Professional Documents

Culture Documents

Material Safety Data Sheet (MSDS) : Msds No: Aluminum Electrode REVISED 12-2009

Uploaded by

Rama Krishna Reddy Donthireddy0 ratings0% found this document useful (0 votes)

23 views2 pagesThis document provides an MSDS for an aluminum electrode used for welding. It lists the hazardous materials in the electrode including various aluminum compounds and fluorides. The main hazards are from inhaling welding fumes, which can cause lung problems from long term exposure and metal fume fever from short term exposure. Protective equipment like ventilation and respirators are recommended to limit exposure to the fumes and gases produced during welding.

Original Description:

ELE

Original Title

al 345

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides an MSDS for an aluminum electrode used for welding. It lists the hazardous materials in the electrode including various aluminum compounds and fluorides. The main hazards are from inhaling welding fumes, which can cause lung problems from long term exposure and metal fume fever from short term exposure. Protective equipment like ventilation and respirators are recommended to limit exposure to the fumes and gases produced during welding.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views2 pagesMaterial Safety Data Sheet (MSDS) : Msds No: Aluminum Electrode REVISED 12-2009

Uploaded by

Rama Krishna Reddy DonthireddyThis document provides an MSDS for an aluminum electrode used for welding. It lists the hazardous materials in the electrode including various aluminum compounds and fluorides. The main hazards are from inhaling welding fumes, which can cause lung problems from long term exposure and metal fume fever from short term exposure. Protective equipment like ventilation and respirators are recommended to limit exposure to the fumes and gases produced during welding.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

MSDSNO: ALUMINUM ELECTRODE

REVISED 12-2009 Page 1

MATERIAL SAFETY DATA SHEET (MSDS)

For Welding Consumables and Related Products

Conforms to OSHA Hazard Communication Standard 29CFR 1910.1200

Standard Must Be Consulted for Specific Requirements

SECTION I - IDENTIFICATION

Manufacturer/Supplier: Washington Alloy Company Telephone No: 704-598-1325

Address: 7010-G Reames Road, Charlotte, NC 28216 Emergency No: 704-598-1325

Trade Name:

Al 345 or Aluminum 345

Specification/Classification:

AWS A5.3 /E4043

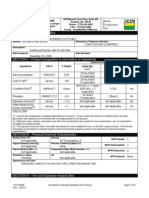

SECTION II IDENTITY INFORMATION and HAZARDOUS MATERIALS*

IMPORTANT: This section covers the materials from which the product is manufactured. The fumes and gases produced during welding with the normal

uses of this product are covered under Section V.

*The term HAZARDOUS MATERIALS should be interpreted as a term required and defined in OSHA HAZARD COMMUNICATION STANDARD

29 CFR 1910.1200 however the use of this term does not necessarily imply the existence of any hazard.

Chemical Composition Percent by Weight

Notes: Single vales are maximum, except where noted, Beryllium shall not exceed 0.0008 percent

Exposure Limit (mg/m

3

)

Alloy Ingredients CAS No. Wt %

OSHA PEL ACGIH TLV

Aluminum (Al)

(1)

7429-90-5 45-75 15 ( total dust) 5 (Resp) 10 (dust) 5 (Resp)

Silicon (Si) 7440-21-3 2-6 15 (dust) 5 (Resp) 10 (NIOSH)

Aluminum Fluoride 7784-18-1 1-6

Lithium Fluoride 7789-24-4 1-6

Lithium Hexafluoraluminate 13821-20-0 4-9

Magnesium Fluoride 7738-40-6 1-6

Potassium Hexafluoraluminate 13775-52-5 1-6

2.5 (as F) 2.5 (as F)

Potassium Fluoride 7789-23-3 2-8 None found None found

Potassium Chloride 7447-40-7 5-25

None found None found

Sodium Chloride 7647-14-5 5-25 None found None found

Other elements or ingredients may be present but in quantities much less than 1%.

(1)

Subject to reporting requirements of Section 302, 304, 311, 312, and 313 of the Emergency

Planning and Community Right-To-Know Act of 1986 and 40CFR 370 and 372; (Resp) = Respiratory/ Respiration

(C)

TLV & PEL for water soluble Cr. III and Cr. VI

,Welding and cutting of products that contain Chromium may produce hexavalent chromium and YOU should read and follow OSHA 's final rules Fed Register # :71:10099-

10385 dated 02-28-2006. Occupational Safety and Health Administration 29 CFR 1910.1000 Permissible Exposure Limit (PEL). American Conference of Governmental :

Industrial Hygienists (ACGIH) Threshold Limit Value (TLV[R]). *Ceiling Limit

SECTION III - PHYSICAL DATA

As shipped these are odorless, silvery, solid rods with white flux coating that are nonflammable, non-explosive, non-reactive and non hazardous

Core wire is Insoluble in water and has a melting point of 950-1215F

SECTION IV FIRE AND EXPLOSION HAZARD DATA

Non-Flammable: Welding arc and sparks can ignite combustibles. See Z-49.1 referenced in Section XIII.

