Professional Documents

Culture Documents

3m Brochure

Uploaded by

api-220815031Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3m Brochure

Uploaded by

api-220815031Copyright:

Available Formats

Innovation

A Culture of

Research & Development:

3M invests generously in research & development

to fuel the innovation pipeline.

Throughout history, many great thinkers have embraced the

maxim that the best way to predict the future is to create it. In

this regard, 3Ms business model is to foster organic growth

by inventing new products that previously did not exist. This

business model has led not only to new products, but also the

creation of new industries, such as coated abrasives, pressure

sensitive tapes, nonwoven respirators and uoromaterials. In

order to foster such growth, the company recognizes the value of

Research & Development (R&D) and allocates approximately six

percent of its yearly revenue to R&D.

Large Aperture Trough (LAT) 73 uses

3M Solar Mirror Film 1100 as a reective

surface and a frame support structure custom

designed by Gossamer Space Frames. The

result is an easy to assemble parabolic trough

collector with the largest working aperture

and the highest geometric concentration ratio

in the world today.

Introduced in 2009, the 3M

Littman

Electronic Stethoscope Model 3200 uses

Bluetooth technology to wirelessly transfer

heart, lung and other body sounds to software

for further analysis.

For more than a century, innovation has

been the hallmark of 3Ms growth,

reecting a culture of shared ideas

and technology. 3M Innovation

enables 3M to continuously deliver

practical and ingenious solutions

to everyday problems around the

world on a daily basis.

Innovation

A Culture of

3M tinkered with 3M

Scotchlite

Reective

Material for eight years before perfecting

the technology. Over the decades, its uses

multiplied and spurred the creation of its own

division in 1943, grossing about $10 million by

1953. Today, Scotchlite reective material is still

a protable product for 3Ms Safety, Security,

and Protection Services Business, as well as for

the Industrial and Transportation Business.

Filtek

Supreme, a dental product that easily

matches natural tooth color, was a huge risk for

3M because it utilized nanotechnology at a time

when its success was largely unproven. The risk

paid off. 3M is now a leading dental composite

provider around the world.

3M Corporate Scientists utilized 3Ms 15

Percent Time and Genesis Grants to invent

Multilayer Optical Films. 3Ms Multilayer

Optical Films have grown into an entire light

management technology platform that is

utilized in multiple 3M products sold in ve

different divisions.

Bold Talent:

3M encourages risk-taking and persistence.

In todays fast-paced, pressure-packed business climate, many

companies take a very short-term approach to the new product

development pipeline. Because innovation does not occur on a

set timeline, 3M takes a different path thanks in large part to

the principles that former CEO, William L. McKnight instilled in

the company. McKnight believed in the imperatives of hiring the

right people, tolerating mistakes and giving employees freedom

to explore in order to foster a culture of innovation. 3M has put

the McKnight Principles into practice by encouraging employees

to dedicate a signicant portion of their time to projects and

research that go beyond their core responsibilities. Although it

may take years for such innovative tinkering to bear fruit, the

results of 3Ms storied 15 Percent Time are truly remarkable.

Examples include Scotch

Brand Tapes, Post-it

Notes,

Scotchgard

Fabric Protector, automobile window treatment

lms, multilayer optical lms and silicon adhesive systems for

transdermal drug delivery.

1

3 4

5 6

2

Microreplication at 3M

Microreplication has spread to virtually every

business in 3M. Here are some examples:

1 Reective materials (such as 3M

Diamond

Grade

Reective Sheeting) 2 Abrasives

(3M

Trizact

Abrasives) 3 Scotch

Fur

Fighter

Hair Remover 4 Various optical

lms (3M

Brightness Enhancement Film)

5 Adhesives (3M

Comply

Adhesive used

in graphics and automotive blackout lms)

6 Microneedles used in transdermal drug

delivery products

Over the years, the 3M nonwovens technology

platform has migrated across several

industries and has been applied to create

hundreds of 3M products.

3M Non-Woven

Technology Platforms

3M initially developed the Pentamix

Automatic Mixing Unit technology

for dental application with crown moldings. Recognizing that such

technology could be applied to solve similar challenges in automotive

body shops, 3M shared this technology across divisions. 3M Dynamic

Mixing System is now a highly protable product line for 3Ms

automotive business.

