Professional Documents

Culture Documents

AA SM 205 003 Tools Joints Rivets

Uploaded by

Mani Rathinam Rajamani0 ratings0% found this document useful (0 votes)

107 views4 pagesAA SM 205 003 Tools Joints Rivets

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAA SM 205 003 Tools Joints Rivets

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

107 views4 pagesAA SM 205 003 Tools Joints Rivets

Uploaded by

Mani Rathinam RajamaniAA SM 205 003 Tools Joints Rivets

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 4

Author: R.

Abbott Document Number: AA-SM-003

Check: Revision Level : IR

Date: 20/10/2013 Page: 1 of 2

Title: BEAM IN A SOCKET METHOD

IMPORTANT INFORMATION

About us:

About Our Spreadsheets:

Proprietary information:

If you have any questions regarding legal issues please contact us at:

Things you have to know before using our Spreadsheets:

The Add-In is available for download at the top of this page:

Click on the link to download AA-SM-99-001

And Finally:

Find out more about the services we provide:

Put the .xlam file in the C:\Program Files (x86)\Microsoft Office\Office12\Library directory. Start Excel and install

the Add-in by following these instructions:

http://office.microsoft.com/en-ca/excel-help/add-or-remove-add-ins-HP010342658.aspx

www.abbottaerospace.com

The spreadsheets contain no proprietary information from outside of Abbott Aerospace Inc. If you think that we

have used proprietary information inappropriately please let us know.

Abbott Aerospace Inc. grants the user the right to use, modify, reproduce and redistribute these spreadsheets.

We just ask that if possible you maintain a credit naming Abbott Aerospace Inc. as the source.

Our analysis spreadsheets in general do not use Visual Basic routines. The MS Excel add-ins on the site are

written in visual basic and are password protected. They are password protected because the visual basic code

is proprietary, private, confidential and copyrighted to Abbott Aerospace Inc. The MS Excel add-in AA-SM-99-

001 which is made freely available may be copied and redistributed without charge.

enquiries@abbottaerospace.com

Our spreadsheets are provided without any restrictions on use - but the display of information on the screen

does rely on a free Excel Add-In we created that displays equations easily. The mathematics of the spreadsheets

wil work fine without the free Add-in but the spreadsheets may display many errors.

http://www.abbottaerospace.com/Welcome/Spreadsheets

spreadsheets@abbottaerospace.com

We help people develop new aircraft structure and systems and make modifications to existing structure and

systems. We do all types of aircraft - Part 23, Part 25, Civil, Military, Prototype, Experimental - and have

extensive experience with composite laminate material selection, process control, manufacture, design,

substantiation and certification.

We love to do things right first time and get the job done as quickly and completely as possible

Our in-house structural analysis toolbox is our collection of spreadsheets. The sheets that we make available on

our website are a small proportion of the sheets that we have developed for our own use.

They are intended to be used by engineers. They are not protected software packages and can be changed in

every way by the user.

All of our spreadsheets are provided 'as is' with no warranty or guarantee explicitly given or implied. We have

made every reasonable effort to remove all errors but some may still exist and all analysis work should be

thoroughly checked. If you do find errors plese notify us at:

ABBOTT AEROSPACE INC. PROPRIETARY INFORMATION

Subject to restrictions on the cover or first page

Author: R. Abbott Document Number: AA-SM-205-003

Check: Revision Level : A

Date: Dec-09 Page: 1 of 1

Rivets

Ref: MMPDS Metallic Materials Properties Development and Standardization

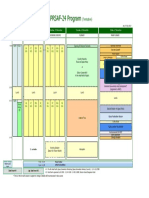

Rivet Rivet Drill Nominal

Size Size No. Hole Dia. AD D DD M

[in] [in] [in] 2117-T4 2017-T4 2024-T4 Monel

1/16 0.063 51 0.067 106 134 145 183

3/32 0.094 41 0.096 217 275 297 376 Table 8.1.2(a).

