Professional Documents

Culture Documents

Hot Runners

Hot Runners

Uploaded by

anisashraf90Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hot Runners

Hot Runners

Uploaded by

anisashraf90Copyright:

Available Formats

INTRODUCTION

ADVANTAGES&DISADVANTAGES

The use of hot runner systems is increasing due to the fact that they provide a more efficient method of molding plastic parts. The cost savings can be substantial, and the part quality is very often much better than a cold runner system. With the increasing sophistication of today's plastic injection molds, the use of a hot runner system is becoming an industry standard. Many applications simply are not possible with the old standard sprue and cold runner system, and hot runners offer a great way to maintain uniform wall thickness and eliminate knit lines and flow lines. ot runners offer the following advantages! " #o loss of melt and thus less energy and work input. " $asier fully automatic operation. " %onger holding pressure, which leads to less shrinkage. " &horter cycles' cooling time no longer determined by the slowly solidifying runners' no no((le retraction required. " Machines can be smaller because the shot volume, around the runners, is reduced, and the clamping forces are smaller because the runners do not generate reactive forces since the blocks and the manifold block are closed. " &uperior quality because melt can be transferred into the cavity at the optimum sites. " )ates at the best position' thanks to uniform, precisely controlled cooling of the gate system, long flow paths are possible. " *ressure losses minimi(ed, since the diameter of the runners is not restricted. " +rtificial balancing of the gate system can be performed during running production by means of temperature control or a special mechanical system ,e.g. adjustment of the gap in a ring shaped die or use of plates in low channel-. The disadvantages are! " .onsiderably higher costs involved. " Much more comple/ to work with. " More work involved with the start up of the production cycle. " Thermal isolation from the hot runner manifold block is problematic. " The risk of decomposition and production stoppages in the case of materials with low thermal resistance. " More susceptible to breakdowns, higher maintenance costs ,leakage, failure of heating elements, and wear caused by filled materials-. " 0isk of thermal damage to sensitive materials because of long flow paths and dwell times, especially on long cycles. " More efficient temperature control required, because a nonuniform temperature cycle will cause different melt temperatures and thus nonuniform filling.

INSULATED RUNNERS 1nsulated runner moulds have oversi(ed passages formed in the mould plate. The passages are of sufficient si(e that, under conditions of operation, the insulated effect of the plastic ,fro(en on the runner wall- combined with the heat applied with each shot maintains an open, molten flow path. The main advantages of the insulated systems over the heated systems is the low cost, the ability to have thorough color changes, low pressure loss due to the large diameter runners, and that it introduces less heat to the partforming cavities. The moulds are designed such that a parting line is located along the melts flow channel. This parting line can easily be opened while the mould is still in the moulding machine. 2nce the melt has fro(en, this parting plane can be opened and the runner completely removed. This technique provides for very thorough color changes as well as for servicing the mould if the runner inadvertently free(es off. 1f this system is used, it is normally limited to low tolerance parts and commodity plastics such as polyethylenes, polypropylenes, and polystyrenes.

Internally heated manifold and nozzle. INTERNALLY HEATED RUNNERS

This system takes advantage of the insulating effect of the plastic melt to reduce heat transfer ,loss- to the rest of the mould. The second consists of a cartridgeheated manifold with interior flow passages. The manifold is designed with various insulating features to separate it from the rest of the mould, thus reducing heat transfer ,loss-. 1nternally heated systems eliminates most leaking problems, provides good isolation of the heater from the surrounding mould and provides good gate tip control. +s heaters are internal, there is no need for a separate manifold block, which must be heated and insulated from the surrounding mould with an air space. *lastic around the perimeter of the flow channel free(es against the colder mould, solidifies, and provides a thermally insulating boundary of plastic. This reduces the challenge with e/ternally heated hot runner systems of insulating the heat from the partforming cavity where you are trying to free(e the plastic. 1n addition, without the air gap surrounding the manifold in an e/ternally heated system, leakage concerns are virtually eliminated. Therefore, these systems are not recommended for use with thermally sensitive materials. 1n addition, the pressure drop during mould filling will be the highest of any of the hot runner molds per amount of material in the runner. The flow cross section can be increased to reduce the pressure but will result in increased residence time for the molten material. The development of the fro(en layer around the perimeter of the flow channel continues to create a challenge with regard to color changes.

Internally heated manifold and nozzle.

EXTERNALLY HEATED RUNNERS $/ternally heated systems have the ability to provide the lowest pressure drop compared to other systems, e/cept possibly for insulated hot runners. The flow channels are cylindrical in cross section and generally have a larger diameter than a cold runner system. The cylindrical flow channel is the most efficient shape for melt flow. +s cooling of the runner and regrind are not issues in the case of hot runners, a larger diameter is permissible. 3oth the larger diameter and the fact that there is no growing fro(en layer in the runner system, contribute to the relatively low pressure drop of these systems. This type of system may also provide the most homogeneous melt temperature of all hot runner systems. + melt injected at a temperature of 456 7. can be surrounded by a flow channel that is heated at 456 7.. Therefore the temperature gradient across the flow channel can be reduced, in contrast to an internally heated system, which is surrounded by a cold wall. 8isadvantages of an e/ternally heated runner system include the potential for leaking of molten plastic and the amount and location of the required heat from the heaters. 1mproper design or operation can result in plastic leaking between the no((le and the manifold. This leaking plastic can engulf the manifold, entombing it and destroying heaters, wires, and thermocouples. 1n

addition, the e/ternal heat source is in direct conflict with the cooling of the mould. The hot no((les often must be surrounded by an airspace, which helps insulate them from the cavity.

