Professional Documents

Culture Documents

Renault Megane-Scenic 1996-2002 General

Uploaded by

DanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Renault Megane-Scenic 1996-2002 General

Uploaded by

DanCopyright:

Available Formats

77 11 176 201 APRIL 1995 Edition Anglaise

General

"The repair methods given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The methods may be modified as a result of changes introduced by the

manufacturer in the production of the various component units and accessories

from which his vehicles are constructed."

All copyrights reserved by the Regie Nationale des Usines Renault.

Copying or translating, in part or in full, of this document or use of the service part

reference numbering system is forbidden without the prior written authority of the

Regie Nationale des Usines Renault.

Rgie Nationale des Usines Renault S.A. 1995

SPECIFICATIONS

LIFTING

TOWING

LUBRICANTS CONSUMABLES

DRAINING, RE-FILLING

BA0A - BA0E - BA0F - BA0G - BA0L - BA0U

C

VALUES AND SETTINGS

SECTION VIEW

TOWING

All types

Contents

SPECIFICATIONS

Engine - Clutch - Gearbox

Vehicle identification

01-1

01-2

LIFTING

Trolley jack - Axle stands

Vehicle lifts

Page

01

02

03

General

02-1

02-2

03-1

LUBRICANTS - CONSUMABLES

Packaging 04-1

DRAINING, RE-FILLING

Engine

Gearbox

Power assisted steering

04

05

05-1

05-3

05-4

VALUES AND SETTINGS

Dimensions

Capacity - Grades

Belt tension

Accessories belt tension

Timing belt tension

Tightening the cylinder head

Dimensions of the main braking

components

Values for checking the front axle

geometry

Values for checking the rear axle

geometry

Underbody heights

Brake limiter

07

07-1

07-2

07-5

07-7

07-13

07-15

07-17

07-18

07-21

07-22

07-23

SPECIFICATIONS

Engine- Clutch - Gearbox

01

Vehicle type

Engine

Type Capacity

Clutch type

Type of manual gearbox and

automatic transmission

BA0E E7J 1390

180 DST 3050

180 CP 3300

JB1

BA0F

BA0L

K7M 1598 200 HR 4000 JB1

BA0G F3R 1998 215 HRN 4000 JB3

BA0A

BA0U

F8Q 1870

200 HRV 4600

200 HRV 3100

JB1

BA0F K7M 1598 - AD4

VEHICLE IDENTIFICATION

Example : BA0E

B : Body type (example 5 door hatchback)

A : Project code (example 64)

0E : Engine suffix (example E7J 764)

01-1

SPECIFICATIONS

Vehicle identification

near to the emergency spare wheel (B) with a

duplicate label of the oval plate on the lower

section of the passenger door (C).

01

LOCATION OF THE VEHICLE IDENTIFICATION

PLATE

Two possible locations on the vehicle:

in the engine compartment (A),

98485-1R

98517R

98516R

01-2

SPECIFICATIONS

Vehicle identification

01

REGIE NATIONALE DES

USINES RENAULT S.A.

e000-00/00000-0000-00

VF0000000

00000000

0000 kg

0000 kg

1 - 0000 kg

2 - 0000 kg

10

0 0 0 0

0 0 0 0 0 0 0 0

0 0 0 0 0 0 0

11

0 0 0 0 0 0 0 0

7

13

8

14

9

12

Renault

1

2

3

4

5

6

VF0000000

00000000

0000

00 000 000

00 000 000

0000000

9

10

12

11

1

2

8

7

14

13

B

A

01-3

SPECIFICATIONS

Vehicle identification

01

It shows:

At A : the name of the manufacturer,

At B : the E.E.C. approval number

At 1 : the type mines of the vehicle preceded by the world manufacturers identification code (VF1 corre-

sponds to RENAULT FRANCE),

At 2 : the chassis number,

At 3 : the maximum permissible weight,

At 4 : the maximum permitted total train weight,

At 5 : the maximum permitted weight on the front axle,

At 6 : the maximum permitted weight on the rear axle,

At 7 : the first figure indicates the gearbox or factory options,

the second figure indicates the equipment level,

At 8 : the vehicle type,

At 9 : the technical equipment code,

At 10 : additional factory optional equipment,

At 11 : the equipment level,

At 12 : the paint code,

At 13 : a letter describing the factory of manufacture followed by the fabrication number,

At 14 : the trim code.

NOTE : Depending on the country of export, certain details might not be given. The plate described above

shows all possible information.

ALLOCATION OF TECHNICAL EQUIPMENT CODES

The equipment code, the three letters which appear in (9), must be documented for vehicle identification

reasons (ordering spare parts, warranty claim, etc.)

01-4

LIFTING

Trolley jack - Axle stands

AXLE STANDS

When putting the vehicle on axle stands, they

must be positioned:

- either under the reinforcements designed for

lifting the vehicle using the vehicles jack,

- or under the points located behind the

reinforcements.

Axle stands are positioned at the rear when the

vehicle is lifted from the side.

02

98699R

Safety symbol (special precautions to be taken when carrying out operations).