1/8 0.125 30 0.1285 389 493 532 674 and

5/32 0.156 21 0.159 596 755 814 1030 Table 8.1.2(b).

3/16 0.188 11 0.191 860 1085 1175 1490

1/4 0.250 F 0.257 1555 1970 2125 2695

5/16 0.313 P 0.323 2455 3115 3360 4260

3/8 0.375 W 0.386 3510 4445 4795 6085

Fig. 1 Standard Rivet-Hole Drill Sizes and Nominal Hole Diameters

Single Shear Strength [lbs]

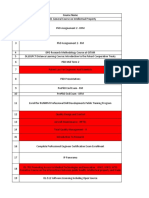

In computing protruding-head rivet design shear strengths, the shear strength values obtained from

Table 8.1.2(b) should be multiplied by the correction factors given in Table 8.1.2.1(b). This

compensates for the reduction in rivet shear strength resulting from high bearing stresses on the rivet

at t/D ratios less than 0.33 for single-shear joints and 0.67 for double-shear joints.

ABBOTT AEROSPACE INC. PROPRIETARY INFORMATION

Subject to restrictions on the cover or first page

Author: R. Abbott Document Number: AA-SM-205-003

Check: Revision Level : A

Date: Dec-09 Page: 2 of 1

Rivets

Sheet

Thickness

[in] 1/16 3/32 1/8 5/32 3/16 1/4 5/16 3/8

0.016 0.964

0.018 0.981 0.912

0.020 0.995 0.933

0.025 1.000 0.970 0.920

0.032 1.000 1.000 0.964 0.925

0.036 1.000 1.000 0.981 0.946 0.912

0.040 1.000 1.000 0.995 0.964 0.933

0.045 1.000 1.000 1.000 0.981 0.953

0.050 1.000 1.000 1.000 0.995 0.970 0.920

0.063 1.000 1.000 1.000 1.000 1.000 0.961 0.922

0.071 1.000 1.000 1.000 1.000 1.000 0.979 0.944 0.909

0.080 1.000 1.000 1.000 1.000 1.000 0.995 0.964 0.933

0.090 1.000 1.000 1.000 1.000 1.000 1.000 0.981 0.953

0.100 1.000 1.000 1.000 1.000 1.000 1.000 0.995 0.972

0.125 1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.000

Sheet

Thickness

[in] 1/16 3/32 1/8 5/32 3/16 1/4 5/16 3/8

0.016 0.687

0.018 0.744 0.518

0.020 0.789 0.585

0.025 0.870 0.708 0.545

0.032 0.941 0.814 0.687 0.560

0.036 0.969 0.857 0.744 0.630 0.518

0.040 0.992 0.891 0.789 0.687 0.585

0.045 1.000 0.924 0.834 0.744 0.653

0.050 1.000 0.951 0.870 0.789 0.708 0.545

0.063 1.000 1.000 0.937 0.872 0.808 0.679 0.550

0.071 1.000 1.000 0.966 0.909 0.852 0.737 0.622 0.508

0.080 1.000 1.000 0.992 0.941 0.891 0.789 0.687 0.585

0.090 1.000 1.000 1.000 0.969 0.924 0.834 0.744 0.653

0.100 1.000 1.000 1.000 0.992 0.951 0.870 0.789 0.708

0.125 1.000 1.000 1.000 1.000 1.000 0.935 0.870 0.805

0.160 1.000 1.000 1.000 1.000 1.000 0.992 0.941 0.891

0.190 1.000 1.000 1.000 1.000 1.000 1.000 0.981 0.939

0.250 1.000 1.000 1.000 1.000 1.000 1.000 1.000 1.000

Table 2 Table 8.1.2.1(b). Shear Strength Correction Factors for Solid Protruding Head Rivets (*)

(*) Sheet thickness is that of the thinnest sheet in single-shear joints and the middle

sheet in double-shear joints. Values based on tests of aluminum rivets, Reference 8.1.

