INTRODUCTION

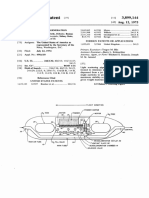

A bucket elevator, also called a grain leg, is a mechanism for hauling

flow able bulk materials (most often grain or fertilizer) vertically. It

consists of:

1. Buckets to contain the material

!. A belt to carry the buckets and transmit the "ull

#. $eans to drive the belt

%. Accessories for loading the buckets or "icking u" the material, for

receiving the discharged material, for maintaining the belt tension

and for enclosing and "rotecting the elevator. A bucket elevator

can elevate a variety of bulk materials from light to heavy and from

fine to large lum"s.

A centrifugal discharge elevator may be vertical or inclined. &ertical

elevators de"end entirely on the action of centrifugal force to get the

material into the discharge chute and must be run at s"eeds relatively

high. Inclined elevators with buckets s"aced a"art or set close together

may have the discharge chute set "artly under the head "ulley. 'ince

they don(t de"end entirely on the centrifugal force to "ut the material into

the chute, the s"eed may be relatively lower.

)early all centrifugal discharge elevators have s"aced buckets with

rounded bottoms. *hey "ick u" their load from a boot, a "it, or a "ile of

material at the foot "ulley.

*he buckets can be also triangular in cross section and set close to on

the belt with little or no clearance between them. *his is a continuous

bucket elevator. Its main use is to carry difficult materials at slow s"eed.

+arly bucket elevators used a flat chain with small, steel buckets

attached every few inches. ,urrent construction uses a rubber belt with

"lastic buckets. -ulleys several feet in diameter are used at the to" and

bottom. *he to" "ulley is driven by an electric motor.

*he bucket elevator is the enabling technology that "ermitted the

construction of grain elevators. A diverter at the to" of the elevator

allows the grain to be sent to the chosen bin.

A similar device with flat ste"s is occasionally used as an elevator for

humans, e.g., for em"loyees in "arking garages. (*his sort of elevator is

generally considered too dangerous to allow use by the "ublic.)

Bucket Elevator Working Principle

Bucket elevator is made u" of the move "art (ho""er and drag ta"e), the

u""er "art that has transmission drum and the under "art that has

cocking rotary drum, middle machine shell, driving device, o""osite

brake device. It is suit for lifting loose, density less than ../t0m#

"owdery, granularity and small block loose materials. 'uch as coal,

sand, charcoal "owder, cement, crushing mineral stone.

PARTS OF BUCET E!E"ATOR

*he motion of belt or chain is un1directional. Bucket elevator is a very

sim"le yet reliable device for lifting of bulk materials. Bucket elevators

en2oy a few advantages, which include sim"licity of design and

fabrication, re3uires minimum floor s"ace, low initial investment.

*y"es of bucket elevators:

4ften bucket elevators are classified according to the bucket s"acing

and mode of discharge. *hey are:

.. ,entrifugal discharge elevators

!. 5ravity or ,ontinuous discharge elevators

#. -ositive discharge elevators

,om"onents of bucket elevators:

*he essential com"onents of a bucket elevator are:

.. Buckets

!. ,arrying medium

#. Boot arrangement

%. 6ead arrangement

/. ,asings

A bucket elevator is a conveyor for carrying bulk materials in a vertical or

inclined "ath. Bucket elevators for the mechanical, vertical trans"ortation

of materials have become a crucial link in the "roduction "rocess in

many industrial sectors.

*y"ical elevator consists of:

.. An endless belt,

!. A chain or chains, to which buckets are attached,

#. )ecessary loading and discharging terminal machinery,

%. A drive arrangement,

/. 'u""orting frame or casing.

$aterial and convey it u" to and over the head s"rocket0"ulley, then

throwing the material out the discharge throat. *he em"tied buckets then

continue back down to the boot to continue the cycle.

Industrial Bucket +levators are made in a variety of sha"es, weights and

sizes, utilizing centrifugal buckets or continuous buckets. *he belt can be

made of natural fibres, rubber, "lastic or metal.

