Professional Documents

Culture Documents

Project Water Temperature and Flow Control Measurement For Thermal Discharge Model Using PID Controller

Uploaded by

Akbar AliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Project Water Temperature and Flow Control Measurement For Thermal Discharge Model Using PID Controller

Uploaded by

Akbar AliCopyright:

Available Formats

Krishna Prasad Dasari, Dr.A.M.

Prasad,

V.Sai Krishna Prasad

/ International Journal of

Engineering Research and Applications (IJERA) ISSN: 2248-9622 www.ijera.com

Vol. 2, Issue4, July-August 2012, pp.2198-2202

2198 | P a g e

Water Temperature and Flow control Measurement for Thermal

Discharge Model using PID controller

Krishna Prasad Dasari

1

Dr.A.M.Prasad ME,Ph.D

2

V.Sai Krishna

Prasad

3

Department of ECE, University College of Engineering

Jawaharlal Nehru Technological University Kakinada (JNTUK), Kakinada, India

1. ABSTRACT:

This main aim of this paper is evaluate

the method of environmental impact of power

plant discharge by reducing the temperature

difference between effluent and costal water and

flow control. Water temperature control and flow

control measurement have been designed in

advance technology of industrial control area for

thermal discharge model test. Digital temperature

sensors, level sensors, Flow meters, different

modulated circuits, dedicated interface are used in

the test and controlling of the system is adopted in

software designing and programming.

Measurement procedure, data processing and

controlling are done by Proportional Integral

Derivative (PID) controller. The numerous

analyses of these applications it is shown that

measurement is satisfactory, precise and reliable

meeting the requirement of test. This technology

can be implemented where the thermal effluent

are discharged in coastal areas.

KEYWORDS: Thermal discharge, Temperature

measurement, Flow Control, level measurement,

Temperature/Flow control System

2. INTRODUCTION:

A lot of electricity is produced by the

thermal power plants constructed along the coast.

Every day they are pumping the hundred thousand

tonnage of sea water as heat sink from thermal power

plant. Through in this process more number of heat

wastes is emitted to the environment of sea or river.

Various human living and industrial activity also

cause for this thermal discharge. This is not so sever

to aquatic ecological system but also not negligible.

Thermal discharge from many factories and plants

along coasts results environmental impact especially

huge power plants has been big issue in the socio-

economic viewpoints of coastal eco-system.

Water temperature is an important factor to

water quality and ecology, which almost affects the

entire physical, chemical and biochemical properties

of water. Large number of thermal pollution is caused

by heat regression effect due to emission of thermal

discharge from power plants to surrounding water,

so the physical model test on the warm water

temperature region prediction is very necessary.

Water temperature is not only an important parameter

for the test, but is also important for the process

control. For this experiment, we generally require

sensors to measure temperature, flow rate and this

automatic synchronized signal is displayed

at remote place and recorder is also necessary in the

test. Besides, model discharge needs to get

temperature, flow and level in control and not just be

measured. Obviously, mercury thermometers cannot

be competent, but electronic thermometer is suitable.

The general temperature sensors include IC LM35,

thermistor, resistance temperature detector (RTD)

and thermocouples, etc. However, electronic

thermometers (including IC shunt sensor) need

separate signal cable transmission, separate

amplification, shaping circuit, A/D converters and

multichannel analog switch, this will make hardware

system complex. Let analog circuits and digital

circuits coexist in one system and the assembly and

commissioning is troublesome and with higher cost

and magnetic level sensors are used in order to

measure the level of the liquid at regular intervals.

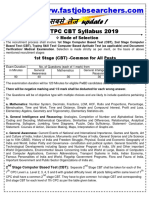

3. SYSTEM STRUCTURE AND

OPERATION

The system design has been adopted with

digital temperature sensors, Flow Meters, level

sensors with the latest extreme fast control

technology several modules computers and dedicated

interface is shown in the below figure 3.1

Krishna Prasad Dasari, Dr.A.M.Prasad,

V.Sai Krishna Prasad

/ International Journal of

Engineering Research and Applications (IJERA) ISSN: 2248-9622 www.ijera.com

Vol. 2, Issue4, July-August 2012, pp.2198-2202

2199 | P a g e

Figure 3.1

A.WATER TEMPERATURE MEASUREMENT

AND CONTROL

The digital temperature sensor is a thermal

transistor of temperature measurement. when the

water temperature changes then the sensor detect and

the physical quantity of temperature is converted in

to digital quantity in computer through temperature

sensitive devices and corresponding circuits such as

analog to digital convertor, controller, data

acquistion. Herewe undergo with a Resistance

Temperature detector(RTD) sensor for temperature

measurement which has a range of -202C to 855C

and accuracy of 0.1 C and resolution 0.0625.