SPECIAL TOOLING REQUIRED

Cha. 280 -02 Adaptable cross piece for trolley

jack

Cha. 408 -01

or Adaptable socket for trolley jack

Cha. 408 -02

If a trolley jack is used, appropriate axle

stands must always be used.

It is forbidden to lift the vehicle by supporting its

weight under the front suspension arm or under

the V shaped part of the rear axle.

Depending on the type of trolley jack, use sockets

Cha. 408-01 or Cha. 408-02 to position the cross

piece Cha. 280-02.

To lift the front or rear, support the vehicles

weight under the vehicles jacking points .

TROLLEY JACK USED FROM THE SIDE

Use cross piece Cha. 280-02.

Take the weight under the sill, level with the front

door.

Position the flange correctly in the groove of the

cross piece.

98336G

85679-1G7

02-1

LIFTING

Vehicle lifts

02

SAFETY INSTRUCTIONS

Several scenarios should be considered:

1 - WHEN REMOVING COMPONENTS

In general, never use a 2 post lift, if a four post lift

can be used.

If this is not possible, position the lifting pads

under the body sill, level with the vehicles jacking

points.

2 - SPECIAL CASE - REMOVING AND REFITTING

THE ENGINE AND TRANSMISSION ASSEMBLY

In this special case, the body of the vehicle must

be firmly attached to the arms of the two post lift

using the special pads.

FOG

Reference FOG 449 8111 - 449 8411

or

CHEMICO

Reference 39 2550 0001

or

SCHENCH

Reference 776 684

98703S

FRONT

98704S

REAR

These must be positioned in line with the vehicles

jacking points. They must be clipped into the

holes in the body sill.

02-2

TOWING

All types

FRONT

03

OBSERVE THE LEGAL TOWING REQUIREMENTS OF THE COUNTRY YOU ARE IN.

NEVER USE THE DRIVESHAFTS FOR TOWING THE VEHICLE.

The towing points may only be used for towing the vehicle on the road. They should never be used for remo-

ving the vehicle from a ditch or for any other similar breakdown operation or to lift the vehicle, either direct-

ly or indirectly.

98705S

REAR

98702S

03-1

DESCRIPTION PACKAGING PART NUMBER

1 kg tin

100 g tube

80 ml tube

180 g sachet

Aerosol

77 01 421 145

77 01 028 179

77 01 422 307

77 01 366 100

77 01 422 308

LUBRICANTS

LUBRICANTS - CONSUMABLES

Packaging

04

MOLYKOTE "BR2"

for main bearing journal faces, thrust pad

guide tubes, clutch fork pads, lower suspension

arm bearings, torsion bar splines, steering box,

driveshaft splines.

MOLYKOTE "33 Medium"

tubular rear axle rings

anti-roll bar rings.

ANTI-SEIZE

(high temperature grease) Turbo etc.

"MOBIL CVJ" 825 Black star

or MOBIL EXF57C

for driveshaft joints

MULTIPURPOSE LUBRICANT

wheel sensor

Perfect-seal "LOWAC"

coating fluid for seals.

Mastic

for sealing exhaust pipe unions.

HARDENER KIT

("CAF 4/60 THIXO")

for sealing sides of bearing caps.

AUTO joint blue

sealing paste.

100 g tube

1.5 kg tin

Kit

100 g tube

45 g tube

77 01 417 404

77 01 421 161

77 01 421 080

77 01 396 227

77 01 397 027

MECHANICAL SEALANTS

04-1

DESCRIPTION PACKAGING PART NUMBER

24 cc bottle

24 cc bottle

24 cc bottle

50 cc bottle

77 01 394 070

77 01 394 071

77 01 394 072

77 01 400 309

ADHESIVES

LUBRICANTS - CONSUMABLES

Packaging

04

"LOCTITE - FRENETANCH"

stops bolts coming loose and allows them to be

undone.

"LOCTITE - FRENBLOC"

locks bolts.

"LOCTITE SCELBLOC"

for bonding bearings.

"LOCTITE AUTOFORM"

for bonding the flywheel to the crankshaft.

CLEANING AGENTS - LUBRICANTS

150 g aerosol

Aerosol

250 ml can

300 ml aerosol

355 ml can

500 ml aerosol

Aerosol

400 ml aerosol

77 01 408 464

77 01 422 379

77 01 393 112

77 01 393 111

77 01 423 189

77 01 408 466

77 01 405 952

77 01 421 282

"NETELEC"

unseizes, lubricates.

NC1 cleaner

electrical contact cleaner

Carburettor cleaner

Injector cleaner

Super concentrated unseizing agent

"DECAPJOINT " (FRAMET) for cleaning the

gasket faces of aluminium cylinder heads

Brake cleaner

MECHANICAL SEALANTS

AUTO joint grey

sealing paste.

LOCTITE 518

for sealing the gearbox housing.