Diverse Technologies:

3M creates uncommon connections with

access to multiple 3M technologies.

No company can match the breadth and depth of 3Ms more

than 40 technology platforms in as many combinations, for as

many purposes across as many geographies. With more than

55,000 products, 3M continues to demonstrate an uncanny

ability to combine highly innovative technologies in new and

unexpected ways. Imagine dental technology applied to car

parts, or nonwoven technology incorporated into kitchen

cleaning tools and respirators. 3M has also pioneered unique

ways to migrate its microreplication, adhesives and a multitude

of other technologies to develop innovative solutions to everyday

problems. While such innovation often yields end-user products,

3Ms rich pool of technology is also incorporated into a vast

array of solutions developed by outside partners, making

their products more innovative and their businesses

more successful.

Every company seeks

the keys to innovation, but

few nd them. Over the

decades, 3M learned how

to be innovative and today

the company uses that

skill to great competitive

advantage.

Jerry I. Porras,

Co-author, Built to Last

Every year, 3M holds its Tech Forum event

where all 9,200 members of the 3M technical

community from around the world gather

together to share ideas.

Robust Network:

3M scientists share ideas

and practices on a global scale.

Applying innovative technology across a global company as

diversied as 3M presents not only great opportunity, but

also substantial challenge. As a company with more than

85,000 employees and operations in more than 60 countries

worldwide, new developments are happening every day. Thats

why communication plays as important a role as technical

skill enabling innovation to ourish without boundaries. For

example, members of 3Ms science community ignite the engine

of innovation through the 3M Technical Forum. Founded in 1951,

the Technical Forum unites more than 9,000 members of the 3M

technical community, including theoretical mathematicians, human

factors engineers, biological psychologists and scientists from

around the world. This culture of cooperation, communication and

cross-pollination of ideas among marketers, scientists and other

employees generates enthusiasm to share technologies and best

practices across 40 business units and 30 research labs around

the world.

3M has fostered a culture of

For more than 100 years,

creativity and

new ideas.

Innovation is more than just a bright idea; it is an

idea that gets implemented and has a real impact.

In other words, somebody has to make it happen.

Ernest Gundling,

Author, The 3M Way to Innovation:

Balancing People and Prot

Scott Cullers leadership in innovative

technology and product development has

re-energized one of 3Ms oldest businesses:

Abrasive Systems Division. On more than

one occasion, his work had game-changing

impact on the abrasives industry, specically

with the launches of the 3M

Trizact

line

of structured abrasive products and 3M

Cubitron

II Fibre Discs and Belts utilizing

new shaped Cubitron

mineral. Both product

lines leverage microreplication technology

to achieve precision and performance that

are unparalleled by conventional coated

abrasives constructions.

Andrew J. Ouderkirk identied and created

multilayer optical lms a major new 3M

technology product platform. His visionary

leadership, creativity, foresight, persistence

and guidance resulted in several revolutionary

new product families. He created the

technology, led development efforts,

identied applications and championed

new businesses.

Carlton Award Recipients

Celebrated Experts:

3M rewards employees who drive

innovation forward.

3M was one of the rst companies to create a dual career

ladder for scientists and managers that offered the 3M technical

community the same prestige, compensation and perks as

corporate management. 3M also rewards its innovators through

several technical achievement programs, such as the Circle of

Technical Excellence & Innovation, Genesis Grants Program and

the Carlton Society. The Carlton Society, named after former 3M

President Richard P. Carlton, was created in 1963 to honor top 3M

scientists who develop innovative new products and contribute to

the companys culture of innovation in myriad ways. To date, more

than 160 scientists have been inducted into the Carlton Society,

which serves as an enduring reminder that innovation is cherished

throughout 3M and remains integral to the companys success.

The Carlton Award, named for President

Richard P. Carlton, is given to technical

employees who demonstrate innovation

and collaborative research.

Customer Connection:

3M develops products tied to unmet

and often unarticulated customer and

consumer needs.

Oftentimes, the most successful new products arise from an unmet

and sometimes unarticulated customer or consumer need.

3M stays ahead of the curve by regularly conducting empirical

research and maintaining strong relationships with customers

and consumers on a regional, national and global scale. In fact,

3M has more than 30 Innovation/Customer Technical Centers

around the world that are dedicated solely to conducting innovation

processes with customers. Scientists and researchers observe

behaviors, identify needs and take their thoughts back to the lab to

marry new ideas with sophisticated technologies to ignite the next

spark of innovation.