SECTION V REACTIVITY& STABILITY DATA

Hazardous Decomposition Products

Welding fumes and gases cannot be classified simply. The composition and quantity of these fumes and gases are dependent upon the metal being welded,

the procedures followed and the electrodes used. Workers should be aware that the composition and quantity of fumes and gases to which they may be

exposed, are influenced by: coatings which may be present on the metal being welded (such as paint, plating, or galvanizing), the number of welders in

operation and the volume of the work area, the quality and amount of ventilation, the position of the welders head with respect to the fume plume, as well as

the presence of contaminants in the atmosphere (such as chlorinated hydrocarbon vapors from cleaning and degreasing procedure). When the electrode is

consumed, the fumes and gas decomposition products generated are different in percent and form from the ingredients listed in Section II, The composition

of these fumes and gases are the concerning matter and not the composition of the electrode itself. Decomposition products include those originating from

the volatilization, reaction, or oxidation of the ingredients shown in Section II, plus those from the base metal, coating and the other factors noted above.

Reasonable expected fume constituents of this product would include: Complex oxides of aluminum, manganese, silicon, magnesium, beryllium and copper.

Fume limit for Cr (VI) may be reached before limit of 5 mg/m3 for general welding fumes is reached. Watch the (Cr VI) level. Other complex oxides may be

present when using fluxes. Gaseous reaction products may include carbon monoxide and carbon dioxide Ozone and nitrogen oxides may be formed by the

radiation from the arc. One method of determining the composition and quantity of the fumes and gases to which the workers are exposed is to take an air

sample from inside the welders helmet while worn or within the workers breathing zone. See ANSI/AWS F1.1 publication available from the American

Welding Society 550 N.W. LeJeune Road, Miami, Florida 33126.

Stability: This product is stable.

Incompatibility: Strong chemical like acids, oxidizers, halogens and chlorides.

Continued on page 2

SECTION VI ENTRY DATA

Common Entry Is by Inhalation- During the welding/brazing processes inhalation of fumes may give the most common route of over exposure. Contact

with skin, eyes, ingestion or injection should not be a source for exposure with proper protection.

SECTION VII Threshold Limit Value

Threshold Limit Value: The ACGIH recommended general limit for welding fume NOC (Not otherwise classified) is 5 mg/m3. ACGIH-1985 preface

states: The TLC-TWA should be used as guides in the control of health hazards and should not be used as fine lines between safe and dangerous

concentrations. See section V for specific fume constituents, which may modify this TLV.

SECTION VIII HEALTH HAZARD DATA

Effects of Overexposure: Inhalation of welding fumes and gases can be dangerous to your health. Short-term (acute) overexposure to welding fumes may

result in discomfort such as dizziness, nausea, or dryness or irritation of nose, throat, or eyes. Continued inhalation of welding fumes could cause loss of

consciousness and death. Nickel oxides present in the fume may cause tightness around the chest, fever and allergic reactions in some people. Long-term

(chronic) over-exposure to welding fumes can lead to siderosis (iron deposits in lung) and is believed to affect pulmonary function. Repetitive exposure to

fluoride fumes and/or gases may cause excessive calcification of the bones and ligaments of the ribs, pelvis and spinal column. Workers exposed to nickel

compounds and/or cadmium oxides have a higher incidence of lung and nasal cancers. Nickel and cadmium compounds are on the IARC (International

Agency for Research of Cancer) list as posing a carcinogenic risk to humans.

Arc Rays can injure eyes and burn skin... Electric shock can kill. See Section XIII.

SECTION IX- Emergency and First Aid Procedures

Emergency and First Aid Procedures: Remove to fresh Air. Call for medical assistance. Use first aid procedures recommended by the American Red

Cross. If breathing is difficult or not breathing give oxygen or use CPR (Cardiopulmonary Resuscitation) by trained personnel.

Consult a physician if irritation of the eyes and skin or flash burns develops after exposure.

