Professional Documents

Culture Documents

Underwater Technology Vol 31 No 2 Subsea System Readiness Level Assessment

Uploaded by

Rizki PerdanaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Underwater Technology Vol 31 No 2 Subsea System Readiness Level Assessment

Uploaded by

Rizki PerdanaCopyright:

Available Formats

77

doi:10.3723/ut.31.077 International Journal of the Society for Underwater Technology, Vol 31, No 2, pp 7792, 2013

T

e

c

h

n

i

c

a

l

P

a

p

e

r

Subsea system readiness level assessment

Sirous Yasseri

Safe Sight Technology, London, UK

Abstract

Both the American Petroleum Institute (API) 17N: 2009 and

Det Norske Veritas (DNV) RP-A203 (2011) recommend that

the technologies inserted into subsea installations should

be assessed during design and manufacturing using a tech-

nology readiness level (TRL) scale. This should be used as

a measure of maturity of all the individual technologies, for

qualication and readiness assurance. This paper proposes

the creation of a system-based approach for managing

the development of subsea systems and making effective

decisions to ensure the efcient progress of the project. It

recommends complementing TRL with an integration readi-

ness level (IRL) scale, to address IRL between the inserted

technologies, along with a system readiness level (SRL)

scale to assess the overall project status. It also presents a

method for combining the current TRL scale and the pro-

posed new IRL scale to determine an estimate of SRL at all

stages of a subsea system development. This provides a

composite metric for determining the system readiness level

for project delivery. The application of the new proposed

scales is demonstrated using a case example.

Keywords: system readiness level (SRL), technology readi-

ness level (TRL), integration readiness level (IRL), subsea

technology qualication, subsea production technical risk

Acronym list

BoD basis of design: This is the systems engineering

requirements.

DP dynamic positioning

DSM design structure matrix

FAT factory acceptance test

IRL integration readiness level

Integration is the combining of separate compo-

nents into a seamless unit. This is an integra-

tion-specic metric, to determine the integration

readiness between two or more components,

and/or subsystems (hardware and/or software).

SRL system readiness level

This is a metric that incorporates the maturity

level of the integrated system, as well as the

interoperability of the entire system.

SRLest system readiness level estimate

This is the SRL estimate at a review stage, which

determines the current state of the system readi-

ness. It is a derived metric, which aggregates TRL

and IRL of all components of a system that may

be at various levels of development at a given time.

TRL technology readiness level

This is a metric for determining technology matu-

rity before incorporating into a system.

1. Introduction

Technology readiness levels (TRLs) were rst used

by NASA in the 1980s as part of an overall technol-

ogy risk management process. By the early 1990s,

TRLs were routinely used within NASA to support

technology maturity assessments and consistent

comparisons of the maturity between different

technologies (Mankins, 2002).

The US Department of Defense (USDOD)

adopted TRL for risk assessments in 1999 (USDOD,

1998). Current USDOD guidance (2008; 2009)

requires the use of TRL (or an equivalent method-

ology) as part of an overall system technical risk

assessment. These TRLs range from 1 to 9, with

9 signifying the highest degree of readiness and

1 the lowest.

In the UK the Ministry of Defence (MOD)

adopted TRL to improve technology management

to reduce the project delay. In 2007, the UK MOD

updated its TRLs section to bring more focus to

the importance of project and sub-project inter-

action when conducting a TRL assessment (MOD,

2008). The MOD replaced NASAs broad generic

terms with denitions aligned to specic milestones

(MOD, 2011). Because of the success of TRL, a vari-

ety of other maturity metrics have been proposed

as decision support tools (Bilbro, 2007), such as

design readiness level; manufacturing readiness

level; software readiness level; operational readi-

ness level; human readiness levels; habitation read-

iness level; and capability readiness levels.

Many industries have embraced the concept of

TRL as a metric for measuring technology matu-

rity. The American Petroleum Institute (API) RP

17N (2009) adopted TRL methodology for subsea

equipment qualication and Det Norske Veritas

(DNV) RP-A203 (2011) followed later. Bureau

Veritas (2010) addresses the same issue using a

risk-based approach. The API recommended prac-

tice is now written into major petroleum compa-

nies procedures as a tool to assess the level of

progress of subsea design, fabrication and com-

ponents qualication. Such policies require con-

tractors to hold design and manufacturing reviews

using TRL. Examples of TRL application to the

offshore oil and gas can be found in US Mineral

Management Service (MMS, 2010) and Millheim

et al. (2011). E-mail address: sirous.yasseri@gmail.com

Yasseri. Subsea system readiness level assessment

78

Undoubtedly, TRL is a useful tool for determining a

technologys maturity before inserting it into a sys-

tem. However, TRL was not intended to assess the

integration of technologies and hence the readiness

of the complete system comprising them. It was orig-

inally used by NASA and later by the USDOD as a

tool for tracking contractors progress (Gove et al.,

2007; Sauser et al., 2008a). Therefore, expecting that

TRL will be able to monitor the readiness of a sys-

tem comprising a collection of technologies, which

are individually assessed against TRL, is optimistic.

If the integration of two pieces of technology fol-

lows the same maturation path, just as the technol-

ogies do, then TLR can provide an assessment of

integration readiness, which is true towards the

high maturity end of TRL scale. However, TRL is

not always capable of capturing the many small

errors that can occur when two different compo-

nents of software and/or hardware are brought

tighter to exchange data.

The need to explicitly address the integration of

technology is evident from failures of high prole

projects. For example, in NASAs Mars Climate

Orbiter, the failure of two independently evaluated

technologies to use the same units (i.e. metric ver-

sus imperial) contributed to the loss of the space-

craft (Sauser et al., 2008b). Discovering that different

components designed and fabricated by different

vendors do not match or were designed for a differ-

ent set of conditions is not rare. The problem of

integration becomes more acute when there are a

feed-back and feed-forward loops between vendors,

as changes in one part affect the other, and hence

several iterations may be required to resolve the

interdependent design issues, even though each

design, on its own, looks complete. TRL, as used,

determines where the readiness of a module or com-

ponent lies on the scale, and integration readiness

between modules or the entire system with the envi-

ronment is only implied or is not assessed.

This paper presents the new concept of an inte-

gration readiness level (IRL) scale. Just as a TRL

has been used to assess the risk associated with

developing components, an IRL is designed to

assess the risk associated with integrating these

components. The introduction of an IRL to the

assessment process not only provides a check as to

where the technology is on an integration readi-

ness scale, but also presents a direction for improv-

ing integration with other technologies.

Obviously, at a given review stage components

may not be at the same level of readiness. A meth-

odology is proposed to combine TRL and IRL into

one composite index, termed SRL

est

, which is an

estimate of a third scale termed the system readi-

ness level (SRL), a third scale. The resultant SRL

est

can provide an assessment of overall system devel-

opment and identify problem areas that require

management attention.

The following section introduces a methodology

to map a subsea system, and section 3 discusses the

current TRL for the subsea component readiness.

The paper then introduces the new IRL concept in

section 4 and describes the new concept of SRL in

section 5. The case example in section 6 demon-

strates how a composite scale can be derived and

used in conjunction with the SRL table to deter-

mine what has been accomplished to date. Section

7 discusses issues of the subsea system readiness and

section 8 summarises the conclusions of the paper.

