Professional Documents

Culture Documents

Development of Sodium Leak Detectors For PFBR

Uploaded by

William MunnyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Development of Sodium Leak Detectors For PFBR

Uploaded by

William MunnyCopyright:

Available Formats

Nuclear Engineering and Design 249 (2012) 419431

Contents lists available at SciVerse ScienceDirect

Nuclear Engineering and Design

j our nal home page: www. el sevi er . com/ l ocat e/ nucengdes

Development of sodium leak detectors for PFBR

J.I. Sylvia

, P. Vijayamohana Rao, B. Babu, K. Madhusoodanan, K.K. Rajan

Indira Gandhi Centre for Atomic Research, Kalpakkam, Tamil Nadu, India

a r t i c l e i n f o

Article history:

Received 2 November 2011

Accepted 16 April 2012

a b s t r a c t

The 500 MWe Prototype Fast Breeder Reactor (PFBR) is under advanced stage of construction at

Kalpakkam near Chennai in India. The wide and high operating temperature, highly chemically active

nature of sodium and its reaction with air make the sodium instrumentation complex over the conven-

tional instrumentation. Over the years, traditional instruments such as wire type leak detectors, spark

plug type leak detectors were developed and used in different sodium systems. The redundant and diverse

leakdetection method calls for development of special instrumentation for sodium systems which include

sodium ionization (leak) detector for detecting minute sodium leak in addition to those systems based

on mutual inductance principle. For detection of sodium leak from reactor Main Vessel (MV), diverse

methods are used such as miniature, remotely locatable, Mutual Inductance type Leak Detector(MILD)

and specially modied spark plug type leak detector. The design of MILD is suitably modied for detecting

leak in double wall pipes and Diverse Safety Rod drive Mechanism (DSRDM). Steam/water leak in steam

generator produces hydrogen and leads to high pressure and temperature in the system. Rupture disc

is used as a safety device which punctures itself due to sudden pressure rise. To detect the discharge of

sodium and its reaction products at the downstream of the rupture disc due to bursting of the rupture

disc, cross wire type leak detector has been designed, developed and tested. The selection of the leak

detection system depends on the location where leak has to be detected. This paper describes the recent

developments carried out in leak detector systems to meet the challenges involved in developing robust

sensors for PFBR including miniaturization of leak detectors and the ability to locate or withdraw them

remotely through a long guide tube with complex prole.

2012 Elsevier B.V. All rights reserved.

1. Introduction

Sodium, because of its good heat transfer and nuclear prop-

erties, is used as coolant in fast reactors. Liquid sodium meets

almost all the requirements of a fast-reactor coolant with its high

thermal conductivity, reasonable specic heat, low neutron mod-

eration and absorption, and high boiling point at near atmospheric

pressure. Different types of leak detectors are used in PFBR for

detecting sodiumleak. As sodiumis good conductor of electricity,

sensors based on electrical conductivity are found very attractive

for sodiumleak detection system. Different types of leak detectors

are used for detecting sodium leak in single wall pipelines, dou-

ble wall pipelines, tanks and components in PFBR as discussed in

Vijayakumar et al. (2004).

The primary and secondary circuits of PFBR uses large inven-

tory of sodium as coolant. Leaks in sodium systems have the

potential of being exceptionally hazardous due to the reaction of

liquid sodium with oxygen and water vapor in the air. Sodium is

Corresponding author. Tel.: +91 044 27480500x22352; fax: +91 044 27480086.

E-mail address: sylvia@igcar.gov.in (J.I. Sylvia).

reactive with air and catches re depending on the temperature

of sodium. Temperature in the plant ranges from150

C to 550

C.

Leaked sodium also reacts with concrete leading to damage and

loss of strength. Steam/water leak into sodium in steam genera-

tor produces hydrogen and leads to high pressure and temperature

in the system. Even though these systems are designed to make

sodium leak most improbable, it is essential to detect the leaks at

anearly stage. Detectors are providedsuchthat leak is detectedand

contained before any possible damage could occur.

As per standards on performance requirements for sodiumleak

detectors stipulated by ASME Boiler and Pressure Vessel Code, Sec-

tion XI, Division 3; a leak rate of 100g/h of sodium in air lled

vaults must be detected in 20h and a leak in inert vault within

250h.

2. Detectors based on electrical conductivity of sodium

Wire type, spark plug type and Extended spark plug type leak

detectors (ESPLD) work on the principle of electrical conductiv-

ity of sodium. The detector wire or detector electrode makes a

short circuit during sodiumleak with the pipeline which is already

electrically earthed and results in grounding.

0029-5493/$ see front matter 2012 Elsevier B.V. All rights reserved.

http://dx.doi.org/10.1016/j.nucengdes.2012.04.010

420 J.I. Sylvia et al. / Nuclear Engineering and Design 249 (2012) 419431

Fig. 1. Wire type leak detector.

2.1. Wire type leak detection system

This is the simplest method of leak detection systememployed

in the experimental sodiumsystems, single walled pipelines, com-

ponents and tanks of secondary system of PFBR. It consists of a

metallic Nickel wire insulated with ceramic bead insulators. The

cross shapedceramic insulator is stung over the wire andthis string

is laidonthesurfaceof thepipeall alongits lengthas showninFig. 1.

The exposed portion of the wire is in close proximity to the pipe

surface. Sodium leaks from the pipe make contact with the wire

and bridges the small air gap between the wire and the pipe sur-

face results in earthing. The electronics systemdetects the earthing

and gives sodiumleak alarm.

In order to make the leak system more effective, the ceramic

insulatedwireis laidunderneaththehorizontal pipelines of smaller

diameter. For larger pipes of sizes 250mmandabove(not invertical

run) the wire type leak detectors are provided at 90

, 180

and

270

taking top as 0

. These three leak detectors along the length of

5mhelps in reducing the distance between the leak point and the

detectors. For vertical run of the pipe wire type leak detectors are

woundhelicallywiththe pitchof 0.5msothat the maximumlength

between a leak point and a detector is less than 0.5m. They are

grouped in series to minimize the number of electronic channels.

The series grouping ensures healthiness of system as any fault in

the circuit is also indicated as a leak alarm.