,entrifugal Bucket +levators are most commonly used to convey free

flowing materials. *hey o"erate at high s"eeds, which throw the

materials out the buckets into discharge throat by centrifugal force.

,ontinuous Bucket +levators have buckets s"aced continuously and

o"erate at slower s"eeds. *he continuous bucket "lacement allows the

force of gravity to discharge their load onto the inverted front of the

"receding bucket. *he bucket then guides that material into the

discharge throat on the descending side of the elevator. *hey minimize

"roduct damage or are used to handle light, fluffy materials where

aeration of the "roduct must be avoided.

T#PE OF BUCET E!E"ATOR

APP!ICATION

*y"ical average materials which can be conveyed by bucket elevators

are:

7 8ime stone crushed to !/ to #9 mm size,

7 :oundry sand,

7 ,oal,

7 ,oke,

7 'ugar

7 Animal feed

7 ,hemicals

7 -hos"hate rock,

7 ,ement mill clinker

7 :riable

7 :ragile materials

7 ,andy

7 'nacks

7 ,offee

7 ;ice

7 'eed

7 'oa"s

7 <etergents

7 -lastic 5ranules

!I$ITATIONS

8imitations of the system include the following "oints:

7 8um" size should be under .99mm

7 *he material should not be very sticky

7 *he tem"erature of the materials should be ambient or slightly above

7 *he materials should not be e=cessively corrosive or abrasive

Advantages of belt system over chain system:

*he traction element may be either endless belt or endless chain, but

belt system is "referred under certain conditions for the following

reasons:

7 6igher s"eeds "ossible

7 >uieter o"eration

7 -ossess better abrasive resistance to materials like sand, coke etc.

BUCET E!E"ATOR %ORSE POWER

AND

CA!CU!ATIONS

*here are many variables to consider when designing a Bucket +levator.

*hese include bucket size, bucket s"acing, s"eed, and various

com"onents. *his information can act as a guide for determining the

6orse -ower (6-) re3uirements of a Bucket +levator.

?hen designing a Bucket +levator there are more variables to be

consider that can be listed here. It should be noted that a small mistake

in calculating the re3uired 6- of a small, low ca"acity Bucket +levator

may not result in a unit failure, but a small mistake on a large, high

ca"acity bucket elevator may result in a catastro"hic failure. *his is why

it is im"ortant to always work with an e="erienced Bucket +levator

$anufacturer who can hel" in the design and im"lementation of a

successful "ro2ect.

Deter&ining %or'e Po(er

*o be able to accurately determine the "ower re3uirements of a Bucket

+levator, it must first be understood the internal forces acting on the unit.

Although there are many com"onents in the Bucket +levator, only the

u"ward movement of the conveyed "roduct needs to be considered.

*his is because the weight of the Belt0,hain and ,u"s are identically

balanced on both sides of the head shaft. 4nly the internal friction

caused by the movement of these com"onents needs to be considered

when calculating the 6- re3uirements.

*here are many variations of 6orse -ower (6-) calculations found in

historical and individual manufacturer@s literature. *he formulas below

are used to determine the "ower re3uirements of a Bucket +levator

throughout the industry.

E)uation * + Po(er For&ula

A basic "ower calculation is the measure of force over a distance "er

time "eriod.

+3uation 'ymbols

- -ower

: :orce

< <istance

* *ime

E)uation , + Bucket Elevator Po(er For&ula

In a Bucket +levator the "ower re3uirement can be directly calculated

using this formula.

+3uation 'ymbols

- -ower to convey the "roduct

? ?eight of material being lifted

6 8ift 6eight

* *ime

, 6- re3uired overcoming the friction in the system.

E)uation - + Bucket Elevator Po(er For&ula

Asing the above formula and substituting the gravimetric rate of a bucket

elevator, the following e3uation can be derived.

+3uation 'ymbols

- -ower (6-)

5 5ravimetric ;ate (-ounds -er 6our)

<6 <ischarge 6eight (:*)

, 6- re3uired overcoming the friction in the system.