2. Mapping the subsea system architecture

The system architecture is a relationship map,

which shows the position of components and/or

modules and their relationship with each other

(Yassine et al., 2003; Yassine and Braha, 2003;

Danilovic and Browning, 2007). Components can

implement one or more functions, and interfaces

between components (i.e. linkages) must be well

dened. A component is a hardware (or a software)

object with clearly dened interfaces, which

embodies specic functionality and interacts with

other components and/or with the environment to

enable the overall system to function. In this paper

technologies and components are used inter-

changeably, and it also takes readiness and maturity

to be the same entity and uses interchangeably.

An effective method of understanding a com-

plex system is to:

identify the system boundaries, i.e. the terminal

points and where the system integrates with its

environment (or neighbours);

break it down into components (and/or mod-

ules), which are easier to understand; and

identify the interfaces (i.e. dependencies or

relationships) between the components (or mod-

ules) that enable the system to function as a sin-

gle entity (Sharman and Yassine, 2004).

Subsea systems are generally modularised for

ease of installation and parallel engineering. Mod-

ularising requires specifying the architecture and

interfaces governing the modules interactions. In

a modularised design the system components are

spilt up and assigned to various modules according

to a formal architectural plan (Eppinger, 1991).

Modules are distinct parts of a larger system;

although designed and produced separately they

must function together.

Modularisation enables managing complexity

and parallel work, such as sourcing from different

79

Vol 31, No 2, 2013

suppliers and accommodating future expansion.

Good architecture enables each individual module

and its interfaces to be changed out without under-

mining the functionality of the system. A failed

module can be retrieved and repaired or replaced.

Although in theory modules can be organised in

such a way to minimise the number of interfaces,

the manufacturers specialisation largely deter-

mines the subsea modules and their interfaces.

This does not undermine the concept of modulari-

sation, as the linear (sequential) nature of the sub-

sea production system determines the line-up of

components into natural modules.

Fig 1 shows the block diagram of a simple system

consisting of ten components grouped into two

modules at an advanced stage of development.

There are interfaces between components of each

module and between components of the two mod-

ules. Interfaces between two components are shown

by a double-headed arrow, implying that the readi-

ness of two components to be integrated is inter-

dependent. The arrow is not intended to indicate

the direction of ow, but to show dependency. This

paper assumes dependency and interface to be the

same entity. The system matrix is a simple represen-

tation of a system architecture, which captures the

relationship between different components. This is

also a suitable tool for system modelling and analy-

ses, especially for the purposes of decomposition

and integration. Matrix-based approaches are used

for managing complex systems and interactions of

their elements (Steward, 1981).

The DSM (Simon, 1962), which is a square

matrix, has been used in modelling of a variety of

products, processes and organisational structures in

the past (Browning, 2001; Browning and Eppinger,

2002). DSM models can incorporate the concepts

of hierarchy (Eppinger and Browning, 2012), direc-

tion of information ow and dependency. In this

paper, a variation of DSM is tailored, for represent-

ing the subsea architecture and is used as a visual

aid for decomposition and housekeeping when

combining TRL and IRL into a single index. How-

ever, it has a wider application in grouping together

components forming modules for enhancing man-

ufacturing exibility by reducing the number of

interfaces (Eppinger and Browning, 2012).

The block diagram of Fig 1 is mapped into

design structure matrix (DSM) as shown in Fig 2.

The DSM maps the elements of a system to each

other (like a two-way table), enabling concise rep-

resentation and integration analysis. One reads

across a row of the matrix to see where the element

in that row sends its outputs and reads down a col-

umn to see from where the element in that column

receives its inputs (Browning, 2001).

For example, the element E provides an output

to elements A, D, F and J (reading across row 6)

and receives an input from element A, D, F and J

(reading down column 6). Hence a component

location is known by its column and row. Informa-

tion about dependency or interface is added by

using a marker in the cells to represent relation-

ships (x in Fig 2). An off-diagonal x signies the

Fig 1: The block diagram for a system with two modules and 10 components (A to J). The double arrows indicate

the interfaces between connected components

IRL=5

IRL=4

F

TRL=5

I

TRL=6

E

TRL=5

G

TRL=5

H

TRL=5

J

TRL=5

IRL=4

IRL=5

IRL=5

ENV=5

IRL=4

IRL=5

IRL=5

IRL=4

B

TRL=5

D

TRL=6

A

TRL=6

C

TRL=5

ENV=5

IRL=5

IRL=6

D to E IRL=5

C to J IRL=5

D to H IRL=6

A to F IRL=6

A to E IRL=5

Yasseri. Subsea system readiness level assessment

80

dependency (interface) of one component on

another. The numerical values of X in Fig 2 are the

IRL of the interacting components; they may be

different and thus no symmetry is implied.

Fig 2 shows that C and B are going to be con-

nected. The readiness of C to be integrated with B

is noted at the intersection of column 3 and row 4,

and the readiness of B to be integrated with C is

noted at the intersection of column 4 and row 3,

which are not necessarily equal.

Matrix-based tools provide some insight into the

internal relationship of a complex system (i.e. a

dependency map and their complexity); however,

they do not expose the logic behind these depend-

encies. That is, if component A is shown to relate to

component F, it is not clear why and how this rela-

tionship exists and where it originates from. Such

information can be represented on block diagrams.

The value of the relationship maps is to be able

to show/capture that element A is dependent on F

through some characteristic of A. In doing so, the

analyst would understand better the complexity

of a system and, in turn, has more information

to manage dependencies and leverage them to

improve system performance and mange interfaces

between elements (Eppinger and Browning, 2012).

The block diagram of Fig 1 offers an alternative

method to expand the relationship maps.

3. Technology readiness level

Metrics are an integral part of management activities

for performance measurement, risk management,

quality control and assurance, and maturity

level assessment. Most organisations successfully

employ various metrics in project management and

system engineering. The primary purposes of any

metric are:

identify critical parameters;

establish milestones to assess progress;

provide direction for risk management/

mitigation;

establish a common understanding of progress;

and

establish entry and exit criteria for major

milestones.

TRL satises all the requirements listed above.

Given the pragmatic benets of TRL concept, API

(2009) adopted a similar scale. APIs TRL has

8 levels, starting at 0 being unproven idea and

ending with 7 as the highest level of maturity, which

is proven in the eld. Table 1 is an adaptation of

APIs TRL, where 0 to 6 (more or less) follows 1 to

7 the NASAs TRL, and APIs 7 combines NASAs

8 and 9. The dependencies between modules and

the dependency of the system to its environment

are not explicitly addressed by APIs TRL. TRL

does not completely capture the risk involved in

the adopting a new technology, since it does not

address the architectural needs related to integra-

tion. Various studies (Mankins, 2002; Shishko et al.,

2003; Valerdi and Kohl, 2004; Dowling and Pardoe,

2005; Smith, 2005) have discussed the inadequacy

of TRL to address the technology integration issues.