Leak detector

100 g tube

24 ml syringe

Aerosol

77 01 422 750

77 01 421 162

77 11 143 071

04-2

DESCRIPTION PACKAGING PART NUMBER

LUBRICANTS - CONSUMABLES

Packaging

04

"CIRCUIT PLUS"

varnish for repairing heated screens

"CONTACT PLUS"

varnish for repairing rear screen supply termi-

nals

Bottle

Kit

77 01 421 135

77 01 422 752

VARNISHES

BRAKES

Brake fluid 0.5 litre bottle DOT 4 77 01 421 940

04-3

DRAINING, RE-FILLING

Engine

E7J - K7M ENGINE

05

F3R - F8Q ENGINES

98486R

TOOLING REQUIRED

Engine drain plug spanner

DRAINING: plug(1)

98701R

FILLING: plug(2)

F3R ENGINE

F8Q ENGINE

98487R

98489R

05-1

DRAINING, RE-FILLING

Engine

05

FILLING: plug(2)

E7J ENGINE

K7M ENGINE

98700R

98437R

05-2

DRAINING, RE-FILLING

Gearbox

05

DRAINING: plug(1)

F3R - F8Q ENGINE

FILLING: plug(2)

98486R1

E7J - K7M ENGINE

98701R1

05-3

DRAINING, RE-FILLING

Power assisted steering

05

CHECKING THE LEVEL

POWER ASSISTED STEERING PUMP LEVEL

For topping up or filling, use ELF RENAULTMATIC

D2 or MOBIL ATF 220 oil.

The level, when correct, should be visible between

the MINI and MAXI marks on the reservoir (1).

98489R1

98487R1

F8Q ENGINE

F3R ENGINE

98437R1

K7M ENGINE

98700R1

E7J ENGINE

05-4

VALUES AND SETTINGS

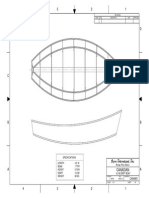

Dimensions

* Unladen

** Depending on version

Dimensions in metres

07

98336R2

07-1

API SG 5W30

API SH 5W30

API SG 10W40

API SH 10W40

API SG 15W40

API SH 15W40

VALUES AND SETTINGS

Capacity - Grades

07

Components

After

draining

3,5

5,5

(plus 0.5 litres

for the oil

filter)

E.E.C. countries

Other countries

Capacity

in litres

Grade

Petrol engine

(oil)

E7J

K7M

F3R

0C

+30C

-30C

+10C +20 C

-20C -10C

-15C

CCMC-G5 10W30 - 10W40 -

10W50

CCMC-G5 5W40 - 5W50

CCMC-G5 5W30

CCMC-G4 15W40 - 15W50

API SG 10W30

API SH 10W30

0C

+30C

-30C

+10C +20 C

-20C -10C

-15C

07-2

VALUES AND SETTINGS

Capacity - Grades

07

Components

After

draining

5

(plus 0.5 litres

for the oil

filter)

E.E.C. countries

Other countries

Capacity

in litres

Grade

Diesel engine

(oil)

F8Q

0C

+30C

-30C

+10C +20 C

-20C -10C

-15C

+15C

CCMC-PD2 15W40

CCMC-PD2 10W40

API CD 10W30

0C

+30C

-30C

+10C +20 C

-20C -10C

-15C

+15C

API CD 15W40

API CD 10W40

07-3

AD4 4

ELF RENAULT MATIC D2 (D20104)

or use: MOBIL ATF 220 (D20104 or D21412)

TEXAMATIC 4011

Automatic

transmission

VALUES AND SETTINGS

Capacity - Grades

07

3 .4

Manual gearbox

Components

Capacity in

litres

Grade Features

JB1 3 .4

Brake circuit

Brake fluids must be approved by the Technical

Department

SAE J 1703

and DOT 3

All countries: TRANSELF TRX 75 W 80 W

( API GL5 or MIL-L 2105 C or D standards)

Normal : 0.7

ABS : 1

Fuel tank approximately

60

Unleaded

petrol/diesel

JB3

Separate

reservoir

1.1

Cooling circuit

F3R

F8Q

E7J - K7M

GLACOL RX

(type D)

Only add coolant 7

7 .5

6

Power assisted

steering

ELF RENAULT MATIC

D2 or

MOBIL ATF 220

07-4

VALUES AND SETTINGS

Belt tension

07

96601R

SPECIAL TOOLING REQUIRED

Mot. 1273 Tool for checking belt tension

A Sensor

B Display

C Connecting lead

D Calibration checking plate

Principle

The sensor, through the adjusting button (1), the

pressure device (2) and the outer lugs (3), applies a

constant force to the belt.

The reaction from the belt is measured using a

test piece (4) fitted with strain gauges.

Any movement on the gauges creates a variation

in their electrical resistance. This variation, once it

has been converted by the device, is displayed on

the display in SEEM units (US).

Calibrating the device

The device is set in the factory, however it must be

recalibrated every six months.

Procedure

Resetting zero:

- switch the device on (button E) with the adjus-

ting button (1) fully screwed in,

- if 0 is displayed, do not touch anything,

- if nothing is displayed, check the condition of

the 9 volt battery in the device ,

- if a value other than 0 is displayed, adjust screw

(F) until 0 is displayed.

07-5

VALUES AND SETTINGS

Belt tension

07

Checking the calibration

Switch the device on (button E).