Single-Shear Rivet Strength Factors

Double-Shear Rivet Strength Factors

ABBOTT AEROSPACE INC. PROPRIETARY INFORMATION

Subject to restrictions on the cover or first page

Author: R. Abbott Document Number: AA-SM-205-003

Check: Revision Level : A

Date: Dec-09 Page: 3 of 1

Rivets

Sheet

Thickness

[in] 1/16 3/32 1/8 5/32 3/16 1/4 5/16 3/8

0.012 80

0.016 107

0.018 121 173

0.020 134 192 See Note 2

0.025 168 240 321

0.032 214 307 411 509

0.036 241 346 462 572 688

0.040 268 384 514 636 764

0.045 302 432 578 716 860

0.050 335 480 642 795 955 1285

0.063 422 605 810 1002 1203 1619 2035

0.071 476 682 912 1129 1356 1825 2293 2741

0.080 536 768 1028 1272 1528 2056 2584 3088

0.090 603 864 1156 1431 1719 2313 2907 3474

0.100 670 960 1285 1590 1910 2570 3230 3860

0.125 838 1200 1606 1988 2388 3212 4038 4825

0.160 1072 1536 2056 2544 3056 4112 5168 6176

0.190 1273 1824 2442 3021 3629 4883 6137 7334

0.250 1670 2400 3210 3975 4775 6425 8075 9650

Table 2 Table 8.1.2.1(a). Unit Bearing Strength of Sheet on Rivets, F

br

= 100 ksi

(based on nominal hole diameters)

Rivet = AD Rivet Type

D = 3/8 in Nominal Rivet Hole Diameter

t = 0.071 in Sheet Thickness

Material = 2024-T3 Clad

F

bru

= 127 ksi Ultimate Bearing Strength

Joint = SS SS = Single Shear, DS = Double Shear

P = 3510 lbs Uncorrected Rivet Shear Strength

a = 0.909 Single-Shear Rivet Strength Factor

P

RS

= 3191 lbs Corrected Rivet Shear Strength

P

BR

= 3481 lbs Ultimate Sheet Bearing Strength

P

ALL

= 3191 lbs Joint Allowable, min(P

RS

, P

BR

)

The joint is shear critical.

Unit Bearing Strength for Indicated Rivet Diameter [lbs]

ABBOTT AEROSPACE INC. PROPRIETARY INFORMATION

Subject to restrictions on the cover or first page

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Pronto Plant Maintenance V700 PDFDocument155 pagesPronto Plant Maintenance V700 PDFRonald Chandhla100% (3)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ProgramDocument1 pageProgramMani Rathinam RajamaniNo ratings yet

- Catalog For Bearing DesignDocument70 pagesCatalog For Bearing DesignHameer ReddyNo ratings yet

- Product, Process, and Problem Analysis Quality SystemDocument25 pagesProduct, Process, and Problem Analysis Quality SystemMani Rathinam RajamaniNo ratings yet

- List of Certifications DiscontinuedDocument30 pagesList of Certifications DiscontinuedMani Rathinam RajamaniNo ratings yet

- M.SC Result 2017Document1 pageM.SC Result 2017Mani Rathinam RajamaniNo ratings yet

- Leave PlanDocument2 pagesLeave PlanMani Rathinam RajamaniNo ratings yet

- Computer Aided Process Planning Techniques: Mani Rathinam Rajamani PHD RoadmapDocument6 pagesComputer Aided Process Planning Techniques: Mani Rathinam Rajamani PHD RoadmapMani Rathinam RajamaniNo ratings yet

- TL 9000 Quality Management System Measurements Handbook NPR ExamplesDocument7 pagesTL 9000 Quality Management System Measurements Handbook NPR ExamplesMani Rathinam RajamaniNo ratings yet

- D. All of The AboveDocument3 pagesD. All of The AboveramarajanenggNo ratings yet