They have also stressed the need for metrics and

Fig 2: DSM for the system shown in Fig 1. Components A to J are mapped along the diagonal

and interfaces are indicated by a maker

A B C D E F G H I J ENV

A A

B B

C C

D D

E E

F F

G G

H H

I I

J J

ENV

81

Vol 31, No 2, 2013

Table 1: TRL for subsea technology readiness level assessment (API, 2009)

Phase TRL Development stage Development stage denition

System validation 7 Field proven

Production system

eld proven

Production unit integrated into intended operating system,

installed and operating in the same environment and

operating conditions for more than 10% of its design life

with acceptable reliability, demonstrating low risk of early

life failures.

6 System installed

Production system

installed and tested

Complies with all requirements of TRL 5.

Production unit or full-scale prototype built and integrated

into intended operating system.

Full interface and functional test programme performed

in intended or closely simulated environment and

operated for less than three years.

New technology equipment may require additional

support for rst 12 to 18 months of operation.

Technology validation 5 System tested

Production system

interface tested

Complies with all requirements of TRL 4.

Designed and built as production unit or full-scale

prototype and integrated into intended operating system

with full interface and functional test, but not usually in

intended eld environment.

4 Environment tested

Preproduction system

environment tested

Complies with all requirements of TRL 3.

Designed and built as a production unit or full-scale

prototype and put through qualication programme in

simulated environment (e.g. hyperbaric chamber to

simulate pressure) or actual intended environment

(e.g. subsea environment) but not installed

or operating.

Reliability testing is limited to demonstrating that

prototype function and performance criteria can be

complied within the intended operating condition and

external environment.

3 Prototype tested

System function,

performance and

reliability tested

Prototype built and put through generic functional and

performance tests.

Reliability tests are performed in relevant laboratory

testing environment, including reliability growth tests,

accelerated life tests and robust design development

test programme.

Tests are performed without integration into

broader system.

The extent of application compliance requirements

are assessed and potential benets and risks are

demonstrated.

Concept validation 2 Validated concept

Experimental proof of

concept using physical

model tests

Concept design or novel features of design validated

by physical model, system mock-up or dummy, and

functionally tested in laboratory environment.

No design history. No environmental tests.

Materials testing and reliability testing performed on key

parts or components in testing laboratory prior to

prototype construction.

1 Demonstrated

concept

Proof of concept as

desk study or R&D

experimentation

No design history.

Essentially desk study not involving physical models but

may include R&D experimentation.

Technology concept and/or application formulated.

Concept and functionality proven by analysis

or reference to features common with/to

existing technology.

0 Unproven concept

Basic research and

development (R&D)

in papers

Basic scientifc/engineering principles observed and

reported in papers.

No analysis or testing completed available.

No design history.

Yasseri. Subsea system readiness level assessment

82

methodology for the coupling and measuring the

maturity of multiple technologies within systems.

4. Integration readiness level

Integration is the process of assembling the system

from its components (Buede, 2000). This seems to

imply that putting together a system from its com-

ponents entails no complication, since components

are built from specications, which are recognisa-

ble to any system engineer. However, integration

can be a complex process containing multiple over-

lapping and iterative tasks to create a delivery sys-

tem, built to the user requirements and that will

function in the marine environment.

The need for a reliable method becomes more

imperative as a systems complexity increases and

components are sourced from difdent manufac-

turers. Water depth and availability of installation

vessel (the deck space for assembling components)

and crane capacity could demand a specic inter-

face type and hence add to complexity.

A technology can only be successfully inserted

into a system if its functionality, maturity and com-

patibility allow it to integrate with the rest of the

system. The integration should not pose a problem

if the technology and system evolve along similar

maturation paths. However, the core technology

components of a system receive more attention than

the linkages between them. Inadequately conceived

linkages can cause the integration of components

from different suppliers to be problematic.

The application of metrics to support integration

has been extensively used in the computer industry

to dene coupling of components (Orme et al.,

2006; 2007). Mankins (2002) proposes an inte-

grated technology analysis methodology to estimate

an integrated technology index and used it for

a comparative ranking of competing systems.

Mankins highlights the difculty of using the TRL

index when choosing between alternatives.

The USDOD and MOD developed a technology

insertion metric that includes an integration matu-

rity level (Dowling and Pardoe, 2005). Gove et al.

(2007) created an IRL to measure integration

maturity on a scale similar to TRL.

An IRL metric should be able to:

determine the integration maturity between two

or more components and/or modules;

provide a means to reduce the uncertainty in

integrating new technology into a system;

meet the system requirements in terms of deliv-

ery time and functionality; and

provide a common platform for tracking the

system development and maturity assessment

(Sauser et al., 2008a).

For a metric to be useful (Dowling and Pardoe,

2005), it must be:

unambiguous;

understood by stakeholders with little effort;

adequately measure the integration maturity;

mirror the TRL for ease of implementation; and

simple to apply.

By drawing upon these studies, this paper

extends the same concept to the subsea technology

integration. Table 2 shows the proposed metric to

measure the subsea IRL, which moves in parallel

with TRL.

IRL, as TRL, consists of three stages: (1) concept

validation; (2) technology validation; and (3) sys-

tem validation (see Table 2). Concept validation is

about deciding if a number of technologies can be

brought together to perform a function. Clarity

and differentiation are important factors at this

stage. Thus IRL 02 are considered fundamental

to describing the three principles of integration,

namely interface, interaction and compatibility.

The next stage is technology validation, which

is dened as a conformance to rules. Thus IRLs

35 are about assurance that an integration solu-

tion is in compliance with specications. The nal

stage is system validation, which relates to practical

considerations. IRLs 6 and 7 are about the assur-

ance afforded by integration testing (in-place test-

ing and actual performance in service).

There are also three aspects to the readiness

measure: (1) readiness of components to be inte-

grated into a module; (2) readiness of modules to

be connected together to make an assembly; and

(3) the readiness of the assembly to be integrated

into the marine environment. Both components

and modules are tested at the factory for compli-

ance. The factory acceptance test (FAT) qualies

a module as ready to be transported to the site (i.e.

IRL exceed 4). The assemblies of a few modules are

leak-tested at the site to assure their interface read-

iness for deployment. IRL must be 5 before it can

be installed.

Now that both the technologies and integration

elements can be assessed and mapped along a

numerical scale, the next challenge is to develop a

metric that aggregates TRL and IRL.

5. Systems readiness level

The application of an IRL in the assessment proc-

ess provides a check as to where the technology

maturity is on an integration readiness scale. Just as

a TRL has been used to assess the risk associated

with developing technologies, an IRL is designed

to assess the risk associated with integrating these

83

Vol 31, No 2, 2013

Table 2: IRL for subsea technology readiness level assessment

Phase IRL Development stage Development stage denition

System

validation

7 Integration is eld

proven through

successful

operations

The integrated subsea system is in production and is in compliance with all

its functionality requirements.

Inserted components are fully integrated and comply with all performance

requirements decided at the outset. All components are maturing

to TRL 7.

The integrated subsea system is operating successfully with suffcient

reliability for more than 10% of its service life.

6 Integration is

completed and

qualied through

sufcient and

rigorous testing

in the marine

environment

All interfaces meet and exceed all requirements of IRL 5 and below.

The entire system is installed and tested both at component level

and at system level. The interfaces of assemblies are proven to

be reliable.

Interfaces compatibility are assured by testing in the marine

environment.