Position the calibration spring plate (Z) on the sensor as shown on the diagram (checking value engraved to-

wards the top, (A) minimum value, (B) maximum value).

Tighten the adjusting button (1) until it goes "CLICK - CLICK - CLICK".

Check that a value X between the values (A and B) (A X B) is displayed.

Note: it may be necessary to perform several preliminary tests in order to obtain the correct value.

If the correct value if still not obtained after several attempts, contact SEEM.

NOTE : each device has its own calibration spring plate and they are not interchangeable.

96602R

1 Adjusting button

A

B

Z Calibration plate

Calibration plate checking value

SEEM

For further information contact your After Sales

Head Office.

GENERAL INSTRUCTIONS:

- Never refit a belt which has been removed, re-

place it.

- Never retighten a belt for which the tension

reading is between the fitting value and the

minimum operating value.

- When checking, if the tension is below the mi-

nimum operating value, replace the belt.

07-6

VALUES AND SETTINGS

Accessories belt tension

07

GROOVED BELT

Tensioning process

Engine cold (ambient temperature).

Fit the new belt.

Position the sensor of Mot. 1273.

Turn the adjusting button of the sensor until it disengages (three CLICKS).

Tension the belt until the recommended fitting value is displayed on Mot. 1273 .

Lock the tensioner, check it, adjust the value.

Turn the crankshaft over three times.

Check that the tension value is within the fitting tension tolerance, otherwise readjust it.

NOTE :

Never refit a belt which has been removed.

Replace the belt, if the tension is below the minimum operating tension.

Small cuts or cracks do not mean that the belt has to be replaced.

07-7

VALUES AND SETTINGS

Accessories belt tension

07

98706R

A Crankshaft

B Alternator

C Power assisted steering pump

D Air conditioning compressor

T Tensioner

Tension check point

ALTERNATOR AND POWER ASSISTED STEERING

E7J / K7M

ENGINES

98707R

Tension

(US=SEEM unit)

Multitoothed

air

conditioning

belt (1)

Multitoothed

alternator belt

(2)

Multitoothed

power assisted

steering belt

(3)

Fitting 110 7 84 6 84 6

Minimum

operating

75 52 52

AIR CONDITIONING

07-8

VALUES AND SETTINGS

Accessories belt tension

07

98751R

AIR CONDITIONING ALTERNATOR AND POWER ASSISTED STEERING

F3R

ENGINE

98752R

A Crankshaft

B Alternator

C Power assisted steering pump

D Air conditioning compressor

E Water pump

T Tensioner

Tension check point

Tension

(US=SEEM unit)

Multitoothed

air

conditioning

belt (2)

Multitoothed

power assisted

steering belt

(1)

Fitting 109 3 107 3

Minimum

operating

62 62

07-9

VALUES AND SETTINGS

Accessories belt tension

07

98751R

ALTERNATOR AND POWER ASSISTED STEERING

F8Q ENGINE

Power assisted

steering

A Crankshaft

B Alternator

C Power assisted steering pump

E Water pump

T Tensioner

Tension check point

Tension

(US=SEEM unit)

Multitoothed power

assisted steering belt (1)

Fitting 97 3

Minimum operating 67

07-10

VALUES AND SETTINGS

Accessories belt tension

07

98837-1R2

Remove :

- the lower timing cover,

- the belt.

SPECIAL NOTES FOR REMOVING THE

ACCESSORIES BELT

REMOVAL

Disconnect the battery.

Before removing the accessories belt, check the

value of the tension.

The tension measured must be between 61 and 77

SEEM units.

F8Q ENGINE

Air conditioning

98837R2

Slacken bolt (A) then bolt (B), until the shoulder is

exceeded, whilst holding the automatic tensio-

ning plate using a 9 mm socket (eg. : FACOM J

151 ratchet), then slacken the belt by moving the

ratchet in the direction of the arrow.

Remove the mounting bolt for the diesel pipe re-

taining bracket and move it.

99706R

A Crankshaft

B Alternator

C Power assisted steering pump

D Air conditioning compressor

E Water pump

G Roller

T Tensioner

Tension check point

07-11

VALUES AND SETTINGS

Accessories belt tension

07

REFITTING

Refitting is the reverse of removal.

The belt is tensioned by bringing the automatic

tensioner up against the bolt (B), without forcing

it, using a 9 mm socket (eg. : FACOM J151 rat-

chet).

F8Q ENGINE

Air conditioning

98837-1R3

Check the tension of the accessories belt with the

previously listed values.

NOTE: never refit a belt which has been removed.

07-12

VALUES AND SETTINGS

Timing belt tension

07

98708R

E7J and K7M engine Tensioning process

Engine cold (ambient temperature).

Fit the new belt.

Position the sensor of Mot. 1273.

Turn the adjusting button of the sensor until it di-

sengages (three "CLICKS").

Tension the belt until the recommended fitting

value is displayed on Mot. 1273.

Lock the tensioner, check it and adjust the value.

Turn the crankshaft over three times .

Check that the tension value is within the fitting

tension tolerance ( 10%), otherwise readjust it.