Measured Success:

3M measures accountability for investments.

To enhance accountability for 3Ms sizeable investments in

R&D, the company sets various benchmarks for success and

accountability. In addition to measuring nancial success derived

from new product growth, 3M looks at other areas such as

business processes and intellectual property. For example, 3M

regularly assesses how quickly a product comes to market,

which technologies show the most growth opportunities and

the number of patents issued. Through these various measures

of accountability, 3M is better able to manage the return on

investment for processes related to innovation.

3M introduced the Scotch

Pop-up tape

dispenser with pre-cut strips of tape after

observing consumers lining up strips of tape

when gift-wrapping.

After observing college students switch

between tasks of marking pages and

highlighting text in their books, 3M innovators

developed a 2-in-1 solution with the

Post-it

Flag+Highlighter to help aid

productivity when studying. The invention

has since led to an entire product line of

writing tools from the Post-it

brand.

Innovation/Customer Technical Centers

Igniting the Spark of

Innovation Around

the World

3M operates laboratories in over thirty

countries and has more than 30 Innovation/

Customer Technical Centers around the

world. These Centers draw upon 3Ms global

R&D strength and forty-ve technology

platforms to engage and collaborate with

customers putting innovations to work

to help to meet their needs.

Argentina

Australia

Brazil

Canada

China

Colombia

France

Germany

Iberia

India

Indonesia

Italy

Japan

Korea

Malaysia

Mexico

Netherlands

Peru

Philippines

Poland

Russia

Singapore

South Africa

Taiwan

Thailand

United Arab Emirates, Dubai

United Kingdom

USA

Venzuela

Vietnam

3M Historical

Timeline Highlights:

For more than 100 years, 3M has

been a pioneer in innovation and the

advancement of new technologies.

1902 3M founded in Two Harbors, MN, on

June 13, when ve founders sign articles

of incorporation.

1906 First sandpaper sale to South Bend

Toy Co. totals $2.

1907 3M hires 20-year-old business student,

William L. McKnight, who later became 3Ms

president and rst chairman of the board.

1916 First 3M laboratory established; 3M

Headquarters moves to St. Paul, MN.

1919 Annual sales exceed $1 million.

1921 3M Wetordry

Waterproof Sandpaper

the worlds rst water-resistant coated

abrasive is patented and introduced.

1925 Richard G. Drew, a young lab assistant,

invented Scotch

masking tape and the

Scotch

brand tape product line was born.

1

9

0

0

s

1

9

1

0

s

1

9

2

0

s

1

9

3

0

s

1

9

4

0

s

1930 Scotch

cellophane rst introduced.

1936 Adhesives Division established in Detroit;

adhesives plant and laboratory opened.

1937 The Central Research Laboratory is

established to pursue research in technologies

with long term potential. Here the rst

successful test of reective tape coated

with glass beads is conducted.

1939 First trafc sign featured Scotchlite

reective sheeting erected in Minneapolis.

1945 Supported by Bing Crosby, 3M

Sound Recording Tape revolutionizes the

entertainment industry.

1947 New plants opened in Hutchinson, MN

(tape); Los Angeles, CA (adhesives); and Little

Rock, AR (roong granules).

1948 3Ms rst nonwoven product

decorative ribbon for gifts introduced.

1951 3M establishes its International Division;

new companies are created in Australia, Brazil,

Canada, France, Germany, Mexico and the

United Kingdom.

1

9

5

0

s

1953 3M breaks ground for rst new

corporate headquarters (3M Center), building

on a 325-acre site east of St. Paul.

1954 RCA uses Scotch magnetic tape to

record TV programs for the rst time.

1954 U.S. Post Ofce eet vehicles carry

Scotchlite

reective decals for trafc safety.

1956 3M introduces Scotchgard

fabric and

upholstery protector to the textile industry.

1960 Micropore

surgical tape, the rst

hypo-allergenic tape, is introduced and

transforms 3M Health Care business.

1961 Manufacturing plants established in 12

countries: Argentina, Australia, Brazil, Canada,

Colombia, United Kingdom, France, Germany,

Japan, South Africa, Spain and Mexico.