Externally heated manifold and nozzle. Advantages and disadvantages of hot !nne s"ste#s$

%AINTENANCE O& HOT RUNNER SYSTE%S

ot runner systems require a new level of e/pertise on the part of the mold maker. owever, this does not mean that it is overly complicated or highly speciali(ed. + well designed system is relatively free from maintenance, once it is properly installed. 1t can, and does happen, that mold makers become frustrated with hot runner systems and swear that they are too much trouble. This is usually due to the fact that the system is not properly installed or incorrectly operated in the molding process.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5814)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Universiti Malaysia Perlis: Examination Result Semester 1 Academic Session 2011/2012Document1 pageUniversiti Malaysia Perlis: Examination Result Semester 1 Academic Session 2011/2012anisashraf90No ratings yet

- DataDocument2 pagesDataanisashraf90No ratings yet

- Compass Motor: ControllerDocument1 pageCompass Motor: Controlleranisashraf90No ratings yet

- IDT2 Misconception2Document2 pagesIDT2 Misconception2anisashraf90No ratings yet

- Bi Blog RafiDocument1 pageBi Blog Rafianisashraf90No ratings yet

- Senarai Rajah: 4.4.1.1 Mesin Khn4 (Side Cut) 48Document1 pageSenarai Rajah: 4.4.1.1 Mesin Khn4 (Side Cut) 48anisashraf90No ratings yet

- Building ManagmentDocument27 pagesBuilding ManagmentSharanabasappaDegoanNo ratings yet

- PBL20 Project Compal Confidential: LA-6772P Schematic REV 1.0Document45 pagesPBL20 Project Compal Confidential: LA-6772P Schematic REV 1.0Ramdas KambleNo ratings yet

- Presentation - RbiDocument10 pagesPresentation - Rbianandvishnubnair72% (18)

- Denson Lawsuit Vs LDS ChurchDocument21 pagesDenson Lawsuit Vs LDS ChurchLarryDCurtisNo ratings yet

- Wills and Succession - NotesDocument160 pagesWills and Succession - NotesMaria Divina Gracia D. MagtotoNo ratings yet

- Coke Japan Case Study: Mary Yan Marketing Strategies Spring 2020Document14 pagesCoke Japan Case Study: Mary Yan Marketing Strategies Spring 2020Mary YanNo ratings yet

- Sharp r-5970Document20 pagesSharp r-5970Unu DecebalNo ratings yet

- Cigre TB 498Document79 pagesCigre TB 498jchinchayNo ratings yet

- Trainee Staff For Travel AgencyDocument8 pagesTrainee Staff For Travel Agencym_tahir_saeedNo ratings yet

- Mutual Fund: Mutual Funds in IndiaDocument12 pagesMutual Fund: Mutual Funds in IndiaNirali AntaniNo ratings yet

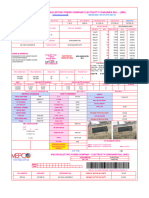

- MEPCO ONLINE BILL BankDocument1 pageMEPCO ONLINE BILL Bankahmadjutt19823No ratings yet

- Sample Paper 6 MathsDocument11 pagesSample Paper 6 Mathsaneeshkilli2008No ratings yet

- The API 2000 LC/MS/MS SystemDocument4 pagesThe API 2000 LC/MS/MS Systemdangerous0No ratings yet

- DAW Set UpDocument14 pagesDAW Set UpKCMNo ratings yet

- BiyDaalt2+OpenMP - Ipynb - ColaboratoryDocument3 pagesBiyDaalt2+OpenMP - Ipynb - ColaboratoryAngarag G.No ratings yet

- Data Structures (Queue) : Madhuri KalaniDocument45 pagesData Structures (Queue) : Madhuri KalaniMadhuri KalaniNo ratings yet

- S7 Edge Invoice PDFDocument1 pageS7 Edge Invoice PDFRajesh KumarNo ratings yet

- Gitam UniversityDocument100 pagesGitam UniversityvicterpaulNo ratings yet

- AGRD04B-15 Guide To Road Design Part 4B Roundabouts Ed3.1Document97 pagesAGRD04B-15 Guide To Road Design Part 4B Roundabouts Ed3.1fbturaNo ratings yet

- The Crusoe EffectDocument12 pagesThe Crusoe EffectCody LeesNo ratings yet

- Brochure B1510-50Hz Horizontal - Inline Selection Rev 12-14-06Document14 pagesBrochure B1510-50Hz Horizontal - Inline Selection Rev 12-14-06احمد الجزار2007No ratings yet

- Dana Inc Provides Civil Engineering Services During October Its TransactionsDocument1 pageDana Inc Provides Civil Engineering Services During October Its Transactionstrilocksp SinghNo ratings yet

- 2019 Grand Prix Hassan IIDocument4 pages2019 Grand Prix Hassan IIfernandoerrecNo ratings yet

- Cohen 2002Document23 pagesCohen 2002fab101No ratings yet

- 20230922Document84 pages20230922ERIC HubbardNo ratings yet

- PT. Falcon Prima Tehnik: Permintaan Pengadaan BarangDocument7 pagesPT. Falcon Prima Tehnik: Permintaan Pengadaan BarangGilang Raka Prima FebriantoNo ratings yet

- Ubc 2010 Fall Mueller JeffDocument168 pagesUbc 2010 Fall Mueller JeffmanojkumarNo ratings yet

- Internet and EcommerceDocument10 pagesInternet and EcommerceBikash15054No ratings yet

- Database Weekly Breakdown Session 2021Document3 pagesDatabase Weekly Breakdown Session 2021Mohammad Hamza NoorNo ratings yet

- PHD in Planning, Governance and Globalization - 2010-2011 Student HandbookDocument40 pagesPHD in Planning, Governance and Globalization - 2010-2011 Student Handbookmarc_evansNo ratings yet