2.2. Spark plug type leak detection systems

Spark plug type leak detectors are used for detecting sodium

leak in enclosed space like bellowsealed valves and thermowell. It

is mounted in a small trough/pocket into which the leaked sodium

collects and causes electrical short between its insulated central

conductor and the body. It is typically used to detect sodium leak

from the double wall pipelines and vessels of fast reactor system

with the inter-space containing nitrogen gas. The leak detector is

mounted in a small trough at the bottommost level of the envelope

surrounding the capacities such as reactor vessel. Same electronics

is used for detection of leak.

2.2.1. Extended spark plug type leak detector (ESPLD)

For detecting leak from Main vessel, two diverse methods are

used. One of which is based on electrical conductivity and other is

based on Mutual Inductance principle. Two numbers of ESPLDs are

used which works on electrical conductivity principle. Sensing end

of the leak detector is located at bottom most point inside safety

vessel where sodiumis getting collected. The active sensor portion

is as showninFig. 2. It consists of acentrecapillarysyringeinsulated

from the outer Stainless steel (SS) tube by alumina. The ceramic

to metal brazing was done in vacuum. The overall dimension of

the active sensor portion is 4mm dia. and 49.5mm long which is

limited by the complex guide tube prole in the Safety Vessel (SV).

25m long MI cable was brought through a 4mm dia thin walled

extension tube to protect the cable fromdamage and also for ease

of insertion/withdrawal. SS sheath of MI cable was removed for

a length of 30mm and the SS conductor was passed through the

ceramic insulators to the detector sensor portion and welded to

the end using laser beamwelding. The active sensor portion (1mm

SS tube) is protected fromdamage by welding an SS protective cap

during insertion and withdrawal. Once the leaked sodiumbridges

the SS protective cap and the centre capillary syringe leak will be

detected. The sensor in assembled condition is shown in Fig. 3.

As per ASME code, a leak rate of 100g/h of sodium should be

detected in 250h in the inert atmosphere. After leaking from MV,

sodiumis collected at the bottomof the SV. 25kg of liquid sodium

takes a level of 20mm from the bottom of the MV. As the active

portion of the sensor is 4mm dia, 4mm height of leaked sodium

can be detected using this sensor which is much earlier than 250h.

Fig. 2. Sensor portion of ESPLD.

J.I. Sylvia et al. / Nuclear Engineering and Design 249 (2012) 419431 421

Fig. 3. ESPLD in assembled condition.

2.3. Electronics for leak detectors

The wire type and spark plug type leak detectors use the similar

electronics for processing the leak signal. Wire type leak detectors

are directly connected to Field Terminal Boxes (FTB) where two

resistors, one is 100 ohm and other is 470 ohms are connected

as shown in Fig. 4. The control card located in the control bin is

the heart of LD system where all the signals are processed, stored

and manipulated. The Control Bin consists of RT20 CPU Card, VME

Ethernet Controller Card for communicating the data through Eth-

ernet, memory card to store the database and conguration, I/O

interface board to convert VME bus to I/O bus where leak detector

cards (analog input) and Relay output cards are located.

Each Leak detector card consists of 32 analogue input chan-

nels in which four channels are used for diagnostics purpose. This

card, after receiving eld signals, converts analog signals to dig-

ital signals. The set values are shown in Table 1. Digital signals

Table 1

Set values of ESPLD.

Condition Voltage (V) Output value in

digital form

Normal 4.2 0100

Leak 1.02 0010

Wire open 11.96 1000

Wire short .020 0001

Undened Other than above values 0000

which represent eld leak conditions are compared with set values

stored in Erasable Programmable Logic Device (EPLD). This sys-

tem consists of one Relay output module and depending on the

group conguration, if any one of the leak detector shows leak or

any unhealthy condition, the relay will be energized to alert the

operator through AlarmAnnunciator window. This electronics was

Fig. 4. Schematic of electronics.

422 J.I. Sylvia et al. / Nuclear Engineering and Design 249 (2012) 419431

Table 2

Sensor specication.

S. no. Leak detector Sensor specication

Sensor Pocket Winding details/features

Material Size Material Size

1. Main vessel leak detector

(miniature & remotely

locatable)

SS410 (magnetic material

improves the sensitivity)

Dia. 5.0mm

Active length 20mm

Total length 25mm

SS316L OD 7.5mm

ID 5.5mm

0.5mmdia. M.I. cable in two layers

in bilar fashion.

Primary: 10 turn

Secondary: 10 turn

Remotely locatable

22mlong free leads inside the

extention tube of 4mmOD and

3.6mmID

2. DSRDMleak detector

(miniature)

SS410

(magnetic material

improves the sensitivity)

Dia. 5.0mm

Active length 20mm

Total length 22mm

SS316L OD 7.5mm

ID 5.5mm

0.5mmdia. M.I. cable in two layers

in bilar fashion.

Primary: 10 turn

Secondary: 10 turn

15mlong free lead installed inside

the EM

3. DWP leak detector SS316L Dia. 32mm

Active length 22mm

SS316L OD 42.16mm

ID 36.62mm

1mmdia. M.I. cable

Primary: 1 layer

22 turns

Secondary: 2 layer

22 turns/layer

developed in-house and tested in the sodiumrigs available in Fast

Reactor Technology group (FRTG).

It was experimentally proved in FRTG that the highest detec-

tion time observed was about 6h for a sodiumleak rate of 222g/h

as discussed in Vijayakumar et al. (2011). A relationship between

leak rate and detection time was established fromthe experimen-

tal results and found that sodiumleak rate of 100g/h is likely to be

detected in 11h which far better than the stipulated value of 20h

in ASME code.

3. Leak detector based on mutual inductance (MI) principle

Mutual InductancetypeLeakDetector (MILD) works ontheprin-

ciple of decrease in mutual inductance between two coils when

sodium surrounds it. The primary coil is excited with AC constant

current of 100mA and an emf will be induced in the secondary coil

of the sensor. The secondary coil emf will be reduced when sodium

surrounds the pocket. The reduction in secondary emf indicates

sodiumleak.