The system mainly consists of heating pool (hot

water) The water temperature of the pool showed by

temperature sensor and this signal will be compared

with the experimental reading with was given

computer as a set point, based on the water

temperature the cooling system is switched ON to

reduce the temperature to the required set point. The

controlling action is been processed by the controller

and the final temperature is displayed in the

computer. The Cooling system is been powered with

the solar panels instead of electric power. The power

can be stored in Battery and can be utilized when the

solar power is interrupted.

Data aquistion is intergrates ETRX2(W-PAN)

transreciver module to transmit the data to remote

place through wireless communication this module is

equiped with power supply.

Digital temperature sensors, data acquisition

converter, dedicated communication interface, and

computer composed, the temperature measurement

system realized the simultaneous multi-point

temperature values detected of synchronous by the

specific software to complete data sampling, transfer,

display and output of graphics and tables.

B. FLOW MEASUREMENT AND CONTROL

The Flow rate of the inlet and the discharge

can be measured by venturimeter or Orifice meter

and the differential pressure is calculated and it is

been transmitted to the computer for the comparison

with the set point with is already fed to the computer.

The flow rate and the valve opening/closing depends

upon the level of the heating pool and it is

continuously monitored by the set point given and

been operated by PID Controller.

C. LEVEL MEASUREMENT AND CONTROL

The level of the system is monitored by

using the magnetic level sensor. The level is

processed by using controller and based on the level

the cooling system is activated and the temperature of

the pool is controlled to the required set point. The

level of the system is displayed on the personal

computer and the controlling action takes place. The

cooling system has to work in a condition that it

should satisfy the pool temperature with the given set

point in between the inlet and outlet valves of the

pool.

4. SOFTWARE DESIGN

The programming of control system is

completed in object oriented program it includes two

operations for temperature control and level control,

MATLAB is used in measurement procedure and

data processing to communicate between two

modules this interface is friendly and easy to operate.

Display of measurement shows each

temperature value measured and all data will be

automatically saves in the form of document for easy

access, the MATLAB code is used for data

processing procedures based on the display

temperature the temperature is controlled to

allowable range, the measured signals are then

calculated in computer for data integration after

processing to keep the consistency results.PID

control method is applied to system, this PID is

suitable for nonlinear problem with large delay and

difference to be simulated in mathematical model.

Temperature measurement and control: In this

control it has two modules those are manual and

automatic. In manual cooling system, the set point

has to be given to the personal computer, so

according to the input value the cooling system

comes into the action. In automatic cooling system, it

operates continuously depending up on the discharge

rate.

Krishna Prasad Dasari, Dr.A.M.Prasad,

V.Sai Krishna Prasad

/ International Journal of

Engineering Research and Applications (IJERA) ISSN: 2248-9622 www.ijera.com

Vol. 2, Issue4, July-August 2012, pp.2198-2202

2200 | P a g e

Level measurement: In this it consists of two

modules those are manual and automatic. In manual

operation cooling system, the set point has to be

given to the personal computer, so according to the

input value the cooling system comes into the action.

In automatic cooling system, it operates continuously

depends up on the discharge rate.

Flow measurement and control: In this it consists of

two modules those are manual and automatic. In

manual operation cooling system, the set point has to

be given to the personal computer, so according to

the input value the cooling system comes into the

action. In automatic cooling system, it operates

continuously depends up on the Temperature and

level.

5. FEATURE OF THE SYSTEM

The system is digitally programmed with

multi functional circuit module high integration, light

simple structure and high precision in temperature

measurement.

The way of transmission with data is highly

reliable because it can transmit the data through large

distance without loss of data by using the ETRX2

module.

