Professional Documents

Culture Documents

Filtration (Plate and Frame Press)

Uploaded by

James Glerry AaronOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Filtration (Plate and Frame Press)

Uploaded by

James Glerry AaronCopyright:

Available Formats

Department of Chemical & Biomolecular Engineering

THE NATIONAL UNIVERIT!

of IN"A#ORE

Chemical Engineering La$orator%

E&periment '(

'ilter #re))

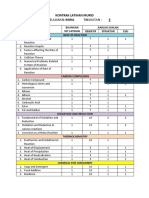

Name *

+etric No, *

"roup *

Date of E&pt, *

Demon)trator-) *

)ignature

"RADE *

Intro.uction*

Many process operations produce SLURRY of solid particles suspended in a liquid which

must be separated into the solid and liquid phases. The simplest method is to FILTR the

slurry throu!h a fine mesh FILTR "L#T$ so that the solid FILTR "%& is deposited on

the cloth whilst the clear liquid FILTR%T flows throu!h. ither the "%& or the

FILTR%T or both may be the useful products of this operation. %s the ca'e builds up on the

cloth the resistance to flow increases and a !reater pressure would be required to force the

liquid throu!h the ca'e itself. In a (acuum filter the ca'e can be scrapped off the cloth

continuously but this is slow and produces a (ery loose ca'e. $i!h pressure filtration is

faster and produces denser ca'es but it is necessary to contain the system within a )RSS

which must then be opened to remo(e the ca'e. This method is therefore only suitable for

batch operations.

The basic filtration equation can be e*pressed as+

R A v V

P A

dt

dV

+

=

,

-./

where 01 (olume of filtrate collected2 m

3

t 1 time2 s

% 1 filtration area2 m

,

4 ) 1 pressure drop2 )a

5 1 (iscosity of the filtrate

6 1 specific resistance of the ca'e2 m

7,

R 1 filter medium resistance2 m

7.

v 1 (olume of ca'e of unit (olume of filtrate

For a filtration at constant pressure2 equation -./ can be rearran!ed as

-&.08&,/ d01 dt -,/

where

/ -

.

,

P A

v

K

=

and

/ -

,

P A

R

K

=

.

Inte!ration of the equation -,/ !i(es

, / -

,

.

K Vi V

K

Vi V

ti t

+ + =

-3/

where ti and 0i are the startin! time of the constant pressure filtration and the correspond

(olume of filtrate. 9y plottin! -t7ti/:-070i/ (s. -080i/2 a linear line can be obtained. &. and

&, can be calculated form the slope and intercept

E&periment /Ne0 )etup1*

This ri! consists of a multi7plate FILTR )RSS fed with water based slurry which is

pumped from a stora!e tan' usin! a pro!ressin! ca(ity pump. The slurry flow rate is

measured by a di!ital flowmeter and the pressure with pressure transmitter. The filtrate

-water in this case/ is allowed to run to waste or a collection tan'.

#roce.ure*

a) Familiarisation

Study and s'etch the layout of this plant so that you are familiar with its operation and the

purpose of each item. You must !et appro(al of the super(isor before proceedin! to the ne*t

sta!e.

b) Operation

"hec' that 90.2 90, and 90; are at the open position and 9032 90<2 =0.2 =0, and =03

are closed. Ma'e sure that there is no built up on the sealin! rims of the filter plates and that

filter sheets han! close to the plates without folds. Shift the filter plates from the shiftin!

plate side to the head side. "lose the release (al(e at the hand pump and pump the hydraulic

closure to ,>>bar. nsure feed tan' is filled up to the mar'ed le(el and the filtrate tan' le(el

is abo(e the low le(el sensor.