MI type sensors have several advantages such as (i) non contact

operation with sodium as it is located inside a thimble; (ii) facili-

tates maintenance, as the sensor canbe removedfromits pocket for

inspectionand/or replacement; (iii) the sensor needs tobe installed

into the thimble only prior to sodium-lling of the vessel and not

during the integrity (pressure/vacuum) testing, normally carried

out on the vessel after fabrication at the manufacturers premises;

and (iv) immune to sodiumwetting. All the above factors weighed

in favour of developing a leak detector based on the MI principle.

This leak detector forms a redundant and diverse method of leak

detection. As remote handling and miniaturization is possible with

this type of detectors it is used for detecting sodium leak in main

vessel, double walled pipes, electromagnet of diverse safety rod

drive mechanismetc. bysuitablymodifyingthe designof the sensor

as indicated in Table 2.

3.1. MI type leak detector (MILD) for main vessel (MV) of PFBR

This is one of the diverse methods for detection of leak, from

the Main Vessel (MV) of PFBR for the safe operation of reactor. In

case of sodiumleak fromthe Main Vessel (MV), the leaked sodium

collects inthe Safety Vessel (SV). One of the detectors developedfor

this purpose is miniature, remotely locatable Mutual Inductance

type Leak Detector. MILD will be positioned at the bottom most

elevation of the inner surface of SV through a guide tube fromthe

top of the reactor vault. Since unhindered space for the in-vessel

inspection vehicle has to be provided, the size of the guide tube

is small and this puts a limitation on the size of the probe bobbin.

The challenges involved in developing this sensor for PFBRincludes

miniaturization of leak detector and the ability to locate/withdraw

themremotely through a long complex guide tube prole.

3.1.1. Design of MILD

The guide tube with three different segmented proles suitable

to the reactor is shown in Fig. 5. The sharp bending radius of the

guide tube is of the order of 350mm. For easy insertion and with-

drawal of the sensor a cylindrical bobbin of 2.8mm diameter and

20mmlong was selected.

The insertion and withdrawal of the probe inside the guide tube

assembled with three different segmented proles suitable to the

reactor has been tested and conrmed. However, the miniature

probe has a limitation on sensitivity of the probe. In order to eval-

uate the sensitivity, sensor with different bobbin material namely

SS316L andSS410 (magnetic) were fabricated. The probe coils were

wound on a cylindrical bobbin of 2.8mm diameter and 20mm

long made up of either SS316 or SS410 using 0.5mm diameter SS

sheathed, MgO insulated, copper conductor (MI) cableover two lay-

ers inbilar fashion. Inorder toevaluatethesensitivityof theprobe,

two probes are fabricated with short free leads of identical dimen-

sions but of different bobbin material namely SS316 & SS410. The

preliminary experiment was carried out in brick sodiumwith two

probes. The sensitivity obtained was around 7% for the probe made

of SS316 material whereas the sensitivity of sensor made of SS410

material was around 30% which is sufcient to provide threshold

setting in the electronics. Therefore SS410 is selected as material

for MILD.

This was again validated by simulation using Finite Element

Modeling and the ux pattern at 5.25kHz for SS410 bobbin with

and without sodium is shown in Fig. 6. The sensitivity obtained is

50% for SS410 bobbin but for SS316L sensitivity is only 9%. Hence

miniature MI probes are designed with SS410 bobbin. The SS410

gives more sensitivity compared with SS316. This is because SS410

is having better permeability compared with SS316. Hence more

ux is generated in SS410 which results in increase in sensitivity.

J.I. Sylvia et al. / Nuclear Engineering and Design 249 (2012) 419431 423

Fig. 5. Location of MILD probe in Safety Vessel (SV) of PFBR.

At one end of bobbin, a collar is provided for attaching to a

thin-walled tube of 4mm OD and 3.6mm ID. MI cable leads from

the probe are brought through the capillary tube. Fig. 7 shows the

photograph of the sensor.

3.1.2. Experimental procedure

The detailedexperiments were carriedout inpure sodiumsimu-

lating the various reactor conditions. Fig. 8 shows the experimental

set up and Detail-A shows the MI type leak detector probe. This

experiment was carried out to nd optimum frequency at which

the sensitivity is maximum. The guide tube is closed at the bottom

and welded with one SS block which simulates the PFBR safety

vessel thickness. The guide tube carrying the MILD is held by gland

and nut arrangement mounted on the top of the ange, which also

provides the leak tightness for the argon cover gas. L1, L2, L3 are

sodiumlevel indicators. Level of sodiumincreases slowly up to the

operating level (L2). The loopis initially lledwithsodiumat 150

C

and the reading is taken fromthe probe (secondary output is mea-

sured in mV). Then the sodium level is quickly drained below the

guide tube end and the reading is again taken. The difference in

readings is the reduction in secondary output of MI probe. This

operationis for one temperature and frequency. Similarly the oper-

ations have to be repeated for temperature upto 550

C in steps

of 50

C and the frequency was varied from 2 to 8kHz in steps of

0.25kHz.

3.1.3. Experimental results

The experiment was conducted up to 8kHz for the temperature

from 150

C to 550

C. It was observed from Fig. 9 that at 550

C

the sensitivity is maximum of 49.5% at a frequency of 5.25kHz.

Sodiumtests of the probe have revealed a sensitivity ranging from

40 to 50% over the sodium temperature range of 150550

C and

the electronics is provided with alarmthreshold corresponding to

the probe output at 550

C (probe fully covered with sodium).

Skin depth corresponding to the frequency of 5.25kHz is

3.8mm. The thickness of sodiumequal to twice the skin depth cor-

responding to the operating frequency is virtually equivalent to an

innite sea of sodium as discussed in Mcgonigal et al. (1971). The

height of the guide tube (8mm) andthe height of the leakedsodium

above the guide tube (8mm) contributes to a total height of 16mm

whichcanbe detectedusingthis sensor. Hence the detectiontime is

earlier than the 20mmheight thereby meeting the recommended

ASME standard.