1961 Scotch

Magic

transparent tape

introduced.

1963 The Carlton Society is created to honor

career technical contributions.

1967 3M develops the rst disposable face-

masks and respiratory protection products.

1

9

6

0

s

1969 3M products are used in the rst moon

walk on July 20; Astronaut Neil Armstrong leaves

a footprint on lunar dust in boots made from

Fluorel

synthetic rubber from 3M.

1970 New products include Scotchban

Paper

Treatment to protect food packaging and 3M box

sealing tapes.

1973 Former 3M president William L. McKnight

retires from the Board of Directors, ending 66

years of service to 3M.

1977 3M Consumer Product Group established.

1978 Red 3M logo introduced.

1979 Thinsulate

Thermal Insulation introduced.

1980 Canary Yellow Post-It

Notes are

introduced nationally in the United States.

1984 3M and NASA announce joint research

program exploring manufacturing in space; In

November, rst 3M research experiments are

conducted on space shuttle Discovery.

1984 Genesis program announced to encourage

technical entrepreneurship in research and new

product development.

1

9

7

0

s

1

9

8

0

s

2

0

0

0

s

1985 First refastenable diaper tapes

introduced by 3M.

1985 Academy of Motion Picture Arts and

Sciences gives 3M a Scientic Engineering

Award for magnetic lm that improves audio

capabilities of movie soundtracks.

1985 The U.S. Food and Drug Administration

approves the sale of 3Ms Tambocor

, a drug

that controls irregular heartbeats.

1988 3M is worldwide sponsor of the

Olympic Games.

1990 3M introduces Pacing Plus product

development programs that receive priority

funding to speed product development.

1991 3M introduces Scotchshield

window

lm, shatter-resistant, heat- and cold-resistant

window protection.

1995 3M receives the National Medal

of Technology the highest award

bestowed by the U.S. president for

technological achievement.

1995 3M introduces the rst metered dose

asthma inhaler free of ozone-depleting

chlorouorocarbons.

1997 Dental Products Division receives

the Malcolm Baldrige National Quality

Award, the most coveted quality award in

American business.

1999 3M reorganizes into six business

segments: Industrial; Transportation; Graphics

and Safety; Health Care; Consumer and

Ofce; Electro and Communications; and

Specialty Material.

2000 3M grows portfolio of light management

products that make electronic displays easier

to read.

2001 3M Acceleration Program introduced to

generate greater returns from R&D.

2002 3Mers around the world proudly

celebrated 3Ms 100th anniversary as a

Century of Innovation.

2002 Minnesota Mining and Manufacturing

Company ofcially changes its name to 3M.

2008 3M scientists develop a breakthrough

ultra-compact, LED-illuminated projection engine

for integration in personal electronic devices.

2012 3M and Gossamer Space Frames

unveil the worlds largest aperture trough

using 3M Solar Mirror Film 1100 for

concentrated solar power.

1

9

9

0

s

Michael Johnson wins

gold in the 2000 Olympics

400-meter sprint wearing shoes

made from 24-carat gold 3M

Scotchlite

Reective Material developed by 3M.

Our Vision

3M Technology Advancing Every Company

3M Products Enhancing Every Home

3M Innovation Improving Every Life

Corporate Headquarters

3M Center

St. Paul, MN 55144-1000

USA

651-733-1110

www.3M.com

3M is a trademark of 3M.

Please recycle. Printed in USA

3M 2012. All rights reserved

www.3M.com

You might also like

- The Management of Additive Manufacturing: Enhancing Business ValueFrom EverandThe Management of Additive Manufacturing: Enhancing Business ValueNo ratings yet

- 3M Case Study Ed 6 PDFDocument2 pages3M Case Study Ed 6 PDFAnonymous mJTxAbdNo ratings yet

- 3M Tech Forum - BackgrounderDocument2 pages3M Tech Forum - Backgroundertseminara1No ratings yet

- Minnesota Mining and Manufacturing Company: Institute of Business and TechnologyDocument12 pagesMinnesota Mining and Manufacturing Company: Institute of Business and TechnologyMuhammad BilalNo ratings yet

- What Makes 3M One of The Most Sustainable Innovators in The World?Document8 pagesWhat Makes 3M One of The Most Sustainable Innovators in The World?Bahadur ShahNo ratings yet