NOTE :

Never refit a belt which has been removed.

Replace the belt if the tension is below the mini-

mum operating tension.

Belt tension (in SEEM units)

Fitting: 30 S.U

Minimum operating : 26 S.U.

07-13

VALUES AND SETTINGS

Timing belt tension

07

F3R engine

96528R1

Belt tension (n SEEM units)

Fitting: 29 S.U.

Minimum operating : 27 S.U.

F8Q engine

99175R

Belt tension (in SEEM units)

Fitting: 38 S.U.

Minimum operating: 36 S.U.

07-14

VALUES AND SETTINGS

Tightening the cylinder head

07

METHOD FOR TIGHTENING THE CYLINDER HEAD

Using engine oil, lubricate the threads and under

the heads of the bolts.

REMINDER: to ensure that the bolts are correctly

tightened, use a syringe to remove any oil which

may be in the cylinder head mounting holes.

Tighten the bolts in the order given below:

90 775

2 7 6 10

1 8 5 9 4

3

1st tightening to 2 daN.m.

2nd tightening (angle) : 97 2.

Wait at least 3 minutes.

Slacken bolts 1 and 2 then tighten to 2 daN.m.

2nd tightening (angle) : 97 2.

Repeat the slackening and retightening opera-

tion for bolts 3, 4, 5, and 6 then 7, 8, 9 and 10.

There is no cylinder head retightening operation.

E ENGINE

METHOD FOR TIGHTENING THE CYLINDER HEAD

Using engine oil, lubricate the threads and under

the heads of the bolts.

REMINDER: to ensure that the bolts are correctly

tightened. Use a syringe to remove any oil which

may be in the cylinder head mounting holes.

Tighten the bolts in the order given below:

90 775

2 7 6 10

1 8 5 9 4

3

1st tightening to 2 daN.m.

2nd tightening (angle) : 100 6.

Wait at least 3 minutes.

Slacken bolts 1 and 2 then tighten to 2 daN.m.

2nd tightening (angle) : 110 6.

Repeat the slackening and retightening opera-

tion for bolts 3, 4, 5, and 6 then 7, 8, 9 and 10.

There is no cylinder head retightening operation.

K ENGINE

07-15

VALUES AND SETTINGS

Tightening the cylinder head

07

METHOD FOR TIGHTENING THE CYLINDER HEAD

All bolts must be systematically renewed after re-

moval.

Using engine oil, lubricate the threads and under

the heads of the bolts.

REMINDER: to ensure that the bolts are correctly

tightened. Use a syringe to remove any oil which

may be in the cylinder head mounting holes.

Tighten the bolts in the order given below:

1st tightening to 3 daN.m.

2nd tightening (angle) : 50 4

Wait at least 3 minutes.

Slacken bolts 1 and 2 then perform a 1st tighte-

ning to 2.5 daN.m.

2nd tightening (angle) : 213 7.

Repeat the slackening and retightening operation

for bolts 3-4, 5-6, 7-8, 9-10.

There is no cylinder head retightening operation.

F ENGINE (diesel)

METHOD FOR TIGHTENING THE CYLINDER HEAD

All bolts must be systematically renewed after re-

moval.

Using engine oil, lubricate the threads and under

the heads of the bolts.

REMINDER: to ensure that the bolts are correctly

tightened. Use a syringe to remove any oil which

may be in the cylinder head mounting holes.

Tighten the bolts in the order given below:

90 775

2 7 6 10

1 8 5 9 4

3

F ENGINE (petrol)

81528-1S

1st tightening to 3 daN.m.

2nd tightening (angle) : 50 4

Wait at least 3 minutes.

Slacken bolts 1 and 2 by 180 then perform :

1st retightening to 2.5 daN.m.

2nd tightening (angle) : 123 7.

Repeat the slackening and retightening operation

for bolts 3-4, 5-6, 7-8, 9-10.

There is no cylinder head retightening operation.

07-16

VALUES AND SETTINGS

Dimensions of the main braking components

07

FRONT BRAKE (dimensions in mm)

Slave cylinder diameter

Disc diameter

Disc thickness

Minimum disc thickness

Lining thickness (including backing plate)

Minimum lining thickness (including backing plate)

Maximum disc run-out

REAR BRAKE (dimensions in mm)

Slave cylinder diameter

Drum diameter

Maximum drum diameter after regrinding

MASTER CYLINDER (dimensions in mm)

Diameter

48

238

12

10.3

18

7

0.07

17.5

203.2

204.4

20.6

BA0G

48

259

20.60

19

18

6

0.07

17.5

203.2

204.4

20.6

48

238

20

18.3

18

6.5

0.07

17.5

203.2

204.4

20.6

Brakes discs cannot be repaired. They must be replaced if large scratches or excessive wear occur.