- Payment Acknowledgment - 180604092233Document1 pagePayment Acknowledgment - 180604092233Mani Rathinam RajamaniNo ratings yet

- LSS Mani Rathinam RajamaniDocument2 pagesLSS Mani Rathinam RajamaniMani Rathinam RajamaniNo ratings yet

- Join The Big Family. Sign Up Is Open For The Time Being... Join Us!!!!Document1 pageJoin The Big Family. Sign Up Is Open For The Time Being... Join Us!!!!Mani Rathinam RajamaniNo ratings yet

- Learning Plan Dec 2017-Apr 2018Document5 pagesLearning Plan Dec 2017-Apr 2018Mani Rathinam RajamaniNo ratings yet

- AS9100 Certification StatusDocument192 pagesAS9100 Certification StatusMani Rathinam RajamaniNo ratings yet

- Month Wise NC TrendDocument2 pagesMonth Wise NC TrendMani Rathinam RajamaniNo ratings yet

- 3x5 Why Worksheet For SuppliersDocument1 page3x5 Why Worksheet For SuppliersMani Rathinam RajamaniNo ratings yet

- Minitab Print Window PDFDocument1 pageMinitab Print Window PDFMani Rathinam RajamaniNo ratings yet

- Flight 1 Mon, Mar 4: Cathay PacificDocument6 pagesFlight 1 Mon, Mar 4: Cathay PacificMani Rathinam RajamaniNo ratings yet

- Letter acknowledges participation in checklist developmentDocument1 pageLetter acknowledges participation in checklist developmentMani Rathinam RajamaniNo ratings yet

- Fod Compliance & Findings - Bay 1Document2 pagesFod Compliance & Findings - Bay 1Mani Rathinam RajamaniNo ratings yet

- How to Prepare Your Manuscript CertificateDocument1 pageHow to Prepare Your Manuscript CertificateMani Rathinam RajamaniNo ratings yet

- VSM TemplateDocument7 pagesVSM TemplateMani Rathinam RajamaniNo ratings yet

- BCB 201 (IB) - Mar 2019 PDFDocument38 pagesBCB 201 (IB) - Mar 2019 PDFMani Rathinam RajamaniNo ratings yet

- Matecconf Imanee2018 08013Document6 pagesMatecconf Imanee2018 08013Mani Rathinam RajamaniNo ratings yet

- BCB 501 (O&G) - Competence Requirements For Inspection Bodies For Accreditation Against PNGRB Regulations PDFDocument10 pagesBCB 501 (O&G) - Competence Requirements For Inspection Bodies For Accreditation Against PNGRB Regulations PDFMani Rathinam RajamaniNo ratings yet

- 09 - Chapter 3Document11 pages09 - Chapter 3Mani Rathinam RajamaniNo ratings yet

- Standards Made Available Free of Cost To Combat COVID-19Document4 pagesStandards Made Available Free of Cost To Combat COVID-19Mani Rathinam RajamaniNo ratings yet

- BCB 110 (IB) - NABCB Accreditation Criteria For IBs - Mar 2017 PDFDocument8 pagesBCB 110 (IB) - NABCB Accreditation Criteria For IBs - Mar 2017 PDFMani Rathinam RajamaniNo ratings yet

- BCB 110 (IB) - NABCB Accreditation Criteria For IBs - Mar 2017 PDFDocument8 pagesBCB 110 (IB) - NABCB Accreditation Criteria For IBs - Mar 2017 PDFMani Rathinam RajamaniNo ratings yet

- How to Prepare Your Manuscript CertificateDocument1 pageHow to Prepare Your Manuscript CertificateMani Rathinam RajamaniNo ratings yet

- Report (Final) 222 PDFDocument62 pagesReport (Final) 222 PDFNavin KumarNo ratings yet

- SystemVerilog DPI TutorialDocument6 pagesSystemVerilog DPI TutorialLiudeNo ratings yet

