingRajendra Kumar YadavNo ratings yet

- Computer Aided InspectionDocument8 pagesComputer Aided Inspectionaqtu12fucNo ratings yet

- Computer Added Assembly PlanningDocument8 pagesComputer Added Assembly PlanningRajendra Kumar YadavNo ratings yet

- CNC SYSTEMS Mechanical ComponentsDocument2 pagesCNC SYSTEMS Mechanical ComponentsRajendra Kumar YadavNo ratings yet

- CNC Program VerificationDocument3 pagesCNC Program VerificationRajendra Kumar YadavNo ratings yet

- An Overview of CNC MachinesDocument8 pagesAn Overview of CNC MachinesRajendra Kumar Yadav100% (1)

- CNC Part Programming LLLDocument8 pagesCNC Part Programming LLLRajendra Kumar YadavNo ratings yet

- CNC Part Programming LLDocument8 pagesCNC Part Programming LLRajendra Kumar YadavNo ratings yet

- Classification of CNC Machine ToolsDocument7 pagesClassification of CNC Machine ToolsRajendra Kumar YadavNo ratings yet

- CNC Part Programming IDocument9 pagesCNC Part Programming IRajendra Kumar YadavNo ratings yet

- Revision Question Bank ME 2204Document11 pagesRevision Question Bank ME 2204Rajendra Kumar YadavNo ratings yet

- Rapid PrototypingDocument15 pagesRapid PrototypingRajendra Kumar YadavNo ratings yet

- CNC WorkingDocument6 pagesCNC WorkingRajendra Kumar YadavNo ratings yet

- GATE 2012 Production and Industrial Engineering Question Paper PDFDocument16 pagesGATE 2012 Production and Industrial Engineering Question Paper PDFakshayupadhyayNo ratings yet

- Revision Question Bank ME 2204Document11 pagesRevision Question Bank ME 2204Rajendra Kumar YadavNo ratings yet

- SSC Jobs SSC CGL Recruitment Notification 2014Document40 pagesSSC Jobs SSC CGL Recruitment Notification 2014Manavarthi RavitejNo ratings yet

- Tool Changing ArrangementsDocument5 pagesTool Changing ArrangementsRajendra Kumar YadavNo ratings yet

- GATE 2014 CE Answer KeyDocument70 pagesGATE 2014 CE Answer KeyJayakumar JanardhananNo ratings yet

- GATE 2014 CE Answer KeyDocument70 pagesGATE 2014 CE Answer KeyJayakumar JanardhananNo ratings yet

- UptuDocument33 pagesUptuRajendra Kumar YadavNo ratings yet

- Engine Fuel System SI Petrol VLEDocument20 pagesEngine Fuel System SI Petrol VLERajendra Kumar YadavNo ratings yet

- Chapter 1 MathDocument44 pagesChapter 1 MathRajendra Kumar Yadav100% (1)

- Vedic MathsDocument26 pagesVedic MathsRajendra Kumar YadavNo ratings yet

- 633651750976290000Document13 pages633651750976290000Rajesh BeheraNo ratings yet

- CO2 System ManualDocument11 pagesCO2 System Manualthugsdei100% (1)

- RhinoGold 4.0 - Level 1 - Tutorial 014P - Half Channel RingDocument2 pagesRhinoGold 4.0 - Level 1 - Tutorial 014P - Half Channel RingJulio mendoza100% (2)

- Longman General Practice Exercises 1-4 Merged and AnsweredDocument64 pagesLongman General Practice Exercises 1-4 Merged and AnsweredHowaida El MadawyNo ratings yet

- Following Is The List Wherein Maharashtra PollutionDocument18 pagesFollowing Is The List Wherein Maharashtra PollutionMld OnnetNo ratings yet

- Linguistic Determinism & Linguistic RealismDocument1 pageLinguistic Determinism & Linguistic RealismTünde KovácsNo ratings yet

- The Hydraulic Pumping SystemDocument12 pagesThe Hydraulic Pumping SystemCarlos Lopez DominguezNo ratings yet

- Dimensões S7 1200Document1 pageDimensões S7 1200iuctmeNo ratings yet

- Data DictionaryDocument4 pagesData DictionaryCamille Lucelo100% (1)

- Field Trip Grading RubricDocument1 pageField Trip Grading Rubricapi-242613835No ratings yet

- Adly 50 RS Parts ListDocument50 pagesAdly 50 RS Parts ListZsibrita GyörgyNo ratings yet

- 13.2.2.13 Lab - Incident HandlingDocument3 pages13.2.2.13 Lab - Incident Handlingc583706No ratings yet

- An Overview of Load Flow Analysis Methods For Electrical Distribution NetworksDocument3 pagesAn Overview of Load Flow Analysis Methods For Electrical Distribution NetworksSantosh Ramana Kumar JogaNo ratings yet

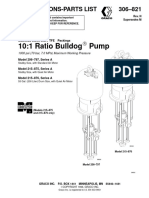

- BulldogDocument20 pagesBulldogFlorinNo ratings yet

- Environmental Life Cycle AssessmentDocument1 pageEnvironmental Life Cycle Assessmentkayyappan1957No ratings yet

- IELTS Writing - Bar ChartDocument2 pagesIELTS Writing - Bar ChartTrí Võ PhạmNo ratings yet

- Euro Ncap Aeb Test Protocol v11 PDFDocument31 pagesEuro Ncap Aeb Test Protocol v11 PDFRTCNNo ratings yet

- Unit: Pltu Bolok Area: UNIT #1 Equipment Standard Measurement Point Unit Minggu 1 Minggu 2 Minggu 3 Minggu 4 StatusDocument18 pagesUnit: Pltu Bolok Area: UNIT #1 Equipment Standard Measurement Point Unit Minggu 1 Minggu 2 Minggu 3 Minggu 4 StatusAchmad Zaki MubarokNo ratings yet

- Manual - Submersible PumpDocument4 pagesManual - Submersible PumpcodersriramNo ratings yet

- Mobilgrease XHP 460Document3 pagesMobilgrease XHP 460Jaime Miloz Masle JaksicNo ratings yet

- SolarDocument4 pagesSolarShweta RawatNo ratings yet

- Multibio BrochureDocument1 pageMultibio Brochuree-ComfortUSANo ratings yet

- How Bangalore Gets ElectricityDocument1 pageHow Bangalore Gets ElectricityNabeel AhmedNo ratings yet

- CarDocument5 pagesCarHarish GundaNo ratings yet

- Hazardous Area Heater Crex 020 Old Version 2721512-544292Document2 pagesHazardous Area Heater Crex 020 Old Version 2721512-544292Achintya KarmakarNo ratings yet

- Windows 10Document28 pagesWindows 10Vibal PasumbalNo ratings yet

- Guide To Port Entry CD: Frequently Asked Questions (FAQ)Document6 pagesGuide To Port Entry CD: Frequently Asked Questions (FAQ)Gonçalo CruzeiroNo ratings yet

- P40 Series: Technical SpecificationDocument2 pagesP40 Series: Technical SpecificationHarry HonchoNo ratings yet

- Math Lesson Plan 7 - Odd & EvenDocument3 pagesMath Lesson Plan 7 - Odd & Evenapi-263907463No ratings yet