The installed system is being commissioned and its functionality

tested.

Technology

validation

5 The integration has

been veried and

validated with

sufcient detail for

the system to be

deployable

The subsea systems integration meets all requirements of IRL

4 and below.

Various parts of the subsea system are tested and interactions

between interfaces are veried through testing in the factory and

on the site.

Installation contactors procedures and tooling are in place and verifed.

Special tools and connectors are on the site and seabed is ready to host.

4 There is sufcient

details to assure

interoperability

between technologies

necessary to

establish, manage

and assure the

integration

The interfaces of all inserted technologies meet all requirements

of IRL 3.

Partly assembled system is tested on the site and the compatibility of

interfaces is veried for the full design specications.

All integration issues and problems with interactions between various

technologies have been teased out.

Interface requirements are documented and interface management is in place to

coordinate the ow of information between contactors.

Quality control and assurance are in place.

3 There is sufcient

detail in the control

and assurance of

the integration

between technologies

to deliver the required

functionality

All requirements of IRL 2 are complied with.

The system performance requirements are developed and translated

into specications for interfacing components, modules and assemblies.

The specifcations include performance requirements, functionality, environment

and interface with other systems already in production.

Technologies to be inserted into system are demonstrated to work

together, either by previous led proven records or by isolated

factory tests.

Concept

validation

2 There is sufcient

evidence of

compatibility

between technologies

within the system,

namely they will work

together and can be

integrated with ease

It can be shown that the constituent components can work together and

realistically can perform the required function, but may need future work.

An interoperability check is made on the components of the system to

assure their compatibility.

Either similar assembly is already in use, or proven in qualifying test.

All likely problems can be solved. Special tools and connectors

are identied.

Interdependencies of components are identifed and the channels for

two-way ow of information/data are determined. Special needs are known

by now.

1 There is some level of

specicity to the

system functionality

to allow identication

of linkage between

technologies

The concept has taken shape and refned to a point where the basic

dimension, materials, technology need, interfaces between them etc. have

been developed.

It is judged that all needed technologies can be made into a seamless

system. The concept or concepts may not meet all requirements,

but there is a promise to meet all functionality requirements by

additional efforts.

0 The interface, i.e.

the linkage, between

technologies can

be identied/

characterised with

sufcient clarity

The linkage between components and modules have been characterised

and are judged as achievable.

The description of functionality and interfaces is general without reference to

specic performance.

The concept has been advanced to a level that the physical principles can

be communicated though reports and sketches.

Yasseri. Subsea system readiness level assessment

84

technologies. Table 3 denes a SRL scale that incor-

porates the maturity level of components and the

interoperability of the entire subsea system.

Sauser et al. (2008a) proposed a method to com-

bine the TRLs and IRLs for a system under devel-

opment, which involves matrix operation. In the

appendix, a simpler methodology is outlined to

aggregate TRL and IRL into a single metric, termed

SRL

est

. This methodology requires all components

to be assessed using TRL (Table 1), as well as their

readiness for integration with each other and the

environment to be assessed using IRL (Table 2).

The method combines TRLs and IRLs into a sin-

gle composite metric, yielding a numerical value

between 0 and 7. The estimated SRL

est

is used in

Table 3 to judge what the system readiness is (com-

pared with what it should be) at the time of assess-

ment. Building a spreadsheet (see the case example

in section 6) will enable the user to regularly review

the state of system readiness and track the projects

progress.

6. Case example

Fig 3 shows a block diagram of a system with ten

components (A to J) arranged in two modules. The

TRL of each component is judged using Table 1

and is noted on its node. The IRL between two

components is shown by a double-headed arrow.

The IRLs of components with dependencies are

judged using Table 2 and are shown on the double

arrows. In this example some components of the

rst module have interface with components of the

second module.

Modules are transported to the site after com-

pletion of the FAT, which is a strength test (hydro-

tested at ~1.5 times of the design pressure). Its

primary focus is the weld quality. At the site, a few of

these modules are assembled and hydro-tested at

~1.25 times of the design pressure tested to detect

interface leaks. These two tests determine if a mod-

ule is ready for integration into the marine environ-

ment. Finally, the entire subsea system is hydro-tested

at 1.1 times the design pressure. The intention is to

assure no leakage at the assembly interfaces.

These are the three minimum hydro-tests, with

the relevant load factors as specied in applicable

codes. Some codes, e.g. API 17N or ASME B31.8

(2010), replace the third test with three separate

hydro tests, known as post installation test, inte-

gration test and operational test. In addition,

sometimes a shallow water test is also performed

by immersing a module into the water to ensure

the centres of gravity and of buoyancy are correct.

The components of this system are mapped onto

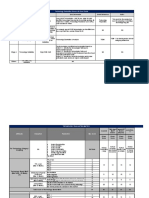

a DSM as shown in Fig 4. The system matrix is

extended horizontally to show the calculation

details. Columns and rows are numbered for the

ease of referencing. The off-diagonal numerical

entries are IRL, corresponding to an interface

readiness between two components. Not every

component of the system interacts with every

other component, but all of the component inter-

actions that do exist are essential to achieve desired

functionality.

IRLs are taken from Fig 3 and entered into DSM

of Fig 4. For example, 6 at the intersection of

components A (row 3) and F (column 9) is the IRL

of their interface; the same value is entered at the

intersection of components F (row 8) and A (col-

umn 4), but do not need to be the same value. The

matrix diagonal represents integration of a compo-

nent with itself, which is left blank, assuming read-

iness of a component to be integrated with itself

is judged by TRL (column 2).

Assuring correct integration of components into

modules, and then modules into assemblies, satis-

es the concept and technology validation stages of

integration. For the system validation, these assem-

blies must work together when inserted into the

marine environment, and hence the interaction

and compatibility of the entire system with its envi-

ronment should be assured.

The environmental readiness is somewhat quali-

ed during the design phase by proper choice of

material, corrosion protection, installation proce-

dure, etc. Similarly, it is assured during the rst two

stages of interfacing, namely concept validation

and technology validation, by complying with

engineering specications. However, without the

strength test at the factory and the leak tests, envi-

ronmental readiness remains subjective. This paper

does not introduce another scale for the environ-

mental readiness, but assumes that it matures along

the same timeline as modules and hence can be

measured using the same scale of 0 to 7.

A single value for each module is entered in the

last column of Fig 4 to indicate the modules envi-

ronmental readiness level. In most cases the envi-

ronment must be prepared (e.g. pre-sweep, seabed

remediation, sand bag markers, foundation) to

host the subsea modules, which is performed just

before installation, when the system reaches matu-

rity level 4.

Note that in Fig 4, the part of the seabed where

a module occupies is not part of the module, but

the module is superimposed on the environment,

and the column 14 represents the environment.

The alternative is to add the associated seabed as a

component to the module.

For this case example, it is assumed that two

interfacing components could be at different

85

Vol 31, No 2, 2013

Table 3: SRL for subsea system readiness level assessment

Phase SRL Development stage Development stage denition

System validation 7 Field proven

operational

system

The subsea system is in production and it is in compliance with

all its functionality requirements.

The subsea system is operating successfully with suffcient

reliability for more than 10% of its service life.

Assure the operation support will meet all of its

expected functions.

