Professional Documents

Culture Documents

Fire Pump Application Packet - 0

Uploaded by

Cep's Lobush0 ratings0% found this document useful (0 votes)

44 views4 pagesFire Pump Plans Submittal Checklist is required information for Fire Pump Installation permit review. Use of the form does not guarantee that plans will be accepted on the first submittal, but will aid in reducing the number of re-submittals required due to lack of information or conflicting information being provided.

Original Description:

Original Title

Fire Pump Application Packet_0

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFire Pump Plans Submittal Checklist is required information for Fire Pump Installation permit review. Use of the form does not guarantee that plans will be accepted on the first submittal, but will aid in reducing the number of re-submittals required due to lack of information or conflicting information being provided.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

44 views4 pagesFire Pump Application Packet - 0

Uploaded by

Cep's LobushFire Pump Plans Submittal Checklist is required information for Fire Pump Installation permit review. Use of the form does not guarantee that plans will be accepted on the first submittal, but will aid in reducing the number of re-submittals required due to lack of information or conflicting information being provided.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

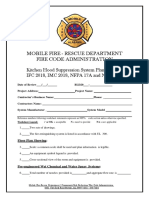

Fire Safety Application

Escambia County, Florida

Fire Safety Permit Number:

Building Permit Number:

Approved By:

Date:

Revised 08/07/2012

Nature of J ob:

Hood Suppression Sprinkler System Underground Piping Fire Suppression

J ob Address: Building or Unit Number:

Owner Name: Phone Number:

Project Name:

Name of Installer: Phone Number:

Name of Company: Phone Number:

Please complete all secti ons below that may apply:

Sprinkler System: (Circle One)

Number of Fire Hydrants

Partial (P) or Complete (C) Number of Fire Department Hoses

Standpipe System: (Circle One)

Number of Fire Pump Connections

Class I, Class II, or Class III Number of Underground Stub-Ins (ONLY)

Number of Units

Number of Heads

Number of Units Per Floor

Number of Hood Suppression Systems

Number of Floors

Number of Garbage Chutes

Total Square Feet

Number of Laundry Chutes

Number of Hose Cabinets

Number of Underground Fire Mains

Number of Fire Water Storage Tanks

Other:

Additional Information:

NOTICE: No work shall be commenced until a permit has been secured. All work must be inspected

before covering. At least twenty-four (24) hours notice must be given for inspection.

I hereby make application to perform the work as described herein. All Provi sions of the Law

shall be complied with whether they have been specified herein or not.

Applicants Signature:

Date:

County License Number:

Escrow Account Number:

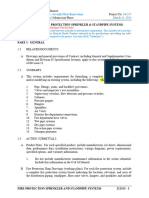

FI RE PUMP

PLANS SUBMI TTAL CHECKLI ST

NFPA 20, (2007 EDI TI ON)

FIRE PREVENTION DIVISION

PUBLIC SAFETY BUREAU

The following Fire Pump Plans Submittal Checklist is required information for Fire Pump Installation permit review.

Use of the form does not guarantee that plans will be accepted on the first submittal, but will aid in reducing the

number of re-submittals required due to the lack of information or conflicting information being provided. This

checklist should not be considered to be all-inclusive. Additional information may be required. Use of this

checklist will not eliminate the requirement for a good knowledge and understanding of NFPA 20.

For issuance of the Installation of Stationary Pumps for Fire Protection permit and prior to any installation and

inspection request, the following information and/or forms shall be completed, submitted and approved.

Completed & approved permit application.

Include payment for permit fees.

Three (3) sets of shop drawings/plans.

Any material installed or work performed prior to the issuance of a permit will be subject to two times the

permit fee and/or required to be removed. A hard copy of the permit and an the approved set of plans are

required to be maintained on the Job site at all times and must be on site prior to any work being performed

unless a limited early start request has been granted. Limited early start requests are considered on a case

by case basis, are required to be submitted in writing on letter head and are not automatically granted.