SECTION X- TOXICOLOGICAL INFORMATION

Acute toxicity: Overexposure or inhalation of large amounts of welding/brazing fumes may cause symptoms such as metal fume fever, dizziness, nausea,

dryness and irritation of your nose, throat or eyes as well as other lung disease.

Chronic toxicity: Overexposure or prolonged inhalation of large amounts of welding/brazing fumes with chromium compounds may cause cancer. Other

overexposure or prolonged inhalation of large amounts of welding fumes symptoms related may include damage to the central nervous system, respiratory

system, skin and could affect organs such as pancreas and liver

Carcinogenicity; OSHA(29 CFR 1910.1200) no items of this product.

California Proposition 65: These products contains or produces chemicals known to the State of California to cause cancer, and/or birth defects (or other

reproductive harm).( Health and Safety Code section 25249.5 et seq.)

SECTION XI SAFE HANDLING AND STORAGE

Handling: Do not eat or drink while using these products and ensure proper ventilation is used.

Storage: Store in a cool dry place away .Avoid extreme temperatures and incompatible items such as acids, oxidizers and halogens

SECTION XII DISPOSAL & WASTE

Waste Disposal Method: Recycle when possible. Discard any un-wanted product, residues, containers, or liners in a suitable disposal container in an

environmentally acceptable manner approved by Federal, State and Local regulations

SECTION XIII CONTROL MEASURES AND PERSONAL PROTECTION

Read and understand the manufacturers instructions and precautionary label on this product and your employers safety practices. See American Standard

Z49.1 Safety in Welding and Cutting, published by the AMERICAN WELDING SOCIETY, 550 N.W. LeJeune Road, Miami, Florida 33126 and OSHA

Publication 2206 (29 CFR1910), U.S. Government Printing Office, Superintendent of Documents, P.O. Box 37954, Pittsburg, Pa 15250-7954 for more

details on the following topics. Keep work area and all personal equipment and tools/equipment clean and dry

Ventilation: Use plenty of ventilation and/or local exhaust to keep the fumes and gases below the threshold limit value within the workers breathing zone

and the general work area. Workers should be advised to keep their head out of the fumes.

Respiratory Protection: Use respirable fume respirator or air supplied respirator when working in a confined space or general work area where local

exhaust and/or ventilation does not keep exposure below the threshold limit value.

Eye Protection: Wear a helmet or face shield with a filter lens to prevent injury. Shield other workers by providing screens and flash goggles.

Protective Clothing: Wear approved head, hand and body protection, which help to prevent injury from radiation, sparks and electrical shock. See ANSI Z-

49.1. This would include wearing welders gloves and a protective face shield and may include arm protectors, apron, hats, shoulder protection, as well as

dark substantial clothing. Welders should be trained not to allow electrically live parts to contract the skin or wet clothing and gloves. The welders should

insulate themselves from the work and ground.

SECTION XIV OTHER INFORMATION

Approval Date: 12-29-2009 NFPA CODES : FIRE: 0 HEALTH: 0 REACTIVITY: 0

Washington Alloy Co. Believes that the information contained in this (MSDS) Material Safety Data Sheet is accurate. However,

Washington Alloy Co. does not express or implies any warranty with respect to this information.

Download the most current MSDS and product information @ www.weldingwire.com

MSDS NO: ALUMINUM ELECTRODE

REVISED 12-2009 Page 2

You might also like

- Method Statement For Installation, Testing & Commissioning of VRF & Split System Rev.01Document36 pagesMethod Statement For Installation, Testing & Commissioning of VRF & Split System Rev.01vhin8467% (6)

- Protec Optimax 2010 - User ManualDocument52 pagesProtec Optimax 2010 - User ManualManuel FloresNo ratings yet

- Material Safety Data Sheet: What Is The Material and What Do I Need To Know in An Emergency?Document9 pagesMaterial Safety Data Sheet: What Is The Material and What Do I Need To Know in An Emergency?haharameshNo ratings yet

- Standard Check ListsDocument136 pagesStandard Check ListsRama Krishna Reddy Donthireddy100% (2)

- Service Life and Life Cycle of Building StructuresDocument5 pagesService Life and Life Cycle of Building StructuresYuny Ayu MaharaniNo ratings yet

- DocumentDocument45 pagesDocumentMuhammad IqmalNo ratings yet

- Coal Gasification - EastmanDocument44 pagesCoal Gasification - Eastmanstavros7No ratings yet

- Lecture 7Document193 pagesLecture 7Melinda GordonNo ratings yet

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesFrom EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesNo ratings yet