6 The system is

installed tested and

commissioning

in progress

The entire subsea system is installed and tested both at

component level and at the system level, and it is ready for

its intended operation condition.

The subsea system is being commissioned with

operation support.

Any remaining problems being rectifed.

The Health and Safety Executive (HSE) policy is monitored.

Technology validation 5 Manufacturing

and installation

in progress

The system with all inserted assemblies will meet all

requirements of SRL4 and below.

Partly assembled/installed system is tested and compliance

veried for the full design specications.

Operational support availability is identifed and assured.

HSE, pre-commissioning and handover policy are established.

Operation support needs are established.

4 Detail design and

nal procurement

The chosen concept is detailed.

Procurement date for long lead items is assured.

Installation and commissioning contactors are ready.

Integration and manufacturing risk are reduced.

Procurement is advanced.

Seabed is being prepared to host the system.

3 Front end

engineering,

sourcing long

lead items

The frst choice and the competing option are moved forward to

a level that the difference between them becomes obvious.

Vendors, installation and commissioning contactors are selected

and appointed, and assurance that they can meet the delivery

dates is made.

Possible integration problems are checked.

Logistics are considered.

The concept is in compliance with the demands by the

marine environment.

Seabed is being surveyed.

Concept validation 2 Concept selection,

where an optimal

concept has

emerged

Two or more options which best satisfy all requirements

are identied.

Technology risk is reduced.

Aspect of technologies to be used is clarifed.

The most promising option is selected.

The project schedule is determined.

1 Concept

renement

Two or more

competing concept

being considered

Promising concept is refned to an adequate level of maturity.

The concepts are priced and ranked according to

their desirability.

Technologies that are needed are researched to see if they can

be procured and at what price.

The available infrastructure, means of transportation and

installation contactors availability are studied.

Operational requirements are considered.

Fabrication, transportation and installation are considered.

The infuence of the marine environment on the system is

studied and written into the basis of design.

0 Concept denition,

where various ideas

are being considered

or discounted

Reservoir data, geotechnical data, drilling requirements,

distances and existing infrastructure information is collected.

Concepts are developed.

Economically or technically unfeasible concepts are

screened out.

The schedules are established and checked if they

are realistic.

Finance is considered.

Yasseri. Subsea system readiness level assessment

86

TRL, but their IRLs are the same and equal to the

less ready component (because of mutual depend-

ency), hence yielding a symmetric matrix. In gen-

eral, if two components have to come together to

create a connection, there may be different degrees

of integration readiness for each component and

therefore the matrix is not symmetric. Symmetry

assumption is not necessary for the success of

the method and can be dropped, if it is believed

that retaining two different IRL for interfacing

components would yield useful information.

The distance between the furthest off-diagonal

terms to the diagonal is known as the bandwidth of

the matrix. A narrow bandwidth is an indication

of a good system line-up (modularisation). A high

bandwidth, as in this example, signies that too

many components from different modules are

dependent on each other, which adds to the cost of

managing the interface and will probably lead to

delays. There are algorithms to collect components

into modules in order to reduce the bandwidth

and lower the dependencies.

Each row of column 15 of Fig 4 is the average IRL

for the row, determined by summing up of IRLs of

all interfaces across the row and dividing it by the

number of interfaces e.g. (5 + 6 + 5 + 6)/4 = 5.5.

Column 16 gives the results of multiplication of the

components TRL by the average of its IRLs, e.g. in

row 3, it is 6 5.5 = 33. The square root of column

16 is given in column 17, giving a composite compo-

nent readiness index. Column 18 is the square root

of mean of squares noted in column 16, which is

the sum of all squares in column 16 divided by the

number of components in the module.

Fig 3: A simple system consisting of 10 components arranged in two modules. Interfaces are shown by double

headed arrow

Previous

Module

IRL=5

IRL=5

F

TRL=5

I

TRL=6

E

TRL=5

G

TRL=5

H

TRL=5

J

TRL=5

IRL=5

IRL=5

IRL=4

IRL=4

IRL=4

ENV=5

ENV=5

IRL=6 IRL=5

Next

Module

IRL=5

IRL=4

B

TRL=5

D

TRL=6

A

TRL=6

C

TRL=5

A to E IRL=5

D to H IRL=6

C to J IRL=5

D to E IRL=5

A to F IRL=6

87

Vol 31, No 2, 2013

The readiness for the rst module is calculated as:

33 25.00 23.33 31.50

4

5.31

1

M

R

=

+ + +

= (1)

The denominator of 4 is the number of compo-

nents of the rst module. Similarly for the second

module, the readiness is calculated as:

25.00 25.00 22.50 25.00 26.0 23.75

6

4.95

2

M

R

=

+ + + + +

=

Therefore, the readiness of each module to be

integrated into its environment is judged to be 5 for

both modules of the case example using Table 3.

Hence, the aggregate system readiness index (SRI) is:

=

+

=

(5.31) 5 (4.95) 5

7 2

4.34

2 2

SRI

(3)

The denominator of 7 is the highest IRL in Table

2; this number is used to normalise the environmen-

tal integration readiness level, namely 5/7, which is

the same for both modules in the example. From a

metric point of view, SRL

est

and SRL are meant to

measure the same things on the same scale. How-

ever, SRL is dened (Table 3), while SRL

est

is derived

by aggregation of attributes of all components,

which may be at different levels of TRL and IRL. If

all components mature simultaneously along the

same path, then SRL

est

reduces to SRL.

Entering Table 3 with 4.34, the system must be at

assembly and installation stage; if the project sched-

ule requires a different level then this must be justi-

ed. This index informs the management when

and where to intervene if the system readiness is lag-

ging behind the schedules. The markers in each

row identify which other components must be ready

for the integration to become complete; hence

interfaces must be adequately managed. A tightly

controlled project ensures that TRL, IRL and SRL

closely follow each other. The derived system readi-

ness index of 4.34 indicates that some components

are not maturing within the desired time frame. In

this hypothetical example, components with TRL

or IRL lower than 4.34 need to be scrutinised.

While this case example is simple, the underlying

methodology is important. It demonstrates how to

use DSM to combine TRL and IRL into a new met-

ric, which indicates the readiness of the system. In

addition to this housekeeping advantage, DSM pro-

vides a visual aid to present the system audit results

to the senior managers. The advantage becomes

more evident when dealing with more than

200 components manufactures in various locations

that must mate and work together when assembled.

7. Discussion

Measuring technology and system maturity is a

multidimensional process that cannot be per-

formed adequately by a one-dimensional metric

such as TRL. Although TRL has been employed by

many industries, it captures only a part of the infor-

mation needed to support stakeholders decisions.

TRL was not designed to assess the quality of the

system architecture, design or integration, but only

to measure the readiness of system components

based on what has been accomplished at the time

of assessment.

IRL addresses this shortcoming, but it must be

aggregated with TRL into a single composite index

to be useful. In turn, there is a need for a scale to be

used with this composite index. It is also proposed

to use DSM as a visual aid to bring together all three

elements of system maturation metrics. Readiness

of components to be integrated into a module,

or modules to be connected together, may be

assessed by engineering judgment in formal

reviews, assisted by measurements, specications,

codes and procedures.