BA0F

BA0A

BA0E

BA0L

BA0U

07-17

H5-H2= 76.5 mm

H5-H2= 96.5 mm

H5-H2= 116.5 mm

H5-H2= 136.5 mm

H5-H2= 156.5 mm

81603S1

93011-1S

93014-1S

93013-1S

93012-1S

VALUES AND SETTINGS

Values for checking the front axle geometry

07

UNLADEN

NOT ADJUSTABLE

NOT ADJUSTABLE

NOT ADJUSTABLE

CAMBER

VALUES

CASTOR

230

2

130

1

030

Maximum left /

right difference =

1

114

- 008

025

030

Maximum left /

right difference =

1

ADJUSTMENT

POSITION OF FRONT

AXLE

KING PIN INCLINATION

1110

1301

1329

1429

Maximum left /

right difference =

1

H1-H2= 33 mm

H1-H2= 90 mm

H1-H2= 109 mm

H1-H2= 188 mm

H1-H2= 33 mm

H1-H2= 90 mm

H1-H2= 109 mm

H1-H2= 188 mm

PARALLELISM

RUBBER BUSHES

Adjustable by

rotating track

rod sleeves

1 turn= 30

(3 mm)

(For 2 wheels)

(toe-out)

10 10

(1 1 mm)

ANGLES

UNLADEN - -

30

30

30

E7J ENGINE - TUBULAR AXLE - MANUAL STEERING

07-18

H5-H2= 76.5 mm

H5-H2= 96.5 mm

H5-H2= 116.5 mm

H5-H2= 136.5 mm

H5-H2= 156.5 mm

81603S1

93011-1S

93014-1S

93013-1S

93012-1S

VALUES AND SETTINGS

Values for checking the front axle geometry

07

UNLADEN

NOT ADJUSTABLE

NOT ADJUSTABLE

NOT ADJUSTABLE

CAMBER

VALUES

CASTOR

430

4

330

3

230

Maximum left /

right difference =

1

135

- 020

- 035

- 030

Maximum left /

right difference =

1

ADJUSTMENT

POSITION OF FRONT

AXLE

KING PIN INCLINATION

1045

1321

1348

1432

Maximum left /

right difference =

1

H1-H2= 22 mm

H1-H2= 102 mm

H1-H2= 122 mm

H1-H2= 188 mm

H1-H2= 22 mm

H1-H2= 102 mm

H1-H2= 122 mm

H1-H2= 188 mm

PARALLELISM

RUBBER BUSHES

Adjustable by

rotating track

rod sleeves

1 turn= 30

(3 mm)

(For 2 wheels)

(toe-out)

10 10

(1 1 mm)

ANGLES

UNLADEN - -

30

30

30

E7J - E7M - F8Q ENGINE - TUBULAR AXLE - POWER ASSISTED STEERING

07-19

H5-H2= 71,5 mm

H5-H2= 91,5 mm

H5-H2= 111,5 mm

H5-H2= 131,5 mm

H5-H2= 151,5 mm

81603S1

93011-1S

93014-1S

93013-1S

93012-1S

VALUES AND SETTINGS

Values for checking the front axle geometry

07

UNLADEN

NOT ADJUSTABLE

NOT ADJUSTABLE

NOT ADJUSTABLE

CAMBER

VALUES

CASTOR

430

4

330

3

230

Maximum left /

right difference =

1

135

- 020

- 037

- 030

Maximum left /

right difference =

1

ADJUSTMENT

POSITION OF FRONT

AXLE

KING PIN INCLINATION

1045

1320

1353

1432

Maximum left /

right difference =

1

H1-H2= 22 mm

H1-H2= 102 mm

H1-H2= 122 mm

H1-H2= 188 mm

H1-H2= 22 mm

H1-H2= 102 mm

H1-H2= 122 mm

H1-H2= 188 mm

PARALLELISM

RUBBER BUSHES

Adjustable by

rotating track

rod sleeves

1 turn= 30

(3 mm)

(For 2 wheels)

(toe-out)

10 10

(1 1 mm)

ANGLES

UNLADEN - -

30

30

30

F3R ENGINE - 4 BAR AXLE - POWER ASSISTED STEERING

07-20

- 30 20

(Toe-in)

or

- 3 2mm

- 050 15

NOT ADJUSTABLE

93013-2S

93011-2S

81603S1

VALUES AND SETTINGS

Values for checking the rear axle geometry

07

UNLADEN

CAMBER

VALUES ADJUSTMENT

POSITION OF REAR

AXLE

PARALLELISM

ANGLES

UNLADEN - 1 15 NOT ADJUSTABLE

- 50 20

(Toe- in)

or

- 5 2mm

UNLADEN - -

RUBBER BUSHES

TUBULAR AND 4

BAR REAR AXLE

TUBULAR AND 4

BAR REAR AXLE

REAR AXLE

TUBULAR 4 BAR

07-21

VALUES AND SETTINGS

Underbody heights

07

Axle type Tubular axle 4 bar axle

Vehicle type BA0A - BA0E - BA0F - BA0L - BA0U BA0G

Wheel diameter (inches) 13" 14"

H1 - H2 (mm) 121 5 123.5 5

H4 - H5 (mm) 44.5 11 52 11

07-22

VALUES AND SETTINGS

Brake limiter

07

These vehicles are fitted with limiters which are load sensitive.