- Pipe Inspection SpecificationDocument49 pagesPipe Inspection SpecificationRama Krishna Reddy DonthireddyNo ratings yet

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesFrom EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNo ratings yet

- Dredger Pumps For SlurryDocument4 pagesDredger Pumps For SlurryvehptNo ratings yet

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesFrom EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesRating: 5 out of 5 stars5/5 (2)

- Field Methods For Geologists and Hydrogeologists (Fakhry A. Assaad, Philip E. LaMoreaux SR., Travis H. Hughes, 2004) PDFDocument404 pagesField Methods For Geologists and Hydrogeologists (Fakhry A. Assaad, Philip E. LaMoreaux SR., Travis H. Hughes, 2004) PDFMichelAndriamahazonoroRaherimanantsoaNo ratings yet

- M - ENG - MSDS v1.2Document157 pagesM - ENG - MSDS v1.2sunthron somchaiNo ratings yet

- Examiners Report Specialist Diploma Environmental Management (Aug 2003 Spec) 247200841938Document12 pagesExaminers Report Specialist Diploma Environmental Management (Aug 2003 Spec) 247200841938Rehman Muzaffar100% (1)

- Material Safety Data Sheet (MSDS)Document2 pagesMaterial Safety Data Sheet (MSDS)Heri SusantoNo ratings yet

- Tungsten MSDS 09Document2 pagesTungsten MSDS 09Serkan ApayNo ratings yet

- Aluminum Wires and Rods 1Document2 pagesAluminum Wires and Rods 1OteranmoralesNo ratings yet

- La 71 MSDSDocument2 pagesLa 71 MSDSdeepak2803No ratings yet

- Aluminum Msds 8-05Document3 pagesAluminum Msds 8-05mohamed AdelNo ratings yet

- 62super Ti Se en 0Document4 pages62super Ti Se en 0Jhony MedranoNo ratings yet

- ZULFI E6013 Welding ElectrodesDocument1 pageZULFI E6013 Welding ElectrodesJunard M. Lu HapNo ratings yet

- 360, 370, 380 Brazing Rod MG MSDS 6-09Document3 pages360, 370, 380 Brazing Rod MG MSDS 6-09orcbane27No ratings yet

- 103 Solution EC Msds 5-08Document3 pages103 Solution EC Msds 5-08Brian HernandezNo ratings yet

- MSDS NiCrDocument2 pagesMSDS NiCrBety FajriaNo ratings yet

- S 800wtxm 12k Msds EngDocument2 pagesS 800wtxm 12k Msds Eng이상훈No ratings yet

- Heat Fence Inorganic MineralsDocument3 pagesHeat Fence Inorganic MineralsmeNo ratings yet

- Material Safety Data SheetsDocument5 pagesMaterial Safety Data SheetsSuryanarayanan VenkataramananNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoNo ratings yet

- MSDS AlloysDocument15 pagesMSDS AlloysMaryam EradewiNo ratings yet

- Rci RodDocument2 pagesRci Rodabdul rochimNo ratings yet

- Material Safety Data Sheet: Emergency Phone Number: 1-866-272-4378Document1 pageMaterial Safety Data Sheet: Emergency Phone Number: 1-866-272-4378So MayeNo ratings yet

- K 87 009 - PrintDocument3 pagesK 87 009 - PrintVictor MoraesNo ratings yet

- 51 EX Msds 9-07Document3 pages51 EX Msds 9-07Mohamed AdelNo ratings yet

- Hot-Dip Galvanizing Material Safety Data SheetDocument5 pagesHot-Dip Galvanizing Material Safety Data SheetyeezeeNo ratings yet

- Flux Core Welding WireDocument3 pagesFlux Core Welding Wiremuhamad bukhari abu hassanNo ratings yet

- MsdsDocument3 pagesMsdsTobi MazzoccaNo ratings yet

- M S D S: Aterial Afety ATA HeetDocument4 pagesM S D S: Aterial Afety ATA HeetJhony MedranoNo ratings yet

- MSDS Er70s 6Document1 pageMSDS Er70s 6RosyidiMuhammadMahfudzNo ratings yet

- Lincoln 5P+ MsdsDocument2 pagesLincoln 5P+ MsdssalcabesNo ratings yet

- Product Name: Galvalume Sheet Severstal Sparrows Point LLCDocument4 pagesProduct Name: Galvalume Sheet Severstal Sparrows Point LLCT Bagus Tri LusmonoNo ratings yet