3.2. MI type leak detector for DSRDM

In PFBR there are two shutdown systems, one of the systems is

DiverseSafetyRodDriveMechanism(DSRDM). Inbottomportionof

the DSRDMthere is a dissimilar weldjoint, betweenElectro Magnet

(EM) made of iron and stainless steel. The failure of weld can result

in entry of sodium inside the electro magnet, which can increase

the response time of electromagnet, thereby increasing Shutdown

Control Rod Accelerated Drive Mechanism (SCRAM) time. So it is

necessary to detect the entry of sodium inside the EM. Consider-

ing the space, Miniature MILD was required for detecting the leak.

As remote handling is not required as in MILD for MV, extension

tube over the free leads are not provided. But 15m long MI free

leads are required to mount the sensor within the electromagnet

housing.

Miniature MI type sodium leak detector to detect the sodium

leak in electromagnet housing in DSRDM is indigenously devel-

oped and fabricated. The sensor construction is same as that of

MILD for MV except the mounting arrangements. Special jig was

fabricated for winding the M.I. cable on the bobbin without twist-

ing and damaging the MI cable sheath. Jig was fabricated in such

a way that during winding, the free lead (15m) also rotate along

withthe bobbinandthe MI cable sheathshouldnot touchanymetal

part, otherwise the sheath will get damaged (sheath thickness is 50

microns). Special jig facilitates to get the repeatability of winding

without damaging the free leads of the M.I. cable.

The detailed assembly drawing is shown in Fig. 10. After wind-

ing the bobbin the free leads are inserted through bobbin support

tube and sensor ange which is having 4 holes of 0.8mmdiameter

on 2mm PCD. The bobbin was welded with the support tube by

Laser beamwelding. The primary and secondary leads are twisted

to cancel the noise. Then the sensor assembly will be inserted into

the pocket and tack welded between pocket and sensor ange to

avoid rotation. Insert the cap over the sensor ange and x with 3

screws. The screws and the cap are tack welded to avoid unscrew-

ing during vibrations inthe DSRDM. The coldends are preparedand

sealed after improving the insulation value. The insulation value is

measured at every stages of assembly.

424 J.I. Sylvia et al. / Nuclear Engineering and Design 249 (2012) 419431

Fig. 6. Flux pattern in sodium& air at 200

C for SS410 bobbin.

Fig. 7. MILD Sensor for Main Vessel (MV). Fig. 9. Frequency vs sensitivity of the probe at 550

C.

Fig. 8. Experimental setup & probe.

J.I. Sylvia et al. / Nuclear Engineering and Design 249 (2012) 419431 425

Fig. 10. Assembly drawing of DSRDMleak detector.

The above assembly is qualied in three stages. Before fabri-

cation, chemical composition of raw materials and dimensional

checks are carried out, welding procedures are qualied and

approved. During fabricationdimensional checkof fabricatedparts,

surface treatments and welding qualication are carried out. After

fabrication, visual inspection and Liquid penetrant inspection of

weld joints, dimensional inspection of nal assembly, and perfor-

mance checking of sensor were carried out. Three numbers of leak

detectors are successfully fabricated with qualication procedures

as showninFig. 11. Thesensor was not onlyindigenouslydeveloped

and fabricated but also l it was nally installed inside the DSRDM

for deployment in PFBR.

3.3. MI type leak detector for double walled pipeline

In the double wall piping the leaking sodium spreads and

reaches the pocket since the piping is with little inclination. Since

the guard pipe is provided with pockets for every compartment,

the maximum distance sodium is to travel is the length of the

compartment before reaching the pocket. MI type leak detectors

are provided where the leaked sodium gets collected in a pocket

designed for the purpose. The main function of the MI type leak

detector is to detect the leak of sodium from the main pipe line

into the annulus space lled with Nitrogen envelope in the pipe.

The primary and secondary coils of the detector are wound on

a cylindrical bobbin of length 22mmand diameter of 32mmusing

SS sheathed 1mm dia. MI cable, with copper conductor and mag-

nesium oxide insulation. The sensitive portion of the detector is

of hollowcylindrical cross section made of SS316. This detector as

shown in Fig. 12 is a probe type, which can be kept inserted into a

thimble fromthe pocket bottom.

The electronics as shown in Fig. 13 is made simple as tempera-

ture compensation over an operating range from150

C to 550

C is

not required as the length of the probe is much smaller. The sodium

leak of the order of 100gm/h can be detected in a few hours with

this detector.

4. Sodiumionization detector (SID)

SIDis usedas global leakdetectionsysteminPFBRsecondarycir-

cuit area. Details of developmental works related to SID is given in

Elumalai et al. (1984). Sodiumcooled fast reactors have numerous

requirements for instrumentation capable of detecting the leakage

of sodium from component or piping faults into the surrounding

gaseous atmosphere. Detection of these leaks by a sensitive early

warning system is highly desirable to limit piping deterioration,

component destruction, re damage or corrosive effects from the

sodium. The amount of oxygenandwater impurities guarantee that

any leaking sodiumwill be partially reacted to oxide or hydroxides

and that sodium aerosol will be generated in addition to sodium

vapour. Therefore the leak detector should be capable of respond-

ing to sodium compounds as well as to elemental sodium. One of

the major advantages of SIDis its operating simplicity. Detection of

leak is obtained under ambient atmospheric conditions.

Fig. 11. Photograph of DSRDMleak detector.

426 J.I. Sylvia et al. / Nuclear Engineering and Design 249 (2012) 419431

Fig. 12. Leak detector for double walled pipeline.

Fig. 13. Electronics for MILD.

4.1. Theory of operation

The SID works on the principle of preferential ionization of

aerosols of sodium and its compounds (oxides and hydroxides) in

carrier gases such as argon, nitrogen and air. The schematic of SID

is as shown in Fig. 14. The detector carries a heated lament on

which the sodium aerosols in the carrier gas fall and get ionized.

These ions are then collected on an adjacent electrode which is

maintained at a negative potential relative to the lament, leading

to readily detectable current. In the absence of an easily ionisable

substance like sodium near the lament, the SID produces only

a small background current, arising primarily from alkali metal

impurities inthe lament material as discussedinRef. Bauerle et al.

(1976).