They are checked and adjusted when :

- the vehicle is unladen,

- the fuel tank is full,

- the driver is in the vehicle.

Vehicle

type

Fuel tank

Front Rear

Control pressure (Bar)

BA0G

100 72

BA0A

BA0E

BA0F

BA0L

BA0U

100

Full

90966S

+0

-8

62

+0

-8

07-23

You might also like

- Tpi 2029086 - 1Document9 pagesTpi 2029086 - 1Marius SuvarNo ratings yet

- Peugeot 306 FuseDocument2 pagesPeugeot 306 FuseNacho Hatikvah LibrěNo ratings yet

- SSP 25 Octavia ClimatronicDocument42 pagesSSP 25 Octavia Climatronicahmedsalehawad100% (1)

- Scenic 130 BSIDocument4 pagesScenic 130 BSICharaf-eddine RamehNo ratings yet

- Pozitie ReleeDocument13 pagesPozitie ReleesecelleanuNo ratings yet

- MR341LAGUNA1Document326 pagesMR341LAGUNA1kuvi100% (2)

- Defecte ABS PDFDocument85 pagesDefecte ABS PDFKorisnik1956No ratings yet

- Electric Power Steering (Eps) : Group 37Document51 pagesElectric Power Steering (Eps) : Group 37johnatan chuiNo ratings yet

- Diesel Injection: Fault Finding - Fault Summary TableDocument3 pagesDiesel Injection: Fault Finding - Fault Summary TablemanualNo ratings yet

- Service: Audi A6 1998Document77 pagesService: Audi A6 1998Kovács EndreNo ratings yet

- SSP 513 Golf '13Document56 pagesSSP 513 Golf '13GabrielNo ratings yet

- SSP 35 Petrol Engines 1.4l 16V 55kw 74kwDocument50 pagesSSP 35 Petrol Engines 1.4l 16V 55kw 74kwKaloyan MarinovNo ratings yet

- DFM Explanation: Pos Service HollandDocument4 pagesDFM Explanation: Pos Service HollandJhonny Eduardo Suarez GretaNo ratings yet

- Volkswagen Workshop Manual (6-Speed Manual Gearbox 0A8)Document210 pagesVolkswagen Workshop Manual (6-Speed Manual Gearbox 0A8)jerryalfaNo ratings yet

- Gsm/Gprs/Gps Tracker User Manual: PrefaceDocument13 pagesGsm/Gprs/Gps Tracker User Manual: PrefaceMichel PaisibleNo ratings yet

- Gearbox 02R PDFDocument114 pagesGearbox 02R PDFPaul LazaNo ratings yet

- Rover 75 IPK Diagnostic ModeDocument2 pagesRover 75 IPK Diagnostic ModeRichard0% (1)

- Autocom Popravak E60 90Document2 pagesAutocom Popravak E60 90Danijel HrvojNo ratings yet

- 13-Service Manual Air ConditioningDocument198 pages13-Service Manual Air ConditioningronNo ratings yet

- T5 Pin Connector Assignments Selected Connections PDFDocument10 pagesT5 Pin Connector Assignments Selected Connections PDFSasa MitrovicNo ratings yet

- 3587ADocument45 pages3587Aainginer100% (2)

- KU01 KYO8M v2.4 User Manual enDocument52 pagesKU01 KYO8M v2.4 User Manual enDamir MerdanNo ratings yet

- Yamaha AX-396 & 496 PDFDocument42 pagesYamaha AX-396 & 496 PDFnod69ass67% (3)

- VW Jetta 5 Auxiliary Heater Webasto Thermo Top V EngDocument49 pagesVW Jetta 5 Auxiliary Heater Webasto Thermo Top V EngJanos HallaNo ratings yet

- Summer Training 1Document34 pagesSummer Training 1nitinNo ratings yet

- How To Activate Remote Windows - Diagnostics & VCDS - BRISKODADocument17 pagesHow To Activate Remote Windows - Diagnostics & VCDS - BRISKODAMohammed AbdelrahmanNo ratings yet

- Golf 3 SIBER - RoofDocument9 pagesGolf 3 SIBER - RoofDejan Djukic100% (1)

- Error Codes XMDocument14 pagesError Codes XMnilomell100% (1)

- Rover 75 ATC DiagnosticsDocument1 pageRover 75 ATC DiagnosticsRichardNo ratings yet

- Skoda Fabia - Demarorul AlternatorulDocument5 pagesSkoda Fabia - Demarorul AlternatorulbuerebistaNo ratings yet

- A5 Octavia Audience CarRadioDocument17 pagesA5 Octavia Audience CarRadioJesús NuñoNo ratings yet

- Acronime BMWDocument7 pagesAcronime BMWmaciu1No ratings yet

- Westfalia Wiring For AudiDocument38 pagesWestfalia Wiring For AudiThomas Egbert0% (2)

- Turn Signals Mirrors Passat b6Document6 pagesTurn Signals Mirrors Passat b6mc_keith23No ratings yet

- Toyota Avensis Verso 2000 - 2006 Fuse Box DiagramsDocument9 pagesToyota Avensis Verso 2000 - 2006 Fuse Box Diagrams1percentninjaNo ratings yet