5.2.1 Stationary pumps shall be selected based on the conditions under which they are to be installed and used.

5.2.2 The pump manufacturer or its authorized representative shall be given complete information

concerning the liquid and power supply characteristics.

5.2.3 A complete plan and detailed data describing pump, driver, controller, power supply, fittings,

suction and discharge connections, and liquid supply conditions shall be prepared for approval.

5.2.4 Each pump, driver, controlling equipment, power supply and arrangement, and liquid supply shall

be approved by the authority having jurisdiction for the specific field conditions encountered.

5.12.1* General Requirements. The fire pump, driver, controller, water supply, and power supply

shall be protected against possible interruption of service through damage caused by explosion, fire,

flood, earthquake, rodents, insects, windstorm, freezing, vandalism, and other adverse conditions.

5.12.1.1.1* Indoor fire pumps in high-rise buildings shall be physically separated or protected by 2

hour fire-rated construction.

5.12.1.1.2 Indoor fire pumps in non-high-rise buildings shall be physically separated or protected by

fire-rated construction in accordance with Table 5.12.1.1.2..

5.12.1.1.3 Location and access to the fire pump room shall be pre-planned with the fire department.

5.12.1.1.4 Rooms containing fire pumps shall be free from storage and penetrations not essential to

the operation of the pump and related components.

5.12.1.2.1 Fire pump units located outdoors shall be located at least 50 ft (15.3 m) away from any

exposing building.

5.12.1.2.2 Outdoor installations also shall be required to be provided with protection against possible

interruption in accordance with 5.12.1.

Page 1 of 3

New 10/31/12

FI RE PUMP

PLANS SUBMI TTAL CHECKLI ST

NFPA 20, (2007 EDI TI ON)

FIRE PREVENTION DIVISION

PUBLIC SAFETY BUREAU

5.12.1.3 Fire Pump Buildings or Rooms with Diesel Engines.

Fire pump buildings or rooms enclosing diesel engine pump drivers and day tanks shall be protected with

an automatic sprinkler system installed in accordance with NFPA 13, Standard for the Installation of

Sprinkler Systems.

5.12.2.1 An approved or listed source of heat shall be provided for maintaining the temperature of a

pump room or pump house, where required, above 40F (5C).

5.12.2.2 The requirements of 11.6.5 shall be followed for higher temperature requirements for internal

Combustion engines.

5.12.3 Normal Lighting. Artificial light shall be provided in a pump room or pump house.

5.12.4.1 Emergency lighting shall be provided in accordance with NFPA 101, Life Safety Code

5.12.4.2 Emergency lights shall not be connected to an

engine-starting battery.).

5.12.5 Ventilation. Provision shall be made for ventilation of a pump room or pump house.

5.12.6.1 Floors shall be pitched for adequate drainage of escaping water away from critical equipment such

as the pump, driver, controller, and so forth.

5.12.6.2 The pump room or pump house shall be provided with a floor drain that will discharge to a frost-free

location.

5.14.3.4 The size of that portion of the suction pipe located within 10 pipe diameters upstream of the pump

suction flange shall be not less than that specified in Section 5.25.

5.19.1.1* A fire pump installation shall be arranged to allow the test of the pump at its rated conditions as well

as the suction supply at the maximum flow available from the fire pump.

11.6.6.1 The sequence for emergency manual operation, arranged in a step-by-step manner, shall be

posted on the fire pump engine.

14.1.3* The installing contractor shall furnish a certificate for flushing and hydrostatic test prior to the

start of the fire pump field acceptance test.

14.2 Field Acceptance Tests.

14.2.1 The pump manufacturer, the engine manufacturer (when supplied), the controller manufacturer,

and the transfer switch manufacturer (when supplied) or their factory authorized

representatives shall be present for the field acceptance test. (See Section 5.4.)

14.2.2* All the authorities having jurisdiction shall be notified as to the time and place of the field

acceptance test.