The most critical and also the most complex aspect of SID oper-

ation involve the detailed processes by which the sodiumparticles

are converted to free sodiumions. This can be thought of as occur-

ring in the following steps:

[1] The collision of sodiumparticles with the hot lament surface

and their subsequent Melting. The rapid surface diffusion of the

melted sodium over the lament to form a layer of adsorbed

sodiumatoms

[2] The transfer of valence electrons from some of the adsorbed

sodium atoms to the lament, converting them to adsorbed

sodiumions

[3] The desorptionof these sodiumions fromthe surface tobecome

free ions; also the desorption of neutral sodiumatoms.

The rst andsecondsteps produce a monolayer of sodiumatoms

in the lament surface. In the third and fourth steps, these atoms

are theneither thermallyionizedtobecome free sodiumions, or are

evaporated as neutral sodiumatoms. Only the free ions contribute

to the SID response. Temperature of the lament contributes to

the ionization efciency. The work function of the lament metal

Fig. 14. Schematic of SID.

J.I. Sylvia et al. / Nuclear Engineering and Design 249 (2012) 419431 427

Fig. 15. Photograph of SID.

surface should be greater or comparable to the ionizationefciency

of the sodiumatoms.

4.2. Sensor design

The optimumsensor designusedinPFBRis toachieve maximum

sensitivity with minimumbackground sodiumion current. The SID

as shown in Fig. 15 scores over other detectors in the sense that it

can detect a quantity of as lowas one nanogramof sodiumpresent

in a cubic centimeter of carrier gas.

Filament used : platinumlament of 50mmlong, 25

micron thick and 1mmwidth

Collector plate material : perforated cylinder made of Stainless

Steel (12mmOD 10mmID, 35mm

long) 1.8mmdia perforated hole

Filament to collector spacing : 5mm

Collector voltage : 200V

Filament temperature : 9501000

C

Carrier gas ow : 1l/min

Maximumbackground current : 0.08nA

Sensitivity : varies from0.1 to 1 nanoampere per

nanogramof sodiumper cubic

centimeter of gas

Minimumdetectable sodium

concentration

: better than 0.3 nanogramof sodium

per cubic centimetre of gas

4.3. Electronics for the SID

The electronics unit for the SID consists of

[1] an adjustable current source for heating the lament

[2] a mediumvoltage power supply to provide the electric eld for

collecting the sodiumions

[3] a wide range electrometer (10

12

to 10

6

ampere) for measur-

ing sodiumion current

[4] Thermal cycling circuitry to maintain the sensitivity of the la-

ment

The electronics chassis was qualied for immunity level to EMI

noise. To maintain the sensitivity of the lament, thermal cycling

circuit has also been incorporated in the SID electronics.

4.4. Sampling system

The SID system consists of SID sensor and the sampling sys-

tem with uted pipelines as shown in Fig. 16. Hence a single

detector can cater to many locations through sampling of the

carrier gas. The inherent response time of the SID to a single

Fig. 16. SID as area monitoring.

428 J.I. Sylvia et al. / Nuclear Engineering and Design 249 (2012) 419431

Fig. 17. Sensitivity of SID with long sampling lines.

aerosol particle should be comparable to the ion drift time between

the lament and the collector, typically less than a millisecond.

In a practical detection system employing aerosol sampling line,

however the time response is controlled by the much slower

processes of gas ow to the sensor chamber and mixing in the

chamber as discussed in Swaminathan and Elumalai (1984). The

sensitivity of SID system using long sampling lines, has been

demonstrated experimentally as shown in Fig. 17. The SID work-

ing on sampling method has been used in experimental area and

secondary circuit area of PFBR. The installation of SID is shown

in Fig. 18. The response of SID to burning 5g of sodium in the

experimental area is shown in Fig. 19. Every time the test is car-

ried out, the alarm threshold set at 1nA is exceeded by the SID

response, conrming the sensitivity and effectiveness of the SID

system.

During the operation of SID system it was observed that

there was an increase in background value crossing the thresh-

old limit. After cleaning the sensor, sampling lines and blower

with water the background started coming down. As part of the

surveillance periodic cleaning of sensor and sampling system is

recommended.

Fig. 18. Installation of SID.

Fig. 19. Sodiumre test.

5. Cross wire type leak detector

The main function of the Cross Wire type Leak Detector (CWLD)

is to detect the discharge of sodiumand its reaction products at the

downstreamof the rupture disc due to bursting of the rupture disc.

This provides the informationonsodiumwater reactioncauseddue

to water/steamleak inthe SteamGenerator (SG) and the developed

hydrogen gas pressure bursts the rupture disc. Literature survey

shows that this type of sensor is deployed in Monju reactor works

on bursting technique as in Takahashi et al. (1983). These S. S. foils

are located at the downstream of the rupture disc in the vertical

pipe as shown in Fig. 20. When sodium/sodium reaction products

ow past the S. S. foils break themand the loss of electrical conti-

nuity of the foils is detected and alarm signal is given. The CWLD

was designed with following specication and the functionality

was checked in experimental water test setup.

5.1. Sizing of SS foil

Based on calculations the width and thickness of the SS foil

were xed to 15mm& 50 microns respectively. Experiments were

carried out to optimize the design of the foil. Based on these exper-

iments, the depth and number of V-notches were determined. The

effect of thermal stress in the foil due to the temperature difference

between pipe and foil was studied by numerical simulation. It was

foundthat, inorder toavoidyieldingof the foil due tothermal stress

J.I. Sylvia et al. / Nuclear Engineering and Design 249 (2012) 419431 429

Fig. 20. Location of CWLD.

Fig. 21. Dimensions of CWLD.

430 J.I. Sylvia et al. / Nuclear Engineering and Design 249 (2012) 419431

the foil temperature (whichwill be nearly equal to the temperature

of argongas surrounding the foil) shouldbe limitedto 15

Conly. As

this is difcult toachieve, slight extra length(23mm) of foil will be

provided. This will prevent any thermal stress getting developed in

the foil and thus prevent the breakage of the foil due to differential

temperature.

5.2. Specication of SS Foil

Material : SS304

Length of foil : 338mm

Width of foil : 15mm

Thickness : 0.05mm

Number of V notches : 7 NOS.

Depth of V notches : 6mm

V notches are kept at a distance of 40mmas shown in Fig. 21.