- VW Passat b6 Heating Air Conditioning System EngDocument174 pagesVW Passat b6 Heating Air Conditioning System EngFadel B ChNo ratings yet

- VW Passat Sistem InjectieDocument126 pagesVW Passat Sistem InjectieIulian Doru Mîță100% (1)

- TLB30Document11 pagesTLB30Victor GuzmanNo ratings yet

- 3504a PDFDocument95 pages3504a PDFfernando100% (1)

- b6 70 PDFDocument81 pagesb6 70 PDFVlad ZahiuNo ratings yet

- Automatic Level Control PDFDocument82 pagesAutomatic Level Control PDFRicardo Cornejo Lafuente100% (1)

- Pioneer Deh p390mp, 3900mpDocument68 pagesPioneer Deh p390mp, 3900mpmatiasolsenNo ratings yet

- VW Passat b6 Brake Systems EngDocument93 pagesVW Passat b6 Brake Systems EngDanyBobNo ratings yet

- Coduri de Eroare ECU - C20NEDocument3 pagesCoduri de Eroare ECU - C20NERobert TocaNo ratings yet

- ADocument14 pagesAKatarina Petrovic0% (1)

- 1.577 81 1.655 66 77 KW TDI CR Engine (CAYA CAYB CAYC CLNA CWXB CWXC)Document577 pages1.577 81 1.655 66 77 KW TDI CR Engine (CAYA CAYB CAYC CLNA CWXB CWXC)Kunji ManiNo ratings yet

- iDEA Classic Katalog 2020 PDFDocument100 pagesiDEA Classic Katalog 2020 PDFMirko NedovicNo ratings yet

- Range Rover - 1995 - 4th EditionDocument569 pagesRange Rover - 1995 - 4th EditionJorge TeixeiraNo ratings yet

- SSP 414 4MOTION With Four-Wheel Drive Coupling Generation IVDocument28 pagesSSP 414 4MOTION With Four-Wheel Drive Coupling Generation IVfrancois.garcia31100% (1)

- Grand Scenic: Quick GuideDocument24 pagesGrand Scenic: Quick GuideSaša RadićNo ratings yet

- MR337CLIO0Document36 pagesMR337CLIO0mv777No ratings yet

- VNX - Su Clio 2 PDFDocument1,290 pagesVNX - Su Clio 2 PDFr-en-o94% (17)

- VNX - Su Clio 2Document1,289 pagesVNX - Su Clio 2cvn2100% (2)

- General Vehicle InformationDocument20 pagesGeneral Vehicle InformationBloorimNo ratings yet

- General: Specifications Lifting Towing Lubricants and Consumables Oil Change and Engine Oil Refilling Values and SettingsDocument84 pagesGeneral: Specifications Lifting Towing Lubricants and Consumables Oil Change and Engine Oil Refilling Values and Settingsfsantosjsilva8267No ratings yet

- Vehicle General InformationDocument18 pagesVehicle General InformationNatasa DurdaNo ratings yet

- Crawler Loader 12G 101-1000, 43C01001 UpDocument316 pagesCrawler Loader 12G 101-1000, 43C01001 UpcristiannnnnnnnnnNo ratings yet

- VNX - Su Master Propulsion 2003Document469 pagesVNX - Su Master Propulsion 2003cvn2100% (3)

- Lube Truck ManualDocument43 pagesLube Truck ManualbdsisiraNo ratings yet

- VW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)From EverandVW Transporter T4 (Petrol and Diesel - 1990-1995) Workshop Manual: Owners Edition (Owners' Workshop Manuals)No ratings yet

- How To Replace An Engine Air Filter On Mercedes W245Document15 pagesHow To Replace An Engine Air Filter On Mercedes W245DanNo ratings yet

- Burritos Ingredients: Sausage and Egg CasseroleDocument17 pagesBurritos Ingredients: Sausage and Egg CasseroleDanNo ratings yet

- Build A Boat!: Step 1: Materials SelectionDocument9 pagesBuild A Boat!: Step 1: Materials SelectionDan0% (1)

- DIY Kitchen Island: Tools ListDocument14 pagesDIY Kitchen Island: Tools ListDanNo ratings yet

- The New Picnic Cookbook - A Picn - BookSumo PressDocument205 pagesThe New Picnic Cookbook - A Picn - BookSumo PressDan100% (1)

- Canadian Metric StudyDocument2 pagesCanadian Metric StudyDanNo ratings yet

- t3 Free PlansDocument46 pagest3 Free PlansDan100% (1)

- Julie SkiffDocument4 pagesJulie SkiffDan100% (1)

- DocDST2000 EnglishDocument12 pagesDocDST2000 EnglishDanNo ratings yet

- 23 Mai 2014 Desfasurator MatinalDocument1 page23 Mai 2014 Desfasurator MatinalDanNo ratings yet

- Universal TheosophyDocument132 pagesUniversal TheosophyDanNo ratings yet

- Successful Goose FarmingDocument14 pagesSuccessful Goose FarmingDanNo ratings yet