Turn on the main supply. Reset the system by to!!lin! the reset button to the ri!ht hand side

and hold until the red li!ht is ?#FF@. Run the system in auto mode. Start the mi*er and allow

it to run for ,> minutes. Set conditions for the filtration on the control panel. Switch on the

feed pump and start recordin! the pressure and flow rate. #bser(e any chan!es in clarity of

the filtrate. You should allow the process to continue until the feed le(el is lower than the

propeller or the feed pressure is fluctuatin! (iolently. Switch off the pump and stirrer.

c) Dismantling

#pen the release (al(e at the hand pump. The sprin! in the sin!le actin! cylinder will pull

bac' the piston rod. )ush bac' the shiftin! plate. "arefully lift out the frame containin! the

filter ca'e and the filter cloth. The ca'e2 which should be firm and compact2 can be pushed

out of the frame into the buc'et. Slide the ne*t plate and lift out the ne*t frame and so on.

Ahen all the frames ha(e been remo(ed wash them carefully to remo(e all traces of filter

ca'e from the surfaces. )ut the filter ca'e bac' into the tan' and fill up the tan' to the

mar'ed le(el.

f/ "arry out a set of constant pressure filtration e*periments on the slurry and apply the

filtration theory to interpret the data.

E&periment /Ol. )etup1*

This ri! consists of a multi7plate FILTR )RSS fed with water based slurry which is

pumped from a stora!e tan' usin! a positi(e displacement -M#B#/ pump. The slurry flow

rate is measured by collectin! the filtrate and the pressure with a 9ourden tube )RSSUR

C%UC. The filtrate -water in this case/ is allowed to run to a collection tan'.

#roce.ure*

a) Familiarisation

Study and s'etch the layout of this plant so that you are familiar with its operation and the

purpose of each item. You must !et appro(al of the super(isor before proceedin! to the ne*t

sta!e.

b) Operation

"hec' that the )RSS is ti!htly closed by tryin! to turn the R%T"$T %RM cloc'wise.

"hec' that the tan' is filled to the correct le(el2 two 9)7)%SS 0%L0S are open2 and

)RSS IBLT 0%L0 is closed. Switch on the )UM) and STIRRR. "hec' that slurry is

flowin! bac' to the tan'. %llow the pump to run for .> minutes.

c) Testing

In quic' succession2 close one of the two by7pass (al(es2 start the ST#)A%T"$ and open

the press inlet (al(e. Record the FL#A R%T and )RSSUR at one minute inter(als and

obser(e any chan!es in clarity of the filtrate. You should allow the process to continue until

the feed le(el is lower than the propeller. Switch off the pump and stirrer.

d) Dismantling

9F#R =ISM%BTLIBC T$IS UBIT Y#U MUST #9T%IB % )RMIT T# A#R&

FR#M T$ SU)R0IS#R A$# AILL L#"& #FF T$ L"TRI"%L SU))LYDD

Slac'en the press by usin! the ratchet le(er and then open it completely usin! the smaller

handle. Startin! from the bac' -near the ratchet handle/2 lift out the M#0%9L $%=

)L%T carryin! the first filter cloth. "arefully lift out the ne*t element2 which is a hollow

FR%M containin! the filter ca'e. The ca'e2 which should be firm and compact2 can be

pushed out of the frame into the buc'et. Slide the ne*t )L%T alon! and lift out the ne*t

FR%M and so on. Ahen all the FR%MS ha(e been remo(ed2 ta'e them to the sin' and

wash them carefully to remo(e all traces of filter ca'e from the surfaces2 the four holes at

the corners of each plate and the small passa!es connectin! these holes with the plate

surface. Remo(e the filter cloths notin! that there is a stiff 9%"&IBC "L#T$ which

pro(ides support for the finer mesh FILTR "L#T$. %lso note that there are two sin!le7

side cloths on the FIE= $%= )L%T and the M#0%9L $%= )L%T. Aash the

filter plates and cloths carefully in the sin' as before. Remo(e any filter ca'e from the inlet

passa!e of the fi*ed head plate and the surfaces of both head plates.

e) Reassembly

Replace the filter plates between the frames and fit the cloths startin! at the fi*ed head end

and slidin! each element up to this end as it is complete. It is important that you ensure that

the cloths are fitted the ri!ht way round !i(in! a continuous hole for the inlet and filtrate

portsDDD $a(e the assembly chec'ed by the super(isor and then replace the ma'e7up pieces

and ti!hten the press with the ratchet handle. )ut the filter ca'e bac' into the tan' and fill up

the tan' to the mar'ed le(el usin! the nearest water hose. $ose down any filtrate on the

floor ta'in! care not to soa' the electrical supply to the motor. Fill the press with tap water

and carry out the lea' test before ne*t run.

f/ "arry out a set of constant pressure filtration e*periments on the slurry and apply the

filtration theory to interpret the data.