14.2.3 All electric wiring to the fire pump motor(s), including control (multiple pumps) interwiring,

normal power supply, alternate power supply where provided, and jockey pump,

shall be completed and checked by the electrical contractor prior to the initial startup and acceptance

Page 2 of 3

New 10/31/12

Page 3 of 3

New 10/31/12

FI RE PUMP

PLANS SUBMI TTAL CHECKLI ST

NFPA 20

FIRE PREVENTION DIVISION

PUBLIC SAFETY BUREAU

, (2007 EDI TI ON)

14.2.4.1 A copy of the manufacturers certified pump test characteristic curve shall be available for

comparison of the results of the field acceptance test.

14.2.4.2 The fire pump as installed shall equal the performance as indicated on the manufacturers

certified shop test characteristic curve within the accuracy limits of the test equipment.

14.3 Manuals, Special Tools, and Spare Parts.

14.3.1 A minimum of one set of instruction manuals for all major components of the fire pump system

shall be supplied by the manufacturer of each major component.

14.3.2 The manual shall contain the following:

(1) A detailed explanation of the operation of the component

(2) Instructions for routine maintenance

(3) Detailed instructions concerning repairs

(4) Parts list and parts identification

(5) Schematic electrical drawings of controller, transfer switch, and fire pump control panels

I attest that all required and applicable information noted above has been provided for review and

approval and understand that inadequate or incorrect content is cause for permit denial.

Signature of Contractor or Contractors Representative

Date

You might also like

- Genset Load TestDocument10 pagesGenset Load Testjavad100% (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsFrom EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsRating: 3.5 out of 5 stars3.5/5 (3)

- Emergency Generator SpecificationDocument54 pagesEmergency Generator SpecificationHussainRazviNo ratings yet

- NFPA 13D (2010 Edition)Document19 pagesNFPA 13D (2010 Edition)angel darioNo ratings yet

- Specification For Fire Water HydrantDocument5 pagesSpecification For Fire Water HydrantThiru AnanthNo ratings yet

- 21 13 13 Wet Pipe Fire Sprinkler SystDocument7 pages21 13 13 Wet Pipe Fire Sprinkler SystMichel CorrêaNo ratings yet

- Electrical DesignDocument250 pagesElectrical Designpardeep100% (2)

- Fire-Suppression Piping System-13915 PDFDocument21 pagesFire-Suppression Piping System-13915 PDFMohammad Jugnu100% (1)

- Petition For ReviewDocument18 pagesPetition For ReviewJay ArNo ratings yet

- Ariston Micro Genus 23 MFFI 27 MFFI Installation Manual 47 116 14 15 PDFDocument62 pagesAriston Micro Genus 23 MFFI 27 MFFI Installation Manual 47 116 14 15 PDFMuresan Sandu100% (2)

- STANDARD 14.7.3 Fire Protection Systems Installation of Fire AlarmsDocument8 pagesSTANDARD 14.7.3 Fire Protection Systems Installation of Fire AlarmsMohd SayutiNo ratings yet

- Natural Gas Installation Standards Handbook 2018Document57 pagesNatural Gas Installation Standards Handbook 2018Anonymous ggRTHDKe6100% (1)

- Technical Specification Hydrogen Generation PlantDocument404 pagesTechnical Specification Hydrogen Generation PlantSHIVAJI CHOUDHURY100% (1)

- FireSuppression Review #1 27-7-2015Document18 pagesFireSuppression Review #1 27-7-2015riyasudheenmh100% (1)

- Automatic Fire Sprinkler SystemDocument16 pagesAutomatic Fire Sprinkler SystemArnel ArnaoNo ratings yet

- Installation Instructions Type C Boilers: Leave These Instructions With The End-UserDocument24 pagesInstallation Instructions Type C Boilers: Leave These Instructions With The End-UserDaniel James KimmonsNo ratings yet

- 10 Vol Ii Sec 4 Fire Protection Alarm and Gas Suppression Works Technical Specifications PDFDocument116 pages10 Vol Ii Sec 4 Fire Protection Alarm and Gas Suppression Works Technical Specifications PDFrajaNo ratings yet