- MuiztDocument7 pagesMuiztMuhammed RasidNo ratings yet

- Innovation)Document15 pagesInnovation)bhavuk4No ratings yet

- 3 Way To InnovtionDocument15 pages3 Way To InnovtionSneha ChatterjeeNo ratings yet

- © 2008 Professor Pal Burns. Extract From: Corporate Entrepreneurship: Building The Entrepreneurial Organization (2 Edition), Paul Burns, Palgrave Macmillan, 2008Document0 pages© 2008 Professor Pal Burns. Extract From: Corporate Entrepreneurship: Building The Entrepreneurial Organization (2 Edition), Paul Burns, Palgrave Macmillan, 2008snafarooqiNo ratings yet

- The Innovation Mindset in Action - 3M CorporationDocument6 pagesThe Innovation Mindset in Action - 3M CorporationNamita DeyNo ratings yet

- By M.Zeeshan Sheikh (420) Al-Nassar Surani (51750) Syed Akbar Ali (51989)Document19 pagesBy M.Zeeshan Sheikh (420) Al-Nassar Surani (51750) Syed Akbar Ali (51989)Ashal KhanNo ratings yet

- Case StudyDocument4 pagesCase StudymizicebolNo ratings yet

- 3M HistoryDocument3 pages3M HistoryOwlNo ratings yet

- 3 M Project ReportDocument41 pages3 M Project ReportAtif AliNo ratings yet

- 3M's Organizational CultureDocument7 pages3M's Organizational CultureKaran Vashee100% (2)

- 3M0280 3M PSD Catalogue 2018 - 19 - ALL - FA - LR - Final (Single Pages) - Full LoRes 15nov17Document244 pages3M0280 3M PSD Catalogue 2018 - 19 - ALL - FA - LR - Final (Single Pages) - Full LoRes 15nov17Nathan NadavNo ratings yet

- Entrepreneurship: 3M InnovationDocument14 pagesEntrepreneurship: 3M InnovationNoorazian NoordinNo ratings yet

- 3 MDocument3 pages3 MCusio WoNo ratings yet

- 2011 NZ Innovation Council 3M Innovation StoryDocument21 pages2011 NZ Innovation Council 3M Innovation StorycjpatinomisenaNo ratings yet

- 3M'S Organizational CultureDocument19 pages3M'S Organizational CultureDivya GirishNo ratings yet

- Innovation at 3M CorporationDocument28 pagesInnovation at 3M Corporationsanazh100% (1)

- 3M PresentationDocument18 pages3M PresentationMuhammad BilalNo ratings yet

- 3M CorpDocument10 pages3M CorpNichole WilliamsNo ratings yet

- 3 M InnovationDocument2 pages3 M InnovationIoanna ThayrenNo ratings yet

- Organiza C5 - 3M India For IndiaDocument17 pagesOrganiza C5 - 3M India For IndiaDivya GiriNo ratings yet

- Presented By: Nandhini.TDocument31 pagesPresented By: Nandhini.TNandhini PandianNo ratings yet

- FortuneDocument4 pagesFortunemanishNo ratings yet

- 3M: Profile of A PioneerDocument15 pages3M: Profile of A PioneerPriyanka PradhanNo ratings yet

- Evolution of Additive ManufacturingDocument20 pagesEvolution of Additive ManufacturingVaibhav KatharNo ratings yet

- Masters of Innovation: How 3M Keeps Its New Products Coming: Lose SomeDocument7 pagesMasters of Innovation: How 3M Keeps Its New Products Coming: Lose SomeAbhishek KunduNo ratings yet

- 3M PDFDocument19 pages3M PDFmichaell_121No ratings yet

- CW July 2012Document58 pagesCW July 2012Clint FosterNo ratings yet

- Innovation Organisations: Damian GordonDocument38 pagesInnovation Organisations: Damian GordonCharles RoyNo ratings yet

- (C2) Innovation at 3M CorporationDocument33 pages(C2) Innovation at 3M Corporationchiragjain040% (1)

- Evolution of AdditivemanufacturingDocument19 pagesEvolution of AdditivemanufacturingVaibhav KatharNo ratings yet

- Case Study AnswersDocument2 pagesCase Study Answerssugarpuffz67% (3)

- Example - Innovation at 3M CorporationDocument29 pagesExample - Innovation at 3M Corporationellenaj.janelle69840% (1)