Using this XFC (extreme fast control)

technology provides a real time control and fast

accurate response. Using XFC technology, I/O

response time 100s, XFC components achieves

the cycle time of 50s in the Windows system, I/O

distributed processing time is 30s, time stamp and

the over-sampling ensure high precision timing (up

to 10ns). These greatly meet the process control

requirements of real time. Meanwhile, we can

improve the precision and resolution by optimizing

the system cycle, and we can also reduce the

response time and improves the function of the

system. Standard tasks, measurement tasks and fast

control tasks can be executed parallel in hardware

and software platform because XFC are compatible

with the system.

6. DATA ANALYSIS

The power plant has to sign a protocol with

local government to reduce influences on marine

environment by thermal discharge. The thermal

discharge standard of MKS Power Plant in America

points, temperature-rise of power plant should be less

than 5C, dissolved oxygen concentration must be

more than 5mg/L, and temperature should be less

than 28.33C in summer. Internationally, main

marine countries all made some management

regulations about thermal discharge. Table I shows

limited value of water temperature by some European

countries regulations. Belgium highest temperature is

30-35C, Holland highest temperature rise is 3C and

highest temperature out fall is 30C.

For France highest Temperature rise is 3C

and for Italy highest temperature rise is 3C, highest

temperature is 30C and highest temperature of out

fall is 35C.

India published more perfect standard on the power

plants thermal discharge. There are also

concentration limit about other pollutants in the

thermal discharge. Table II shows Indian power plant

discharge standard of water cooling. Table III shows

Egyptian power plant standard of thermal discharge.

There are some regulations for temperature

monitored at bay shore plants for intake and

discharge process, in summer months the maximum

intake of plant must be 28.9C and maximum

discharge must be 34.3C and in winter months

maximum intake must be 13.8C and maximum

discharge must be 18.1C, for summer months

minimum intake must be 17.9C and minimum

discharge is 21.4C and in winter months minimum

intake must is 1.1C and minimum discharge is

3.4C.

Krishna Prasad Dasari, Dr.A.M.Prasad,

V.Sai Krishna Prasad

/ International Journal of

Engineering Research and Applications (IJERA) ISSN: 2248-9622 www.ijera.com

Vol. 2, Issue4, July-August 2012, pp.2198-2202

2201 | P a g e

The mixing of the discharge to the river or sea is not

a physical process. But it must be regulatory designed

to discharge the effluent before all the required

standards are met. Reasonable amount of dilution of

thermal water results in minimizing the

environmental effect by mixing zone size. The

'mixing zone' is simply the region within which a

contaminant plume is legally allowed to interact with

the surrounding water. The contaminant may cause

impact to the environment due to presence of heat of

any other chemical effluent.

China hasnt special standard aiming at

cooling water, but only has clear clauses about water

temperature-rise in some environment regulations.

For example, in Standard of Surface Water

Environment Quality the Water temperature term

points, Artificial environmental water temperature

change should be limited under an average of 1C per

week in summer and 2C in winter. And in Sea

Water Quality Standard it is said that Artificial

Temperature-rise should be no more than 4C higher

than that place at that time. However, compared to

foreign related standards, Chinas regulations about

water temperature is very general, and has no clear

regulation on neither aspects such as discharge

intensity and range of mixed zone, nor temperature

rise limit related to regional or ecological features.

7. EXPERIMENTAL RESULTS

Temperature control using PID at 35C

Figure 7.1

Flow Control Using PID at 50% Opening

Figure 7.2

Krishna Prasad Dasari, Dr.A.M.Prasad,

V.Sai Krishna Prasad

/ International Journal of

Engineering Research and Applications (IJERA) ISSN: 2248-9622 www.ijera.com

Vol. 2, Issue4, July-August 2012, pp.2198-2202

2202 | P a g e

Flow Vs Level

Figure 7.3

8. CONCLUSION:

By using this proposed method we can

reduce the temperature of the thermal discharge from

power plant up to desired set point by controlling the

desired flow rate and we can also measure the level

of the system and get displayed on the computer.

Selection of the higher grade of sensors can

add advantage to the project and gives the better

performance. This method have multiple effect of

reducing the carbon dioxide emissions from hot water

which cause thermal pollution and the effects would

be proportionally magnified if plants are added and

expanded.