5.3. Experimental setup

In order to validate the design, experiment was carried out. The

experimental test set up for testing the S.S. foils along with the

detector electronics is shown in Fig. 22. The tests were carried out

in a water loop in Engineering Hall-II by suddenly allowing water

at some pressure to owover the foils. To measure the pressure in

the pipeline at the time of opening of the valve, a dynamic pressure

Fig. 22. Experimental test setup of CWLD.

transmitter is installed. Inthis set-up, all the 3 foils are installed ina

pipe at uniformgap of 10mmand 60 degree apart without making

contact with each other. To electrically insulate the foils from the

metallic pipeline, a spark plug is installed in pipe with the help of

Fig. 23. SS foils before and after breaking.

Fig. 24. Graph showing specimen vs. breaking pressure.

J.I. Sylvia et al. / Nuclear Engineering and Design 249 (2012) 419431 431

sleeves. A triangular piece welded to the central electrode of the

spark plug is used to hold the foil rmly. Electronic connections

are given to the terminals of the spark plug. Fig. 23 shows the SS

foils before and after breaking. The breaking of these SS foils are

detected electronically using two out of three logic.

It was found from the hydraulic experiments repeated over

42 trials that all the SS foils break at an average pressure of

0.150.25MPa which corresponds to a velocity of 2m/s as shown

in Fig. 24. The expected minimum pressure and velocity in PFBR

is 0.37MPa and 2m/s respectively. It is found that the results are

conservativeandthesnapping/breakingtechniqueof theCWLDhas

been demonstrated successfully.

6. Conclusion

As the commercially available conventional sensors cannot be

used for sodium leak detection, the sensors and instrumentation

are specially designed using the state-of-art technology to suit this

hostile environment. Wire type and spark plug type leak detectors

working on earthing principle is used on pipelines and different

capacities such as bellow sealed valves and leak collection trays

respectively with improved electronics in PFBRs. Miniature Mutual

Inductance type leak detectors with remote insertion/withdrawal

facility was developed for MV leak detector of PFBR. The selec-

tion of SS410 bobbin for improving the sensitivity of this sensor

was experimentally proved. ESPLDs are used as diverse method

for detecting leak in Main vessel. The sensor was assembled and

tested for its functionality and easy insertion and withdrawal. The

DSRDM leak detectors with longer length of free leads (15m) has

been fabricated, qualied and installed in the DSRDMelectromag-

net successfully. For double walled pipe line where pockets are

provided at the lowermost elevation, MI type leak detectors of

larger size was designed and used in multiple numbers. This type

of leak detector is non-intrusive and easily replaceable and hence

it gains importance for usage in the reactor systems. Sodium Ion-

isation leak detectors with improved electronics have been used

in secondary system as area monitoring in PFBR. As this sys-

tem has been employed in sodium facilities, lot of expertise has

been gained in maintaining the same. The Cross wire type leak

detectors are designed and experimentally tested at required pres-

sure of PFBR. The different types of sodium leak detectors were

designed, developed and tested in various sodiumfacilities which

gave us enough condence for deploying themin PFBR and future

FBRS.

Acknowledgements

Authors acknowledge the encouragement, guidance and sup-

port received from K. Swaminathan, Former Head, Component &

Instrumentation Development Division, FRTG, Shri S.C. Chethal,

Director, Indira Gandhi Centre for Atomic Research (IGCAR) and

all other agencies who supported during the course of this

work.

References

Bauerle, J.E., Reed, W.H., Berkey, E., 1976. Development of a sodium ionization

detector for sodium-to-gas leaks. In: International Conference on Liquid Metal

Technology in Energy Production.

Elumalai, G., et al., 1984. Development of sodiumionization detector for sodium-to-

gas leaks. In: 3rd International Conference on LMET, Oxford, UK.

Mcgonigal, G., Dean, S.A., Ferguson, B.G., Harrison, E., U.K. AEA, 1971. Measurement

of sodiumlevel in PFR. Nucl. Eng. Int. 16 (175/6), 6265.

Swaminathan, K., Elumalai, G., 1984. Development of a sodiumionization detector

for sodium-to-gas leaks. In: Liquid Metal Engineering and Technology. BNES,

London.

Takahashi, T., Ohmori, Y., Hoshi, Y., 1983. Inuence of sodium, water reaction on

MONJU steamgenerator, IWGFR/50, Netherlands.

Vijayakumar, V., et al., 2004. Sodium and Steam Generator Leak Detection for Pro-

totype Fast Breeder Reactor (PFBR), ICONE12-ICONE49362.

Vijayakumar, G., et al., 2011. Performance evaluation of PFBR wire type leak detec-

tors. Nucl. Eng. Des. 241 (2011), 22712279.

You might also like

- BergerDocument2 pagesBergerBhanu Pratap ChoudhuryNo ratings yet

- Book of Abstract PDFDocument103 pagesBook of Abstract PDFakkansalNo ratings yet

- Dev Energy - GASIFIERDocument33 pagesDev Energy - GASIFIERvinay1999No ratings yet

- Vol III Rate Schedule For Chimney-BhelDocument18 pagesVol III Rate Schedule For Chimney-BhelMallinatha PNNo ratings yet

- Jacketed Vessel Heat Transfer Coeff and Delta PDocument4 pagesJacketed Vessel Heat Transfer Coeff and Delta Pyamen-691904No ratings yet

- Heat Exchanger Design: Qfuel ContractorDocument27 pagesHeat Exchanger Design: Qfuel ContractorUsama AkramNo ratings yet

- DS 099 Rev01 Zinc Anode 304 MZDocument2 pagesDS 099 Rev01 Zinc Anode 304 MZsojeckNo ratings yet

- SMP - Boiler Prs Part-R02Document41 pagesSMP - Boiler Prs Part-R02Kathir Siva100% (1)

- 7 Fluid Dynamics Tutorial SolutionDocument25 pages7 Fluid Dynamics Tutorial SolutionAldhaAhmadyaningratNo ratings yet

- CLL251 (Boiling and Condensation) oDocument24 pagesCLL251 (Boiling and Condensation) oHriday GoelNo ratings yet

- Process Equipment Design-06Document25 pagesProcess Equipment Design-06PARAG DAHARWAL 20CH10020No ratings yet