- M S D S: Aterial Afety ATA HeetDocument4 pagesM S D S: Aterial Afety ATA HeetJhony MedranoNo ratings yet

- Nic-L-Weld 99 59Document9 pagesNic-L-Weld 99 59CezaryCezasNo ratings yet

- 6010 Usf MSDS 12-06Document3 pages6010 Usf MSDS 12-06mohamed AdelNo ratings yet

- Material Safety Data Sheet: Section I - IdentificationDocument2 pagesMaterial Safety Data Sheet: Section I - IdentificationluisarmandomayonietoNo ratings yet

- Niti Wire SdsDocument4 pagesNiti Wire Sdsfernieves1409No ratings yet

- I. Product Identification: Material Safety Data SheetDocument5 pagesI. Product Identification: Material Safety Data SheetSteel BridgeNo ratings yet

- Material Safety Data Sheet: (Respirable Fraction)Document5 pagesMaterial Safety Data Sheet: (Respirable Fraction)Hernan GirautNo ratings yet

- Boron Nitrite MSDSDocument4 pagesBoron Nitrite MSDSRajaIshfaqHussainNo ratings yet

- Safety Data Sheet: 1. Product and Company IdentificationDocument4 pagesSafety Data Sheet: 1. Product and Company Identificationmohamed AdelNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoNo ratings yet

- Material Safety Data Sheet Gold - Core Material: Section 1: Product and Company IdentificationDocument4 pagesMaterial Safety Data Sheet Gold - Core Material: Section 1: Product and Company Identificationfabiosan5No ratings yet

- Brassmsds 2007Document4 pagesBrassmsds 2007api-256162920No ratings yet

- TruExterior MSDSDocument3 pagesTruExterior MSDS100livNo ratings yet

- 32 EX Msds 9-07Document3 pages32 EX Msds 9-07Mohamed AdelNo ratings yet

- ARCAIR (MSDS) COPPERCLAD POINTED ELECTRODES Expires 16-07-02Document3 pagesARCAIR (MSDS) COPPERCLAD POINTED ELECTRODES Expires 16-07-02PubcrawlNo ratings yet

- 1 TufTrak EC SMAW Msds 2-10Document3 pages1 TufTrak EC SMAW Msds 2-10mohamed AdelNo ratings yet

- 308L-16 EutectrodeDocument10 pages308L-16 EutectrodeJuan LondonoNo ratings yet

- Material Safety Data Sheet: I. Product IdentificationDocument2 pagesMaterial Safety Data Sheet: I. Product IdentificationElMacheteDelHuesoNo ratings yet

- Msds Dow 732 Sealant PDFDocument7 pagesMsds Dow 732 Sealant PDFJake WestlakeNo ratings yet

- OSHA 3136 - CadmiumDocument29 pagesOSHA 3136 - CadmiumWahed Mn ElnasNo ratings yet

- Rescocast 17EG MSDSDocument3 pagesRescocast 17EG MSDSRafael Rojas MeridaNo ratings yet

- Msds Product Name: Aws E7018 Welding ElectrodeDocument2 pagesMsds Product Name: Aws E7018 Welding ElectrodeAdel AbduoNo ratings yet

- Bezpečnostní List S-717 - EngDocument8 pagesBezpečnostní List S-717 - Engz9zsbwnnfvNo ratings yet

- Material Safety Data Sheet Material Safety Data Sheet: Section I - IdentificationDocument2 pagesMaterial Safety Data Sheet Material Safety Data Sheet: Section I - IdentificationAdel AbduoNo ratings yet

- 54L EutectrodeDocument9 pages54L EutectrodeJuan LondonoNo ratings yet

- Superinox 2C MSDS Ador WeldingDocument9 pagesSuperinox 2C MSDS Ador WeldingyogipatilNo ratings yet

- Material Safety Data Sheet: Brass Wire Brushes MSDS #12Document4 pagesMaterial Safety Data Sheet: Brass Wire Brushes MSDS #12LoveNo ratings yet

- CD Msds For Ups SeriesDocument4 pagesCD Msds For Ups Seriesapi-170472102No ratings yet

- Excel 2007 FunctionsDocument24 pagesExcel 2007 FunctionsPopescu AndreiNo ratings yet

- Fe-Fe3c Diagram VerygoodDocument3 pagesFe-Fe3c Diagram VerygoodRama Krishna Reddy DonthireddyNo ratings yet