(2)

Fig 4: DSM for the example case

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18

2 TRL A B C D E F G H I J ENV

Ave.

IRL

TRL*Ave

_IRL

SQRT

(Col16)

3 6 A 5 6 5 6 5.50 33.00 5.74

5.31

4 5 B 5 5 5.00 25.00 5.00

5 5 C 5 4 5 4.67 23.33 4.83

6 6 D 6 4 5 6 5 5.25 31.50 5.61

7 5 E 5 5 5 5 5.00 25.00 5.00

4.95

8 5 F 6 5 5 4 5.00 25.00 5.00

9 5 G 5 4 4.50 22.50 4.74

10 5 H 6 4 5.00 25.00 5.00

11 6 I 4 4 5 4.33 26.00 5.10

12 5 J 5 5 4 5 5 4.75 23.75 4.87

13 4.34

Yasseri. Subsea system readiness level assessment

88

This paper has also introduced the concept of envi-

ronmental integration readiness level (i.e. module/

assemblies-to-marine-environment) for assemblies

consisting of several modules that are large/heavy

enough to be installed in a single operation. The

readiness of all components cannot be assured

until the factory acceptance tests, the leak tests at

the site and in-place operational tests are per-

formed. It should be kept in mind that by IRL = 5,

all of the technical integration issues must be

resolved. Once it reaches this level, the focus should

be on conrmations of integration by more testing

and the actual performance. In the context of this

work, the integration readiness of modules-to-

marine-environment may be judged using the avail-

able physical evidences, e.g. tests and compliance

with rules, specications and codes.

The root mean square (RMS) method was used

for determining SRL

est

(see for example Bissell

and Chapman, 1992). This estimated value incor-

porates not only the current maturation of all

components, but also the physical properties of

interfaces, integrations requirements, interaction,

compatibility, reliability, quality and performance

when assemblies are brought together to deliver a

specic functionality.

The dependency of the system on the seabed is

generally studied at the concept phase, and the

demand of environment, such as geohazards, cor-

rosion, unstable and uneven seabed are identied

and written into the basis of design (BOD). The

compliance of the design with the BOD is reviewed

at all stages of the system development. Thus, the

manufactured modules are expected to withstand

the demand of its environment when installed.

However, the readiness of environment to host the

system is considered when the subsea system is

ready to be installed.

Early seabed surveys help to identify suitable

positions for the subsea system. However, the major

part of making the seabed ready for receiving the

subsea system takes place before installation, when

the modules and assemblies readiness exceed

level 4. The major activities for the installation

preparation are:

acquisition of the permit (permission) for the

vessel to enter the area;

deployment of ships transponder on the

seabed;

deepwater trials to assure redundancy of the

deepwater system and also drift off tests;

as-found survey looking for anomalies, debris

and variation of the seabed;

installation of transponders array to obtain a

frame of reference for poisoning;

seabed corrections and remediation, involving

removal of debris, possibly dredging and shoring

up; and

accurate positioning/laying down buoyancy

markers ballasted with sand bags. These mark-

ers act as visual aids for installation, by for

example, identifying the corner locations for

structures.

The linear asset (e.g. pipelines, owlines) fol-

lows a similar path, but is not necessarily in sync

with the major equipment. Some post installa-

tion interventions, e.g. trenching of pipelines and

piling of subsea structures, may be required to

secure the asset.

The subsea architecture is represented by a

component-component (N-square) matrix the

DSM which can describe a system structure with

respect to the relationships between its compo-

nents. The DSM is an effective representation tool

for mapping subsea equipment and its linkages.

DSM provides a platform for communicating about

quality and alternative architecture, and managing

interfaces. Its use can improve understanding of

the project progress and communicating this to the

senior managers. Simply building the DSM helps to

increase overall awareness and understanding the

relationship between components in the system.

Integration analysis using a DSM promotes trans-

parency by showing all metrics in one picture.

DSMs can also address the following types of

questions:

Should the components be organised differently

to improve interface management and delivery?

How should those modules requiring too many

interfaces be recongured?

Where and which integrative mechanisms might

be prudent?

Are the current choices of integrative mecha-

nisms well balanced?

Are the interactions as shown in DSM correct and

sufcient for the interface management?

Interfaces between components of one module

do not require the same level of management time

as interfaces between components of two or more

modules supplied by different vendors. The goal of

DSM is to analyse the components within a system,

and it allows one to re-sequence these in order to

minimise interface between modules.

DSM identies bottlenecks during design, fabri-

cation and installation. The diagonal entries of the

matrix do not have any interpretation in describing

the system; they are either left blank, or lled in

with the component labels. This is done to separate

the upper and lower triangles of the matrix and to

89

Vol 31, No 2, 2013

show the interfaces more clearly. The number of

markers in a row determines dependencies, as well

as the level of demand on the interface manage-

ment and the criticality of the component. DSM

can become the foundation for the optimal

resource allocation, monitoring and evaluation

tool. It can also be a basis for common measure-

ment and language for delivery managers to

improve the system development and acquisition

process.

The complexity of the interfaces is not shown on

the Fig 4, but it can be indicated by colour coding

of the relevant cell using a ve level designation:

none, minor, moderate, high and very high. No

colour implies that there is no specic interface

requirement or, if there is one, that its complexity

is negligible. An alternative is to use a scale of 1 to

5 with 5 being the highest.

The methodology that is described here is simple

enough to be usable in practice, and yet adequately

captures all relevant data and gives a clear picture

of the entire system. It provides, with little effort

from the user, a view of the system that is valuable

especially during ongoing development. The con-

cepts described here complement the practice of

TRL and offers a vision of the system readiness

that is compatible with the intuition of practicing

engineers.

8. Concluding remarks

This paper presents a system-based approach for

managing subsea system development and mak-

ing effective and efcient decisions for hardware

and software, acquisition and their integration.

This provides system engineers, delivery managers,

quality control managers and project managers a

common metric that can aid them in making effec-

tive and timely decisions during all phases of a sub-

sea system development. This should help reduce

both a projects technical risk and schedule risk.

The new IRL scale, which parallels the current

TRL scale, is necessary because when components

are procured from different sources, integration

could pose a problem if not properly managed.

The proposed IRL mimics the value of the TRL by

being simple to understand and use. A new SRL is

also introduced as a scale for measuring the matu-

ration of the entire subsea system. To tie up these

three matrices, a methodology is described that

combines TRLs and IRLs at the time of evaluation,

into a single composite index termed SRL

est

. This

composite index is an estimate of the system

readiness level. By applying Table 3 and this index,

the stage of advancement of the project can be

determined.

This paper also introduces the DSM for map-

ping the subsea architecture, namely all compo-

nents and their linkages, into a single table (matrix)

as a visual aid. DSM shows interdependencies

between components and the need for information

ow for the interface management. Consequently,

DSM shows TRL and IRL in a single table. These

metrics can identify critical parameters, establish

milestones to assess progress, offer direction for

risk management/mitigation and identify hot spots

requiring management intervention.

In summary, this paper provides a basis for:

collective evaluation of component integration

and system readiness to reduce schedule and

technical risks;

a dynamic assessment tool for tracking the

progress of design, manufacturing and installa-

tion; and

developing contingency, multiple-sourcing and

sparing policy through the comparative analysis

of multiple technologies.