S.'te& Friction

:riction includes the following variables:

7 ,u" <igging

7 Belt sli" on the head "ulley

7 ,hain sli" on s"rockets

7 Bearing friction

7 <rive Inefficiencies

:actor B,C is an estimate of the friction in the system and is re3uired to

accurately determine the "ower re3uirements of a Bucket +levator.

)ote: $otor inefficiency is not used because these formulas are used to

determine the $otor size. $otor 6- ratings include their inherent

inefficiencies.

*here are two methods used to determine the "ower re3uired to

overcome the friction in the system. *he first is the 8ength +3uivalency

$ethod. *his method uses a factor of the tail "ulley diameter to

determine the additional "ower re3uired to account for the system

friction. *he second method is the :riction :actor $ethod. *his method

uses a multi"lication factor of account for the friction in the system.

!engt/ E)uivalenc. $et/o0

E)uation 1 + Bucket Elevator S.'te& Friction 2 !E3 $et/o0

'ystem friction can be accounted for with a length e3uivalency factor.

*his factor is de"endent on the "ulley diameter and is shown below. *he

8ength +3uivalency :actor ranges from / to./, de"ending on the

a""lication. ,onsult your Bucket +levator 'u""lier for additional

information.

+3uation 'ymbols

, 'ystem :riction (6-)

5 5ravimetric ;ate (-ounds -er 6our)

d *ail -ulley <iameter (:*)

8e3 8ength +3uivalency :actor

E)uation 4 + Bucket Elevator Po(er For&ula 2 !E3 $et/o0

,ombining +3uations # and % yields the following e3uation.

+3uation 'ymbols

- -ower (6-)

5 5ravimetric ;ate (-ounds -er 6our)

<6 <ischarge 6eight (:*)

d *ail -ulley <iameter (:*)

8e3 8ength +3uivalency :actor

BE!T BUCET E!E"ATOR DESI5N NOTES

*hese notes are

intended to assist

not a substitute for

conducting

and "ublisher do not

know the

<I',8AI$+;

and "rovide direction in the "rocess of designing belt bucket

elevators. *hey are a thorough engineering analysis of the

design re3uirements. Because the author conte=t in which

the notes are to be used and cannot review the resulting

design

,4)*+)*' 4: <+'I5) )4*+'

..9 4verview of belt bucket elevators and their use.

!.9 <etermine through"ut ca"acity.

#.9 <etermine belt s"eed and throw.

%.9 ,alculate motor "ower.

/.9 ,alculate to" and bottom "ulley shaft sizing.

D.9 <rive arrangement and design.

E.9 'haft bearing and seal arrangement.

F.9 'electing elevator frame structural members.

G.9 Inlet and outlet chute design.

.9.9 ,onsiderations in choosing "anel materials.

...9 'electing belts and buckets.

.!.9 $ethods to take1u" belt tension.

.#.9 -rotection against bogging the buckets.

.%.9 ,lean1out considerations.

./.9 <ust e=traction re3uirements.

.D.9 Installing the bucket elevator in "lace.

.E.9 ,orrect o"eration of belt bucket elevators.

.F.9 $aintenance of belt bucket elevators.

T/e le6t+/an0 colu&n provi0e' 0e'criptive te7t8 )+,+''A;H

I):4;$A*I4)

;e3uired "roduct "arameters.

'ervice use.

$aterial chemical name.

Bulk density I mass0volume I kg0m

#

$a=imum duty I kg0hr or m

#

0hr

$a=imum lum" size 1 dimensions

average size

"ercentage of lum"s in total

6eight "roduct is to be raised (meters) and angle of incline if any.

-rovide enough height at the outlet of the discharge chute so the

"roduct is always falling following discharge. -roduct characteristics I

abrasiveness

flow ability I free0cohesive0slug dam"ness I J moisture

friability I firm0breaks0"owders "article sha"e I

length0size0volume

tem"erature of "roduct

angle of re"ose

corrosiveness

4"erating environment, location and conditions I

corrosive0dam"

'ervice re3uired I continuous0intermittent.

4"en or closed boot design.

'+8+,* BA,K+* 'IL+ A)< '-A,I)5

*he size and number of buckets is determined from the re3uired

through"ut using an iteration "rocess.