- 3M Company RevDocument10 pages3M Company RevNikunjGuptaNo ratings yet

- Individual Case StudyDocument6 pagesIndividual Case StudyShafa TasyuNo ratings yet

- (020320) The Evolution of Lean Six Sigma at 3M. Inc PDFDocument6 pages(020320) The Evolution of Lean Six Sigma at 3M. Inc PDFboiledsalmonNo ratings yet

- How 3M Is DepartmentalizedDocument2 pagesHow 3M Is DepartmentalizedPhuong ThanhNo ratings yet

- Stayfil From A Brazilian DigitalDocument16 pagesStayfil From A Brazilian DigitalFelipe NiñoNo ratings yet

- 3M India T2 22Document17 pages3M India T2 22Navneet SharmaNo ratings yet

- 3M SWOT AnalysisDocument4 pages3M SWOT AnalysisRaghu ThapaNo ratings yet

- Innovation Organisations: The 3M Way: Damian GordonDocument51 pagesInnovation Organisations: The 3M Way: Damian GordonVarun KabraNo ratings yet

- 3M Knowledge Management-Group 1Document22 pages3M Knowledge Management-Group 1Siddharth Sourav PadheeNo ratings yet

- 3M Case Study (Case Study Solution Available)Document5 pages3M Case Study (Case Study Solution Available)Kazriel79% (14)

- How 3M Gave Everyone Days Off and Created An Innovation DynamoDocument3 pagesHow 3M Gave Everyone Days Off and Created An Innovation DynamoPrince GargNo ratings yet

- Lecture # 03 - R&DDocument19 pagesLecture # 03 - R&DRamjan Ali SiamNo ratings yet

- Innovation at 3M CorporationDocument28 pagesInnovation at 3M CorporationTina NugraheniNo ratings yet

- 3M: Cultivating Core Competency: Case Study Reference No. CCA0047PDocument18 pages3M: Cultivating Core Competency: Case Study Reference No. CCA0047PDurgesh BhoirNo ratings yet

- 2011 - 3M's Open Innovation (Baker)Document5 pages2011 - 3M's Open Innovation (Baker)Saba KhanNo ratings yet

- Case 1Document17 pagesCase 1Rajesh Kumar RoutNo ratings yet

- How Design Becomes StrategicDocument9 pagesHow Design Becomes StrategicMariaMartinsNo ratings yet

- 3D Printing and Additive Manufacturing (AM) - DR Rob MartensDocument8 pages3D Printing and Additive Manufacturing (AM) - DR Rob MartensmiltechinsightsNo ratings yet

- Chapter 12 PreliminaryDocument26 pagesChapter 12 PreliminaryAn LiuNo ratings yet

- Injection World April2014Document76 pagesInjection World April2014fahmyazizNo ratings yet

- Maxim in IndiaDocument19 pagesMaxim in IndiaSuryansh SinghNo ratings yet

- Template 001Document1 pageTemplate 001api-220815031No ratings yet

- 11 Facts About Education and Poverty in America Do SomethingDocument2 pages11 Facts About Education and Poverty in America Do Somethingapi-220815031No ratings yet

- Assignment 4 - Parentteacher InterviewDocument3 pagesAssignment 4 - Parentteacher Interviewapi-220815031No ratings yet

- Overcoming The Poverty Challenge - Johns Hopkins ResearchDocument19 pagesOvercoming The Poverty Challenge - Johns Hopkins Researchapi-220815031No ratings yet

- Poverty and Education ReportDocument60 pagesPoverty and Education Reportapi-220815031No ratings yet

- New Diverse Majority UpdateDocument18 pagesNew Diverse Majority Updateapi-220815031No ratings yet

- Assignment 4 - Parentteacher InterviewDocument3 pagesAssignment 4 - Parentteacher Interviewapi-220815031No ratings yet

- Assignment 2 - Classroom NewsletterDocument1 pageAssignment 2 - Classroom Newsletterapi-220815031No ratings yet

- Assignment 4 - Structured External AssignmentDocument1 pageAssignment 4 - Structured External Assignmentapi-220815031No ratings yet

- Assignment 1 - Media HuntDocument5 pagesAssignment 1 - Media Huntapi-220815031No ratings yet