References

American Petroleum Institute (API). (2009). AP RP 17N

Recommended practice for subsea production system reliability

and technical risk management. Washington DC: API.

Bilbro JW. (2007). A suite of tools for technology assess-

ment. Presented at: Technology maturity conference:

multi-dimensional assessment of technology maturity.

Virginia Beach, VA, 1113 September. Available at

www.dtic.mil/cgi-bin/GetTRDoc?AD=ADA507181 last

accessed <10 October 2012>.

Bissell C and Chapman D. (1992). Digital Signal Transmis-

sion. Cambridge University Press. UK.

Browning TR. (2001). Applying the Design Structure Matrix

to System Decomposition and Integration Problems:

A Review and New Directions. IEEE Transactions on Engi-

neering Management 48: 292306.

Browning TR and Eppinger S. (2002). Modelling Impacts

of Process Architecture on Cost and Schedule Risk in

Product Development. IEEE Transactions on Engineering

Management 49: 428442.

Buede DM. (2000). The engineering design of systems: Models

and methods. New York: Wiley.

Bureau Veritas (BV). (2010). BV NI525:2010 Risk based

qualication of new technology methodological guide-

lines. Neuilly-sur-Seine, France: BV, 20pp.

Danilovic M and Browning RT. (2007). Managing complex

product development projects with design structure

matrices and domain mapping matrices. International

Journal of Project Management 25: 300314.

Det Norske Veritas (DNV). (2011). DNV-RP-A203 Recom-

mended practice: Qualication of new technology. Oslo,

Norway.

Dowling T and Pardoe T. (2005). TIMPA Technology

insertion metrics, volume 1. London: Ministry of Defence,

QinetiQ.

Eppinger SD. (1991). Model-based approaches to manag-

ing concurrent engineering. Journal of Engineering Design

2: 283290.

Yasseri. Subsea system readiness level assessment

90

Eppinger SD and Browning TR. (2012). Design structure

matrix methods and applications (engineering systems).

Cambridge, MA: MIT Press, 280pp.

Gove R, Sauser B and Ramirez-Marquez J. (2007). Integra-

tion maturity metrics: development of an integration readiness

level. Hoboken, NJ: Stevens Institute of Technology,

School of Systems and Enterprises.

Mankins JC. (2002). Approaches to strategic research and

technology (r&t) analysis and road mapping. Acta Astro-

nautica 51: 321.

Millheim K, Williams TE and Yemington CR. (2011). Evalu-

ation of well testing systems for three deepwater gulf of mexico

(GOM) reservoir types, SPE 145682. Richardson, TX: Soci-

ety of Petroleum Engineers.

Mineral Management Service (MMS). (2010). US MMS

Enhance Recovery Study, Document and Revision

Number: KRNACRI090620-020FR, total number of

pages 81.

Ministry of Defence (MOD). (2008). System Readiness

Levels (SRLs). AOF Technology Management Policy,

Information and Guidance on the Technology Manage-

ment aspects of Defence Acquisition version 1.0.1.

London: MOD.

MOD. (2011). Defence Technology Strategy for the

Demands of the 21

st

Century. London: MOD.

Orme AM, Yao H and Etzkorn LH. (2006). Coupling Metrics

for Ontology-Based Systems. IEEE Software 23: 102108.

Orme AM, Yao H and Etzkorn LH. (2007). Indicating

ontology data quality, stability, and completeness

throughout ontology evolution. Journal of Software Main-

tenance and Evolution 19: 4975.

Sauser BJ, Ramirez-Marquez JE, Henry D and DiMarzio D.

(2008a). A system maturity index for the systems engi-

neering life cycle. International Journal of Industrial and

Systems Engineering 3: 673691.

Sauser B, Ramirez-Marquez JE, Magnaye R and Tan W.

(2008b). A systems approach to expanding the technol-

ogy readiness level within defense acquisition. Interna-

tional Journal of Defense Acquisition Management 1: 3958.

Sharman D and Yassine AA. (2004). Characterizing

Complex Product Architectures. Systems engineering 7:

3560. DOI: 10.1002/sys.10056.

Shishko R, Ebbeler DH and Fox G. (2003). NASA Technol-

ogy Assessment Using Real Options Valuation. Systems

Engineering 7: 112.

Simon HA. (1962). The architecture of complexity. Proceed-

ings of the American Philosophical Society 106: 467482.

Smith JD. (2005). An alternative to technology readiness

levels for non-developmental item (NDI) software. Paper

read at 38th Hawaii International Conference on System

Sciences.

Steward DV. (1981). The design structure system: a method

for managing the design of complex systems. IEEE Trans-

actions on Engineering Management 28: 7174.

US Department of Defense (USDOD). (1998). Levels of

Information Systems Interoperability, the US Depart-

ment of Defense. Available at www.eng.auburn.edu/

~hamilton/security/DODAF/LISI.pdf last accessed

<13 January 2013>.

USDOD. (2008). DOD Directive 5000.2 Instruction:

Operation of the Defence Acquisition System: US

Department of Defense. Available at www.dtic.mil/

whs/directives/corres/pdf/500002p.pdf last accessed

<13 January 2013>.

USDOD. (2009). Technology Readiness Assessment (TRA) Desk-

book, Research Directorate, Ofce of the Director,

Defence Research and Engineering (DDR&E), US Depart-

ment of Defence. Available at www.acq.osd.mil/ddre/

publications/docs/TRA2011.pdf last accessed <13 January

2013>.

Valerdi R and Kohl RJ. (2004). An approach to technology risk

management. Paper read at engineering systems division

symposium, 2931 March, Cambridge, MA. Available at

http://web.mit.edu/rvalerdi/www/TRL%20paper%20

ESD%20Valerdi%20Kohl.pdf last accessed <13 January

2013>.

Yassine A and Braha D. (2003). Complex Concurrent Engi-

neering and the Design Structure Matrix Method. Vol-

ume 11 Number 3. Concurrent Engineering: Research

and Applications. Sage Publications.

Yassine A, Whitney D, Daleiden S and Lavine J. (2003). Con-

nectivity maps: modelling and analysing relationships in

product development processes. Journal of Engineering

Design 14: 377394.

91

Vol 31, No 2, 2013

Suppose there are J independent components, (X

j

j = 1, 2, . . . , J ), partitioned into M independent

modules as shown in Fig 5. TRL of X

i

(TRL

i

) is

noted next to row X

i

. The readiness level of compo-

nent X

i

to be integrated with the component X

k

is

shown by an x at the intersection of column X

i

with

row X

k

. Similarly, the readiness level for X

k

to be

integrated with X

i

is shown in column X

k

and row

X

i

. It is assumed the mutual readiness levels are the

same, hence yielding a symmetric matrix. The

bandwidth of this matrix indicates the success of

modularisation.

Let TRL

j

, j = 1, 2, . . ., J to be at the TRL level

of X

j

j = 1, 2, . . ., J. Component X

j

(row X

j

) has

interfaces with N

j

components, and the IRLS are

given by IRL

jn

, for a given n = 1, 2, , N

j

.