'elect the bucket from the range in the bucket su""lier@s catalogue. 4nly

!0# (DEJ) of the bucket@s design ca"acity is used in calculations.

,entrifugal discharge conveys usually have a s"acing between buckets

that is ! to # times the bucket "ro2ection, though the s"acing can be

greater for free1flowing "roducts.

<+*+;$I)+ B+8* '-++<

*he bucket s"acing times the number of buckets "er second determines

the re3uired belt s"eed. *he s"eed for centrifugal bucket elevators is

usually in the range of . m0s to ! m0s to insure the "roduct throws into

the chute at the head "ulley.

,A8,A8A*+ 6+A< -A88+H <IA$+*+;

A sim"lifying assum"tion is made that the throw commences at the to"

of the head "ulley. At this "oint the centrifugal force and gravity force are

balanced.

,entrifugal force M m 7 v ! 7 cos /3where

r

m M mass in kg

v M belt s"eed in m0s

M angle from to" dead centre

r M "ulley radius in m 5ravity force M m7 g where

g M gravity constant G.F m0sec

!

. -utting both forces e3ual to each other 1

*he right1hand column "rovides an e=am"le.

)+,+''A;H I):4;$A*I4)

-roduct "arameters.

;aise crushed "roduct from mill outlet to storage silo. Aluminium

'ul"hate.

.E99 kg0m

#

/,999 kg0hr # mm ma= ! mm

)il

/./ m including length of discharge chute into % m high storage silo.

'har" edges

:ree

8ess than !J

:irm

,onsistent

Ambient

#9 degrees

,orrosive if dam" <ry and airy

Intermittent I u" to .! hours "er day D days a week 4"en boot bottom,

elevator will sit on a concrete floor.

'+8+,* BA,K+* 'IL+ A)< '-A,I)5

/,999 kg0hr through"ut.

'elect a bucket ./9 mm wide = .99 mm "ro2ection with a volume of 9.EF

litre.

Asing !0# of the volume give a ca"acity of 9./ litre.

9./ lt. is 9.999/ m

#

and holds 9.F/ kg of "roduct. (9.999/ m# = .E99

kg0m

#

).

*o move /999 kg0hr using ./9 = .99 buckets re3uires D,999 buckets "er

hour or .99 buckets "er minute. 'elect a bucket s"acing of #99 mm.

<+*+;$I)+ B+8* '-++<

.99 buckets "er minute0D9 sec "er minute M ..E bucket0sec. ..E

bucket0sec = 9.# m M 9./ m0sec. *his is too low and will "rove to be

insufficient for a clearance throw into the discharge chute. *he bucket

s"acing will need to be increased and the

calculation re"eated.

*he head "ulley diameter is /9 mm. *his size, though accurately

calculated, is not "ractical. It is far too small. *he buckets cannot deform

sufficiently to go around the "ulley without over1stressing both buckets

and belt.

!

G . F 0 sec

m

g

*he solution is to increase the bucket s"acing or to use smaller buckets.

*his then re3uires a "ro"ortionate s"eed increase to maintain the

through"ut. *he greater velocity needs a larger head "ulley revolving at

the same ;-$. 6owever as we are using the smallest buckets available

it is necessary to increase the bucket s"acing.

v! Mg.r.cos 13

cos /3 M . at to" dead centre.

*herefore r M and diameter (d)M!.r

v

!

g

,A8,A8A*+ *6;4? I)*4 ,6A*+ A)< ,6A*+ 'IL+

Asing the standard tra2ectory formula !

s M u . t N 9 . / . a . t

?here s M dis"lacement (m)

u M initial velocity (m0s)

a M acceleration (m0s

!

) M gravity constant g M G.F m0s

!

t M time (sec)

*he tra2ectory after the "roduct leaves the bucket can be gra"hed and

the chute height determined.

*he horizontal com"onent at to" dead centre of the "ulley where

acceleration due to gravity in the horizontal direction is zero is given by

sh M u . t meters.

*he vertical com"onent at to" dead centre where velocity in the vertical

direction is zero is given by !

s

v

M 9 . / . a . t

meters.