- ARMS TSA Brochure Final 4Document2 pagesARMS TSA Brochure Final 4Hugo AlemanNo ratings yet

- REST API Developer Guide: Version 48.0, Spring '20Document281 pagesREST API Developer Guide: Version 48.0, Spring '20MonrealNo ratings yet

- Datasheet MX 880Document3 pagesDatasheet MX 880jorge_chavez01No ratings yet

- Cloud Pricing Models: Taxonomy, Survey, and Interdisciplinary ChallengesDocument51 pagesCloud Pricing Models: Taxonomy, Survey, and Interdisciplinary Challengesmcclaink06No ratings yet

- HP LJ P2035 P2055 PartslistDocument21 pagesHP LJ P2035 P2055 PartslistalbathorresNo ratings yet

- Jiw 19.3 0Document138 pagesJiw 19.3 0Teppo TammivuoriNo ratings yet

- Lab Exercise 12 - Read JSON Using PyQtDocument3 pagesLab Exercise 12 - Read JSON Using PyQthiteshNo ratings yet

- Ac158a Rem Dec02Document21 pagesAc158a Rem Dec02Your Brand New LookNo ratings yet

- Backup Script DocumentationDocument22 pagesBackup Script DocumentationJuan CarlosNo ratings yet

- Bangalore Jobs 30 JulyDocument8 pagesBangalore Jobs 30 Julyabhimanyu thakurNo ratings yet

- METHOD OF PROCEDURE FOR LTE G2-OSS L17A UpgradeDocument18 pagesMETHOD OF PROCEDURE FOR LTE G2-OSS L17A UpgradeEdu Mmoja Mutai100% (1)

- SMMDocument5 pagesSMMAnkitNo ratings yet

- Agfa CR 35-XDocument82 pagesAgfa CR 35-XPaulo PortelaNo ratings yet

- VACON-ADP-MCAA adapter guideDocument10 pagesVACON-ADP-MCAA adapter guideSharad Soni0% (1)

- Git Cheat SheetDocument1 pageGit Cheat Sheetkzelda100% (1)

- Hacking With AndroidDocument12 pagesHacking With Androidd3referencedNo ratings yet

- Improving Disassembly and DecompilationDocument88 pagesImproving Disassembly and DecompilationAndrea OliveriNo ratings yet

- 8760Document5 pages8760VinNo ratings yet

- TLE 7 1st Quarter Exam SY 2022-2023Document3 pagesTLE 7 1st Quarter Exam SY 2022-2023dodongmakattigbasNo ratings yet

- Um en Visu Vba 8162 en 23 PDFDocument1,269 pagesUm en Visu Vba 8162 en 23 PDFAMR SiderurgicosNo ratings yet

- r05321204 Data Warehousing and Data MiningDocument5 pagesr05321204 Data Warehousing and Data MiningSRINIVASA RAO GANTANo ratings yet

- 10 Hybris Spring AOPDocument4 pages10 Hybris Spring AOPravikanchuNo ratings yet

- How To Design The Perfect PCBDocument33 pagesHow To Design The Perfect PCBDiego Ricardo Paez ArdilaNo ratings yet

- Error Correcting Codes: Oon Boey Lay Rujukan: Emm400 Studyguidefa Emm400Tasks&Solns1Document37 pagesError Correcting Codes: Oon Boey Lay Rujukan: Emm400 Studyguidefa Emm400Tasks&Solns1Noranisah Binti NakimNo ratings yet

- PLC Based Induction Motor Fault Detection TechniqueDocument7 pagesPLC Based Induction Motor Fault Detection Techniquedhaval2430No ratings yet

- Linsn LED Studio User ManualDocument94 pagesLinsn LED Studio User Manualmuhammad salimNo ratings yet

- Example Curriculum VitaeDocument4 pagesExample Curriculum VitaeGugun NugrahaNo ratings yet