Re)ult) an. Di)cu))ion)*

S'etch the plant layout and draw cross7sections of the plate and frame elements to show the

internal flow patterns. )lot !raphs of pressure and flow rate a!ainst time and comment on

their shape. =escribe briefly one other technique for filtration.

Ahat is the practical si!nificance of the filtration equationsF "alculate 62 the a(era!e

specific ca'e resistance and R2 the filter7medium resistance2 and fit an empirical equation to

the results for 6.

Conclu)ion)*

Reference)*

.. "oulson GM and Richardson GF2 "hemical n!ieerin! 0ol,2 Bew Yor'+ )er!amon )ress2

.HH>.

,. )urchas =92 Industrial Filtration of Liquids2 Leonard $ill2 .HI..

3. )erry R$2 "hemical n!ineers $andboo'2 McCraw7$ill2 .HJ,.

<. Mc"abe2 Smith and $arriott2 Unit #perations of "hemical n!ineerin!2 McCraw7$ill2

.HJK.

;. Aa'eman RG and Tarleton S2 Filtration quipment Selection2 Modellin! and )rocess

Simulation2 lse(ier %d(anced Technolo!y2 .HHH

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pub - Quantum Mechanics For Chemists PDFDocument196 pagesPub - Quantum Mechanics For Chemists PDFDouglas SampaioNo ratings yet

- Fitting Table - Iso 8015 (Jis B 0401) (Jis B 0024)Document4 pagesFitting Table - Iso 8015 (Jis B 0401) (Jis B 0024)mysoreyogishNo ratings yet

- Hydrogel Nanocomposites As Remote-Controlled Biomaterials PDFDocument6 pagesHydrogel Nanocomposites As Remote-Controlled Biomaterials PDFBianca Ionela DraganNo ratings yet

- Secondary Containment GuideDocument2 pagesSecondary Containment GuideJames Glerry AaronNo ratings yet

- HiligaynonLessons CecileMotus PDFDocument454 pagesHiligaynonLessons CecileMotus PDFJames Glerry AaronNo ratings yet

- Estimation of The Kinetic Parameters (Chemical Reactions and Stoichiometry)Document3 pagesEstimation of The Kinetic Parameters (Chemical Reactions and Stoichiometry)James Glerry AaronNo ratings yet

- SOP1 Heat ConductionDocument1 pageSOP1 Heat ConductionJames Glerry AaronNo ratings yet

- Presidential Decree No 1151, S 1. Presidential Decree No 1151, S 4Document18 pagesPresidential Decree No 1151, S 1. Presidential Decree No 1151, S 4Myles LaboriaNo ratings yet

- Ethics NotesDocument8 pagesEthics NotesJames Glerry AaronNo ratings yet

- Coca-Cola, Communication, and Confusion: J.S.B. MorseDocument6 pagesCoca-Cola, Communication, and Confusion: J.S.B. MorseJames Glerry AaronNo ratings yet

- Chemical Name: Ca Crystal Structure: Face Centered Atomic Mass: Density at 20 CDocument1 pageChemical Name: Ca Crystal Structure: Face Centered Atomic Mass: Density at 20 CJames Glerry AaronNo ratings yet

- Modern Analytical ChemistryDocument1 pageModern Analytical ChemistryJames Glerry AaronNo ratings yet

- Set A: Test Code: OR-AT-11-23Document35 pagesSet A: Test Code: OR-AT-11-23tanjirouchihams12No ratings yet