*he distance of the chute from the vertical center of the head "ulley

must be sufficient to allow the buckets to clear the wall of the elevator on

the downward leg.

<+*+;$I)+ *6+ <;I&+ A;;A)5+$+)*

?ith the head "ulley size determined and the linear belt s"eed known,

the ;-$ of the head "ulley can be calculated.

RPM V m s .D9

Asually a %1"ole motor at .%/9 ;-$ with a reduction gearbo= of suitable

ratio is selected to drive the head "ulley. *he gearbo= can be a direct

drive or shaft1mounted unit de"ending on the available s"ace and

access.

*he belt velocity using a bucket s"acing of E99 mm with

. .

'6A:* B+A;I)5 A)< '+A8 A;;A)5+$+)*

4nce the shaft size is determined the bearing size can be selected.

:ollow the bearing manufacturer@s selection "rocess for calculating the

re3uired bearing ty"e and configuration for the e3ui"ment design life and

service factors.

-rovide shaft seals for the bearing at the bearing housing and at the

"enetration into the elevator frame. *he bearing must never be e="osed

to dust or dirt or moisture while in the "roduction environment. <o

everything necessary to "rotect the bearing.

*he bearing and seal su""liers can advise other ways of mounting and

"rotecting the bearing.

*he best bearing arrangement design is to stand the bearing off the

elevator frame with a clearance of around !/ mm. +8+&A*4; :;A$+

$+$B+;'

*he frame can either be made of an angle iron skeleton to which sheets

of steel are attached or from sheets of steel "ressed to the re3uired

rectangular sha"e that are flanged and bolted together.

*he thickness and lengths of section used in the frame must be

sufficient to "revent buckling under load. I)8+* A)< <I',6A;5+

,6A*+ <+'I5)

*he inlet chute should be designed to "romote "roduct flow and to

minimise the amount of bucket drag. -referably the "roduct feed falls

into the buckets as they come around the tail "ulley without being

dragged through a fully "lugged boot.

*he feed chute should be made with a slightly smaller width than the

buckets. It should be sufficiently stee" to insure "roduct always flows

and does not build back. *est the "roduct@s flowability if "ossible by

"utting some on a bent sheet of the elevator chute material sha"ed into

a OA@ the same width as the chute. *ilt it to find the angle that "roduces

flow.

Insure there are no restrictions or "rotrusions into the chute that will

cause the "roduct to build back.

*he discharge chute size is known from the initial design. *he angle at

which it is set must meet the same criteria as the inlet. 6+A< A)< *AI8

-A88+H <+'I5)

*he head "ulley dimensions have been determined. :or sim"licity the

tail "ulley should be to the same dimensions as the head "ulley. *his will

kee" the buckets a constant distance off the elevator wall and aid

"roduct "ick1u" and sim"lify chute design and fabrication. Both head

and tail "ulleys need to be crowned to centralise the belt and "ermit the

belt to be tracked if it wanders. *he crowning should be ! degrees both

left and right from the center of the drum.

*he head "ulley could be rubber lagged if desired to increase the

coefficient of friction and lower the belt tension. *his will allow use of a

lighter duty belt. But there is always the "ossibility the lagging will be

stri""ed off during o"eration. It is best to design for a metal drum and

use lagged "ulleys only when detection of bogged conditions is installed.

;ibbing can also be mounted on the to" "ulley to increase friction and

act by Odigging@ into the rubber belt and "roducing a grabbing effect. *he

ribs are "laced across the full a=ial length of the drum and "ositioned so

that at least two ribs are always in contact with the belt. *he rigs should

be # mm to % mm high and contoured into the drum so as not to ri" the

belt.

*he tail "ulley should be a self1cleaning design. *his can be achieved in

two ways I

1 constructing the "ulley drum of !9 mm or !/ mm round bars of length

wider than the belt. *he bars are s"aced around the end "lates with

ga"s for "roduct to fall through. 'ize the s"acing between ribs with

sufficient clearance for small "roduct to fall through. 8arger "roduct will

not fit through the ga"s.