The average of the integration readiness of X

j

is given by:

( ) ,

for 1,..., , and for a given j, =1, ...,

1

X

IRL

N

j j n N

jIRL Ave

jn

n

Nj

j

j

=

=

=

where N

j

is the number of interfaces of X

j

(e.g. component A of the example has N

j

= 4

interfaces);

(A1)

Fig 5: A typical DSM consisting of J components and M modules. Interfaces are shown by x.

TRL of each component are noted in the second column. The last column shows the integration

readiness for each module with the marine environment

J components

X

1

X

2

X

3

X

4

. . X

i

X

j

X

k

X

l

. . . . . . . X

J

ENV

X

1

TRL

1

X

2

TRL

2

X

3

TRL

3

X

4

TRL

4

X

i

X

j

X

k

X

l

X

J

TRL

J

ENV

N

1

dependencies for X

1

Module 1

Module m

Module M

N

J

dependencies for X

J

N

i

dependencies for X

i

Appendix

Yasseri. Subsea system readiness level assessment

92

J is the number of components (e.g. for the

case study, J = 10 components, which are labelled

using the alphabet); and

IRL

jn

, (for a given j, n = 1, , N) is the interface

readiness as entered in row j.

For the component A of the case example:

=

+ + +

= ( )

5 6 5 6

4

5.5 A

IRL Ave

(A2)

The composite readiness of component X

j

is

given by:

( ) , for 1, ..., X TRL X j J

j j j Ave

CR IRL

= = (A3)

In this paper, X

j

= A,B,C, J. For the aggregate

readiness, i.e. weighted mean, of component A

of the case example is:

= = 6 5.5 5.74 A

CR

(A4)

The composite readiness of the module M

i

(i =

1, 2, ..., M) is given by:

=

=

( )

2

1,

M

X

K

i

K

K

K

CR

CR

(A5)

where K is the number of components in M

i

.

This is the RMS (root mean-of-squares), which

gives an estimate the typical mean. RMS, also known

as the quadratic mean, is a statistical measure of

the magnitude of a variable (Bissell and Chapman,

1992). This is calculated for the rst and the second

modules as shown in equation (1) and (2) in the

main text.

If there are M modules with different readiness

to be integrated with its environment, then the

systems composite readiness index is given by:

=

+

+ +

+

( )

( ) ( ) ...

( ) ( ) ...

( ) ( )

7

1 1

2

2

2

SRL

IRL M

IRL M

IRL M

M

estimate

ENV

ENV m m

ENV M M

CR

CR

CR

(A6)

where (IRL

ENV

)m is the readiness of module m to be

integrated with the environment and m = 1,2, , M.

The number 7 in the denominator is the highest

readiness level, which a system can achieve on IRL

scale, and it is used to normalise the readiness of

each module to be integrated with the marine envi-

ronment (IRL

ENV

). Thus, at the highest level of

readiness, a value of 1.0 (100%) can be obtained

for IRL

ENV

/ 7.

For the case example, this is calculated as:

( )

5 (5.31) 5 (4.95)

7 2

4.34

2 2

SRL

estimate

=

+

= (A7)

This paper assumes that the system is dependent

on the seabed, but not vice versa. If it is desirable to

assume that the system and the seabed are inter-

dependent, then the seabed portion of each mod-

ule must be added as another component within

each module. For example, Fig 4 becomes a 12

12 matrix; 5 elements for module 1 and 7 elements

for module 2; the extra element being the seabed.

Then, there is no need for the column and row 14.

The formulae in this appendix should also be

modied to accommodate such addition.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Agency DOD Program Charts Aug 2017Document269 pagesAgency DOD Program Charts Aug 2017jpd1015No ratings yet

- OrMen Lange DecommisioningDocument17 pagesOrMen Lange DecommisioningRizki PerdanaNo ratings yet

- An Approach For Developing Concept of Innovation Readiness LevelsDocument20 pagesAn Approach For Developing Concept of Innovation Readiness LevelsijmitNo ratings yet

- Project Management in RDDocument25 pagesProject Management in RDRahul Jain100% (1)

- Technology Readiness LevelsDocument5 pagesTechnology Readiness LevelsSânzia Almeida CostaNo ratings yet

- Saep 74Document29 pagesSaep 74munna100% (2)

- Blockchain Solutions For Carbon Markets Are Nearing MaturityDocument14 pagesBlockchain Solutions For Carbon Markets Are Nearing MaturityArturoNo ratings yet

- Page 1 of 5 2013 ASHRAE. All Rights ReservedDocument5 pagesPage 1 of 5 2013 ASHRAE. All Rights ReservedRizki PerdanaNo ratings yet

- Bozorgmehrian Thesis 2013Document102 pagesBozorgmehrian Thesis 2013Rizki PerdanaNo ratings yet

- Control Theory IllustrationDocument18 pagesControl Theory IllustrationRizki PerdanaNo ratings yet

- ENPDocument21 pagesENPRizki PerdanaNo ratings yet

- Assignment No. 1: Getting Into The Success MindsetDocument9 pagesAssignment No. 1: Getting Into The Success Mindsetluoie espadaNo ratings yet

- Awards Definition - 2014Document5 pagesAwards Definition - 2014Gaurav GuptaNo ratings yet

- Final ReportDocument42 pagesFinal Reportapi-407735821No ratings yet

- Ai For Net-Zero Energy BuildingsDocument17 pagesAi For Net-Zero Energy BuildingsYanjun MengNo ratings yet

- EIC Accelerator: Guide For ApplicantsDocument25 pagesEIC Accelerator: Guide For ApplicantsOmeragićAmirNo ratings yet

- INCOSE Benefits Limitations of Current Techniques For Measuring System ReadinessDocument36 pagesINCOSE Benefits Limitations of Current Techniques For Measuring System ReadinesslcatarinoNo ratings yet

- Sandia Report PDFDocument97 pagesSandia Report PDFmehedi hasanNo ratings yet

- Navy FA-XX - RFIDocument5 pagesNavy FA-XX - RFIjtreedDTNo ratings yet

- Ship Underwater Radiated NoiseDocument48 pagesShip Underwater Radiated NoiseSubodh ChanderNo ratings yet

- 04 - JTC Template On Project ProposalDocument10 pages04 - JTC Template On Project Proposalbakelm alqamisNo ratings yet

- TRL Technology Readiness Level Developement-Stages-Trl-Mrl-IrlDocument26 pagesTRL Technology Readiness Level Developement-Stages-Trl-Mrl-IrlAsokane NatrajanNo ratings yet

- Re Cri Retd de JagerDocument23 pagesRe Cri Retd de JagerMaitheNo ratings yet

- Nasa Systems Engineering Handbook 0-201-297Document97 pagesNasa Systems Engineering Handbook 0-201-297nazmiNo ratings yet

- The Lab-To-Fab Journey of 2D MaterialsDocument3 pagesThe Lab-To-Fab Journey of 2D MaterialsSergio Graniero EcheverrigarayNo ratings yet

- 187709main NASA Research and Utilization Plan For The ISS PDFDocument94 pages187709main NASA Research and Utilization Plan For The ISS PDFSayanNo ratings yet

- Power BI AssignmentDocument147 pagesPower BI AssignmentAditya SharmaNo ratings yet