- Unit 2 - Week 1: Assignment 1Document4 pagesUnit 2 - Week 1: Assignment 1UmaNo ratings yet

- Diesel Injection System Naturally AspiratedDocument346 pagesDiesel Injection System Naturally AspiratedGreg Hanna100% (1)

- Aod (Q)Document10 pagesAod (Q)Palak RustagiNo ratings yet

- Practice Test Paper-2 - IJSODocument11 pagesPractice Test Paper-2 - IJSOSonal Gupta100% (5)

- Mata Pelajaran: Kimia Tingkatan:: Kontrak Latihan Murid 5Document2 pagesMata Pelajaran: Kimia Tingkatan:: Kontrak Latihan Murid 5hazilah1969100% (1)

- Differential Equations - Driven Simple Harmonic Oscillator - Amplitude of Steady State Motion - Mathematica Stack ExchangeDocument4 pagesDifferential Equations - Driven Simple Harmonic Oscillator - Amplitude of Steady State Motion - Mathematica Stack ExchangemmrmathsiubdNo ratings yet

- Solved Problems in PhysicsDocument22 pagesSolved Problems in Physicsvasudevan m.vNo ratings yet

- NanotechDocument41 pagesNanotechOrange HuntNo ratings yet

- Uzan-The Arrow of Time and Meaning PDFDocument29 pagesUzan-The Arrow of Time and Meaning PDFrochalieberNo ratings yet

- ATOMSDocument17 pagesATOMSsabatsuhani74No ratings yet

- 6.0 Colloidal Silica Laboratory Testing and ResultsDocument47 pages6.0 Colloidal Silica Laboratory Testing and ResultsTATATAHERNo ratings yet

- 9 4Document1 page9 4Prince QueenoNo ratings yet

- No. 114 December 2003Document60 pagesNo. 114 December 2003European Southern ObservatoryNo ratings yet

- Tao Xiang, Congjun Wu - D-Wave Superconductivity-Cambridge University Press (2022)Document401 pagesTao Xiang, Congjun Wu - D-Wave Superconductivity-Cambridge University Press (2022)1277033481No ratings yet

- Aqa 7407 7408 PTT A3 Ans PDFDocument5 pagesAqa 7407 7408 PTT A3 Ans PDFBlack DragonNo ratings yet

- Two-Pan Equal-Arm BalancesDocument31 pagesTwo-Pan Equal-Arm BalancesIsabelle ThraceNo ratings yet

- P H y S I C S Part - I Multiple Correct Answer(s) TypeDocument28 pagesP H y S I C S Part - I Multiple Correct Answer(s) TypeUdayNo ratings yet

- Parker Pgi Gauge SiphonsDocument2 pagesParker Pgi Gauge SiphonstedNo ratings yet

- PHYS 1220 Coulomb's Law and Electric Fields SolutionsDocument20 pagesPHYS 1220 Coulomb's Law and Electric Fields SolutionsHüthâifâ AbdérahmânNo ratings yet

- Failure of MaterialsDocument34 pagesFailure of MaterialsvinayprasadskNo ratings yet

- Analysis 2 IDocument15 pagesAnalysis 2 IMiliyon TilahunNo ratings yet

- Air Pollution Control TechDocument52 pagesAir Pollution Control TechvivekNo ratings yet

- Chem 101 Lab 12 Gas LawsDocument12 pagesChem 101 Lab 12 Gas LawsT Josiah RichardsonNo ratings yet

- 80 % CourseDocument22 pages80 % Coursedhook_mmmNo ratings yet

- Unit I-D - Defects in SolidsDocument16 pagesUnit I-D - Defects in Solidsjyoti kumariNo ratings yet

- SJChO Past Year QuestionDocument26 pagesSJChO Past Year Questionronghui009No ratings yet

- Advanced Topics in Quantum Field Theory A Lecture Course by Shifman M.Document642 pagesAdvanced Topics in Quantum Field Theory A Lecture Course by Shifman M.Amos chenNo ratings yet