1 "rovide a twin o""osed1cone hub with the cone@s base starting at the

center and ta"ering to the shaft at the ends of the "ulley. !9 mm or !/

mm round bars are welded to the outer rim of the cones and gussetted

back to the cone wall for stiffness.

*he "ulley can be mounted to the shaft using ta"er locks fitted to

suitably sized hub, interference "ress fits, retainers screwed and

doweled to the shaft, hubs screwed and doweled to the shaft or key way

in the hub and shaft.

-ostal Address: :++< :4;?A;< -AB8I,A*I4)', -4 Bo= /EF,

B+)*8+H, ?est Australia, D.9!. +1mail Address:

feedforwardPbig"ond.com

Because the authors and "ublisher do not know the conte=t in which the

information "resented in the flyer is to beused they acce"t no

res"onsibility for the conse3uences of using the information contained or

im"lied in any articles

A0vantage o6 Bucket Elevator

,om"ared with the belt1ty"e bucket elevator, ,hain1ty"e bucket elevator

has / main im"rovements.

.. 8onger serving life. ,hain1ty"e bucket elevator with two circular

chains, the moving "arts (ho""er and traction chain), the u""er section

with s"rocket, lower section with taut round, intermediate casing, the

drive, check brake device. *he chain has a very longer service life than

the belt.

!. +asy for o"eration and maintenance. If ,hain1ty"e bucket elevator@s

chain has "roblems, ;emove broken ring link, and then re"laced with a

new one. Belt1ty"e bucket elevator need to constantly ad2ust belt

tightness.

#. +asy to ad2ust. ,hain1ty"e bucket elevator is generally ad2ust the

chain tightness, 2ust ad2ust the tensioning device is ok. Belt1ty"e bucket

elevator for a long time to use, belt wear will tear very large, only to

re"lace a new belt.

%. 8oading and Anloading methods. ,hain bucket elevator dig emulated

load, Qfeeding methodQ discharge. 6igh1efficiency transmission. It also

can design the ty"e of layout according to user re3uirements.

/. 'horten the time of downtime. ,hain as the traction "arts, greatly

reducing downtime, effectively e=tend the "roduction time.

Feature'

.. 8ower "ower consum"tion and driving "ower. Ado"ting the intensive

layout of inflowing feeding, induced discharge and large ca"acity

ho""er.

!. 6igh lifting height, good transmission ca"acity, fully sealed of the body

and small environmental "ollution.

#. 6aving no strict re3uirements on the ty"es and characteristics of the

materials, which can not only lift the general "owdery and granular

materials, but also hoist the abrasive materials.

%. 4"erational reliability, advanced design "rinci"les and "rocessing

methods ensure the reliability of the whole machine o"eration.

Sa6et.

'afety must be considered a basic factor in machinery o"eration at all

times. $ost accidents are the result of carelessness or negligence. *he

following safety instructions are basic guidelines and should be

considered as minimum "rovisions. Additional information shall be

obtained by the "urchaser from other sources, including the American

'ociety of $echanical +ngineers, 'tandard A)'I B!9.., 'tandard A)'I

B./.. 'tandard A)'I L!%%.

It is the res"onsibility of the contractor, installer, owner and user to

install, maintain and o"erate the bucket elevator and elevator

assemblies manufactured and su""lied by $artin ,onveyor <ivision, in

such a manner as to com"ly with the ?illiams1'teiger 4ccu"ational

'afety and 6ealth Act and with all state and local laws and ordinances

and the American )ational 'tandards Institute 'afety ,ode.

PRECAUTIONS

$aintain a safety training and safety e3ui"ment

o"eration0maintenance "rogram for all em"loyees.

.. Bucket elevators shall not be o"erated unless the elevator housing

com"letely encloses the elevator moving elements and "ower

transmission guards are in "lace. I6 t/e elevator i' to be opene0 6or

in'pection9 cleaning or ob'ervation9 t/e &otor 0riving t/e

conve.or i' to be locke0 out electricall. in 'uc/ a &anner t/at it

cannot be re'tarte0 b. an.one9 /o(ever re&ote 6ro& t/e area9

unle'' t/e elevator /ou'ing /a' been clo'e0 an0 all ot/er

guar0' are in place8

!. If the elevator must have an o"en housing as a condition of its use

and a""lication, the entire elevator is then to be guarded by a railing

or fence.