- File Signature LabDocument3 pagesFile Signature LabGheorghe RotariNo ratings yet

- FIRE FIGHTING PUMPING SYSTEMDocument23 pagesFIRE FIGHTING PUMPING SYSTEMvirtech100% (1)

- Fire StationDocument67 pagesFire StationRAGHVENDRA PRATAP SINGHNo ratings yet

- Service Manual Ariston T2Document52 pagesService Manual Ariston T2cris_43100% (1)

- Lucsuhin National High School Daily Lesson Plan on Accounting ConceptsDocument6 pagesLucsuhin National High School Daily Lesson Plan on Accounting ConceptsALMA ACUNANo ratings yet

- Suwannee County Fire Rescue: Fire Service Water Main / Fire Hydrant RequirementsDocument8 pagesSuwannee County Fire Rescue: Fire Service Water Main / Fire Hydrant RequirementsMahmoud AbdallahNo ratings yet

- Commissioning of Fire PumpsDocument3 pagesCommissioning of Fire Pumpskamranarif4161No ratings yet

- Bomani Barton vs. Kyu An and City of Austin For Alleged Excessive Use of ForceDocument16 pagesBomani Barton vs. Kyu An and City of Austin For Alleged Excessive Use of ForceAnonymous Pb39klJNo ratings yet

- Wet Pipe Sprinkler SystemDocument12 pagesWet Pipe Sprinkler SystemrockykrishNo ratings yet

- SDSU PhD Research on Soil HealthDocument2 pagesSDSU PhD Research on Soil HealthTiruneh GA25% (4)

- WHO/PQS/E01/CR-FR01-VP2. Original: English Distribution: GeneralDocument19 pagesWHO/PQS/E01/CR-FR01-VP2. Original: English Distribution: GeneralMohamedRefaatMohamedNo ratings yet

- SolidWorks Motion Tutorial 2010Document31 pagesSolidWorks Motion Tutorial 2010Hector Adan Lopez GarciaNo ratings yet

- NFPA Fire PumpDocument12 pagesNFPA Fire PumpSyed Faizan AliNo ratings yet

- Installation & Testing of Fire PumpDocument12 pagesInstallation & Testing of Fire PumpMd. Biplob HossainNo ratings yet

- 2020 MFD NFPA 13D Sprinkler RequirementsDocument2 pages2020 MFD NFPA 13D Sprinkler Requirementsmichael.quintanaNo ratings yet

- P 1-22 FF Suppression PipingDocument22 pagesP 1-22 FF Suppression PipingMahmoud GwailyNo ratings yet

- 58 A2016 Lpg-Aaa SD PcresponsesDocument275 pages58 A2016 Lpg-Aaa SD PcresponsesRenato BarretoNo ratings yet

- Fire Pump SpecificationDocument5 pagesFire Pump SpecificationThiru AnanthNo ratings yet

- B15 e 1DDocument28 pagesB15 e 1DPaúl ÁlvarezNo ratings yet

- Nfpa 13D Fire Sprinkler Systems (Installation of Sprinkler Systems in One-And Two-Family Dwellings and Manufactured Homes)Document5 pagesNfpa 13D Fire Sprinkler Systems (Installation of Sprinkler Systems in One-And Two-Family Dwellings and Manufactured Homes)kklikojiNo ratings yet

- Tech Spec of PTR 33 11 KVDocument34 pagesTech Spec of PTR 33 11 KVAnonymous sAmJfcVNo ratings yet

- Tidel DG Set Tech SpecsDocument98 pagesTidel DG Set Tech SpecsChandrashekar PatigeNo ratings yet

- Fire Alarm Permit Plan ReviewDocument3 pagesFire Alarm Permit Plan ReviewMark ReinhardtNo ratings yet

- 6.7 - Fire Pumps - Rev A PDFDocument2 pages6.7 - Fire Pumps - Rev A PDFAnonymous WU4bFcBVIg0% (1)