- Combustion Engineering 2020Document113 pagesCombustion Engineering 2020Anthropophobe NyctophileNo ratings yet

- Automatic Boom Gating System: Bachelor of TechnologyDocument14 pagesAutomatic Boom Gating System: Bachelor of TechnologyvimalNo ratings yet

- The Prediction of Mineral Solubilities in Natural Waters: A Chemical Equilibrium Model For The Na-Ca-CI-S04-H20 System, To High Temperature and ConcentrationDocument17 pagesThe Prediction of Mineral Solubilities in Natural Waters: A Chemical Equilibrium Model For The Na-Ca-CI-S04-H20 System, To High Temperature and ConcentrationBiain A SecasNo ratings yet

- 39 Algal Oil Production 1Document21 pages39 Algal Oil Production 1Sai Srivathsava UdathuNo ratings yet

- Chapter 2 Notes PDFDocument25 pagesChapter 2 Notes PDFHassaan SajidNo ratings yet

- End of Chapter Answer Guide: 2nd Class - A1Document59 pagesEnd of Chapter Answer Guide: 2nd Class - A1Ken Manning100% (1)

- Argon Recovery From Silicon Crystal FurnaceDocument7 pagesArgon Recovery From Silicon Crystal FurnaceasdfqwerNo ratings yet

- Brauer 1981Document41 pagesBrauer 1981rodgerNo ratings yet

- Bladeless Wind TurbineDocument4 pagesBladeless Wind TurbineIJIERT-International Journal of Innovations in Engineering Research and TechnologyNo ratings yet

- 1a.calibration of OrificemeterDocument7 pages1a.calibration of OrificemeterArjun P PNo ratings yet

- BoilBal SpreadsheetDocument16 pagesBoilBal SpreadsheetZulkarnain NasrullahNo ratings yet

- Shell and Tube Heat ExchangerDocument7 pagesShell and Tube Heat ExchangerGaurav SharmaNo ratings yet

- CD4mcu Data SheetDocument1 pageCD4mcu Data SheetAde Bagus SetiawanNo ratings yet

- 13 Electrical Pole's TrasverseDocument7 pages13 Electrical Pole's TrasverseReza PahlepiNo ratings yet

- Welded and Riveted ConnectionsDocument58 pagesWelded and Riveted ConnectionsDennis Manejero0% (1)

- 76 9 Design of CranesDocument11 pages76 9 Design of Cranesrip111176No ratings yet

- Is 14164 2008Document45 pagesIs 14164 2008Pukhraj DagaNo ratings yet

- Jamalganj UCG ProspectDocument23 pagesJamalganj UCG ProspectArup Kumar BiswasNo ratings yet

- Understanding Flammability Diagrams: Flammability Diagrams Show The Control of Flammability in Mixtures of FuelDocument1 pageUnderstanding Flammability Diagrams: Flammability Diagrams Show The Control of Flammability in Mixtures of FuelDimitrie BogdanNo ratings yet

- Sap-2 Material Balance: Basis: Unit Hour of ProductionDocument17 pagesSap-2 Material Balance: Basis: Unit Hour of ProductionNandha KumarNo ratings yet

- Biomass (Rice Straw) Fired BoilerDocument9 pagesBiomass (Rice Straw) Fired BoilerSnehashis MaityNo ratings yet

- Calculation of Boiler EfficiencyDocument43 pagesCalculation of Boiler EfficiencyTamer Abd ElrasoulNo ratings yet

- Report On Desiging CompanyDocument53 pagesReport On Desiging CompanyArpit ThumarNo ratings yet

- Nichrome Dew Heater CalculatorDocument2 pagesNichrome Dew Heater Calculatordarklife79No ratings yet

- Design and Construction of A Domestic Passive Solar Food DryerDocument8 pagesDesign and Construction of A Domestic Passive Solar Food DryerMerwin Michael FernandesNo ratings yet

- Flammability of Mixtures of Co2 and HydrocarbonsDocument17 pagesFlammability of Mixtures of Co2 and HydrocarbonsLakshmi Binoy MenonNo ratings yet

- Gases and Vapors (Part 1)Document2 pagesGases and Vapors (Part 1)Khristel PenoliarNo ratings yet

- Synthesis of Paracetamol: Date Title of The Experiment SignatureDocument11 pagesSynthesis of Paracetamol: Date Title of The Experiment Signaturefileg39282No ratings yet

- CH 17Document42 pagesCH 17Bông Cải XanhNo ratings yet

- Hydrogen PresentationDocument57 pagesHydrogen Presentationkamal615No ratings yet

- Ultimate Guide To Shear Force and Bending Moment Diagrams - Engineer4Free - The #1 Source For Free Engineering Tutorials PDFDocument4 pagesUltimate Guide To Shear Force and Bending Moment Diagrams - Engineer4Free - The #1 Source For Free Engineering Tutorials PDFSubhajyoti DasNo ratings yet

- L&T Construction: Rehabilitation of Bhagirathi WTP, Delhi List of Lab EquipmentsDocument1 pageL&T Construction: Rehabilitation of Bhagirathi WTP, Delhi List of Lab EquipmentsRamBinodSharmaNo ratings yet

- 353.1 HEN E5 Manual Design PDFDocument288 pages353.1 HEN E5 Manual Design PDFmazhar955No ratings yet

- Fixed Water Spray Demand Calculations For Fire Protection of TanksDocument2 pagesFixed Water Spray Demand Calculations For Fire Protection of Tankssyamsoelbahri100% (1)

- Cea - Standard Technical Specification For Main Plant Package (2 500 MW)Document1,011 pagesCea - Standard Technical Specification For Main Plant Package (2 500 MW)vasudevapavanNo ratings yet

- Quality Management During Welding-3310 PDFDocument6 pagesQuality Management During Welding-3310 PDFAbhijeet SahuNo ratings yet

- Distributed Temperature Sensor Testing in Liquid Sodium: C. Gerardi, N. Bremer, D. Lisowski, and S. LomperskiDocument10 pagesDistributed Temperature Sensor Testing in Liquid Sodium: C. Gerardi, N. Bremer, D. Lisowski, and S. LomperskiAnup M UpadhyayaNo ratings yet