#. ;A55+< gratings may be used where necessary. If the distance

between the grating moving elements is less than % inches, the

grating o"ening must not e=ceed

.

R! inch by ! inches. In all cases the

o"enings shall be restrictive to kee" any "art of the body or clothing

from coming in contact with moving "arts of the e3ui"ment. '48I<

,4&+;' should be used at all "oints and must be designed and

installed so that "ersonnel will not be e="osed to accidental contact

with any moving "arts of the e3ui"ment.

%. All rotating e3ui"ment such as guards, drives, gears, shafts and

cou"lings must be guarded by the "urchaser0owner as re3uired by

a""licable laws, standards and good "ractice.

/. 'A:+*H <+&I,+' A)< ,4)*;48' must be "urchased and

"rovided by the "urchaser0owner as re3uired by a""licable laws,

standards and good "ractices.

D. -ractice good housekee"ing at all times and maintain good lighting

around all e3ui"ment.

E. Kee" all o"erating "ersonnel advised of the location and o"eration of

all emergency controls and devices. ,lear access to these controls

and devices must be maintained.

F. :re3uent ins"ections of these controls and devices, covers, guards

and e3ui"ment to ensure "ro"er working order and correct

"ositioning.

G. <o not walk on elevator covers, gratings or guards.

.9. <o not "oke or "rod material in the elevator.

... <o not "lace hands, feet or any "art of the body or clothing in the

elevator or o"ening.

.!. <o not overload elevator or attem"t to use it for other than its

intended use.

.#. Inlet and discharge o"enings shall be connected to other

e3ui"ment in order to com"letely enclose the moving elements of the

elevator.

.%. Before "ower is connected to the drive a "re1start u" check shall

be "erformed to ensure the e3ui"ment and area are safe for

o"eration and all guards are in "lace and secure.

./. Bucket +levators are not manufactured or designed to handle

materials that are hazardous to "ersonnel unless s"ecially designed.

*hese materials which are hazardous include those that are

e="losive, flammable, to=ic or otherwise dangerous to "ersonnel.

+levators may be designed to handle these materials. +levators are

not manufactured or designed to com"ly with local, state or federal

codes for unfired "ressure vessels. If hazardous materials are to be

conveyed or if the elevator is to be sub2ected to internal or e=ternal

"ressure, ,onveyor

<ivision should be consulted "rior to any modifications.

.D. ;emoval of backsto" may cause une="ected machine movement.

;emove or block all e=ternal loads before servicing unit. :ailure to

observe these "recautions could result in bodily in2ury.

All e3ui"ment shall be checked for damage immediately u"on arrival. Do

not atte&pt to in'tall a 0a&age0 ite& or elevator8

All bucket elevators sho" assembled by $artin ,onveyor <ivision, have

warning labels affi=ed in many easily seen locations. If the e3ui"ment

e=terior is "ainted, coated or altered in any way or if the material con1

veyed is in e=cess of .E/S: or if a change in the original intended use of

the e3ui"ment is considered, the factory shall be consulted before

modifications are made. Additional stickers are available u"on re3uest.

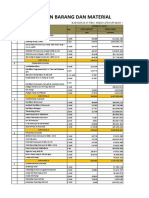

ESTI$ATIN5 AND CONSTIN5

CHS930001

E7po'e0 &oving

part' can cau'e

'evere in:ur.

!OC OUT POWER

be6ore re&oving

guar0

'.)o.

)ame of $aterial with

'"ecification

)ecessary

>uantity

;ate ,ost

. Belt I 6eight ME99 mm . !99 !99

! Bucket M -lastic .9 .9 .99

# 'ilo . #99 #99

% $otor M ! "hase . ./99 ./99

/ ;oller ! F9 .D9

D ?ood cover . .!99 .!99

Total co't #%D9