- Boiler MaintenanceDocument5 pagesBoiler MaintenanceNicole FikingasNo ratings yet

- NTPC - Tech SpecDocument34 pagesNTPC - Tech Specjskrishna_483539628No ratings yet

- 211313P Fire Protection Sprinkler and Standpipe Systems 05-17-2023Document23 pages211313P Fire Protection Sprinkler and Standpipe Systems 05-17-2023fazil yoosufNo ratings yet

- Specification For The Supply, Delivery and Installation of One .Kva Emergency Generator Set ATDocument54 pagesSpecification For The Supply, Delivery and Installation of One .Kva Emergency Generator Set ATJohn Jansen van RensburgNo ratings yet

- Specification For Fire Water MonitorsDocument6 pagesSpecification For Fire Water MonitorsThiru AnanthNo ratings yet

- Fire-Suppression StandpipesDocument11 pagesFire-Suppression StandpipesRaaann100% (1)

- Specification No. CSC-XX-R-III/DH/UH/P&D/2012-2013Document20 pagesSpecification No. CSC-XX-R-III/DH/UH/P&D/2012-2013Pradeep Kumar MaraptlaNo ratings yet

- (Supply, Installation and Commissioning of A Brand New 1-Unit 75-Kva Generator SetDocument5 pages(Supply, Installation and Commissioning of A Brand New 1-Unit 75-Kva Generator SetRoel FranciscoNo ratings yet

- LVFR Sprinkler System RequirementsDocument4 pagesLVFR Sprinkler System RequirementsridwanNo ratings yet

- Contract No:: NWSDB/SBD/S&I/Water Pump/LC: Invitation For Bids DPC - October 2017 - Version 1Document6 pagesContract No:: NWSDB/SBD/S&I/Water Pump/LC: Invitation For Bids DPC - October 2017 - Version 1Ruwantha HerathNo ratings yet

- 15kV and 24.2kV Class Automatic Distribution Recloser GED 823 25022008Document25 pages15kV and 24.2kV Class Automatic Distribution Recloser GED 823 25022008Dante FilhoNo ratings yet

- PCPL 0532 4 407 03Document4 pagesPCPL 0532 4 407 03tceterexNo ratings yet

- Multi Indoor Unit VRFDocument18 pagesMulti Indoor Unit VRFVu SonNo ratings yet

- Technical Specs for Fire Suppression PipingDocument20 pagesTechnical Specs for Fire Suppression PipingImran AzizNo ratings yet

- 5 21 30FirePumpsrev1Document7 pages5 21 30FirePumpsrev1Shipra DuttNo ratings yet

- SECTION 26 3213 Engine Generators Part 1 General 1.01 Section IncludesDocument31 pagesSECTION 26 3213 Engine Generators Part 1 General 1.01 Section IncludesMarcos FernandezNo ratings yet

- Solar Water Pump Spec (1)_pdfDocument19 pagesSolar Water Pump Spec (1)_pdfwondeambaw036No ratings yet

- Interin Guidelines - For - LPG - AddDocument11 pagesInterin Guidelines - For - LPG - AddElijah JohnNo ratings yet

- THE William Francis Galvin, Secretary of The Commonwealth State Publications and RegulationsDocument54 pagesTHE William Francis Galvin, Secretary of The Commonwealth State Publications and Regulationsbubbo07No ratings yet

- General RequirementsDocument4 pagesGeneral RequirementsJosh MazonNo ratings yet

- Technical Requirements, Specifications and Bidding Documents: Dated: 11-14-2016Document20 pagesTechnical Requirements, Specifications and Bidding Documents: Dated: 11-14-2016Savy PhanethNo ratings yet

- Kitchen Hood Suppression Assembly Plan Review NewDocument4 pagesKitchen Hood Suppression Assembly Plan Review NewAlicerp CabanaNo ratings yet

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitFrom EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNo ratings yet