The system will have a wide range of

application where water temperature monitoring is

needed and such as, industries, lakes, rivers etc.

9. REFERENCES:

[1] Wu Xinsheng, Lin Musong, Yao Shiming,

Liao xiaoyong, Huang weidong Design and

application of multi-point water temperature

measurement and control system for thermal

discharge model 2010 International

Conference on Digital Manufacturing &

Automation

[2] G.C. Nihous, M.G. Brown, D.Levrat, M.

Gauthier, J. Ruer, Ocean Thermal Energy

Conversion (OTEC): Principles, problems

and prospects, 2nd International

Conference on Ocean Energy (ICOE 2008),

October 2008, 1-9.

[3] H.Z. Li. Evaluation of Influences on

Environment by Japanese Nuclear Power

Plants Thermal Discharge [J] Research &

Design of Nuclear Engineering,2007,1:14-

16.

[4] Clean Water Act NPDES Permitting

Determinations for Thermal Discharge and

Cooling Water Intake from Mirant Kendall

Station in Cambridge,MA 2004.8.8.

[5]. Wu Xinsheng, Zhou Zhen, Yu Lianqing, and

Chen Fengyu, Development and

application of control facility of warm-water

discharge in river model test, Journal of

Yangtze River Scientific Research Institute,

Wuhan, vol. 20, pp. 5860, Oct. 2003. (in

Chinese)

[6]. He Xicai, Sensor and Its Application Circuit.

Beijing: Electronics Industry Press, 2001.

(in Chinese)

[7] Notification, Ministry of Environment and

Forests, New Delhi,the 22

nd

December,1998.

[8] Cheikh I. Fall, Egypt:EL Kureimat

Combined Cycle Power Plant

Project(ModuleII), Environmental And

Social Management Plan

Summary,2005,Feb 4th .

[9] T. Toyota, T. Nakashima and T. Ikeda,

Overview of research activities on the

utilization of deep seawater in Japan,

International OTEC/DOWA Association,

May 1997, pp.109-118.

[10] Y. H. Kim, "Power plant discharge and its

affect to marine ecological system", Electric

signal science technology press center,

Seoul, June 2000, p.259. (in Korean).

[11] Vega L.A., Ocean Thermal Energy

version. In Encyclopedia of Energy

Technology and the Environment, Vol. 3 (A.

Bisio and S. Boots eds.), John Wiley &

Sons, New York, 1995. pp.2104-2119.

[12] J.R. Adams, "Ecological investigations

related to thermal discharges, Pacific

Electrical Association, Engineering

Operations Section, Annual Meeting, Los

Angeles.

[13] Penney T.R., Daniel T.H, Energy from the

ocean: a resource for the future, Year Book

for 1989, Encyclopedia Britannica, 1989,

pp.98-115.

[14] J.R. Vadus, A strategy for OTEC

Commercialization, International

OTEC/DOWA Association, May 1997,

pp.235-247.

[15] H.J. Kim, D.H. Jung, D.S. Moon and W.Y..

Oh, Development and Application

Direction of Ocean Thermal Energy

Conversion, Proc. Of Korean Society

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- PAT DS 350 M - Modular - GB - New Mit SchreibschutzDocument85 pagesPAT DS 350 M - Modular - GB - New Mit SchreibschutzJorge Alvarez Fernandez83% (6)

- SOLUTION MANUAL Fundamentals of Applied Electromagnetics (6th Ed., Fawwaz T. Ulaby)Document53 pagesSOLUTION MANUAL Fundamentals of Applied Electromagnetics (6th Ed., Fawwaz T. Ulaby)Paul Cary7% (57)

- SIMIS - W - TSpec - Arhitectura SiemensDocument138 pagesSIMIS - W - TSpec - Arhitectura SiemensMihnea MunteanuNo ratings yet

- The Information AgeDocument2 pagesThe Information AgeDin DuqueNo ratings yet

- Visvesvaraya Technological University: "Archery Game"Document38 pagesVisvesvaraya Technological University: "Archery Game"aishwarya kulkarniNo ratings yet