- Aj 601Document25 pagesAj 601Rama Krishna Reddy DonthireddyNo ratings yet

- 000007Document34 pages000007Rama Krishna Reddy DonthireddyNo ratings yet

- Iocl Tank Spec F-601 Rev 0Document18 pagesIocl Tank Spec F-601 Rev 0Rama Krishna Reddy Donthireddy100% (1)

- E3 19 03 09Document7 pagesE3 19 03 09Rama Krishna Reddy DonthireddyNo ratings yet

- Iocl Shell & Tube He's Spec Ea-601 Rev 0Document5 pagesIocl Shell & Tube He's Spec Ea-601 Rev 0Rama Krishna Reddy DonthireddyNo ratings yet

- Ga 603Document9 pagesGa 603Rama Krishna Reddy DonthireddyNo ratings yet

- Nominal Pipe Size NPS, Nominal Bore NB, Outside Diameter ODDocument5 pagesNominal Pipe Size NPS, Nominal Bore NB, Outside Diameter ODRama Krishna Reddy DonthireddyNo ratings yet

- 1.2.1 Explanation of Flow DiagramsDocument26 pages1.2.1 Explanation of Flow DiagramsPratik100% (1)

- Top Links January 2018Document66 pagesTop Links January 2018Andrew Richard ThompsonNo ratings yet

- Tutorial QuestionsDocument4 pagesTutorial Questionsn01910077kNo ratings yet

- O/O Punjab Pollution Control Board, Vatavaran Bhawan, Nabha Road, Patiala - 147 001 Telefax:-0175-2215636Document11 pagesO/O Punjab Pollution Control Board, Vatavaran Bhawan, Nabha Road, Patiala - 147 001 Telefax:-0175-2215636Deepak Kumar YadavNo ratings yet

- Work Life BalanceDocument81 pagesWork Life BalanceMadhuSudan Mittal100% (1)

- HI TECH PROJECTS MagazineDocument36 pagesHI TECH PROJECTS MagazineeiribooksNo ratings yet

- DAF Theory 1Document3 pagesDAF Theory 1rvkumar61No ratings yet

- ORDINANCE NO. - S. 2021 (Proposed Ordinance No. - ) : Explanatory NoteDocument6 pagesORDINANCE NO. - S. 2021 (Proposed Ordinance No. - ) : Explanatory NoteRowie Tallo BorniaNo ratings yet

- C-9503 Loop Isolator Issue2.06Document2 pagesC-9503 Loop Isolator Issue2.06Agung Pramu AjiNo ratings yet

- Wiping of Oils and Emulsion FromDocument4 pagesWiping of Oils and Emulsion FromdoccohonNo ratings yet

- Excel Automatic Locking ScaffoldDocument30 pagesExcel Automatic Locking ScaffoldHendrias Ari SujarwoNo ratings yet

- Thermoplastic Promises New Pultrusion SynergiesDocument6 pagesThermoplastic Promises New Pultrusion Synergiesabilio_j_vieiraNo ratings yet

- SCIENCE 5 DLL Q1 wk1 D5Document6 pagesSCIENCE 5 DLL Q1 wk1 D5Yram Ecarg OudiserNo ratings yet

- TTT - D9R - TEKQ0417 Positive Pin Retention - SalesgramDocument2 pagesTTT - D9R - TEKQ0417 Positive Pin Retention - SalesgramStasNo ratings yet

- Treatment of Chlorophenols From Wastewaters by Advanced Oxidation ProcessesDocument34 pagesTreatment of Chlorophenols From Wastewaters by Advanced Oxidation Processesvijay kumarNo ratings yet

- Paper Vs PlasticDocument2 pagesPaper Vs Plasticapi-135713260No ratings yet

- Detection of Abnormal Conditions in Wastewater Treatment Plant Using Image Processing and AnalysisDocument37 pagesDetection of Abnormal Conditions in Wastewater Treatment Plant Using Image Processing and AnalysishorasiusNo ratings yet

- Third Periodical Test in Ia 6Document4 pagesThird Periodical Test in Ia 6Xyrel MendozaNo ratings yet

- CPCB Water Quality CriteriaDocument2 pagesCPCB Water Quality CriteriaHarikrishnan u.sNo ratings yet

- Project: Water Supply Layout Finals Drawn By: 20141142805 Date: 10/11/2018 Sheet No. 1 of 2Document1 pageProject: Water Supply Layout Finals Drawn By: 20141142805 Date: 10/11/2018 Sheet No. 1 of 2Jabber Reyes AmborNo ratings yet

- Rescocast 17 MSDSDocument3 pagesRescocast 17 MSDSgroovercm15No ratings yet