- DNV Casualty Info 2011 #3Document2 pagesDNV Casualty Info 2011 #3Sureen NarangNo ratings yet

- Delphi28236381 20190611 112907Document2 pagesDelphi28236381 20190611 112907คุณชายธวัชชัย เจริญสุขNo ratings yet

- Module 3 - Design RulesDocument19 pagesModule 3 - Design RulesSamNo ratings yet

- Re-registering a vehicle in Karnataka - A step-by-step guideDocument4 pagesRe-registering a vehicle in Karnataka - A step-by-step guideHidayathulla HasanNo ratings yet

- Themed: MathematicsDocument32 pagesThemed: MathematicsMohamed LamihNo ratings yet

- Execution and Documentation Requirements For Life Cycle Cost AnalysesDocument20 pagesExecution and Documentation Requirements For Life Cycle Cost AnalysessmetNo ratings yet

- The 4 PsDocument7 pagesThe 4 PsJuan Camilo Giorgi MartinezNo ratings yet

- Indexed Addressing & Flow Rate AveragingDocument5 pagesIndexed Addressing & Flow Rate AveragingMestrecal MeloNo ratings yet

- Bank Account Details and Contact NumbersDocument38 pagesBank Account Details and Contact NumbersD-Blitz StudioNo ratings yet

- RAN15.0 Feature ListDocument34 pagesRAN15.0 Feature ListmyososNo ratings yet

- ACL Reconstruction BookDocument18 pagesACL Reconstruction BookSergejs JaunzemsNo ratings yet

- Lecture 9 - StatisticsDocument4 pagesLecture 9 - StatisticsMohanad SulimanNo ratings yet

- SQL Server Management Studio Database Engine Query Editor Window - Microsoft DocsDocument6 pagesSQL Server Management Studio Database Engine Query Editor Window - Microsoft DocsAchamyeleh TamiruNo ratings yet

- Bhushan Steel LTD (BHUS IN) - Balance SheetDocument4 pagesBhushan Steel LTD (BHUS IN) - Balance SheetVamsi GunturuNo ratings yet

- Sensory Marketing: How Toothpaste Brands Appeal to the SensesDocument17 pagesSensory Marketing: How Toothpaste Brands Appeal to the SensesNavodi RathnasingheNo ratings yet

- (GUIDE) Advanced Interactive Governor Tweaks Buttery Smooth and Insane Battery Life! - Page 519 - Xda-DevelopersDocument3 pages(GUIDE) Advanced Interactive Governor Tweaks Buttery Smooth and Insane Battery Life! - Page 519 - Xda-Developersdadme010% (2)

- Handbook of Research On Emerging Pedagogies For The Future of Education, Trauma-Informed, Care, and Pandemic Pedagogy Aras BozkurtDocument535 pagesHandbook of Research On Emerging Pedagogies For The Future of Education, Trauma-Informed, Care, and Pandemic Pedagogy Aras BozkurtBrenda MoysénNo ratings yet

- Kami Export - Exercise Lab - Mini-2Document3 pagesKami Export - Exercise Lab - Mini-2Ryan FungNo ratings yet

- Pangilinan, Zobel de Ayala, Sy Sr., Dangote, Rupert, Jameel - Power and influence of business leaders in Asia and AfricaDocument20 pagesPangilinan, Zobel de Ayala, Sy Sr., Dangote, Rupert, Jameel - Power and influence of business leaders in Asia and AfricaGwenNo ratings yet

- Factors Influencing Consumer Behavior and Marketing Plan ComponentsDocument6 pagesFactors Influencing Consumer Behavior and Marketing Plan ComponentsK59 Ng� V? Minh Th?No ratings yet

- Del Monte Golf Club in BukidnonDocument1 pageDel Monte Golf Club in BukidnonJackieNo ratings yet

- WheelHorse Power Take Off Manual 8-3411Document4 pagesWheelHorse Power Take Off Manual 8-3411Kevins Small Engine and Tractor ServiceNo ratings yet