- Computer: Man Is Still The Most Extraordinary Computer of All John F - KennedyDocument289 pagesComputer: Man Is Still The Most Extraordinary Computer of All John F - KennedyatherNo ratings yet

- The Aesthetics and Practice of Designing Interactive Computer EventsDocument21 pagesThe Aesthetics and Practice of Designing Interactive Computer EventsVinicius MitchellNo ratings yet

- Data and Goliath - The Hidden Ba - Bruce SchneierDocument1,749 pagesData and Goliath - The Hidden Ba - Bruce SchneierdaverncNo ratings yet

- Dell Vostro 3900 ManualDocument38 pagesDell Vostro 3900 ManualAnonymous HrEyjcJBNo ratings yet

- L5 Computer Software For Onboard Stability Calculations L5: ApplicationDocument12 pagesL5 Computer Software For Onboard Stability Calculations L5: ApplicationSarawut JaeNo ratings yet

- Université Sidi Mohammed Ben Abdellah FèsDocument13 pagesUniversité Sidi Mohammed Ben Abdellah FèsSalah-eddine ZitiNo ratings yet

- Ict - Ig 1 (A) - S1T1 2023 - P1Document7 pagesIct - Ig 1 (A) - S1T1 2023 - P1Su YongshengNo ratings yet

- 電子繪本教學對及提升幼兒詞彙與口頭表達能力之研究Document143 pages電子繪本教學對及提升幼兒詞彙與口頭表達能力之研究henrykylawNo ratings yet

- RRB NTPC SyllabusDocument3 pagesRRB NTPC SyllabusRavi shankar kumarNo ratings yet

- Operating System: Time: 3 HRS.) (Marks: 100Document17 pagesOperating System: Time: 3 HRS.) (Marks: 100Aditya Darekar100% (1)

- Information Technology in Marketing or Marketing Information System (MkIS)Document25 pagesInformation Technology in Marketing or Marketing Information System (MkIS)Shamimhstu100% (2)

- CSC-April2010 Computer Masti CurricullumDocument57 pagesCSC-April2010 Computer Masti CurricullumRupesh Kumar ShahNo ratings yet

- Course SyllabusDocument2 pagesCourse Syllabusapi-233040995No ratings yet

- 1ST Lesson in SofappDocument28 pages1ST Lesson in SofappRaymond CatarosNo ratings yet

- Using The Wearable Computer in The Construction IndustryDocument16 pagesUsing The Wearable Computer in The Construction IndustryaliNo ratings yet

- OPERDocument24 pagesOPERPriya BhattNo ratings yet

- RFID and GSM Based Advanced Vehicle Parking Slot Booking SystemDocument3 pagesRFID and GSM Based Advanced Vehicle Parking Slot Booking SystemVidhyadhar Kasukurthi100% (1)

- Eee Sar Part Ii & Iii PDFDocument97 pagesEee Sar Part Ii & Iii PDFpvanitha143No ratings yet

- Program Mod 5 PDFDocument3 pagesProgram Mod 5 PDFvalerio freyNo ratings yet

- Final Date Sheet - Spring2020.v1xlsxDocument11 pagesFinal Date Sheet - Spring2020.v1xlsxRaffay SajjadNo ratings yet

- Flexible Manufacturing Systems (FMS) : A Review: Manu. G, Vijay Kumar. M, Nagesh. H, Jagadeesh. D & Gowtham. M. BDocument14 pagesFlexible Manufacturing Systems (FMS) : A Review: Manu. G, Vijay Kumar. M, Nagesh. H, Jagadeesh. D & Gowtham. M. BTJPRC PublicationsNo ratings yet

- Adventures With The AtariDocument372 pagesAdventures With The AtariIman MirblokiNo ratings yet

- Finale Exam of CTTCDocument189 pagesFinale Exam of CTTCDilip BhagatNo ratings yet

- The Matter-Being Project - Wing Pon MATTER-BEING PARADIGM - A SUMMARYDocument1 pageThe Matter-Being Project - Wing Pon MATTER-BEING PARADIGM - A SUMMARYStephen J. RobertsNo ratings yet

- 5 6075740949730820188 PDFDocument28 pages5 6075740949730820188 PDFharpal_abhNo ratings yet