- Mohit KumarDocument67 pagesMohit KumarbawamatharooNo ratings yet

- Akbar Transport Ledger (Adeel)Document39 pagesAkbar Transport Ledger (Adeel)Imran NavidNo ratings yet

- Thailand DirectoryDocument99 pagesThailand DirectoryDipesh Wadhwani100% (1)

- Accelerated Velocity Quilt PatternDocument10 pagesAccelerated Velocity Quilt PatternMazZzingerZNo ratings yet

- Flowertown Knitting Guild: Warm Hatsand Pet Blankets, Charity KnittingupdateDocument4 pagesFlowertown Knitting Guild: Warm Hatsand Pet Blankets, Charity KnittingupdateScarlett McCrary Jones LmtNo ratings yet

- Neptune Orthopaedics Standard Operating Procedure-ProductionDocument2 pagesNeptune Orthopaedics Standard Operating Procedure-Productiondhir.ankurNo ratings yet

- EuroChem - Europe - Final PDFDocument36 pagesEuroChem - Europe - Final PDFYuvrajNo ratings yet

- DASTEXDocument12 pagesDASTEXMirkaHundNo ratings yet

- Data File Barang BajuDocument12 pagesData File Barang BajuRian YongNo ratings yet

- Ritu KumarDocument15 pagesRitu KumaraskmeeNo ratings yet

- Andheri WestDocument60 pagesAndheri WestNikunj VaghasiyaNo ratings yet

- GP Document MeghaDocument276 pagesGP Document MeghaMEGHA BALDEWA100% (2)

- Gucci & Louis VDocument54 pagesGucci & Louis VNoor Ul Ain100% (1)

- Report - A Business Case For Mattress Recycling (MAP002-002 Nov 12)Document81 pagesReport - A Business Case For Mattress Recycling (MAP002-002 Nov 12)Estoyy de VacacionesNo ratings yet

- Industrial Attachment22222222222222Document63 pagesIndustrial Attachment22222222222222Ashraf ChowdhuryNo ratings yet

- Vodafone ProposalDocument14 pagesVodafone ProposalSudin GabaNo ratings yet

- Training and Development at DawarDocument112 pagesTraining and Development at DawarsuryakantshrotriyaNo ratings yet

- Knitted Fabric Manufacturing: Lecture Note-II Dereje BerihunDocument17 pagesKnitted Fabric Manufacturing: Lecture Note-II Dereje BerihunDereje AdjibarNo ratings yet

- Johnny Crespo's Project and Portfolio 6 Manufacturing AssignmentDocument6 pagesJohnny Crespo's Project and Portfolio 6 Manufacturing AssignmentJohnny CrespoNo ratings yet

- Mmk265 Marketing Research Major Project (3) 1.doc 22891Document26 pagesMmk265 Marketing Research Major Project (3) 1.doc 22891dnlkabaNo ratings yet

- Critical Path - Management Brief - FastReact - Evolve PDFDocument6 pagesCritical Path - Management Brief - FastReact - Evolve PDFSiddharth JhaNo ratings yet

- Carton CalculationDocument4 pagesCarton Calculationsevenlinks apparelsNo ratings yet

- Poster - A Review On The Use of Estabragh (Milkweed) Fibers in Nonwoven ApplicationsDocument1 pagePoster - A Review On The Use of Estabragh (Milkweed) Fibers in Nonwoven Applicationsmahnaz khakpourNo ratings yet

- Mysore District PDFDocument13 pagesMysore District PDFmanjunatha tNo ratings yet

- The Emperor's New UnderwearDocument4 pagesThe Emperor's New UnderwearZaine Mabalasik Briones50% (2)

- Textile Business PlanDocument3 pagesTextile Business PlanJoshua Anim100% (2)

- Sample InvoiceDocument1 pageSample InvoiceHeemel D RigelNo ratings yet

- How Zara Fashions Its Supply ChainDocument4 pagesHow Zara Fashions Its Supply Chain王瓊翎No ratings yet

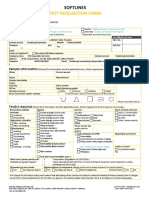

- Test Requisition Form: SoftlinesDocument4 pagesTest Requisition Form: SoftlinesArslan HaiderNo ratings yet

- FindsDocument8 pagesFindsdan4oNo ratings yet