- Cathodic Protection of Offshore StructuresDocument33 pagesCathodic Protection of Offshore Structureskirubha_karan2000No ratings yet

- Durham E-ThesesDocument204 pagesDurham E-ThesesElaf AhmedNo ratings yet

- Vibration Style Ladle Slag Detection Method Based On Discrete WaveletDocument4 pagesVibration Style Ladle Slag Detection Method Based On Discrete WaveletVinay RajputNo ratings yet

- 1 SMDocument6 pages1 SMLimuel EspirituNo ratings yet

- CP Write-Up PDFDocument36 pagesCP Write-Up PDFManish KaushikNo ratings yet

- Inspection Techniques For Detecting CorrosionDocument6 pagesInspection Techniques For Detecting CorrosionCepi Sindang KamulanNo ratings yet

- Inspection Techniques For Detecting Corrosion Under InsulationDocument4 pagesInspection Techniques For Detecting Corrosion Under Insulationsllim776100% (3)

- Methods-Water Leak DetectionDocument6 pagesMethods-Water Leak DetectionAbhijeeth NagarajNo ratings yet

- TUBE INSPECTION by RFETDocument8 pagesTUBE INSPECTION by RFETTusar Kole100% (1)

- Spinel MgAl ODocument60 pagesSpinel MgAl OKOMCINo ratings yet

- Science of The Total Environment: Farhad Misaghi, Fatemeh Delgosha, Mostafa Razzaghmanesh, Baden MyersDocument10 pagesScience of The Total Environment: Farhad Misaghi, Fatemeh Delgosha, Mostafa Razzaghmanesh, Baden Myersmahdi najafzadehNo ratings yet

- Shell Omala S2 GX 100 TDSDocument2 pagesShell Omala S2 GX 100 TDSEdgar Leonel CortésNo ratings yet

- AOC F013 SeriesDocument2 pagesAOC F013 SeriesYap HSNo ratings yet

- Applications of TitrationDocument11 pagesApplications of TitrationLaiba ZulfiqarNo ratings yet

- Gabi Starch As PlasticDocument24 pagesGabi Starch As PlasticJimreenBayAnColigman84% (19)

- Sandvikprocesssystems Kumarswamypaper 120525032106 Phpapp02Document12 pagesSandvikprocesssystems Kumarswamypaper 120525032106 Phpapp02naufalNo ratings yet

- Cryolite JM File 2011Document5 pagesCryolite JM File 2011mutemuNo ratings yet

- Final Exam Study Guide 2014 (High School Chem)Document6 pagesFinal Exam Study Guide 2014 (High School Chem)Brian KimNo ratings yet

- Ucrete General v1 Jac 2Document52 pagesUcrete General v1 Jac 2DeepmalaJayeshNo ratings yet

- List of Important Metals and Their Ores With Chemical Formulas PDFDocument2 pagesList of Important Metals and Their Ores With Chemical Formulas PDFAudibleNo ratings yet

- Sepa CF CellDocument42 pagesSepa CF Cellpolytechnic5scce100% (1)

- Indian Institute of Welding - ANB Refresher Course - Module 07Document55 pagesIndian Institute of Welding - ANB Refresher Course - Module 07dayalram0% (1)

- Taglus Standard MsdsDocument8 pagesTaglus Standard MsdsRushikesh GhagNo ratings yet

- Concept Note For CNGDocument8 pagesConcept Note For CNGadamuNo ratings yet

- The Vortex Atom - A Victorian Theory of Everything - by Helge Kragh !!!!! PDFDocument83 pagesThe Vortex Atom - A Victorian Theory of Everything - by Helge Kragh !!!!! PDFBodan NedNo ratings yet

- Rafiullah Khan PHD Thesis PDFDocument235 pagesRafiullah Khan PHD Thesis PDFShehraam MalikNo ratings yet

- Analysis of Nitrate, Nitrite, and (15N) Nitrate in Biological FluidsDocument8 pagesAnalysis of Nitrate, Nitrite, and (15N) Nitrate in Biological FluidsGoim ArrafiNo ratings yet

- Module 8 Exogenic Process PDFDocument16 pagesModule 8 Exogenic Process PDFNathalieNo ratings yet

- Boyles LawDocument2 pagesBoyles LawjaNo ratings yet

- TaninDocument6 pagesTaninIDA MAESAROHNo ratings yet

- N Environment Protection Act 1986 Manikantamahima20bal7015 Vitapacin 20240314 160855 1 209Document209 pagesN Environment Protection Act 1986 Manikantamahima20bal7015 Vitapacin 20240314 160855 1 209Manikanta MahimaNo ratings yet

- Experiment No 9 mm2 PDFDocument9 pagesExperiment No 9 mm2 PDFMuhammad Zeeshaan JavedNo ratings yet

- Kemwell Bio Pharmaceutical Facility - June 09Document8 pagesKemwell Bio Pharmaceutical Facility - June 09Nik JanardhananNo ratings yet

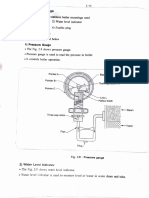

- Phase II Boiler QuestionsDocument12 pagesPhase II Boiler QuestionsNithin VargheseNo ratings yet

- Unit 3 BoilerDocument17 pagesUnit 3 BoilerAnonymous R7wV0zbMNo ratings yet

- Property of Polyfelt TS Nonwoven GeotextilesDocument1 pageProperty of Polyfelt TS Nonwoven GeotextilesAgis Satryo Falck100% (1)

- Fiber Optics Communications: OPTICAL DETECTORSDocument36 pagesFiber Optics Communications: OPTICAL DETECTORSMoneeb Qureshi100% (2)

- Boros Boros: Fire Fighting Boots Certified According To EN 15090Document22 pagesBoros Boros: Fire Fighting Boots Certified According To EN 15090Forum PompieriiNo ratings yet

- BUFFERS For SEM Fixative Preparation (Karnovsky Fixative Adaptation)Document7 pagesBUFFERS For SEM Fixative Preparation (Karnovsky Fixative Adaptation)Salustiano JurandiNo ratings yet